4 minute read

Rebuilding after the fire

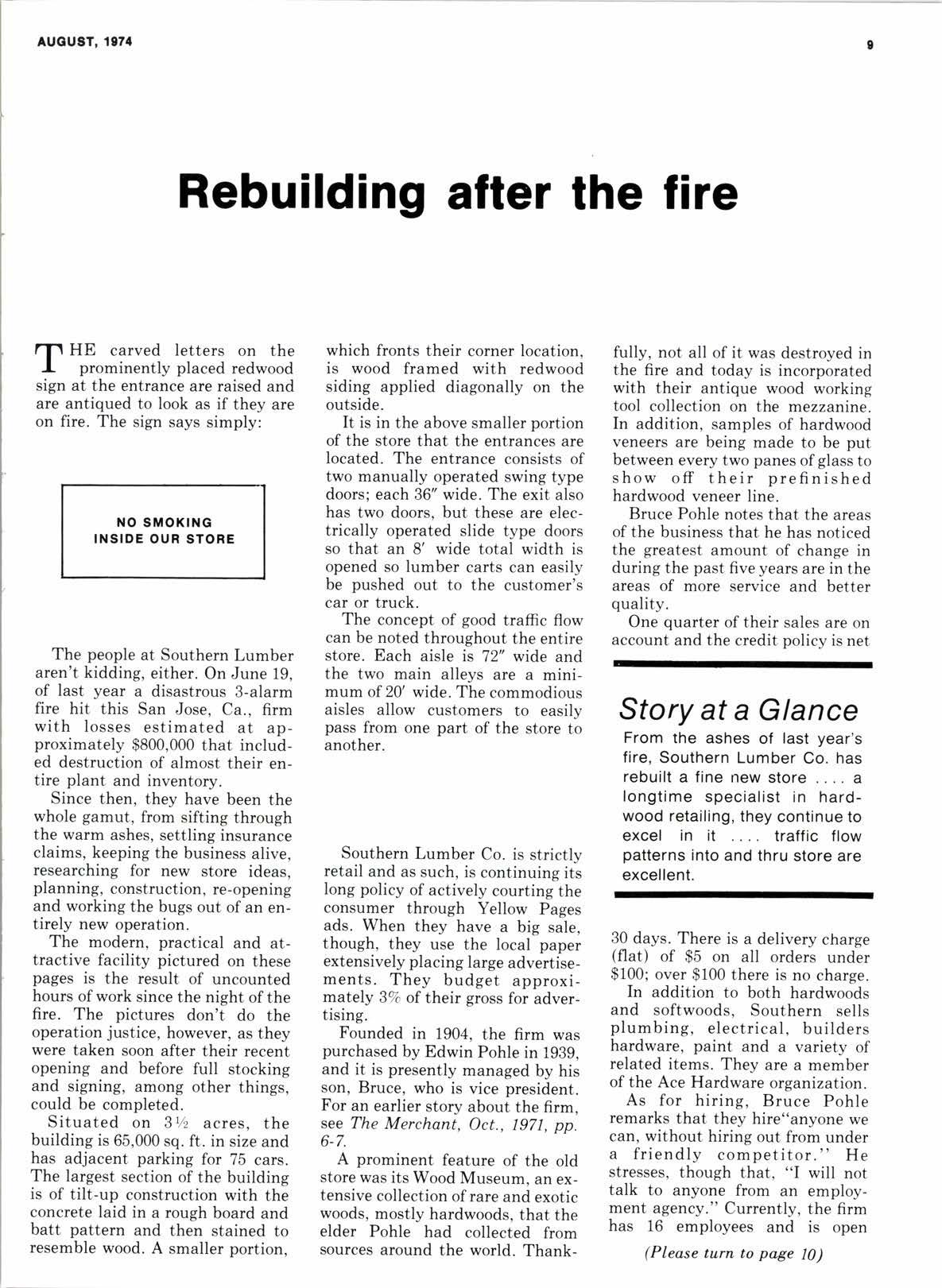

HE carved letters on the prominently placed redwood sign at the entrance are raised and are antiqued to look as if they are on fire. The sign says simply: which fronts their corner location, is wood framed with redwood siding applied diagonally on the outside.

