5 minute read

Ways to keep your |ift truck alive and breathing

By Ronald E. SDooner Project Engineer. Industrial Truck Div Allis-Chalmers Corp.

I IFT TRUCK hydraulic system

L pump wearout at 100 hours of operation seems incredible, considering today's pump design art, but it happens frequently. Why? Users permit conditions to exist in vehicle hydraulic systems that breed this type of failure.

Lacking is an understanding of what leads to hydraulic system contamination and what control of contamination is possible. The effect of such understanding inevitably leads to a conscientious program of filter maintenance.

Such a program is vital where material handling equipment is involved because performance demands on industrial lift trucks are greater than ever. As a result, hydraulic components operate at higher pressures and temperature, sustain higher bearing loads, and are constructed with less clearance between moving parts. In addition, the vehicles are expected to operate with minimal maintenance and show a substantial decrease in downtime. Hydraulic system cleanliness is not longer a virtue, it is absolutely essential.

G\ As hoses flex and component housings yield to Pressure surges, more contamination breaks loose and circulates throughout the system.

(5) As air enters the reservoir, it brings in dirt and moisture.

(6) Maintenance practices contribute a great deal to the contamination problem. As lines are broken for service, they are left uncapped, becoming an entrance point for dirt. Dirty oil is often poured directly back into the truck's reservoir.

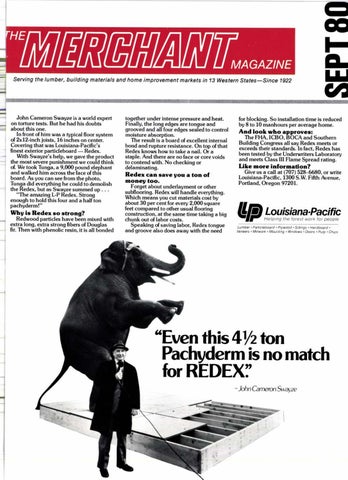

CIRCUIIR SCBATCIIES on the pressure plate

Itop photol are caused by particles ol more than 100 microns in size. lf exoosure t0 this size oarticle is continued, the entire surlace will become rough and heavily grooved. Soft metal obiect llower pholol caught in gear teeth will cause the pump to lock up.

First, tet's examine the sources of contamination, then consider what lift truck users can do to control it. Surprisingly, they can do quite a bit. First, a definition: contamination can be defined as any detrimental matter in hydraulic fluid. This includes both metallic and non-metallic particles, and comes in all sizes, shapes and materials. Every hydraulic system is contaminated to some degreethe dirtier the oil, the shorter your system components effective life.

Contamination can be traced to a number of sources: built-in, internally generated, maintenance generated, or ingested from the environment in which the vehicle operates.

(l) During assembly, varying amounts of core sand, weld splatter, finishing compound, machine chips and paint may collect in the reservorr.

(2) New pumps, valves and cylinders contribute stripped threads, burrs, rust and other contamination to the system.

(3) During equipment break-in, parts begin to wear and generate dirt. Thus, every internal moving part is a potential source of contamination.

(7) Hydraulic fluid is sometimes allowed to combine with other fluids which will react chemically to form sludge and varnish. This material is not necessarily abrasive, but will form gummy coatings on moving parts and clog passages, impairing the system's performance. The coating can also Prematurely clog the pores in the filter element, resulting in fluid bypass prior to the normal filter maintenance interval.

Examples of such combinations include water in petroleum based hydraulic fluid or hydraulic oil in water Glycol fire resistant solutions. Both combinations are harmful.

Today's hydraulic component designs call for extremely close operating clearances, so comPonents are less tolerant of contamination. As abrasive particles enter the spaces between moving parts, they score and wear away the surfaces, increasing these operating clearances. This wear results in excessive internal leakage or slippage, which lowers the efficiency of pumps and cylinders and decreases the ability of valves to meter flow and control pressure within specified limits. (The material removed from the component is also classified as contamination and increases the total contaminent level.)

Decreased efficiency means wasted horsepower and unnecessary heat generation. These effects become obvious as the system becomes sluggish due to the degradation of the pump or valve performance. If left unchecked, this type of component deterioration (degradation failure) will continue until the efficiency has decayed to a degree that will not allow the component to perform satisfactorily. This type of failure is a function of time.

Component seizure or the catastrophic type of failure is normally caused by large particles wedging into the operating clearances of hydraulic components. A pump binding or a priority spooljamming, due to the presence of large particles or chips, are examples of complete component failure. Vehicle flushing after assembly or maintenance service normally will remove most of these particles.

Pumps usually are the first component in hydraulic systems to show the effects of contamination. Damage may be gradual or sudden, depending on the quantity and size of the particle.

Abrasive wear caused by fine particles is the most common type of failure. Contamination circulating through the system causes wear on pressure plates, housing bores and in shaft bearing areas.

In order to reduce the effects of insoluble contamination on hydraulic components in Allis-Chalmers lift trucks, we employ the use of some device within the system to control it. This is the purpose of a filter - to remove large particles that cause immediate component failure and to minimize and control the erosive effect of fine contaminants that cause degradation in performance - in other words, to keep the oil clean. Your filter must be able to break the "chain reaction of wear" contamination breeds more contamination.

Sfory at a Glance

Understanding lift truck hydraulic system contamination... filter maintenance program. keeping trucks on the iob.

There are numerous types and sizes of filters which employ different means of screening and trapping particulate matter. Allis-Chalmers lift trucks use the replaceable element type of filter with a built-in bypass valve set at 25 lbs. per square inch. The element is the surface type which is made of treated paper. As oil flows through the pores of the element, the large contaminants are caught on the surface, while some smaller contaminants are trapped within the pores.

Surface type filter elements have the advantage of increased strength and resistance to fatigue and temperature. In addition, they show a low initial clean pressure differential and the mean pore size is more accurately controlled during manufacture.

Filters are graded by the size of particles that they will effectively trap. This determines the filter micron rating, which is commonly used to advertise its "cleaning ability." lContinued next month)

One micron is 39 millionths of an inch (0.000039). The smallest particle the human eye can see is about 40 microns.

The degree to which the fluid should be filtered is extremely important. Recommended fi ltration is at l0 microns or less in lift truck hydraulic systems. This means that the filter should effectively control particles at the ten micron level and greater. Not all filters rated at ten microns will perform satisfactorily.

The reservoir oil level will rise and fall during system operation, permitting air to enter. Breathers keep air borne contaminants out during this rise-fall cycle, preventing such contaminants from combining with hydraulic fluid. But if a breather is to perform reliably, it must be changed at regularly scheduled intervals.

In brief, regular service for filters and breathers is most important for avoidance of premature wearout of components. Such wearout multiplies rapidly as contamination creates more contamination. Dirt can build up so rapidly and to such a level that even a new filter element will clog up quickly and become ineffective.

BEtlTltfE SIZE of some commonly known materials is shown on this graph. The smallest particle the human eye can see is about 40 microns.

Douglas

- Hem Fir Redwood-Cedar Spruce

and two pages of "symptoms."

Vernor Schenck

Georgia Pacific Corp.