Portfolio Nadine

INTERIOR DESIGN

2019 - 2023 SELECTED WORKS

BACHELORS OF INTERIOR DESIGN 23’

NADINE GHAZAL INTERIOR DESIGNER

CONTACT INFO

Dubai, United Arab Emirates

bynadineghazal@gmail.com

+971 50 708 8956

scenebynadine

AREA OF EXPERTISE

• Sustainable Design Practices

• Space Planning and Layout

• Furniture and Lighting

• Material and Finsihes

• Building Codes and Regulations

• Communitcation and teamwork skills

• Adaptability

• Design thinking

• Problem-solving

• Time-Management

• Attention to detail

LANGUAGES

Arabic English

PROFESSIONAL SUMMARY

High- performing, passionate, and adaptive interior designer. Committed to continuous improvement and contribution to team success. Eager to leverage education and training to support growth of a high-performing organization. Confident in ability to collaborate with cross-functional teams to utilize skill and solve complex problems through the creative process of design.

EDUCATION

BACHELORS OF INTERIOR DESIGN

2019 - 2023

RELEVANT COURSES COMPLETED

Interior Design Studio 201, 202, 301, 302, 401, 402, Architectural Principles, History and Theory of Interior Design, Interior Materials and Methods, Color and Light, Furniture and Furnishings, Environmental Control Systems in Interior Design, Construction, Detailing, and Structures, Professional Practice.

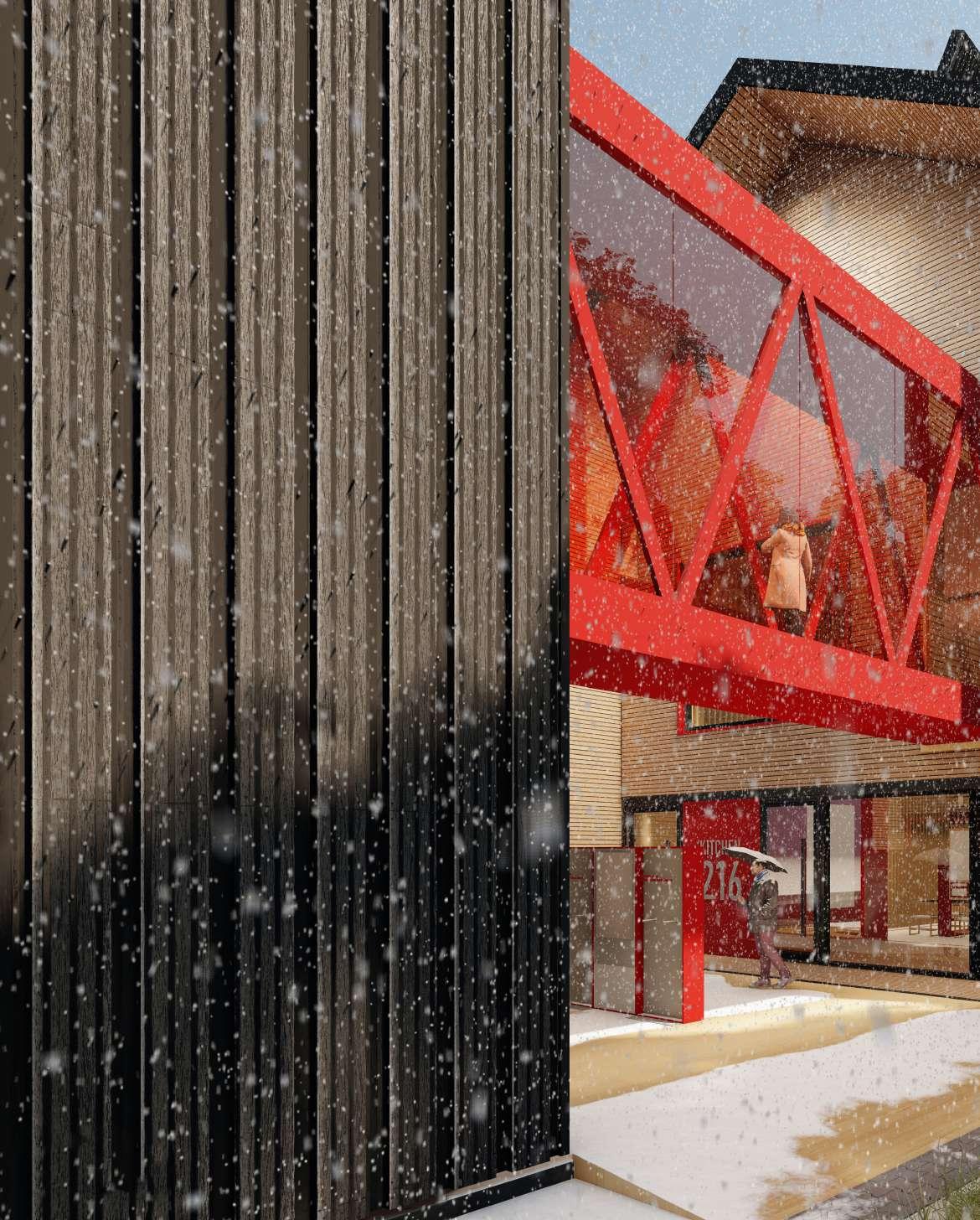

CAPSTONE PROJECT

Comprehensive Studio; designing a soup kitchen in Kyiv, Ukraine. Adressing the basic needs of people in crisis situations and promoting human dignity through social design.

EXPERIENCE

INTERIOR DESIGN STUDENT ASSOCIATION | PUBLIC RELATIONS

From Jan 2022 - May 2023

• Managed the organization’s social media presence and media coverage, resulting in an increase in engagement from interested students.

• Organized and executed successful events and presentations.

• Developed and managed content to keep the public informed about the activities of our student organization

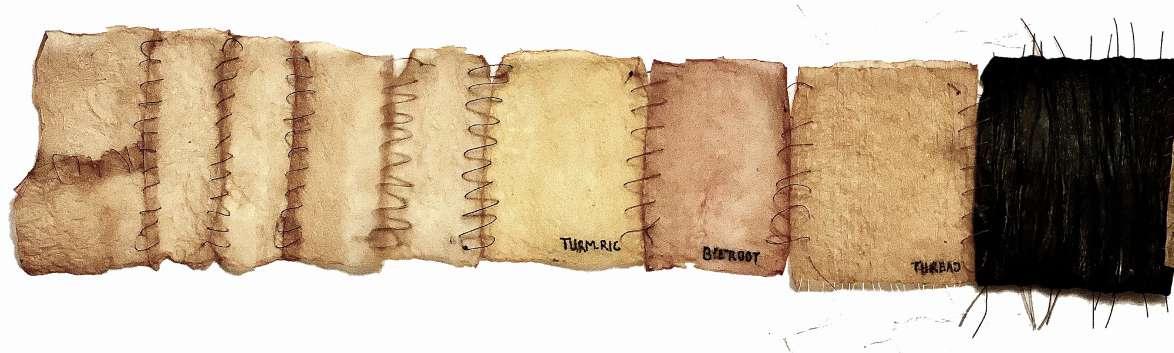

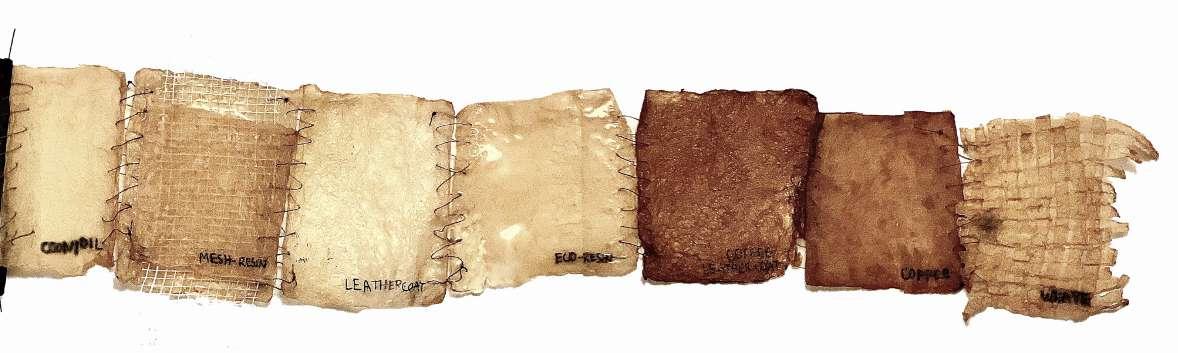

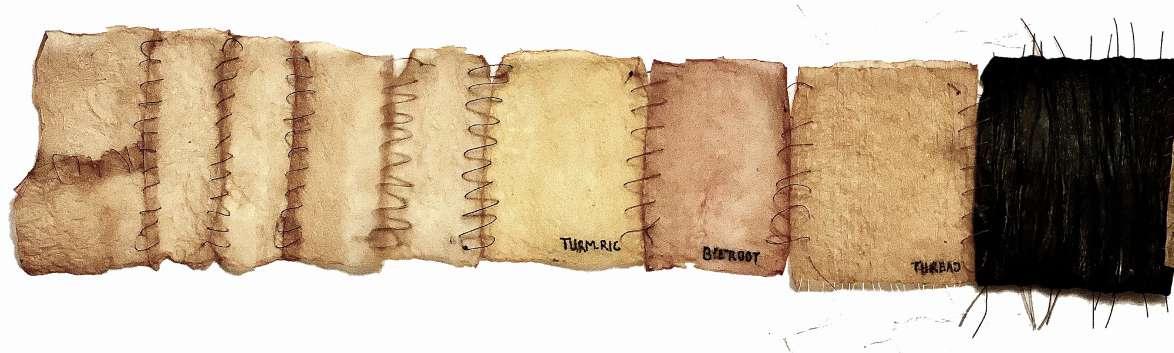

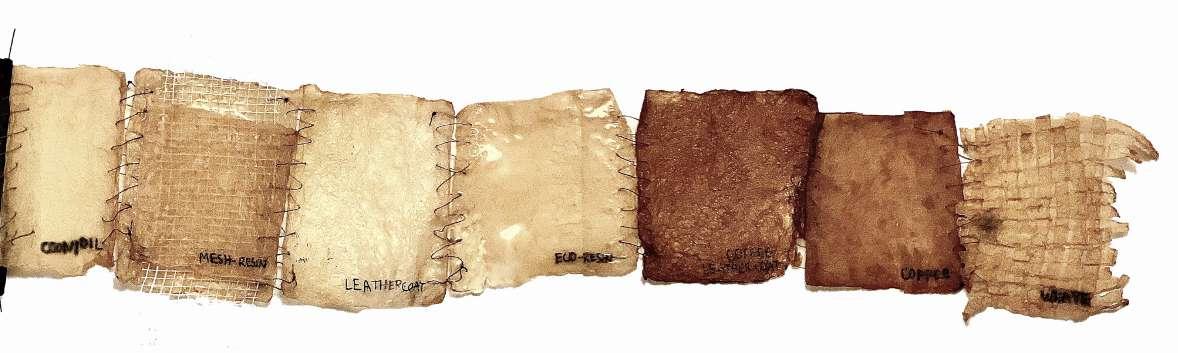

AMERICAN UNIVERSITY OF SHARJAH X IRTHI | RESEARCH ASSISTANT

From October 2022 - March 2023

• Conducted extensive field research and analysis of local materials, resulting in the discovery and development of new sustainable, natural materials

• Evaluated the properties and performance of new materials to increase their potential use in future projects

• Assisted in the creation of a comprehensive database of local sustainable materials and their properties

• Developed and conducted lifecycle analysis of new materials, and comparing their environmental impact compared to traditional interior building materials.

AEDAS | INTERN

From May 2022 - July 2022

• Designed and developed interior and spatial drawings for residential and commercial projects increasing project efficiency.

• Prepared presentations and proposals for clients, resulting in an increase in successful project proposals and design language reports.

• Promoted a rise in team spirit and cooperation through participation in team meetings and contributions to ongoing project improvement activities.

• Collaborated with cross-functional teams, to ensure project deliverables met all requirements.

PROFESSIONAL DEVELOPMENTS

COURSES AND CERTIFICATIONS

• IMMERSIVE BUSINESS TRAINING Revit Architecture Course

• UGREEN Sustainable Interior Design Week

LECTURES

• LECTURE by Todd Reisz Showpiece City: How Architecture Made

• LECTURE by Wael Al Awar Future Vernacula

• LECTURE by Anne Holtrop Site, Matter, Gesture

• LECTURE by Marcos Cruz: Designs From the Biocene

COMPETITIONS

2023 ACCOR - Mercure Hotel

2022 ROCCA 1- Day Design Challenge

2021 SMA x AUS

2019 Young Entrepeneur Competition

ACHIEVMENTS

DEAN’S LIST

2021, 2022, 2023

CHANCELLOR’S LIST

2022, 2023

ACADEMIC EXCELLENCE SCHOLARSHIP

2019 - 2023

VOLUNTEER

SENSES

Residential and Day Care for Special Needs

MEDAF

Art Studio for Children

SKILLS

Digital

AutoDesk AutoCAD

Rhinoceros 3D

Adobe Photoshop

Adobe InDesign

Adobe Illustrator

Adobe Premier Rush

Maya

Blender

Enscape

Dialux

AutoDesk Revit

V- Ray

Microsoft Office

Lumion

Zbrush

Houdini

Adobe substance 3D

Grasshopper

Analogue

Drawing & sketching

Model-making

Laser-cutting

3D-printing

Wood-working

Casting

NADINE GHAZAL

+971 50 708 8956

bynadineghazal@gmail.com

INTERIOR DESIGN PORTFOLIO Bachelors of Interior Design 23’ American University of Sharjah

As a dedicated and constantly improving interior design student, I am driven by my passion for design and my desire to learn and grow. With a strong foundation in design theory and technical skills, I approach each project with an open mind and a commitment to pushing the boundaries of my creativity. I am constantly seeking out new challenges and opportunities for growth with complacency in my craft. This portfolio showcases my design process, my attention to detail, and my passion for learning and improvement. I am eager to share my work with you and demonstrate my potential for continued growth and development as a future interior designer.

Bachelor of Interior Design

American University of Sharjah, UAE

Dubai, United Arab Emirates

bynadineghazal@gmail.com

+971 50 708 8956

scenebynadine

CONTENT Comprehensive Studio: Community Kitchen Design & Build: Student Lounge Wastelab Retail Store Detailing a Mirco-apartment Bathroom Design Material Fabrication Digital Fabrication Illustration & Rendering 01 02 03 04 05 06 07 08 09