It is in the above smaller portion of the store that the entrances are located. The entrance consists of two manually operated swing type doors; each 36" wide. The exit also has two doors, but these are electrically operated slide type doors so that an 8' wide total width is opened so lumber carts can easily be pushed out to the customer's car or truck.

The people at Southern Lumber aren't kidding, either. On June 19, of last year a disastrous 3-alarm fire hit this San Jose. Ca.. firm with losses estimated at approximately $800,000 that included destruction of almost their entire plant and inventory.

Since then, they have been the whole gamut, from sifting through the warm ashes, settling insurance claims, keeping the business alive, researching for new store ideas, planning, construction, re-opening and working the bugs out of an entirely new operation.

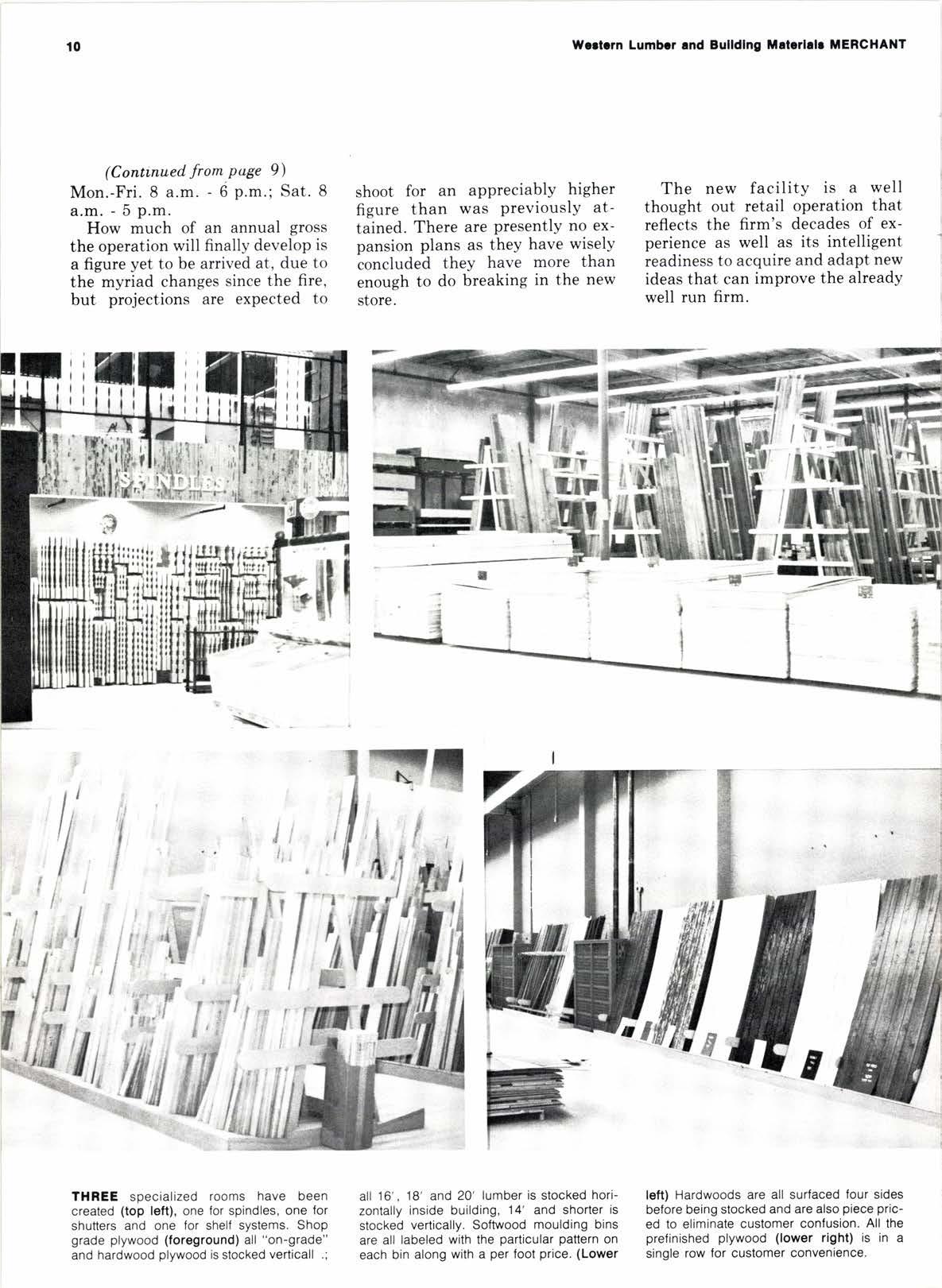

The modern, practical and attractive facility pictured on these pages is the result of uncounted hours of work since the night of the fire. The pictures don't do the operation justice, however, as they were taken soon after their recent opening and before full stocking and signing, among other things, could be completed.

Situated on 3y, acres, the building is 65,000 sq. ft. in size and has adjacent parking for 75 cars. The largest section of the building is of tilt-up construction with the concrete laid in a rough board and batt pattern and then stained to resemble wood. A smaller portion, fully, not all of it was destroyed in the fire and today is incorporated with their antique wood working tool collection on the mezzanine. In addition, samples of hardwood veneers are being made to be put between every two panes ofglass to show off their prefinished hardwood veneer line.

The concept of good traffic flow can be noted throughout the entire store. Each aisle is 72" wide and the two main alleys are a minimum of 20' wide. The commodious aisles allow customers to easily pass from one part of the store to another.

Bruce Pohle notes that the areas of the business that he has noticed the greatest amount of change in during the past five years are in the areas of more service and better quality.

One quarter of their sales are on account and the credit policy is net

Story at a Glance

Southern Lumber Co. is strictly retail and as such, is continuing its long policy of actively courting the consumer through Yellow Pages ads. When they have a big sale, though, they use the local paper extensively placing large advertisements. They budget approximately 3% of their gross for advertising.

