2 minute read

Weyerhaeuser Engineered 4-square Kiln-f)ried Lumber

For 36 years Weyerhaeuser has made the finest Kiln-Dried lumber you can buy. It is known as 4-Square.

Now, a new improvement in electronically controlled kilndryrng enables us to literally throw the book away. Engineered 4-Square Kiln-Dried lumber is the result.

Extra-dry and more uniform lumber

Not one piece of Engineered 4-square lumber contains more than 19% moisture. The average is 157o. These are the narrowest limits ever established for framing lumber and are made possible by new electronic moisture controls. This uniformly dried Engineered framing can be reduced to slightly smaller thickness (1y2') with no sacrifice in strength and stiffness. This is approximately the same size unseasoned lumber will attain in service.

Extra-strong lumber

Uniform low moisture content and lighter weight insure the best performance builders have yet to obtain from framing lumber. Strength, stability and stiffness factors are right on the money for today's building needs.

Recognized technical groups throughout the industry have confirmed that the rtew Uz" thickness at Ig7" maximum moisture content meets the structural requirements of existing Federal Housing Administration span tables.

An improvement that means steady sales for you

Engineered 4-Square lumber is manufactured to the engineered needs of the market. It reduces weight and overbuilding. Gives you a positive way to hold and improve sales against competitive products. Opens additional sales opportunities for you in the growing component building market where uniform size and moisture are vital.

4 important reasons why Engineered 4-Square L, Kiln-Dried Lumber is your best buy

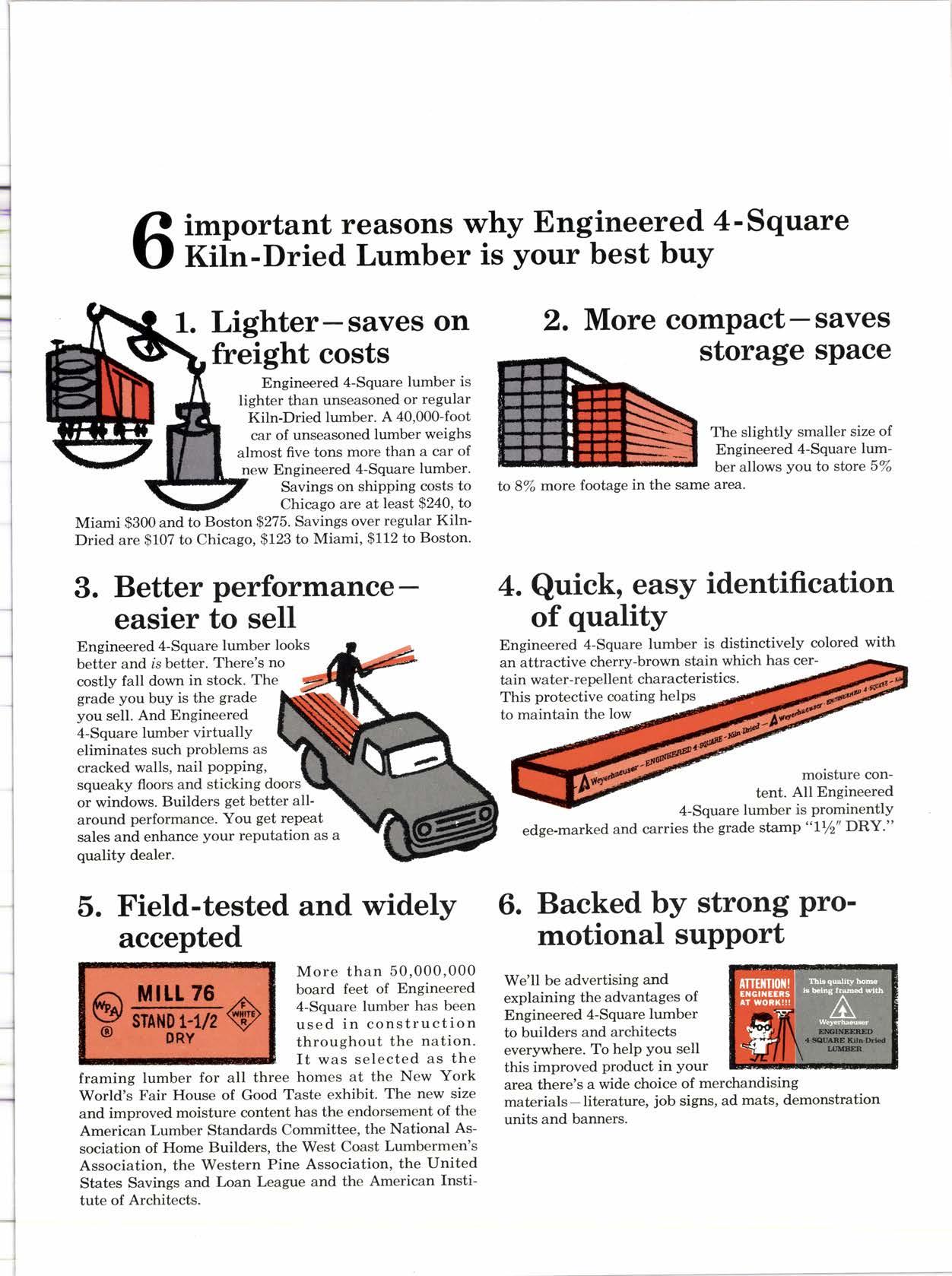

1. Lighter-saves on 2. More compact-saves storage space

Freight Costs

Engineered 4-Square lumber is lighter than unseasoned or regular Kiln-Dried lumber. A 40,000-foot car of unseasoned lumber weighs almost five tons more than a car of new Engineered 4-Square lumber.

The slightly smaller size of Engineered 4-Square lumber allows you to stnre 57o Savings on shipping costs to Chicago are at least $240, to to 87o morc footage in the same area.

Miami $300 and to Boston $275. Savings over regular KilnDried are $107 to Chicago, $123 to Miami, $112 to Boston.

3. Better performance- 4. Quick, easy identification easier to sell of quality

Engineered 4-Square lumber looks better and is better. There's no costly fall down in stock. The grade you buy is the grade you sell. And Engineered 4-Square lumber virtuallY eliminates such problems as cracked walls, nail popping, squeaky floors and sticking doors or windows. Builders get better allaround performance. You get repeat sales and enhance your reputation as a quality dealer.

5. Field-tested and widely

Accepted

More than 50,000,000 board feet of Engineered 4-Square lumber has been used in construction throughout the nation. It was selected as the framing lumber for all three homes at the New York World's Fair House of Good Taste exhibit. The new size and improved moisture content has the endorsement of the American Lumber Standards Committee, the National Association of Home Builders, the West Coast Lumbermen's Association, the Western Pine Association, the United States Savings and Loan League and the American Institute of Architects.

Engineered 4-Square lumber is distinctively colored with an attractive cherry-brown stain which has certain water-repellent characteristics. morsture content. All Engineered 4-Square lumber is ProminentlY edge-marked and carries the grade stamp "lyz' DF"Y '"

6. Backed by strong Promotional support

We'll be advertising and explaining the advantages of Engineered 4-Square lumber to builders and architects everywhere. To help you sell this improved product in your area there's a wide choice of merchandising materials - literature, job signs, ad mats, demonstration units and banners.