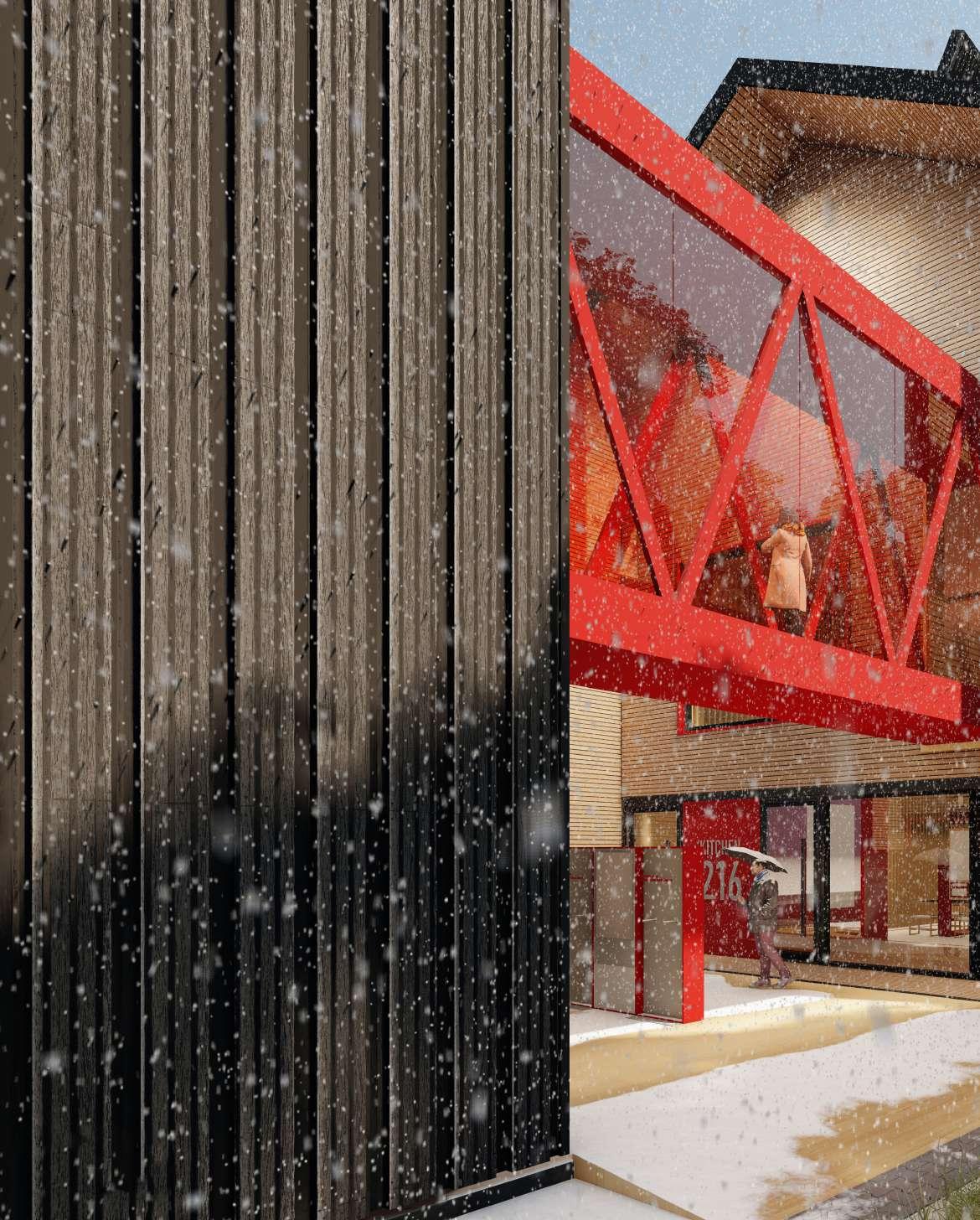

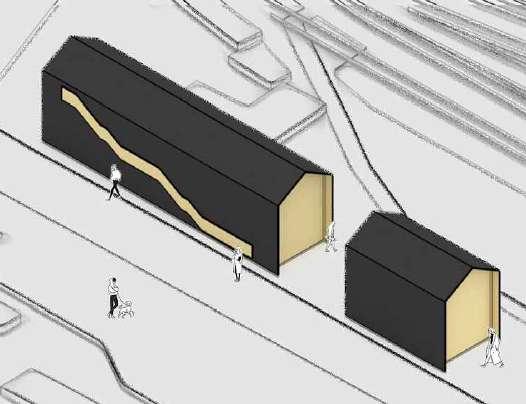

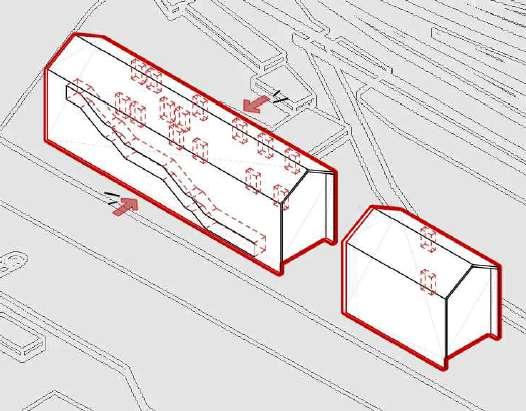

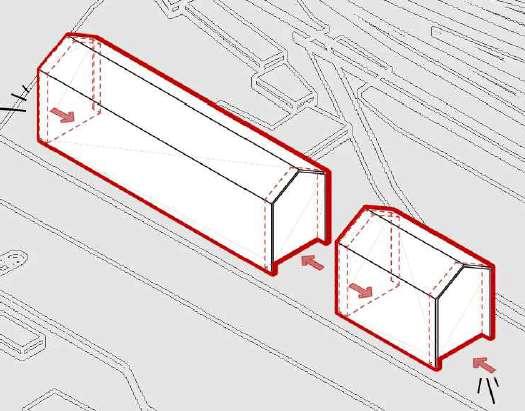

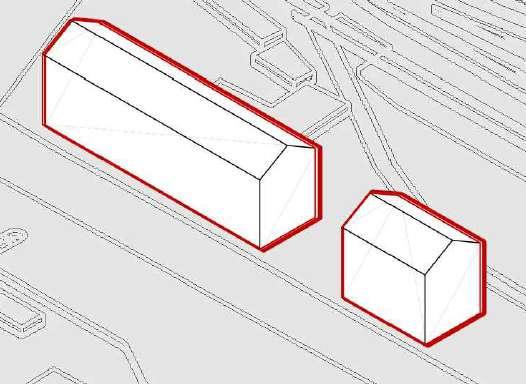

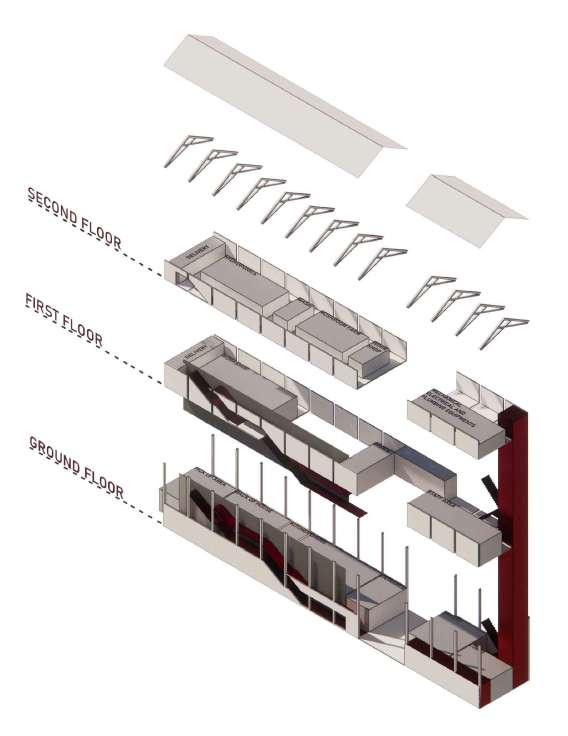

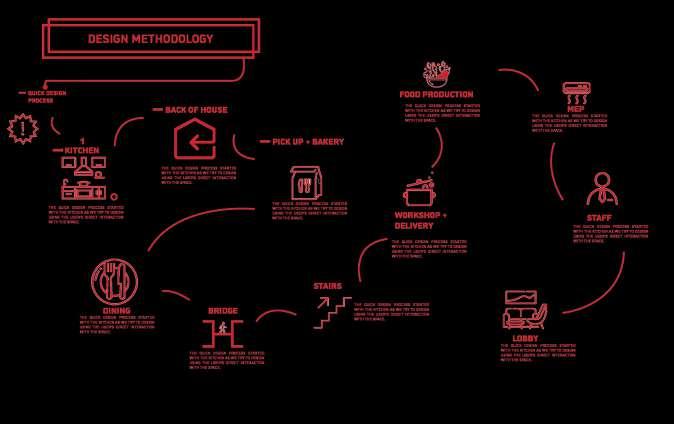

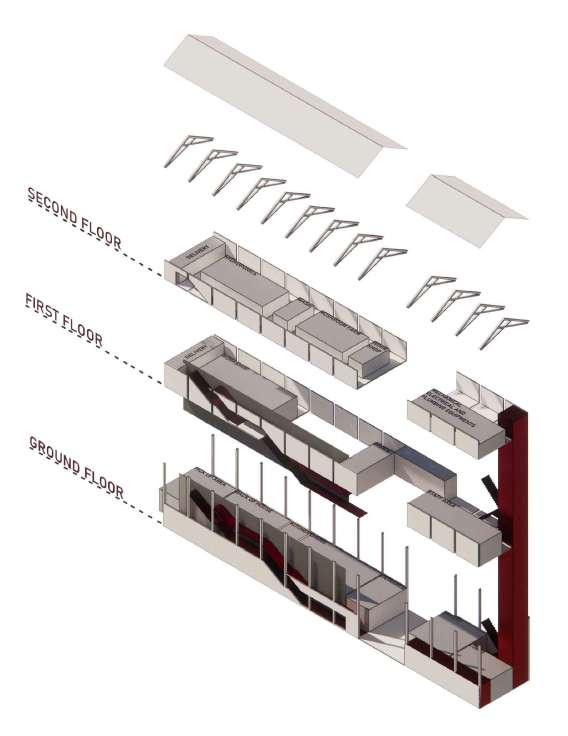

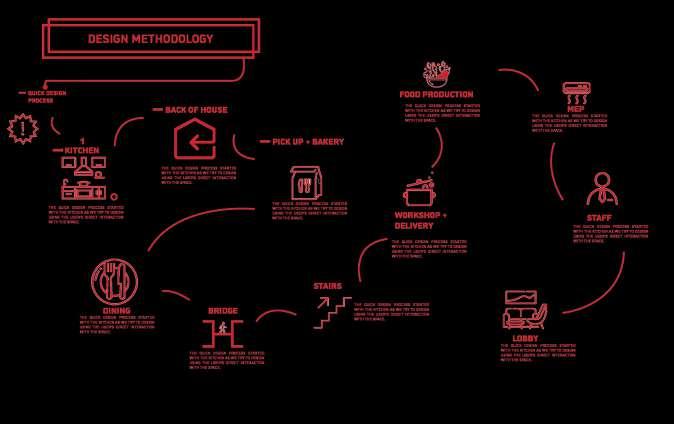

COMPREHENSIVE STUDIO: SOUP KITCHEN IDE402 STUDIO

ADVISOR | CAMILO CERRO PARTICIPANTS | RAND RAHMANI

The aim of this project is to create a soup kitchen that brings people together in times of war. The giving pot provides nutritious meals to people who have been displaced from their homes due to war and conflict. It serves as a place where people can come together to share a meal, connect with one another, and find a sense of community during a time of crisis.Our kitchen

also serves as a hub for community events and activities. It will be a place where people can come together to participate in workshops, educational programs, and cultural events. This will help to foster a sense of community and provide opportunities for people to learn new skills and connect with one another.

13 01 02 690 325 310 141 734 470 4342 310 210 1310 1842 30 165 640 165 30 670 30 1030 154 295 139 202 180 30 30 1030 15 30 1030 375 165 165 85 180 30 258 258 258 180 30 970 30 30 1030 30 165 385 192 168 60 30 30 742 168 60 30 1830 165 76 97 25 21 148 21 424 356 191 314 97 173 98 347 01 02 30 165 640 165 30 275 210 770 105 70 210 70 105 70 140 280 140 70 105 70 140 70 210 70 105 1045 205 140 70 210 1205 30 1030 154 295 139 202 180 30 30 1030 15 30 1030 375 165 165 85 180 30 258 258 258 180 30 970 30 30 1910 210 40 1407 1030 30 165 385 192 168 60 30 30 742 168 60 30 165 76 97 25 21 148 21 424 356 191 314 FIRST FLOOR CONSTRUCTION PLAN 30 4342 01 02 4037 22 970 30 52 91 SECOND FLOOR CONSTRUCTION PLAN 30 4342 670 01 02 4037 22 970 30 52 91 1683 ROOF CONSTRUCTION PLAN 01 690 325 310 141 734 210 70 140 70 105 70 105 70 105 70 105 70 210 470 4342 310 210 1310 1842 30 165 640 165 30 670 30 1030 154 295 202 180 30 30 1030 15 30 1030 375 165 165 85 180 30 258 258 258 180 30 970 30 1030 385 192 168 60 30 742 168 60 30 165 76 97 25 21 148 21 424 356 191 314 97 173 98 347 GROUND FLOOR CONSTRUCTION PLAN

01 02 1118 315 1433 309 107 68 142 68 212 68 142 68 107 68 107 733 212 68 142 68 107 68 107 68 107 68 142 68 212 68 142 204 142 68 212 107 490 01 02 1118 315 1433 309 107 68 142 68 212 68 142 68 107 68 107 733 212 68 142 68 107 68 107 68 107 68 142 68 212 68 142 204 142 68 212 107 490

15 PICK-UP HERE OR ORDER AT +380 84 453 8608! BAKERY 216 01 03 PICK-UP HERE OR ORDER AT +380 84 453 8608! BAKERY 216 01 03 PICK-UP ENTRANCE BAKERY WINDOW

GREY LINOLEUM BLUE LINOLEUM 65 65 65 65 65 65 65 08 GREY BLUE 65 65 65 65 65 65 65 VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 15 15 01 02 03 80 80 80 80 80 80 80 80 80 80 80 257 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 195 80 230 245 265 138 VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY KIDS AT PLAY AT PLAY 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 15 15 01 02 03 80 80 80 80 80 80 80 80 80 80 80 257 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 230 265 138 VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING VERTICAL FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM FARMING MUSHROOM KIDS AT PLAY KIDS AT PLAY KIDS AT KIDS AT PLAY 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 15 15 01 02 03 80 80 80 80 80 80 80 80 80 80 80 257 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 195 80 230 245 265 138 FARMING SYSTEMS FP FRONT ELEVATION BACK ELEVATION

FARMING SYSTEM

MOVEABLE

Self-sufficiency in a war zone like Ukraine can be a challenging but crucial endeavor. However, hydroponic farming and mushroom farming offer innovative solutions to overcome some of these challenges. Despite the difficult circumstances, hydroponic farming can be implemented in a compact indoor space, requiring minimal soil and water resources. This method allows for the cultivation of fresh vegetables, herbs, and even fruits year-round, providing a reliable source of nutritious produce for the soup kitchen.

Additionally, mushroom farming can be an efficient way to produce protein-rich food in limited spaces. Mushrooms have the ability to grow on various substrates, including agricultural waste, making them an ideal choice for a war-torn environment where resources are scarce. By integrating hydroponic and mushroom farming, the soup kitchen can enhance its self-sufficiency, reduce reliance on external food supplies, and provide nourishing meals to those affected by the war, fostering a sense of stability and resilience amidst adversity.

17

BENEFITS OF 03 04 05 06 07 92 165 655 150 150 655 165 62 DELIVERY STATION HYDROPONICS PARKING STATION

FARMING KIDS WORKSHOP

MUSHROOM

01 02 515 07 04 03 06 16 43 457 15 515 43 122 90 189 42 30 107 177 300 165 8 65 8 61 8 61 8 61 8 61 8 61 8 61 8 61 8 65 8 165 640 970 11 263 21 300 20 144 15 84 4 84 4 84 4 84 4 84 4 84 4 84 15 144 20 640 970 82 10 40 10 50 165 148 50 50 48 296 192 108 160 159 159 159 160 23 150 46 27 27 17 182 118 6 11 263 263 300 797 98 362 155 165 708 91 86 335 351 335 266 84 167 351 28 44 28 44 28 44 28 44 28 220 80 300 96 351 13 167 351 167 31 PICK-UP DETAIL FP 04 05 07 10 04 03 15 42 30 165 8 65 8 61 8 61 8 61 8 61 8 61 8 61 8 61 8 65 8 165 640 970 5 11 263 21 300 20 144 15 84 4 84 4 84 4 84 4 84 4 84 4 84 15 144 20 640 970 165 148 280 280 98 77 10 90 50 50 48 50 48 50 214 199 296 708 15 457 43 192 108 192 108 165 70 10 179 10 42 30 515 159 160 23 150 6 11 263 300 98 191 362 155 165 708 91 86 266 84 28 44 28 44 314 34 96 123 96 02 515 05 07 04 03 06 14 43 457 15 515 43 122 90 189 42 30 107 177 300 165 8 65 8 61 8 61 8 61 8 61 8 61 8 61 8 61 8 65 8 165 640 970 5 11 263 21 300 20 144 15 84 4 84 4 84 4 84 4 84 4 84 4 84 15 144 20 640 970 82 10 40 10 50 165 148 280 280 98 5 77 10 90 50 50 48 50 48 50 214 199 296 708 15 192 108 192 108 179 10 42 30 160 159 159 159 160 23 150 46 27 27 17 182 118 6 11 263 263 300 797 98 191 362 155 165 708 91 86 25 25 25 25 290 27 27 300 220 300 300 SIDE VIEW COUNTER FRONT VIEW SEATING FRONT VIEW SIDE VIEW STORAGE WALL BUILT-IN FRONT VIEW

19 01 02 72 773 07 10 11 12 13 04 03 06 09 08 701 10 290 300 91 36 45 31 72 686 15 69 123 16 82 10 10 82 60 45 60 82 60 10 165 15 314 21 263 10 300 576 20 97 10 559 141 21 721 74 74 22 230 70 300 22 69 110 64 54 300 30 10 576 81 30 255 253 92 150 105 253 150 255 162 92 41 32 180 253 KITCHEN DETAIL FP 05 07 04 03 72 686 15 69 123 16 82 10 10 82 60 45 60 82 60 10 165 15 314 15 94 123 94 43 97 10 21 263 10 300 970 639 6 60 6 60 6 60 6 60 6 96 6 60 6 60 6 60 6 60 6 10 82 15 559 141 21 721 74 74 22 424 209 230 70 300 147 22 970 69 110 64 54 300 69 75 118 28 10 62 62 62 62 105 150 255 02 72 773 05 07 04 03 06 09 08 701 10 290 300 91 36 45 31 72 686 15 69 123 16 82 10 10 82 60 45 60 82 60 10 165 15 314 15 94 123 94 43 97 10 21 263 10 300 970 6 60 6 10 82 15 576 20 97 10 559 141 21 721 74 74 22 424 209 230 70 300 147 22 970 69 110 64 54 300 69 75 118 28 10 62 62 62 62 62 62 76 58 76 58 76 30 10 757 576 81 10 30 5 02 72 773 05 07 04 03 06 09 08 701 10 290 300 91 36 45 31 72 686 15 69 123 16 82 10 10 82 60 45 60 82 60 10 165 15 314 15 94 123 94 43 97 10 21 263 10 300 970 6 60 6 10 82 15 576 20 97 10 559 141 21 721 74 74 22 424 209 230 70 300 147 22 970 69 110 64 54 300 69 75 118 28 10 62 62 62 62 62 62 76 58 76 58 76 30 10 757 576 81 10 30 5 SHELVING FRONT VIEW PANTRY WALL FRONT VIEW STATIONS SIDE VIEW PREPPING STATION PLATING STATION PREPPING STATION BACK VIEW MAGNETIC WALL SHOW KITCHEN

21

UP 01 02 05 04 03 06 350 305 52 80 290 727 75 295 228 471 91 15 165 327 100 300 15 80 74 22 106 970 727 165 621 15 235 493 68 142 68 107 68 142 149 15 201 141 54 295 295 139 300 350 970 97 25 02 05 350 1760 305 52 80 290 727 75 295 43 99 171 99 463 335 30 2140 235 493 107 103 212 68 142 68 107 68 142 91 83 196 357 UP 01 03 06 228 471 91 15 165 327 100 300 15 80 74 22 106 106 106 228 350 108 123 121 970 727 165 621 15 147 15 149 15 201 141 54 295 295 139 300 350 970 97 25 PICK-UP DETAIL FP VIEW TO ROAD KITCHEN FRONT VIEW UP 02 05 04 350 1760 305 52 80 290 727 75 295 171 99 350 108 123 121 15 463 335 2140 235 493 107 103 212 68 142 68 107 68 142 02 05 04 350 1760 305 52 80 290 727 75 295 43 99 171 99 463 335 30 2140 235 493 107 103 212 68 142 68 107 68 142 91 83 196 357 UP 01 02 05 04 03 06 350 305 52 80 290 727 75 295 228 471 91 15 165 327 100 300 15 80 74 22 106 106 106 228 350 108 123 121 970 727 165 621 15 147 15 235 493 142 68 107 68 142 149 15 201 141 54 295 295 139 300 350 970 97 25 DINING TO KITCHEN VIEW SEATING FRONT VIEW VIEW TO PARK

23 09 10 11 13 14 16 PICK-UP DETAIL FP 11 12 03 03 103 200 92 79 337 10 11 13 14 10 11 12 13 14 15 STATIONS SIDE VIEW STORAGE WALL CHEF COOKING STATION 01 09 10 11 13 14 16 STAIRS FRONT VIEW

125

25 375 30 80 485 60 5 60

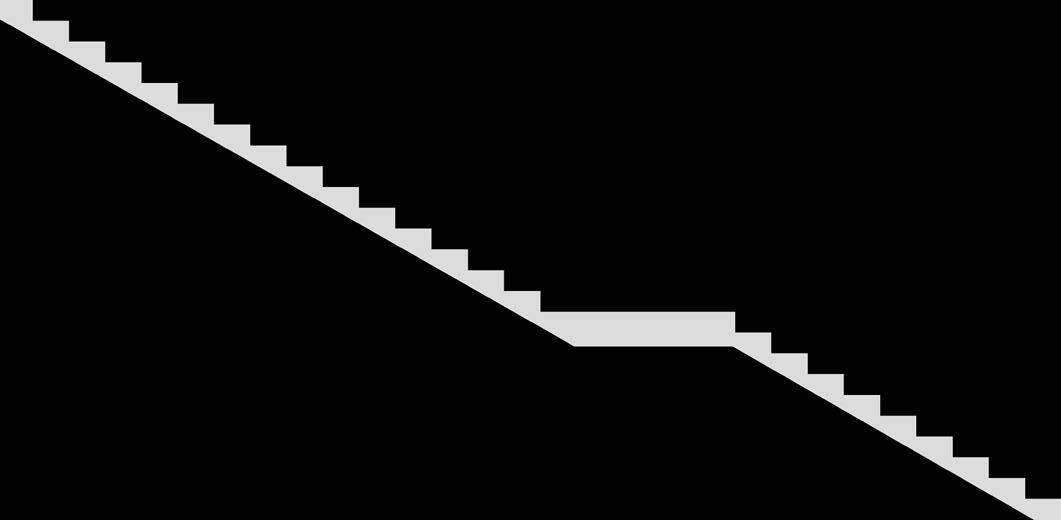

TYPICAL GWB BAKERY WALL AWNING WINDOW 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 UP D2 A500 150 49 205 92 40 72 92 131 64 16 3 290 123 410 10 205 10 184 146 63 165 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 150 01 02 03 ALUMINUM STUD TYPICAL DOOR WITH WOOD ALUMINUM WOODEN STICK WALL ELEVATION 20 48 2 70 124 11 48 20 11 2 2 2 2 55 20 10 37 10 180 99 10 50 CM WR GWB TILES BACKSPLASH WR GWB WOOD STRUCTURE 01 02 03 20 48 2 70 124 11 48 20 48 2 11 2 2 55 180 33 76 86 20 10 37 10 180 99 10 50 CM WR GWB TILES BACKSPLASH WR GWB WOOD STRUCTURE 01 02 03 70 11 20 48 2 11 2 2 2 55 180 33 76 86 20 48 100 50 98 98 50 10 37 10 180 99 10 FLOOR STRUCTURE DROP CEILING STRUCTURAL INSULATION PANEL WOODEN DOUBLE HUNG WINDOW COVER OPERABLE INTERIOR WINDOW FOAM INSULATION 50 CM TILES BACKSPLASH WR GWB WOOD STRUCTURE 02 03 STAIRS DETAIL PLAN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 UP D1 A500 D2 A500 150 49 205 92 40 72 50 92 131 64 16 3 290 123 410 10 205 10 184 146 63 165 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 150 01 02 03 STUD TYPICAL DOOR WITH WOOD ALUMINUM WOODEN STICK WALL ELEVATION 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 UP D1 A500 D2 A500 150 49 205 92 40 72 50 92 131 64 16 3 290 123 410 10 205 10 184 146 63 165 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 28 150 01 02 03 STUD TYPICAL DOOR WITH WOOD ALUMINUM WOODEN STICK ELEVATION STAIRS LONGITUDINAL SECTION STAIRS TRANSVERSE SECTION

27

DESIGN & BUILD: STUDENT LOUNGE

ADVISOR | AMMAR KALO PARTICIPANTS | GROUP IDE401 BATCH 2023

Our work environments are witnessing a revolution in terms of how they define space and production, and the ways in which they engage their users. Technological innovation, social change, and economic stratification are some of the drivers behind such radical transformation, and continue to shape today’s work culture. However, the same cannot be said about design schools and

studios, which tend to take longer to adapt new changes. This studio tackles a tangential problem at CAAD, which is providing non-academic neutral spaces for students to recharge, socialize and perhaps work. The main goal is to create an inviting space that can serve multiple functions and provide a dedicated space where students can socialize without disrupting classes.

STUDIO

IDE401

KEY:

BIG PLANE

PANELS: P1, P2, P3, P4

BOXES: A, B (x2), C (x2)

SURFACES: S1, S2,

MEDIUM PLANE

TABLES: T1, T2, T3, T4, T5

SMALL PLANE

PANELS: E1,E2

WALL PANELS

PANELS: F1 (x2), F2, F3, F4 (x2), F5, F6 (x5), F7, F8, F9, F10

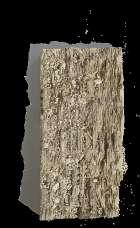

ASH WOOD Pieces

ASH WOOD Blocking

PLYWOOD Panel GLASS Partition

MDF Support Boxes

VENEERED MDF Pieces

MDF Panel

LEATHER Cushions

ASH WOOD Pieces

ASH WOOD Blocking

MDF

PLYWOOD Panel Support Boxes

29

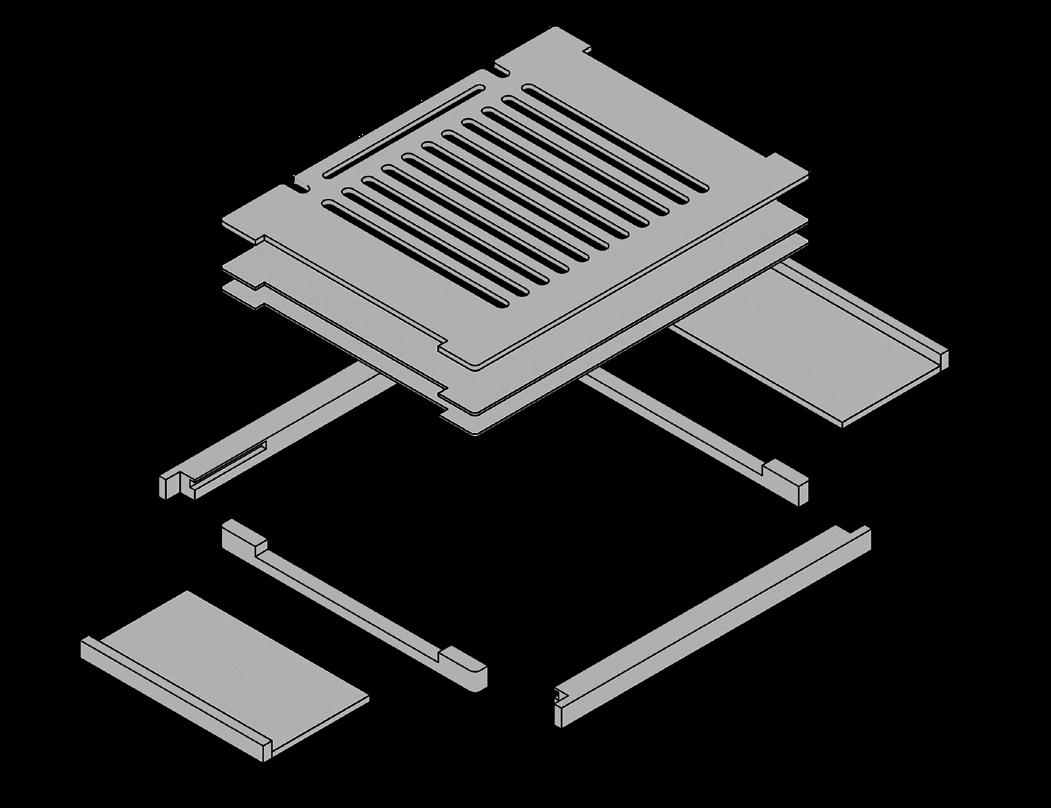

P1 F8 F6 F6 F6 F6 F6 F2 F1 F4 S3 S4 F7 F9 F9 F3 F1 P2 P3 P4 T5 T4 F5 F4 T3 T2 A B B D T1 C C S1 S2 E2 E1 EXPLODED AXONOMETRIC FURNITURE DETAILS

The concept of the project revolves around the idea of folding planes. To accomodate for different functions, we introduced three different planes, which we named the big plane, the medium planes, and the small plane. These planes were carefully textured with ashwood pieces of different sizes and thicknesses.

31

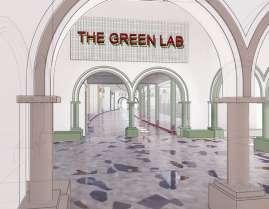

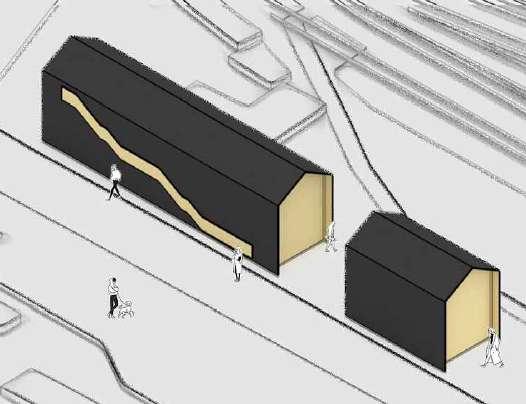

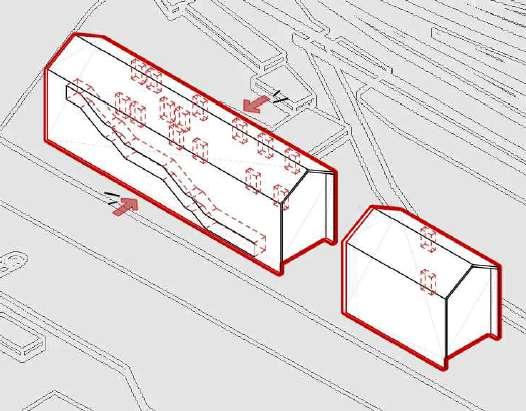

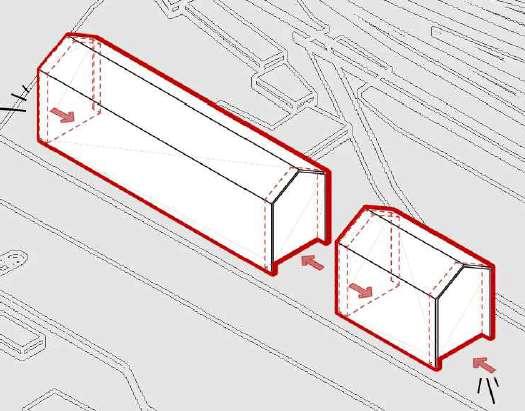

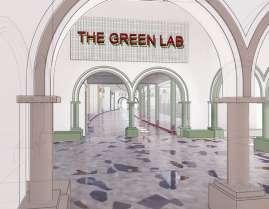

ADVISOR | DALIA HAMATI PARTICIPANTS | INDIVIDUAL

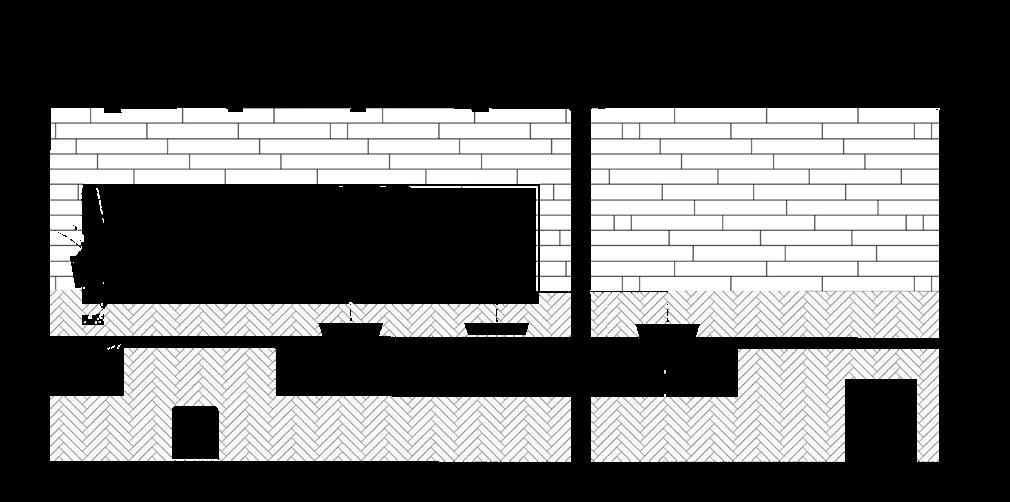

SECTIONAL PERSPECTIVE

The Green Lab serves as an educational institution on waste regulation and prevention. Waste produced by the community is sorted and processed with a high degree of visibility to reveal the latent potential of waste. Precisely slit along its mass, the building in itself raises awareness on constuction waste. The frequency of slits along the building increases gradually across

the space, resulting in various interior conditions. Each slit serves as a portal to the next experience. As you get closer to the end of the lab, you come across the communal garden, in which we grow food using compost generated by The Green Lab, allowing the cycle to begin over from The Transit Lab.

WASTE-LAB IDE302 STUDIO

AROUND 41% OF SOLID -

3. DECONSTURCTION: PLANES SLIT THE SITE

DIAGRAM

4. SHIFTING & RESTITCHING

DIAGRAM

1. RADIAL GRID

ORGANIC WASTE MATERIAL WASTE HANDLING LOADING DOCK CONVEYOR BELT EXHAUST FANS GRINDING 3- BIN COMPOST SYSTEM CEILING LAMPS UPCYCLING WORKSHOP SPACE

2. PLANES SHIFTING: SPARSE TO DENSE

TRANSVERSE SECTIONS

33 LAB 5- DINING SECTION 2.4 3.0 MATERIAL WASTE HANDLING - EXHIBITION ORGANIC WASTE HANDLING - SEPARATING SECTION THROUGH SLIT STEP 1: OFF LOADING WASTE STEP 2: SEPARATING STEP 3: GRINDING STEP 4: MIXING STEP 5: STORING STEP 6: COMMUNITY a b d e f g h i j c 1 2 1 2 3 1 ID303 3.3 2.4 b d c a e MATERIAL WASTE HANDLING - EXHIBITION COMMUNITY GARDEN ORGANIC WASTE HANDLING - STORAGE LONGITUDINAL SECTION

