2 minute read

iltA frlakes Far Reaching Proposals

rnHE NATIONAL Lumber Manufacturers I Association has urged major building rnaterials manufactureri to launch a $3.2 million-a-year promotion program designed ' to encourage increased home ownership.

Endorsement of "Project Home" climaxed the association's four-day meeting at Portland, Ore., attended by more lumbermen than any other spring conference in the association's 62,year history.

"The Project Home" proposal was presented as a means of increasingo or at least sustaining housing's share of"ihe consumer's dollar, reported to have slipped from 25 percent a few years ago to about 11 percent today. Basic objective of the program would be to pull all major build. ing materials manufacturers together in a rsta:. nt nationwide promotion program to the building and buying of single-

' family homes and generally upgrade the tration's housing standards.

Iumber Standards Atternate

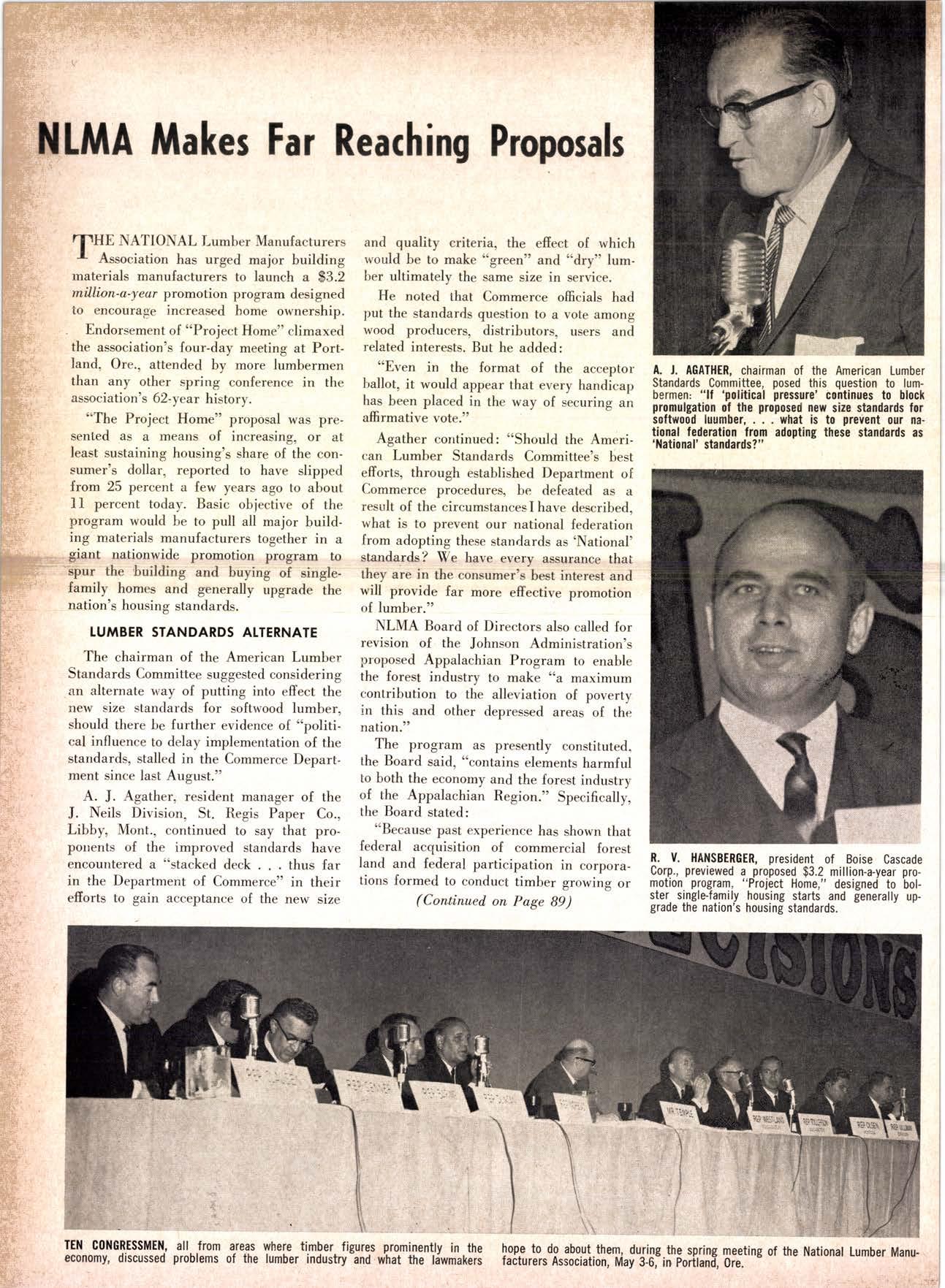

The chairman of the American Lumber Standards Committee suggested considering .an alternate lvay of putting into effect the new size standards for softwood lumber, should there be further evidence of "political influence to delay implementation of the starrdards, stalled in the Commerce Department since last August."

A. J. Agather, resident manager of the J. Neils Division, St. Regis Paper Co., Libby, Mont., continued to say that propouents of the improved standards have encountered a "stacked deck . thus far in the Department of Commerce" in their efiorts to gain acceptance of the new size and quality criteria, the efiect of which would be to make 'ogteen" and o'dry" lumber ultimately the same size in service.

He noted that Commerce officials had put the standards question to a vote among wood producers, distributors, users and related interests. But he added:

'oEven in the format of the acceptor ballot, it would appear that every handicap has been placed in the way of securing an affirmative vote."

Agather corrtinued: "Should the American Lumber Standards Committee's best efforts, through established Department of Commerce procedures, be defeated as a restrlt of the circumstanceslhave described, what is to prevent our national federation from adopting these standards as oNational' standards ? W'e have every assurance that they are in the consumer's best interest and will provide far more effective promotion of lumber."

NLMA Board of Directors also called for revision of the Johnson Administration's proposed Appalachian Program to enable the forest industry to make 'oa maximum contribution to the alleviation of poverty in this and other depressed areas of the nation."

The program as presently constituted, the Board said, "contains elements harmful to both the economy and the forest industry of the Appalachian Region." Specifically, the Board stated:

"Because past experience has shown that federal acquisition of commercial forest land and federal participation in corporations formed to conduct timber growing or (Continued, on Page 89)

Moore Dry Kiln's modern plant in North Portland, Oregon

Modern Moore factories in Portland, Brampton, Ontario, and Vancouver, B. C. are equipped to handle all your lumber seasoning needs. from planning, engineering and manufacturing to complete turn-key installations. Also see us for labor-saving, profit-making lumber sorters, stackers and other lumber handling equipment.

WHY have so many mills installed Moore Kilns over the past half century? BECAUSE they know Moore's reputation in ' the lumber seasoning f ield is unsurpassed . . . they can depend on Moore Kilns to provide the f inest kiln dried lumber at lowest cost!

MOORE DRY KILNS are producing prof its all over the map . .-. you're apt to f ind them most anywhere in the world where lumber is produced! Superior engineering, design, and above all, the superior lumber seasoning which increases profits for mill operators, have made Moore Dry Kilns the standard of the lumber seasoning industry for many, many years.

Before you invest in any type of lumber seasoning equipment, it will pay you to check with Moore.