Keeping safe is a continuous challenge and one we believe is worth taking on. We believe in ZERO HARM.

Copyright© 2024 Bullivants Pty. Ltd. All Rights Reserved

LOAD RESTRAINT

Ratchet Tie-Down

Truck Winch

G70 Ratchet Load Binders

G100 Ratchet Load Binders

G70 Lever Load Binder

G100 Weld On Load Rings

G80 Weld On Load Rings

RUD Lashing Chain ICE-CURT

SafeGuard Cargo Nets

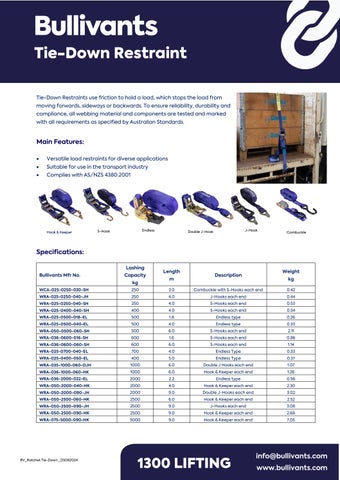

Tie-Down Restraints use friction to hold a load, which stops the load from moving forwards, sideways or backwards. To ensure reliability, durability and compliance, all webbing material and components are tested and marked with all requirements as specified by Australian Standards.

Main Features:

• Versatile load restraints for diverse applications

• Suitable for use in the transport industry

• Complies with AS/NZS 4380:2001

To maintain the friction force during transportation the load must be tensioned correctly and always remain in contact with the vehicle. The tension applied to the load is impacted by the angle at which the lashing is applied. The greater the angle, the less the clamping force. The clamping force is very small when the lashing is near horizontal and more lashings may be required. For example, a single strap at 90 degrees is equivalent to four straps at 15 degrees. The type of surface the load sits on may also impact the tension – a slippery surface provides less friction; however, rubber or other friction surfaces can reduce required lashings

• 50mm wide replacement

• 2500kg lashing capacity

Main Features:

• Versatile load restraints for diverse applications

• Suitable for use in the transport industry

• Complies with AS/NZS 4380:2001

The Bullivants Grade 70 Ratchet Load Binders are suitable for use in transport industry, for Grade 70 transport chains and general tie-down applications

Main Features

• Grab hook end fitting

• Easy to use with no recoil or risk of injury during tensioning

• To be used with Grade 70 transport chain

• Finish: red powder coat

• Complies with AS/NZS 4344

Specifications

Technical Drawings

The Bullivants Grade 100 Ratchet Load Binders are suitable for use in transport industry, for Grade 100 chains and general tie-down applications

Main Features

• Grab hook end fitting

• Easy to use with no recoil or risk of injury during tensioning

• For use with Grade 100 chain

• Ideal for tensioning and general tie-down applications

• Finish: white powder coat

• Complies with EN 12195.3

Specifications

Technical Drawings:

The Bullivants Grade 70 Lever Load Binder is suitable for use in transport industry, for Grade 70 transport chains and general tie-down applications.

Main Features

• Grab hook end fitting

• To be used with Grade 70 transport chain

• Not suitable for industrial lifting purposes

• Finish: red powder coat

• Complies with AS/NZS 4344

Specifications

Please note, these are not recoilless

Technical Drawings:

Weld on Lifting Points are manufactured in Australia using only heat certified Australian Steel. The Working Load Limit and Batch identification is clearly marked on both the Loop and Lug.

Main Features:

• Multi-directional loading

• Forged from fully tested and certified steel

• Ideal for lifting and lashing

• Welding must always be carried out by a qualified welder under AS 1554.1:2014

• Supplied with welding instructions

• Complies with AS 3776

Specifications:

Bullivants Grade 80 Weld on Lifting Points are manufactured using forged alloy steel. The Working Load Limit and Batch identification is clearly marked on both the Ring and Lug.

Main Features:

• Grade 80 Alloy Forged D Ring

• Fatigue tested to >20,000 cycles at 1.5x WLL

• Ideal for lifting and lashing applications

Specifications:

• Each unit is packaged with welding instructions

• Welding must always be carried out by a qualified welder under AS/NZS 1554.1

In 1994, RUD received approval as the first chain manufacturer to produce an approved grade 8S (grade 100) chain system.

VIP-100 – an eye catching pink power coated round steel link chain revolutionised the chain market at that

time, as it could be loaded by up to 30% more using the same nominal size than grade 80.

This resulted in a considerable weight saving and improvement of ergonomics compared to the grade 80 still commonly used in todays market.

13 years on from grade VIP-100, RUD advanced into the next innovative step in chain technology and became the world‘s first to receive approval for round steel link chains in grade 120 by the German BG to stamp “D”.

Special quality class ICE-120 delivers improved safety features, wear indicators and higher working load.

• 60% increase in WLL (means the same load can be lifted by a chain one full diameter size smaller than grade 80.

• Double the impact toughness of AS 2321 grade 80.

• Duplex surface protection provides greater protection against corrosion

• Increase life due to the superior CrNiMo alloy.

The proven technical advantages of the VIP-100 program were maintained and further developed with the ICE120 lashing chain.

Tensioning, connecting and shortening elements were considerably improved in terms to weight and functionality. The ergonomic design provides quick

and easy handling, faster fitting and a substantial increase in safety.

ICE-120 – in ICE-Pink (traffic purple) powder coated – offers significant weight saving for the user.

The standard equivalent grade 80 commercial lashing chains are on average 60% heavier.

Due to the strength of the patented ICE-120 material, a continuous leap in the nominal size could be realised when compared to grade 80, even with smaller dimensions than a diameter of 16 mm.

This means for direct lashing, an ICElashing chain is able to replace a lashing chain of grade 80 of the next larger nominal size.

As a special highlight to the ICE-120 system, the ICE-CURT tensioner offers even more advantages:

• excedees the requirements of EN 12195-3

• magnetically clinging locking device –also suitable as anti-theft system (lockable)

supplied with a RUD-ID-POINT®

ICE-STAR-HOOK:

•Wear marks

• Control mark for widening the mouth width

•Robust, forged safety latch

ICE-Chain:

•Grade 120

•35 % tougher

• 30 % harder

• Up to 60 % more LC

•Up to 45 % lighter

Shortening

•Quick, easy handling

•Locking device by shape

ICE Identification Tag:

•integrated testing gauge

Convenient anti-loosening

•Theft protection possible

RUD-ID-POINT®

•Movable on the chain

Easy, quick handling / maintenance

RUD‘s lashing chain calculation program and lashing protocol enables the user to easily select the correct RUD sling chain and lifting points!

Based upon a questionnaire, the most important selection data is collected ie:

• weight of load

• horizontal- and vertical angle

• sliding friction value

The optimal RUD lashing chain will automatically be determined in only a few seconds.

You can then print out the: drawing scheme, parts list and calculation protocol at your convenience!

Main Features:

• UV Stabilised polyester webbing and mesh

• Anti tangle design

• Multiple anchor points

• Nets load rated up to 1,000kg

• perfect for utes, trucks, trailers and more

Replacement Cargo Straps Specifications: