4 minute read

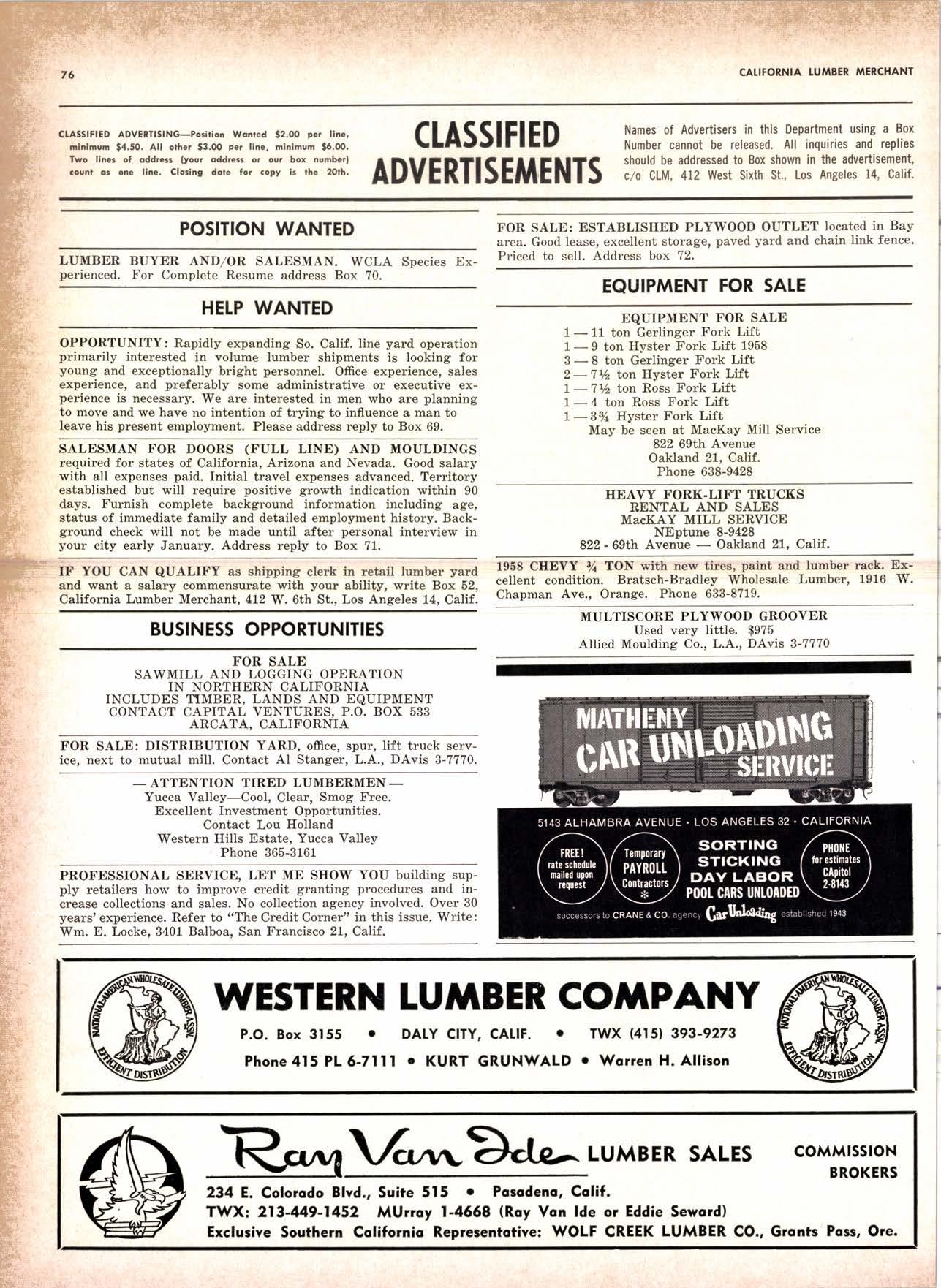

Use this chart as your k"y Gef into the Profit-packed Glu Lam Market

The glue laminated beam, an exciting example of new products being developed by dynamic scientific research programs, has definitely stirred the imagination of members of the construction industry sinc€ its inception several years ago.

Each day new applications for the bearirs are being developed. Glu lams have been specified for a wide variety of construction' projects, ranging from churches and' schools to restaurants and apartment houses.

Industry acceptance of the beams has not been without reason, however. In many installations glu lams have proven to be more fire resistant than steel and have been found to be cheaper than any comparable building material. GIu lams also have a rich beauty that allows architects and engineers to design structures with exposed beams.

With the ever-increasing popularity oI the glue laminated beam in construction, glu lam fabricators are asked frequendy to recommend a beam size to replace steel "It' beams specified for a particular job.

