2 minute read

American Hardwood celebrates its 75th birthday

E. E. and his oldest son, Charles, were touring the west coast of the United States and Canada, calling on potential customers for their Memphis, Tn., sawmill operation when they learned of the outbreak of World War I. Taenzer & Co. had recently shipped 250,000 bf of hardwood lumber to Belgium that was confiscated by the German army and it seemed unlikely that any of it would be paid for. Taenzer decided to divest himself of his timberlands and sawmill operations in the Mississippi Valley in order to take advantage of the growth he foresaw in the west. He set up a brokerage operation in Los Angeles and, soon after, a hardwood distribution yard.

Charles and his brother. Milton. assumed control of American in 1929 after the death of E. E. The depression hit, but, with attention to quality and service, they guided the company through that time.

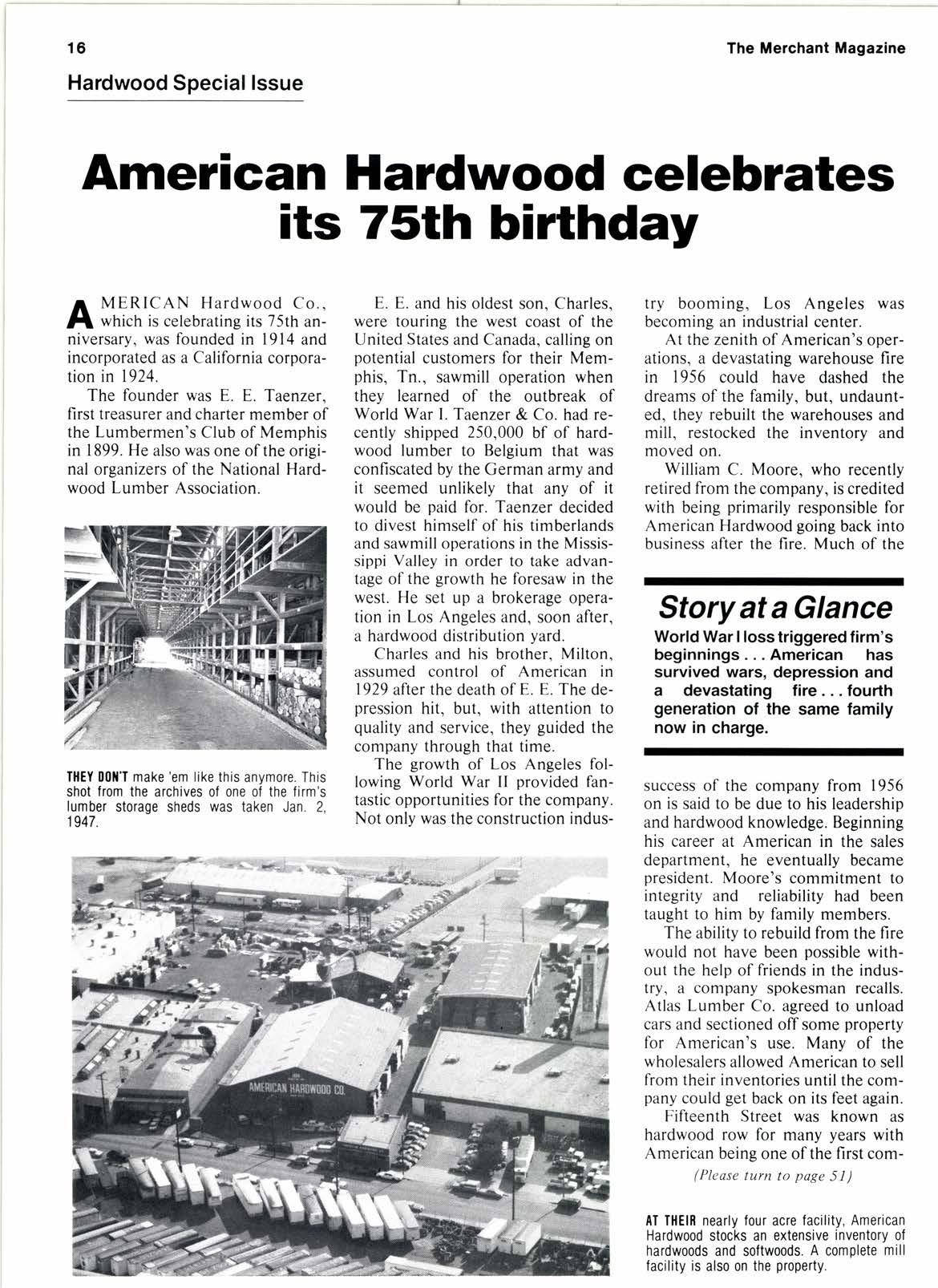

The growth of Los Angeles following World War II provided fantastic opportunities for the company. Not only was the construction indus- try booming, Los Angeles was becoming an industrial center.

At the zenith of American's operations, a devastating warehouse fire in 1956 could have dashed the dreams of the family, but, undaunted, they rebuilt the warehouses and mill, restocked the inventory and moved on.

William C. Moore, who recently retired from the company, is credited with being primarily responsible for American Hardwood going back into business after the fire. Much of the

Story at a Glance

World War I loss triggered firm's beginnings...American has survived wars, depression and a devastating fire. fourth generation of the same family now in charge.

success of the company from 1956 on is said to be due to his leadership and hardwood knowledge. Beginning his career at American in the sales department, he eventually became president. Moore's commitment to integrity and reliability had been taught to him by family members.

