3 minute read

Outstonding New Plywood Products Previewed crr 1957 DFPAnnuqli Cqliforniq's Agnew President

Listen to your customers if you want to keep growing.

That was the gist of the keynote speech before the Douglas Fir Plywood Association by DFPA Managing Director W. E. Difford at Gearhart, Oregon, in the 21st annual meeting of the trade promotion group which represents close to 90/o of the 'ivestern fir plywood output.

He told the 250 fir plywood mill officials they must bccome more responsive to the needs of their customers if fir plywood demand is to keep climbing higher than its current annual mark of five billion square feet.

Difford also made these points:

1. Several startling new construction techniques such as an arched honeycomb structural sandwich-type panel and a lightweight dome-like plywood roof shell for mass school construction are opening up entirely new fir plywood markets.

2. Three other new fir plywood panels have recently been introduced to help increase plywood demand. These include PlyScord sheathing panels with an exterior (waterproof) glueline; Marine Exterior, a premium boat building panel; and the thick combination subflooring-underlayment panel called 2.4.1.

3. Intensified promotion is helping plywood capture a greater part of the industrial market such as pallets to take up sales slack which has resulted from ferver new housing starts.

Difford suggested the mill officials should think not only in terms of standard 4x8 panels but should consider making cut-to-size panels for soecialized end-uses in the construction and industrial fields. He pointed out that the fir plyrvood industry has scarcely scratched the surface in the industrial market rvhere there is an estimated potential of 49-million square feet of plyrvood consumption in pallets alcine.

The DFPA managing director also predicted that industry promotion over the next few years would raise the use of fir plywood in new home construction to an average of 3,000 square feet per house from its present average of 1,300 square feet per house. He also outlined how the DFPA is intensifying its promotion in the farm and school fields.