This request has been most prevalent in apartment house construction for beams over first floor garages. Glue lami:i$ nated beams are most economical in this type of installation where fire resistance is critical and where steel beams must be "fireproofed" at a cost of 50y' to $I per lineal foot. Glu lams of sufficient cross section do not need to be fireproofed.

Glue laminated Beam Estimator for Apartment House Jobs

Steel beams sell in a price range of $10 to $20 per cwt, depending on quantity, cutting and waste (from standard lO-foot increments). To this must be added {abrication, that is drilling for connections and nailers, and fireproofing when required. A t2WF 2-36 foot long beam would cost approximately $4 per lineal foot, plus drilling ($20-$40), plus fireproofing ($20-$40), plus bringing steel workers on the job. The total cost for such a common beam could be approximately $6 per lineal foot.

Compare this to a glue laminated beam at approximately $3.70 per lineal foot, witll a l0 per cent profit to the lumberman.

The table of conversion sizes on this page was circulated to many retail lumbermen in Southern California by the Ed .Fountain Lumber Co. several months ago to assist and encourage retail yard customers to seek glu lam business. Since that time several jobs have used glue laminated beams where steel beams were originally specified.

lichord G. Burion, Strucf. Engr.

278O Sepulvedo, Torronce, Phone 325-2834

NOTES: l.f fhe lobles obove rePreseni equiv. bending slrenglh for preliminory estimofing of FLOOR beqms.

2.1 BeorinE, da0eclion ond sheor hqve not been considered os they vory from iob to iob.

3.1 G.t.B. stress 260Of Ino increosef Astm. A-7 2O,OOOf. Astm. A-36 22,OOOi.

4.1 When comporing coels cor3ider cosf of noiler ond noiler bolting,

5.1 G.f.B. sizes of equiv, seclion rnodulus moy be used in ploce of lhosc tobuloted. Depth ir usuolly importont in qppt. hou3e con3truclion.

,We suggest that you keep this conversion table and explain it to your salesmen. The retailer can save his customer a considerable sum and make himself a handy profit by recommending glue laminated beams instead of steel.

It should be kept in mind, however, that the table is merely a guideo and any final determination of sizes should be made by a licensed engineer.

The second home market is one of the brightest spots in the building picture. lt's grown from the 75,000 units built in 1958 to 100,000 this year-and may double that in 1970. ffi But the market is not only bigger than it was five years ago. lt's different. Has your sales strategy kept up with these important changes?

E The second home is no longer just a cabin. lt's more apt to be a substantial small house built for eventual retirement. So you're selling to older couples as well as young families, and often through builders. E The size of the do-it-yourself market may have been exaggerated. So you'll get more husiness if you offer a package in- cluding at least a structural shell and utilities. The customer may do some of the f inishing. E Most prospects don't own a lot. So you need to tie in with realtors and developers. Promote your model second home, but offer land, too. E In fact, the most successful programs of all involve complete vacation-retirement developments with recreation facilities. This way, you can sell a lot, a house and a way of life. ffi DFPA research and merchandising materials have kept pace with this changing market. For more information on how the DFPA Second Home Promotion Kit can help you get more of this profitable business, see the coupon at right.

Here's what the DFPA

Second Home Promotion Kit includes:

Second Home Sales Guide-complete, upto'date manual on building and selling leisure homes. Practical pointers on financing.. package sales of lot and house how to sell materials.. kind of customers to look for. tested merchandising ideas. Shows sales aids available.

Second Home ldea Book-40 colorful pages of vacationhome ideas, designed to interest consumers. Shows floor plans and artist's renderings for 18 vacation homes. Plans available for all. Kit has 25 books in self-selling box.

Gonstruction Plans- Kit contains sample set of easy-to-follow drawings for 18 DFPAdesigndd vacation homes. Also, details on seven new compact home plans developed for the second home market by DFPA and National Plan Service.

Sales Promotion Portfolio-contains advertising layouts, ad mats, radio commercials, direct mail and display ideas.

Disptay Materials-includes two window banners and an eye-catching mobile to sell the plywood second home idea.

Cost of the Second Home Promotion Kit is just $10. Send for yours today, or ask for more details-see coupon below.

DOUGLAS FIR PLYWOOD ASSOCIATION

Tacoma, Wash. 98401 (USA only) that they're going to "hit it lucky" are Redwood

E Please send me more information on DFPA'S Second Home Promotion Kit, including the Second Home Sales Guide.

[ | enclose $10. Please send me the Second Home Promotion Kit.

Dick Stocke compare "systems." (l-D Joe

Bill

Herb

Farrell Top right, mascot for the trip was the flight's pert and Sun Valley's Bruce lacobsen. Center inset,