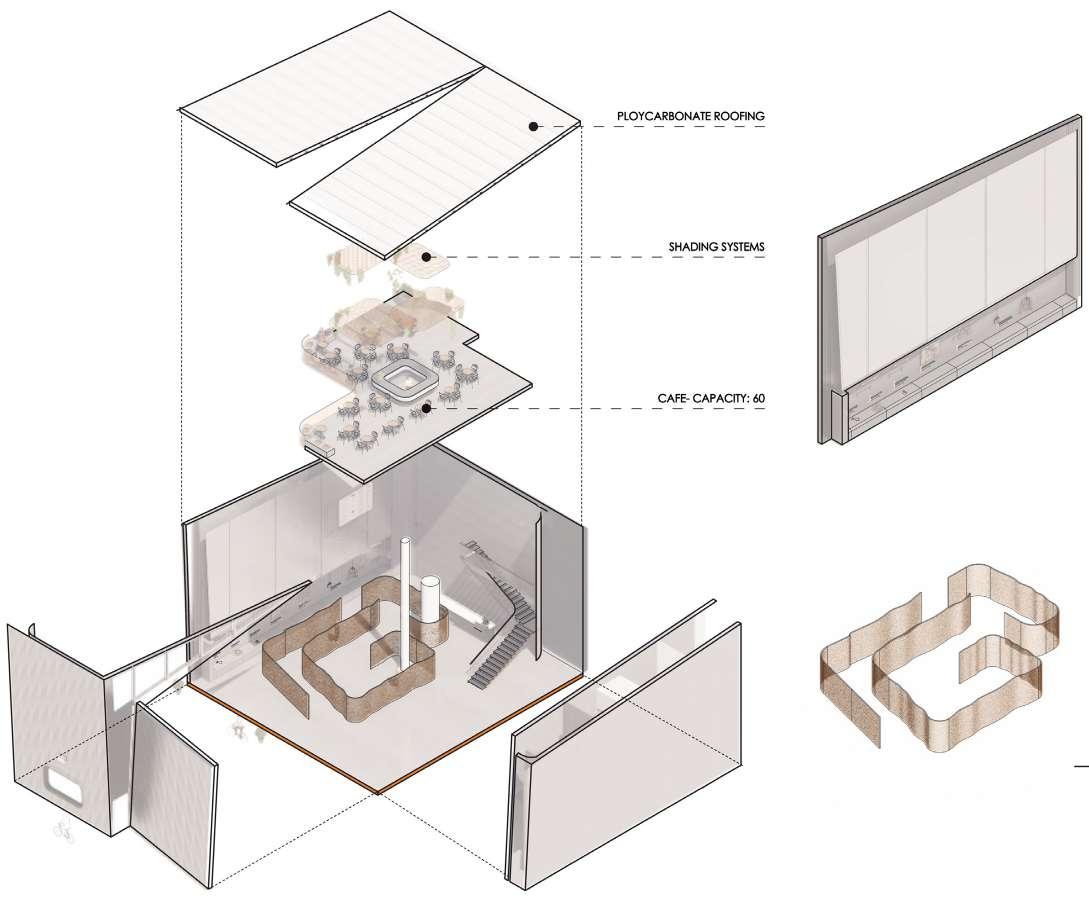

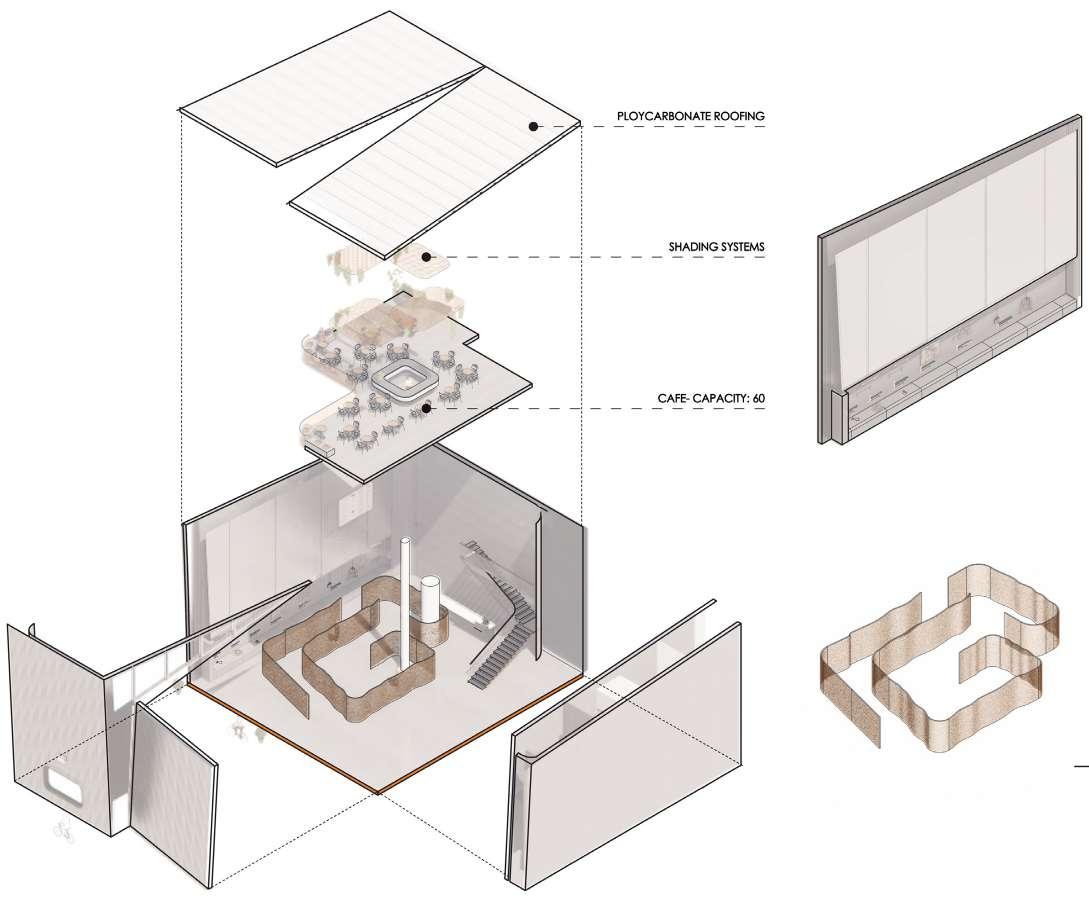

RETAIL STORE: KOMBUCOUTURE

ADVISOR | TANIA URZMAZARO PARTICIPANTS | INDIVIDUAL

SECTIONAL PERSPECTIVE

STUDIO

IDE301

EXPLODED AXONOMETRIC

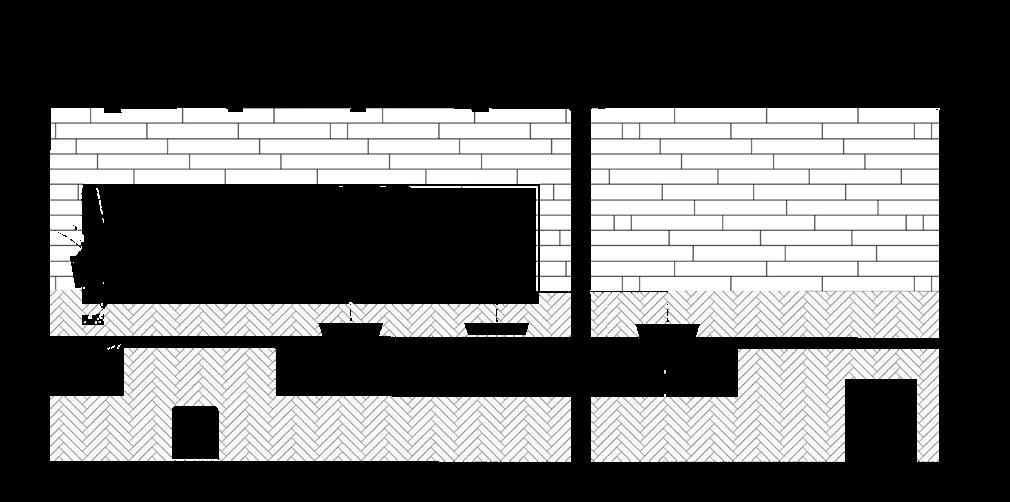

The aim of the project is to transform Warehouse 46 in AlSerkal Avenue into a retail store. KombuCouture is a hub that houses a gallery, a retail space, as well as a cafe. It serves as a community extension by commissioning various Kombucha goods from the avenue’s creatives. The material used for the project has skinlike properties in its transparency and delicateness, connecting

the human body to nature. Various design interventions create a dim setting to stimulate our senses and bring a feeling of coldness, like a refrigerator that houses the kombucha leather. The cafe serves kombucha dishes, to link the care we put into our bodies when choosing what to eat and how that must replicated when choosing materials to put into our planet.

35

SHADING SYSTEMS

POLYCARBONATE ROOFING

CAFE (CAPACITY: 60)

KOMBUCHA PARTIONS

BUILT-IN DISPLAY

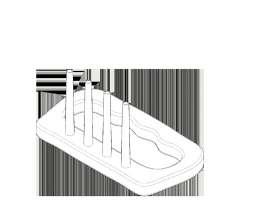

ADVISOR | JASON CARLOW PARTICIPANTS | INDIVIDUAL

S1 A2.1

3300

285

1706 88 1296 1256 604 4950 1500 100 600

93

880

7 treads at 216 mm OPEN TO BELOW OPEN TO BELOW

S2

S3 A2.2 E1 A3.1 E2 A3.1

REFRIGERATOR BELOW LOWER FP SCALE 1:20 1 A1.1

E1 A3.2

1700 106

1500 744 LONGITUDINAL SECTION SCALE 1:20 1 A2.1

285

E2 A3.2 D1 A4.1 GROUND FP SECTIONAL ELEVATION

1500 744 LONGITUDINAL SECTION SCALE 1:20 1 A2.1

GENERAL NOTES: DRAWING: LOWER FP

CHECKED BY: JASON CARLOW DRAWN BY: NADINE GHAZAL STUDENT ID: 84206 DATE DRAWN: DECEMBER 19, 2022 CONSTRUCTION, DETAILING,& STRUCTURES MIRCRO APARTMENT SCALE 1:20

IDE434: SECTION 01 ASSIGNMENT 05

A1.1

2300 8 risers at 287.5 mm BOSCH REFRIGERATOR

D6 A4.1 2300 risers at 287.5 mm BOSCH built-in oven with microwave function

A 2300 8 risers at 287.5 mm BOSCH REFRIGERATOR

2045

612 612 D3 A4.1 D4 A4.1 D5 A4.1 D2 A4.1 PLUMBING FIXTURE & FURNITURE SCHEDULE: KEY UMS

A GENERAL NOTES: DRAWING: SECTIONS

UMS OVEN

OVEN FR

612 612 D3 A4.1 D4 A4.1 D5 A4.1 D2 A4.1 PLUMBING FIXTURE KEY UMS

FR Undermount Foster Sink KE - R15 in foster brushed stainless steel BOSCH Series 8, built-in compact oven with microwave function BOSCH series 6 built-under fridge

UMS OVEN

OVEN FR

SECTION THROUGH STAIRS SCALE 1:10 1

Description

Description

A2.1 2045

FR Undermount foster brushed BOSCH oven with BOSCH

IDE434 CONSTURUCTION, DETAILING, & STRUCTURES

DETAILING A MIRCO- APARTMENT

This design and detailing project tested our abilities to apply materials and systems to an interior space and design their relationships in detail. We were asked to design a micro unit for dwelling for which an imaginary client has already approved a basic layout for the space and has provided a list of items to be included in the project. It is our responsibility to designate IDE434: SECTION 01 ASSIGNMENT 05

finish materials and systems to the space and provide the client and potential contractor with detailed drawings of your proposal for review and preliminary pricing. By focusing on creating functional solutions, I designed and detailed a space that is aesthetically pleasing, and reflective of the intended purpose. CHECKED BY: JASON CARLOW DRAWN BY: NADINE GHAZAL STUDENT ID: 84206 DATE DRAWN: DECEMBER 19, 2022 CONSTRUCTION, DETAILING,& STRUCTURES MIRCRO APARTMENT SCALE 1:20

BATHROOM DESIGN

ADVISOR | CAMILLO CERRO PARTICIPANTS | PARTNER SARAH AL OTHMAN

In this project, we were expected to design a bathroom using market components. By blending contemporary and art deco elements, we designed a bathroom that is both practical and visually appealing for him and her. We used contrasting black

and white tiles to create a striking and sophisticated look. The geometric patterns in the tiles and the pop of color evoke the art deco style.Pairing it with Japanese wood and sleek and minimalistic fixtures gives the bathroom a modern touch.

FURNITURE &

IDE334

FURNISHINGS

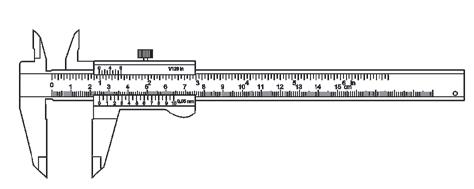

39 23 218 41 15 67 92 230 23 259 387 23 15 23 707 150 857 59 460 155 54 86 166 90 7 136 105 92 98 127 12 82 50 92 98 130 38 20 55 116 GARDEN KOHLER RAINHEAD TOWEL WARMER TOTO CABINETRY JAPANESE WOOD KOHLER FREE-STANDING BATH DURAVIT CAPE COD BOWL GROHE ESSENCE FAUCET IKEA LAUNDRY BASKET DURAVIT CAPE COD GROHE ESSENCE FAUCET KOHLER RAINHEAD KOHLER FLOOR MOUNTED FAUCET FLOOR PLAN INTERIOR ELEVATIONS

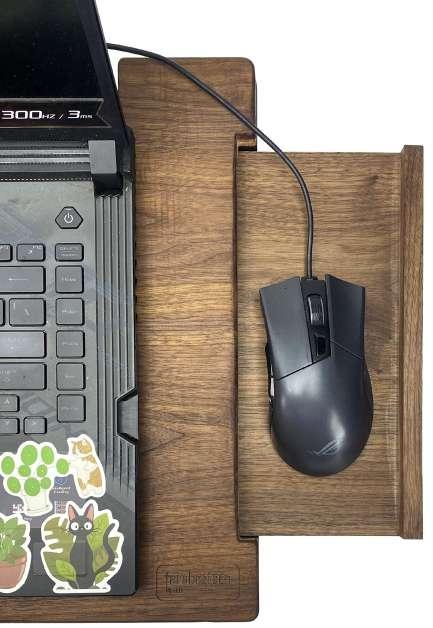

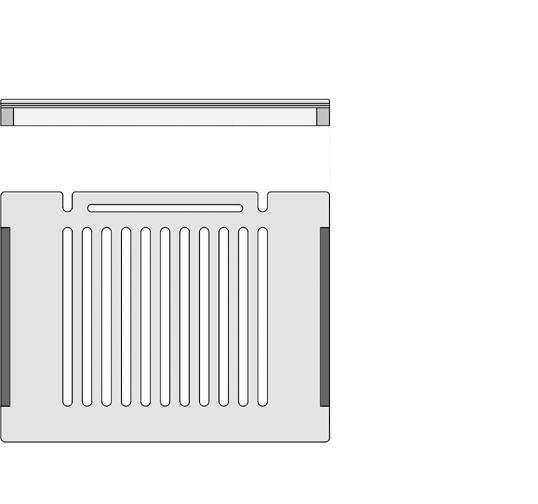

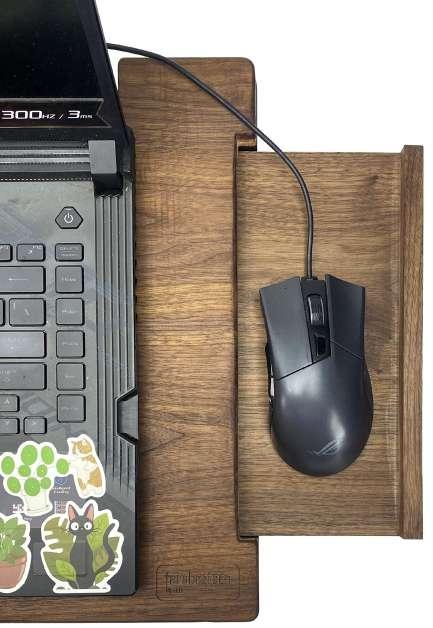

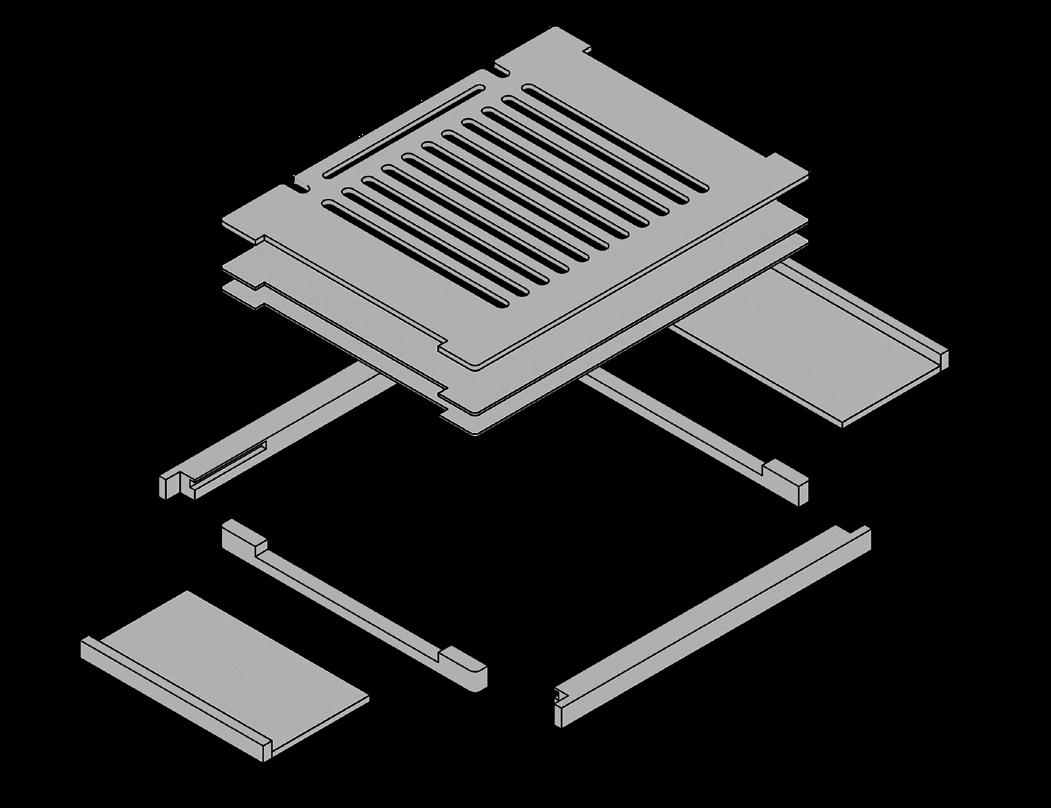

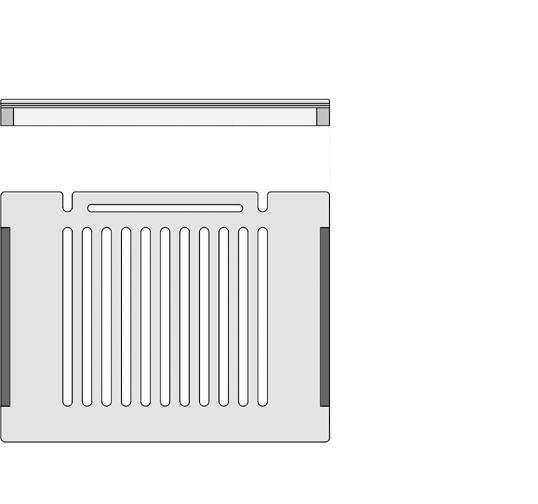

ADVISOR | JUAN ROLDAN PARTICIPANTS | PARTNER HANEEN SHARAFELDEEN

Using the process of lamination, we designed and built a portable desk using walnut and beech wood. By removing material from the surface, we allowed for heat to escape from laptops; this design decision was also to allow for a lightweight desk that is easy to carry. This balanced approach allowed us

to reduce weight while maintain the desk’s structural integrity and ergonomic design. Moreover, creating drawers acts as an extension to the surface to provide additional surface area for the user. This creates a versatile and functional workspace solution that is crucial for promoting comfort and productivity.

FABRICATION ARC346 INTRODUCTION TO MATERIAL FABRICATION

MATERIAL

46 cm 35 cm

41 3 4 2 1

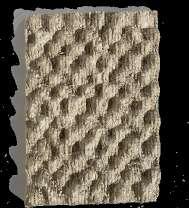

DIGITAL FABRICATION

ARC233 INTRODUCTION TO DIGITAL FABRICATION

PROJECT: IMAGE SAMPLING

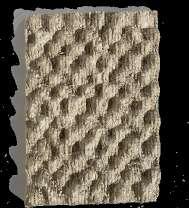

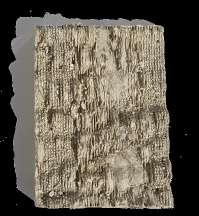

For this project, we used Grasshopper Image Sampling to generate a digital surface from a pattern that has a potential for casting. We extruded this pattern into a solid form and contoured it to a thickness of chipboard. We nested those pieces to minimize material wastage and prepare for laser cutting. Finally, we used our 20 x 20 x 15 cm acrlyic formwork to cast plaster into our mold.

ITERATIONS : RELEASE AGENTS

Final Cast 7

2 Acrylic Base

35CM 35CM

5

6

4

1

3 Acrylic Walls & Chipboard Mold De-constructing

De-molding

Drytime: 24 hours Pouring Plaster

Cast Requirements 20CM 20CM

ADVISOR | MARCUS FARR PARTICIPANTS | PARTNER RAND RAHMANI

PLASTIC WRAP COOKING SPRAY GLUE GLUE & COOKING SPRAY

PROCESS

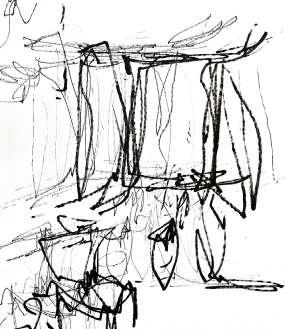

First, we tested the ergonomics of painting with four sticks. This was a crucial decision to our design and strategy, as it is an unusual way to create drawings.

3 Given the dimensions of the Makerbot printer, we made sure to design the tool to fit in its tray size.

1 Next, we chose a type of wood that is lightweight to allow for the tool to be easily carried and measured the needed dimensions.

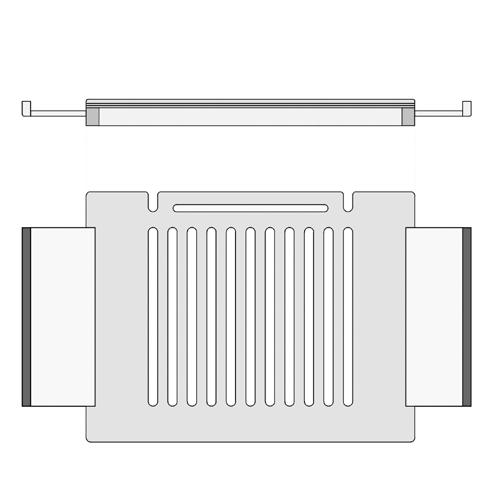

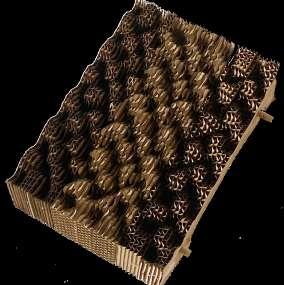

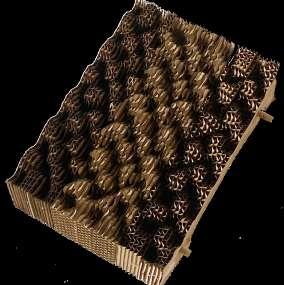

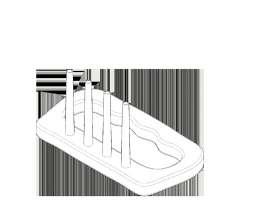

PROJECT: 3D PRINTING TOOLS FOR EXTENSION OF ARTISTIC PRODUCTION

The tool is designed to support long sticks with counterweight support. The tool is then converted into a mesh and rotated to be printed.

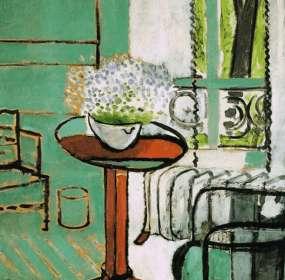

For this project, our aim was to create a tool that serves as an extension for the artistic process of gesture painting or drawing. Artists, like Henri Matisse, have used tools as such to create large scale drawings with fluid strokes.

PROCESS

TESTS: ITERATION 1

ITERATION 2

SKETCHES

To hold the sticks in place, we designed grips on the inside of the holes. However, this was not tight enough for the sticks to adhere onto.

First, we tested the ergonomics of painting with four sticks. This was a crucial decision to our design and strategy, as it is an unusual way to create drawings.

a fine-tip medium, such and charcoal. This is along the different lines make. Moreover, changing create hierarchy and depth in resulting in moments of density

TESTS: ITERATION 1

To hold the sticks in place, we designed grips on the inside of the holes. However, this was not tight enough for the sticks to adhere onto.

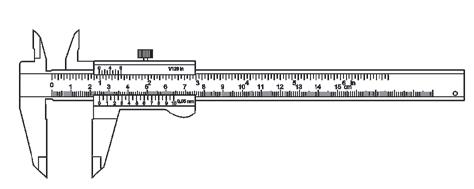

SHOP DRAWINGS THE MEDIUM

SHOP DRAWINGS

SCALE 1:2

SHOP DRAWINGS

Extensions of Artistic Production

3 Given the dimensions of the Makerbot printer, we made sure to design the tool to fit in its tray size.

To better hold the sticks, especially of such long legnth, tapering the hole held them up firmly, even when pressure was applied while drawing.

