4 minute read

mardTfui

Dwyer Lumber & Plywood Co. Enters Component Field

Entering the rapidly growing pre'cut component field, Dwyer Lumber & Plywood Company of Portland, has developed a machine lor rapid production of many types cf components used in home and commercial building. They are now {urnishing components to many builders in the Port' land area and is prepared to ship anywhere in the United States.

The machine difiers from most setups in that saws can be angled for any common angle cuts, and are rigidly held at a bearing point near the saw-{ace for a high degree of accuracy.

"There are other machines that do some of the same things we do, but we built our own machine for absolute rigidity and accuracy," said E. C. Dwyer, vice president. "Part of the secret is in the way the material is held. In most machines, the saws are stationary and the material is pushed past them. In our machine, the material is clamped in a fixed position and the saws cut through it."

f)wyer is able to pre-cut almost any type of member commonly employed in building-roof truss members, ceiling and floor joists, studs, sills, plates, panel members, and special stock. An example of the latter was an order for framing pieces to {orm an octagonal housing for a large pipe.

Green & Dry Uppers

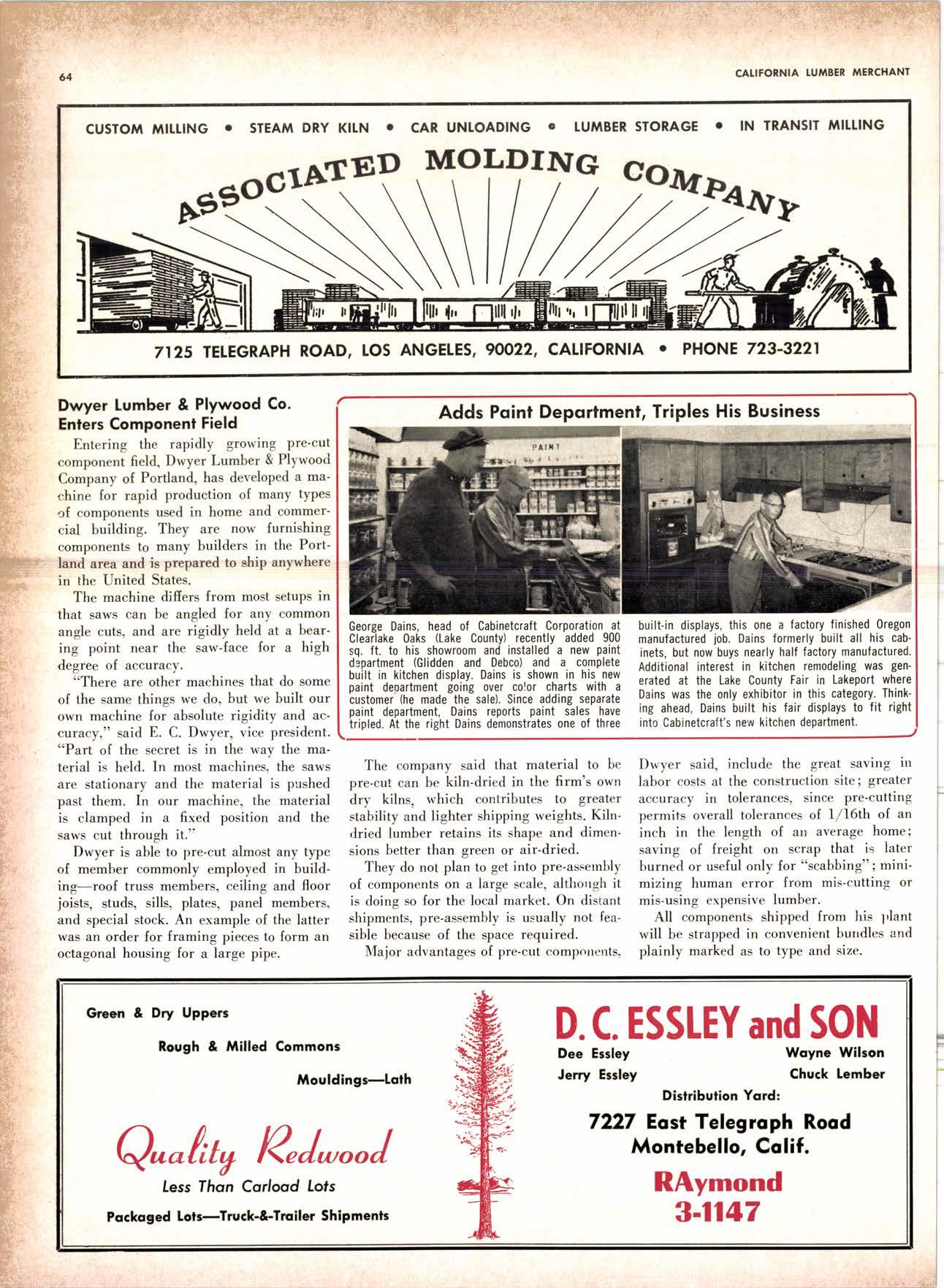

Adds Point Deportment, Triples His Business

George Dains, head

Corporation at Cleailake 0aks (Lake County) recently added 900 sq. ft. to his showroom and installed a new paint deoartment (Glidden and Debco) and a complete built in kitchen display. Dains is shown in his new paint deoartment going over color charts with a customer (he made the sale). Since adding separate paint department, Dains reports paint sales have tripled. At the right Dains demonstrates one of three

The company said that material to be pre-cut can be kiln-dried in the firm's own dry kilns, which contributes to greater stability and lighter shipping weights. Kilndried lumber retains its shape and dimen' sions better than green or air-dried.