The ability to rebuild from the fire would not have been possible without the help of friends in the industry, a company spokesman recalls. Atlas Lumber Co. agreed to unload cars and sectioned off some property for American's use. Many of the wholesalers allowed American to sell from their inventories until the company could get back on its feet again.

Fifteenth Street was known as hardwood row for many years with American being one of the first com(Please turn to page 51)

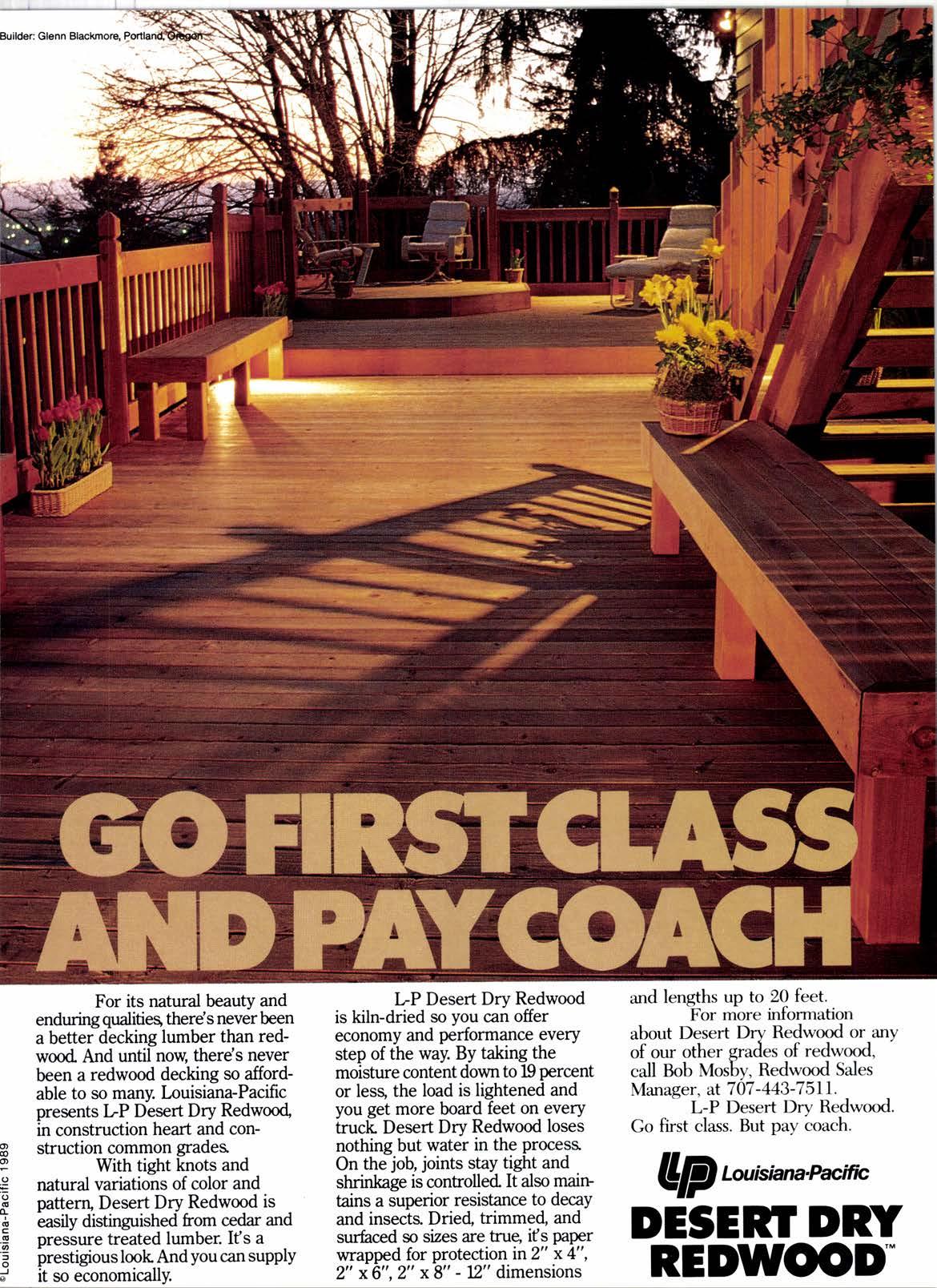

For its natural beauty and enduringqualities, there s never been a better decking lumber than redwood And until now therds never been a redwood decking so affordable to so many. lnuisiana-Pacific presents LP Desert Dry Redwoo4 in construction heart and construction common grades With tight knots and natural variations ofcolor and patterq Desert Dry Redwood is easly aistinguished from cedar and pressure treated lumber. It's a prestigious look And you can supply it so economicallv.

LP Desert Dry Redwood is kiln-dried so you can offer economy and performance every step of the way. By taking the moisture contentdownto 19 percent or lesg the load is lightened and you get more board feet on every truck Desert Dry Redwood loses nothing but water in the process On the job, joints stay tight and shrinkage is controlled It also mairr tains a superior resistance to decay and insects Drie4 trimmed, and surfaced so sizes are true, ifs paper wrapped for protectiorl in2" x 4", 2" x6",2" x8" - 12" dimensions and lengths up to 20 feet. For more inlormation about Desert Dry Redwood or any of our other qrades of redwood, call Bob Mosby, Redwood Sales Marrager, at 7 07 -443-7 5lI.

- L-P Desert Dry Redwood. Go first class. But pay coach.