1 Next, we chose a type of wood that is lightweight to allow for the tool to be easily carried and measured the needed dimensions.

Starting off, the scale of drawings was small, hence the short length. The focus at this stage was much rather on the medium. As the intended scale grew bigger, we thought of an arm support that is tied with velcro straps at the wrist, however this would not accomodate for every hand size as it take the specific shape. Then we decided to go with a versatile, ergonomic handle.

DRAWINGS

The tool is designed to support long sticks with counterweight support. The tool is then converted into a mesh and rotated to be printed.

ITERATION 2

To better hold the sticks, especially of such long legnth, tapering the hole held them up firmly, even when pressure was applied while drawing.

SKETCHES

Starting off, the scale of drawings was small, hence the short length. The focus at this stage was much rather on the medium. As the intended scale grew bigger, we thought of an arm support that is tied with velcro straps at the wrist, however this would not accomodate for every hand size as it take the specific shape. Then we decided to go with a versatile, ergonomic handle.

THE MEDIUM DRAWINGS

We chose to use a fine-tip medium, such as markers, pens, and charcoal. This is for us to follow along the different lines each of those make. Moreover, changing thicknesses create hierarchy and depth in the drawings resulting in moments of density and sparsity.

RAND RAHMANI & NADINE GHAZAL | 83782 & 84206 | FALL 2022 | FARR

Wall: up and down, and sideways motion

SCALE 1:2

Extensions of Artistic Production

RAND RAHMANI & NADINE GHAZAL | 83782 & 84206 | FALL 2022 | FARR

down motion

Floor: front and back motion (slow)

43

165mm 295mm 195mm

2

4 121mm 234mm 125mm

2 165mm 295mm 195mm

4 121mm 234mm 125mm

as Extensions of Artistic Production

The Window by Matisse Open Window at Collioure by Matisse Wall: fluid motion Wall: up and down, and sideways motion Floor: front and back motion (slow) Floor: rotated front and back motion (fast) Floor: front and back with one controlled stick

motion

Wall: up and down

The Window by Matisse

Open Window at Collioure by Matisse

Floor: rotated front and back motion (fast) back with one controlled PROCESS

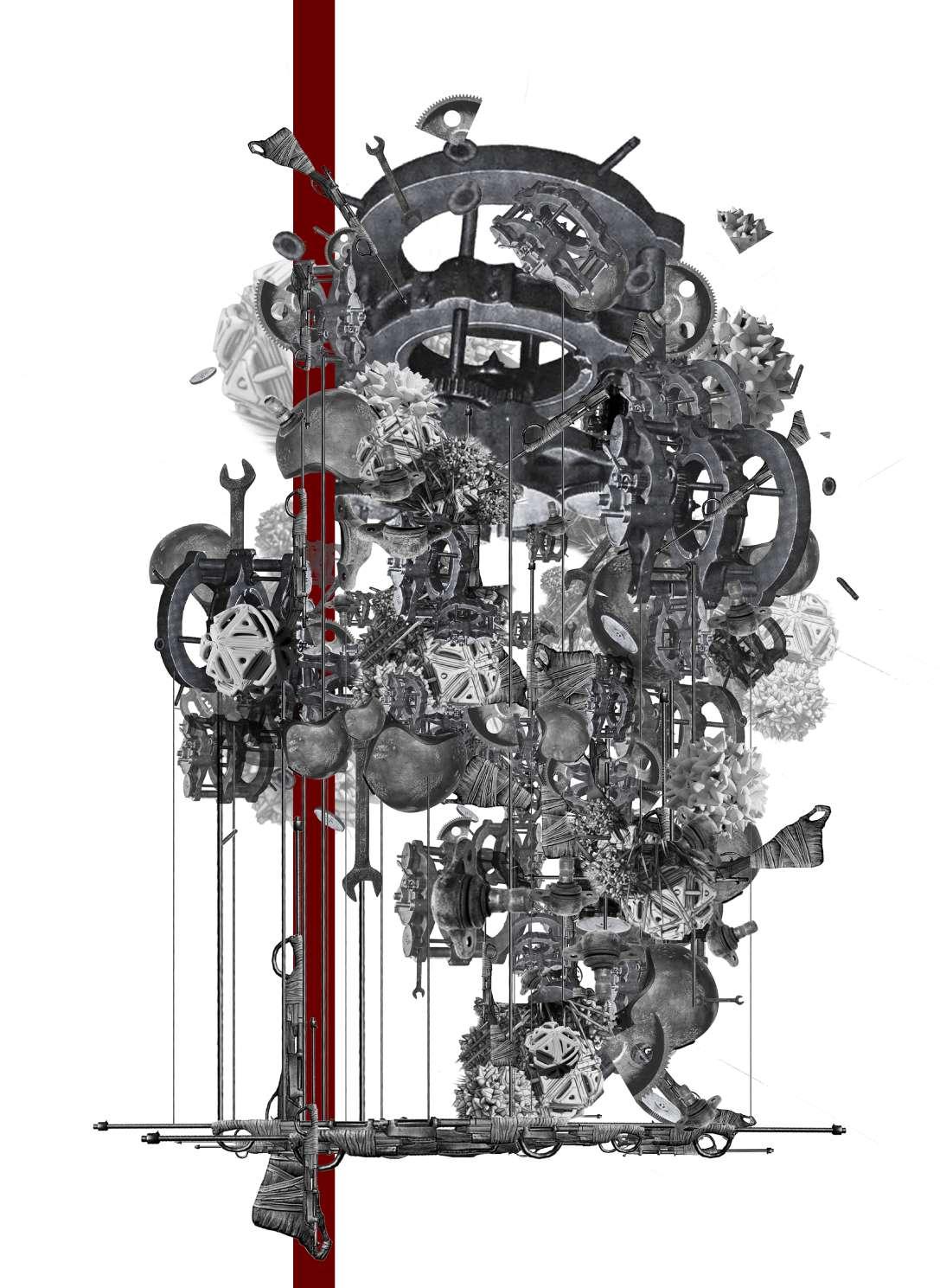

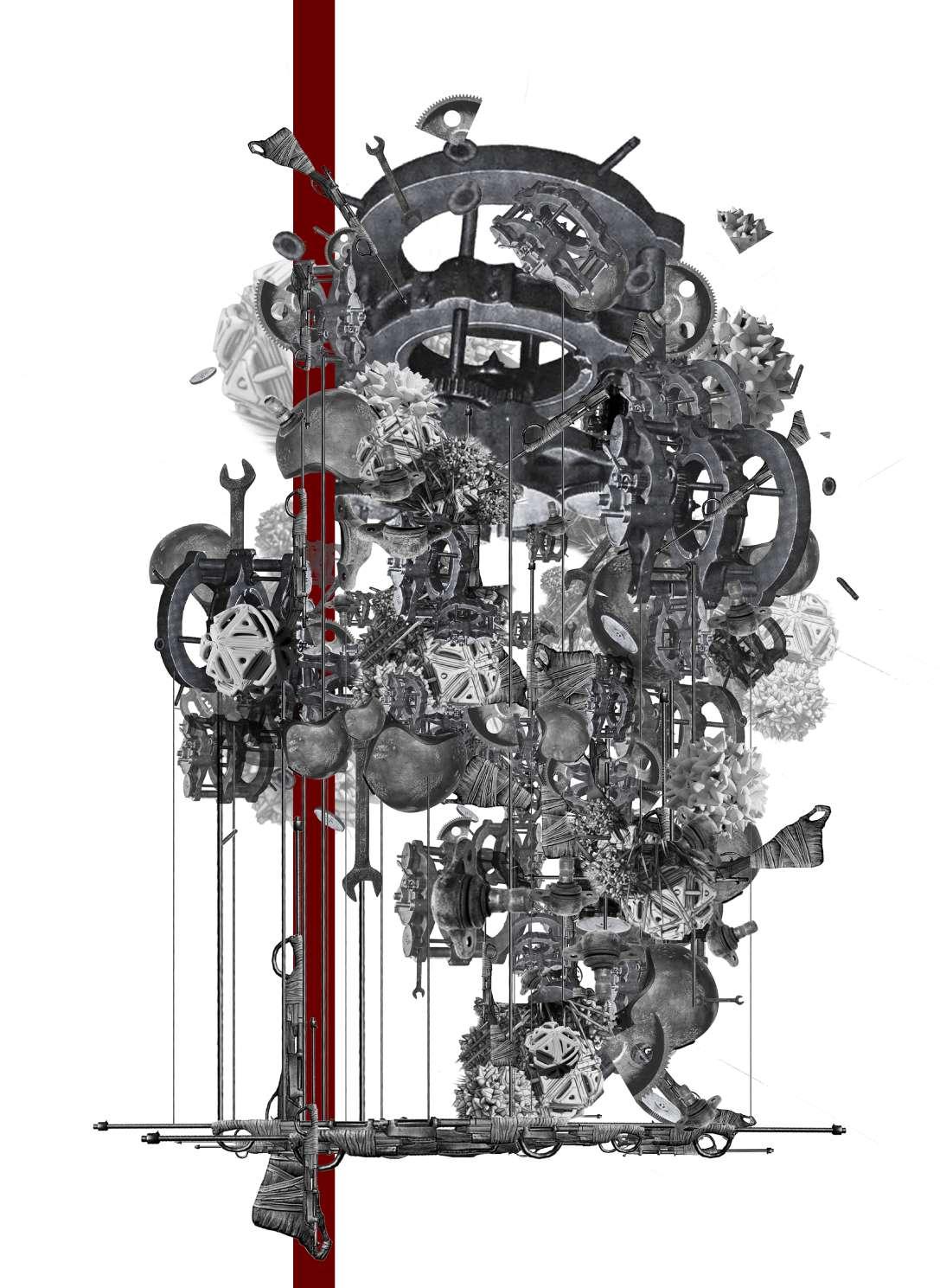

COLLAGING

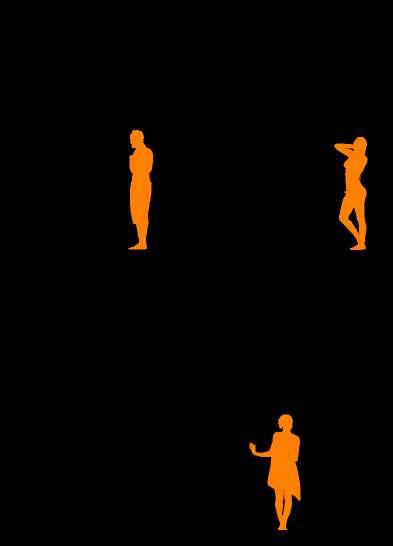

ARC311 ILLUSTRATION & RENDERING

ADVISOR | GEORGE KATODRYTIS PARTICIPANTS | INDIVIDUAL

45

These collages made using a hybrid of analogue and digital techniques. By layering found objects and modeled objects, I created a series of highly vertical objects in space as well as interior spaces.

BACHELORS OF INTERIOR DESIGN 23’

NADINE GHAZAL +971 50 708 8956 bynadineghazal@gmail.com