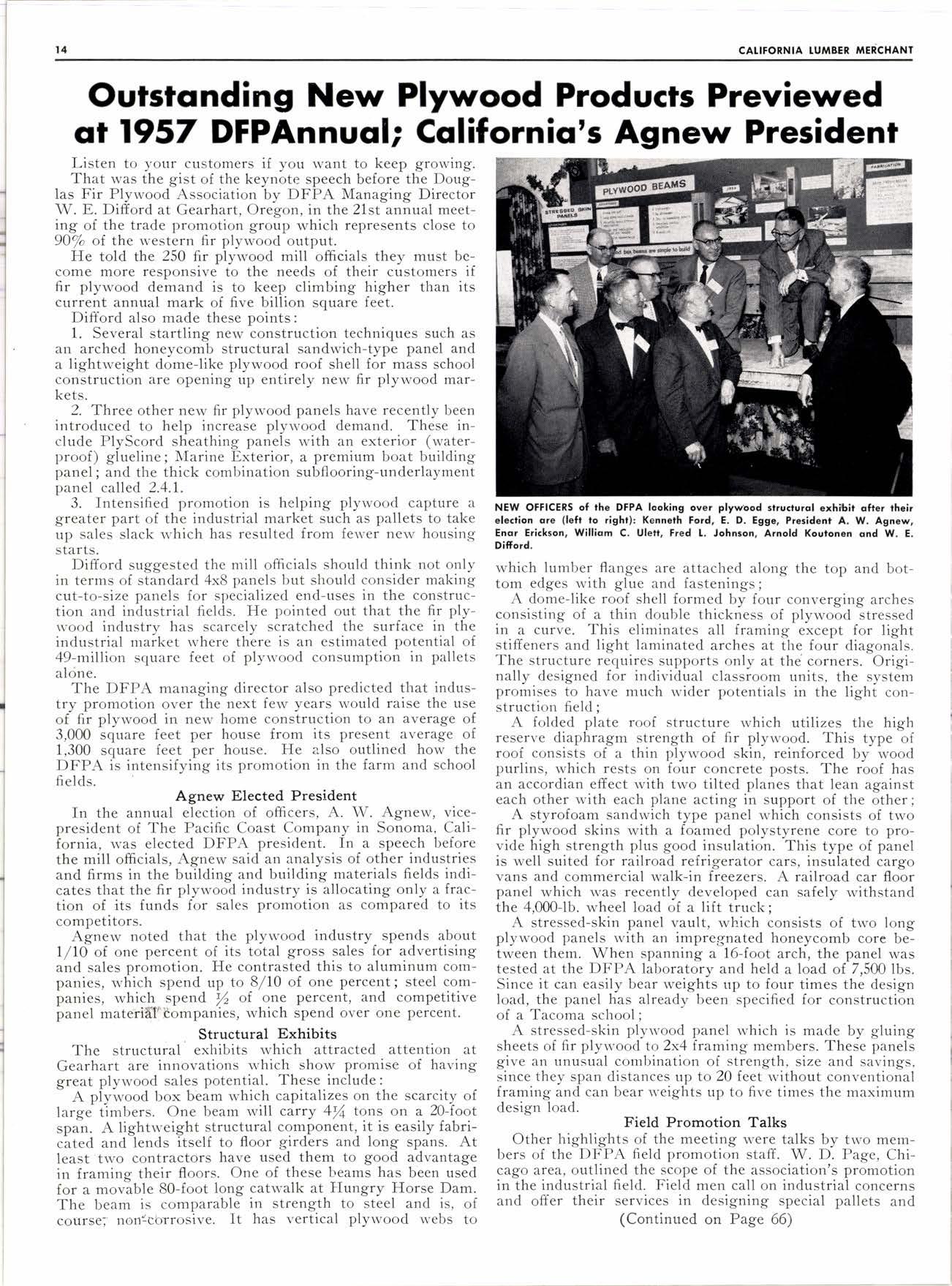

Agnew Elected President

In the annual election of officers, A. W. Agnew, vicepresident of The Pacific Coast Company in Sonoma, California, was elected DFPA president. In a speech before the mill officials, Agnew said an analysis of other industries and firms in the building and building materials fields indicates that the fir plywood industry is allocating only a fraction of its funds for sales promotion as compared to its competitors.

Agnew noted that the plywood industry spends about l/lO of" one percent of its total gross sales for advertising and sales oromotion. He contrasted this to aluminum companies, wliich spend up to 8/10 of one percent; steel companies, which spend f of one percent, and competitive panel materiffT''tompanies, which spend over one percent.

Structural Exhibits

The structural exhibits which attracted attention at Gearhart are innovations which show promise of having great plywood sales potential. These include:

- A piywood box treim which capitalizes on the scarcity of large timbers. One beam will carry 4fu tons on a 20--foot span. A lightweight structural component, it is easily fabri cated andlends itself to floor sirders and long sDans. A corrrP0rren., cited andlends floor girders and cated and lends girders spans. At least two contractors have used them to good advantage in framing their floors. One of these beams has been used for a mov-able S0-foot long catwalk at Flungry Horse Dam. The beam is comparable in strength to steel and is, of course; non"-cbrrosive. It has vertical plyrvood webs to which lumber flanges are attached along the top and bottom edges with glue and fastenings;

A dome-like roof shell formed by four converging arches consisting of a thin double thickness of plywood stressed in a curve. This eliminates all framing except for light stiffeners and light laminated arches at the four diagonals. The structure requires supports only at the corners. Origi- nally designed for individual classroom units, the system promises to have much wider potentials in the light construction field:

A folded plate roof structure which utilizes the high reserve diaphragm strength of fir plywood. This type of roof consists of a thin plywood skin, reinforced by wood purlins, which rests on four concrete posts. The roof has an accordian effect with two tilted planes that lean against each other with each plane acting in support of the other;

A styrofoam sandwich type panel which consists of two fir plywood skins with a foamed polystyrene core to provide high strength plus good insulation. This type of panel is well suited for railroad refrigerator cars, insulated cargo vans and commercial walk-in freezers. A railroad car floor panel which was recently developed can safely withstand the 4,000-1b. wheel load of a lift truck;

A stressed-skin panel vault, which consists of trvo long plywood panels with an impregnated honeycomb core between them. When spanning a 16-foot arch, the panel was tested at the DFPA laboratory and held a load of 7,500 lbs. Since it can easily bear weights up to four times the design load, the panel has already been specified for construction of a Tacoma school;

A stressed-skin plyrvood panel which is made by gluing sheets of fir plywood to 2x4 framing members. These panels give an unusual combination of strength, size and savings, since thev span distances uD to 20 feet without conventional framing i.rd can bear rveiglits up to five times the maximum design load.

Field Promotion Talks

Other highlights of the meeting were talks by two members of the DF PA field promotion staff. W. D. Page, Chicago area, outlined the scope of the association's promotion in the industrial field. Field men call on industrial concerns and offer their services in designing special pallets and

(Continued on Page 66)