ACHIEVING

BUSINESS

EXCELLENCE

ONLINE

BusinessExcellence Weekly ISSUE No. 74 | www.bus-ex.com

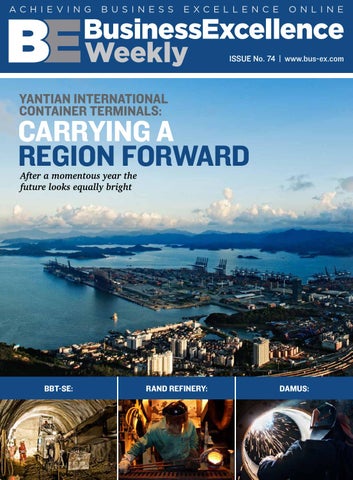

Yantian International Container Terminals:

Carrying a region forward After a momentous year the future looks equally bright

bbt-se:

rand refinery:

damus:

ACHIEVING

BUSINESS

EXCELLENCE

ONLINE

BusinessExcellence Weekly ISSUE No. 74 | www.bus-ex.com

Yantian International Container Terminals:

Carrying a region forward After a momentous year the future looks equally bright

bbt-se:

rand refinery:

damus: