4 minute read

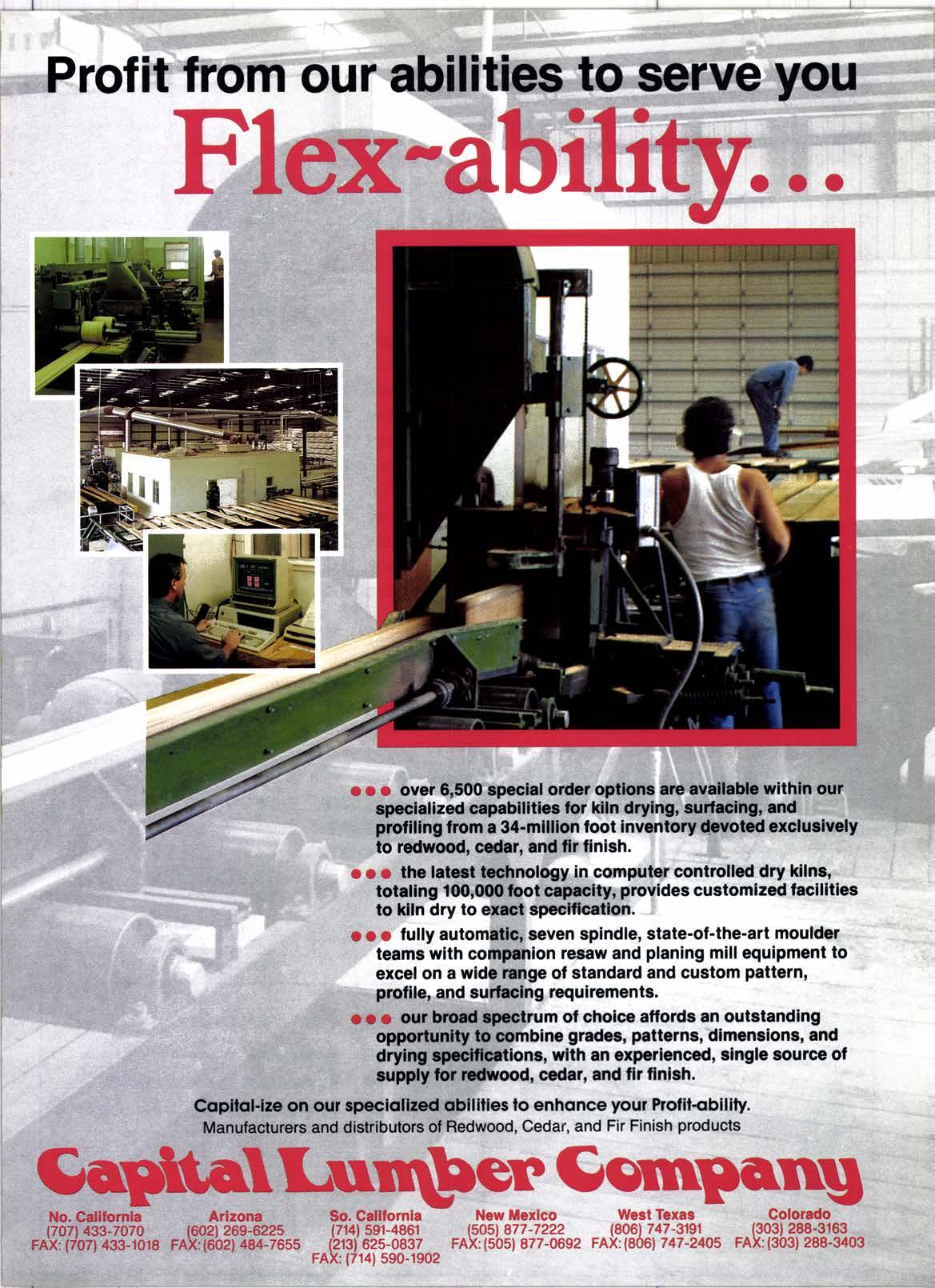

Profit from our abilities to serve you

over 6,500 special order options are available within our specialized capabilities for kiln drying, surfacing, and profiling from a 34-million foot inventory devoted exclusively to redwood, cedar, and fir finish.

the latest technology in computer controlled dry kilns, totaling 100,000 foot capacity, provides customized facilities to kiln dry to exact specification.

fully automatic, seven spindle, state-of-the-art moulder teams with companion resaw and planing mill equipment to excel on a wide range of standard and custom pattern, profile, and surfacing requirements.

our broad spectrum of choice affords an outstanding opportunity to combine grades, patterns, dimensions, and drying specifications, with an experienced, single source of supply for redwood, cedar, and fir finish.

Copifol-ize on ou1 speciolized obilifies fo enhonce your Profilobility. Manufacturers and distributors ol Redwood, Cedar, and Fir Finish products

Plus Alaska & Hawaii

Serving 13 Western

Editor-Publisher David Cutler

Senior Editor Juanita Lovret

Associate Editor David Koenig

Contributing Editors Dwight Curran, Gage McKinney, Ken Thim

Art Director Martha Emery

Staff Artist Eric Kruske

Circulation Lynnette A. Perkins

The Merchant Magazine (USPS 79656000) is published monthly rit 4500 Campus Dr., Suite 4EO Nerport Beach, Ca. 9266t0, phone (Tl4)852-1990, byThe Merchant Magazine, Inc. Second-class postage rates paid at Newport Beach, Ca., and additional offices. POSTMASTER: Send address changes to The Merchant Magazine, 4500 Campus Dr, Suite 480, Newport Beach. Ca. 92660.

ADVERTISING OFFICES

Advertising rates upon request.

I-'rom all stales east of the Rocky Mountains: Contact Jean Waggoner Gogerly, national sales manager. I--rom Arizona, Nevada and California: Contact David Cutler. Both may be reached at (714) 852-1990 or by writing 4500 Campus Dr., Suite 480, Newport Beach, Ca. 92660.

From washington State, Oregon, Idaho, Wyoming, Montana, Utah, Colorado, Northern California and Canada: Contact Carole lfolm at (206) 774-3713 or 21819 77th Place West, Edmonds, Wa. 98020, Change of Address-Send subscription orders and address chanses to Circulation Dept., The Merchant Mdlazine, 4500 Campus Dr., Suite 480, Newport Beach, Ca. 9266O. Include address label from recent issue ifpossible, new address and zip code.

Subscription Rates-U.S.: $1 l-one year; $17-two years; $22-three years. Foreign: one year payable in advance in U.S. funds-Canada or Mexico: air-$35; surface-$30; South America: air-$55; surface$30; Asia: air-$68; surface-$30; Europe: air-$98; surface-$30. Single back copies-$4.50 when available plus shipping & handling.

The Merchant Magazine is an independently owned publication for the retail, wholesale and distiibution levels ofthe lumber and home center markets in 13 western states.

EDITOR[AL

Don't poop out in midstream

llt E THINK it's great that the hardwood inUU dustry has begun in recent years to overcome its ingrained conservatism and really get serious about promoting hardwood and hardwood products, But we worry that the enthusiasm and support for the various promotions will fade before the job gets done. It has happened too often before in many areas of wood products.

Today, various associations and trade groups, bolstered by individual companies, have created hang tags, videos and designer showcases, placed stories in major consumer magazines, advertised in trade journals and hit the road telling the story by tv and radio. In fact, the new Hardwood Institute campaign using CNN Headline News and Turner Broadcasting System has increased its number of television spots from 168 to l9l.

These are exciting programs and they rightly have been well received by clear thinking industry members. But the problem is not today or

DAVID CUTLER

next year. Inevitably it comes later when these promotions have not solved every little industry complaint and problem. Unrealistic expectations often kill campaigns prematurely. Effective campaigns take time and are by nature intangibles. No one can absolutely quantify their results or the lack thereof.

While getting people's attention is both difficult and expensive, no one seriously can claim that advertising and public relations don't work. They do work, but the results don't always satisfy the bean counters. You know promotions work, but you can't always account for every last nickel.

We appeal to those who control the purse strings to be farsighted enough to allow these promotions plenty of time to work. Because when today's campaign concludes they need to follow it with yet another. When the investment lessens, results drop, endangering the whole effort. Don't let that happen. It's too important to every member of the hardwood industry.

HARDWOODS of all tyWs used by:

Furniturc Manufacturers, Millwork Shops, C-abinet Shops

Rculn

COiIPANY

MAIN OFFICE

2150 Oakdale Ave.

San Francisco, Ca.

Qrs) 647-0182

FAX (41s) 647-7766

Berkeley, Ca. 930 Ashby Ave.

(415) 843-4390

FAX (41s) 843-e378

Montebello, Ca. 7653 Telegraph Rd. Complete millwork facilities

Qr3) 723-330r

Ca. Wats 1-(800) -325-2170

FAX (213) 888-1291

Salt Lake City, Utah 1576 South 300 West (801) 484-7616

Ut. Wats 1-(800)-225-37 43

FAX (801) 484-7633

Edinburgh, Indiana 2ll Ward St.

Concentration Yard & Drv Kilns and Millwork Facilities

(8r2\ 526-9143 / FAX (grD s26-6032

Domestic HardwoodsFeaturing Northern Red Oak, Indiana White Oak. Walnut

Imported Hardwoodswith special attention to . Genuine Mahogany o Teak o Rosewoods. Bocote o Apitong . Zebrawood Rare exotic hardwoods

October 1989 tr HE REASONS may change, but I rumors that there is a hardwood shortage persist. Gypsy moths, poor forestry management, exPorts and preservationists share the blame in attempts to explain high prices and spot shortages.

There's not much basis for any of the rumors according to some hardwood experts. James L. Gundy, executive vice president of the Appalachian Hardwood Manufacturers Inc., says that the U.S. has a greater volume of hardwood trees than at any time in the last 50 years and is growing twice as much as is being harvested annually.

"Growth is assured in the mountains through natural regeneration," he explains. "With management of these stands in Appalachia, Prime species will provide future generations with ample supplies of superior red and white oak, ash, maPle, walnut, cherry, poplar, beech and birch."

The U.S. Department of Agriculture reports that about 11.5 billion board feet of hardwood lumber was produced last year, up from I l.l billion in 1987 and l0 billion in 1986. Growth, on the other hand, has been estimated at more than 25 billion board feet each year since 1985 and is escalating each year.

Lumbermen point out that hardwoods in the mountains grow back naturally when the forest floor is exposed to light and moisture as old growths of mature trees are removed. As many as 50 to 60 thousand shoots per acre come out in the Year following a harvest. Those new seedlings that are not eaten or damaged by wildlife are thinned after further growth. Dominant species then take over and the weaker or less shade tolerant trees recede or die out.

According to Robert Joslin, deputy director, timber management staff, USDA Forest Service, "The nation's appetite for forest products is increasing, and for the most part