They do not plan to get into pre-as-sernbly o{ components on a large scale, althorrgh it is doing so for the local market. On distant shipments, pre-assembly is usually not feasible because of the space required.

N{ajor advantages of pre-cut components,

Rough & Milled Gommons Mouldings-Loth /\/) tnt less fhon Corlood lots

Pockaged Lols-Truck-&-Truiler Shipments

Dee Essley

Jeny Essley built-in displays, this one a factory finished 0regon manufactured iob. Dains formerly built all his cabinets, but now buys nearly half factory manufactured. Additional interest in kitchen remodeling was gen' erated at the Lake County Fair in Lakeport where Dains was the only exhibitor in this category. Think' ing ahead, Dains built his fair displays to fit right into Cabinetcraft's new kitchen department. f)wyer said, include the great saving in labor costs at the construction site; greater accuracy in tolerances, since pre'cutting permits overall tolcrances of 1/16th of an inch in the length of an average home; saving o{ {reight on scrap that is later burned or useful only for 'oscabbing"; mini' mizing human error from mis-cutting or mis-using erpensive lumber.

All components shipped from his plant will be strapped in convenient bundles and plainly marked as to type and size.

Son

Woyne Wilson

Chuck Lember

Polin Promoled ln Omork lnduslries

Omark Industries, Inc. has promoted David Palin, formerly Seattle branch manager, to the new position of W'est Coast Regional Manager. Guy E. Sabin, vice president-marketing, forthe Portland, Oregon-based firm, has announced.

Palin will work from the company's regional office in San Francisco and will oversee sales and administrative activities for Omark in Oregon, Washington, California. Nevada. Arizona and Western ldaho and Montana. Omark factory offices in the resion are located in Seattle. San Fran-

CATIFORNIA LU}IBER'YIENCHANT cisco, Los Angeles, San Diego, Sacramento and San Jose. All carry the full Omark product line of saw chain; fastening, sawing and drilling equipment for concrete and masonry; and percussive stud welding equipment.

Prior to assuming the branch manager's post in Seattle, Palin was owner and president from 1958 to 1962 of. Intermountain Distributors, Inc. which was acquired by Omark in 1962.

Previously in his varied career, he has been a pilot for a British airline, a public relations executive in Karachi. Pakistan. and U. S. sales manager for a chain saw manufacturer.

QUIGK.DRYING SEALER

This pole gloss cooting seols ond finishes wood surfoces. lt is fqst drying woterproof . ond resistont to grime, dirt, soop scrubbing ond hord weor. TH|S lS A CUSTOMER PTEASER THAT CAN'T BE BEAT.

CaIl or u:rite asith prices & lor catalog color chart

Togger Turned Author

(Continued. lrom Page 34) of American Foresters, the Society of American Historians, the American Antiquarian Society and other organizations.

The award was presented at American Forest Industries' annual meeting at the Shoreham Hotel by J.D. Bronson of Yaki' ma, Wash., AFPI president. AFPI is the forestry education and public information arm of the nation's forest industries. It sponsors the industry's Tree Farm program to grow timber as a renewable crop on private forest land, and is national sponsor of the Keep America Green {orest fire-pre vention-education campaign.

Holbrook's wife, Sibyl, was present for the award ceremony. The industry award includes $500.

This is the third such award to be made by A['PI. Earlier recipients were Samuel Trask Dana, dean emeritus of the University of Michigan's School of Natural Resources, and Ernest F. Swift, conservation advisor of the National Wildlife Federation.

Hoo-Hoo-Ettes Help Two Fqmilies ot Christmqs

The December Board Meeting of HooHoo-Ette Club No. I met at the Westwind

Restaurant in Downey as guests of PacificMadison Lumber Company with Dian Dar' nold as hostess.

The Christmas Party on December 9th had no formal program, but many were surprised at how well the voices blended in the old familiar Christmas Carols.

Plans to provide holiday cheer for two families were carried out. Money and canned goods were brought' Dian Darnold and Estelle Seemayer made and gave beau' tiful wreaths and ornaments. John Crowell of Mullin Lumber Co. in San Gabriel made the unusual wreaths and candles he do' nated. All oI these items were auctioned to swell the cofiers for the two families.

SPECIAIIZING in-Douglos Fir Dimensions, Boords & Studs