Founded in 1904, the firm was purchased by Edwin Pohle in 1939, and it is presently managed by his son, Bruce, who is vice president. For an earlier story about the firm, see The Merchant, Oct., 1971, pp. 6-7.

A prominent feature of the old store was its Wood Museum, an extensive collection ofrare and exotic woods, mostly hardwoods, that the elder Pohle had collected from sources around the world. Thank-

From the ashes of last year's fire, Southern Lumber Co. has rebuilt a fine new store .... a longtime specialist in hardwood retailing, they continue to excel in it .... traffic flow patterns into and thru store are excellent.

30 days. There is a delivery charge (flat) of $5 on all orders under $100; over $100 there is no charge.

In addition to both hardwoods and softwoods, Southern sells plumbing, electrical, builders hardware, paint and a variety of related items. They are a member of the Ace Hardware organization.

As for hiring, Bruce Pohle remarks that they hire"anyone we can, without hiring out from under a friendly competitor. " He stresses, though that, "I will not talk to anyone from an employment agency." Currently, the firm has 16 employees and is open

(Please turn to page 10)

(Continued from.Puge 9 ) Mon.-Fri. 8 a.m. - 6 p.m.; Sat. 8 a.m. - 5 p.m.

How much of an annual gross the operation will finally develop is a figure yet to be arrived at, due to the myriad changes since the fire, but projections are expected to shoot for an appreciablY higher figure than was PreviouslY attained. There are Presently no expansion plans as they have wiselY ioncluded they have more than enough to do breaking in the new store.

The new facility is a well thought out retail operation that reflects the firm's decades of experience as well as its intelligent readiness to acquire and adapt new ideas that can improve the already well run firm.

Ct INCE there is a sPecific D piece of equiprnent best suited for aimost any need, Your best buYing approach is to analYze ,Your oplration requirements in order to identify that equiPment which best fills those needs.

A structured aPProach to industrial lift truck selection follows a pattern like this:

(l) Your loads. Are theY handled on skids? If so, Your best bet may be platform trucks with large load wheels which can fit in under the load. Platform trucks are very maneuverable, handling anY skid wider than the platform, and theY are light and stable'

In most operations, however, at least some material is handled on pallets. In this case, fork trucks are a better choice, since theY can handle both skids and pallets.

Depending on the nature of Your product or supplies, don't overlook the possibility of handling cartonized loads on sliP sheets, with push-pull attachments or with carton clamps. Such equiPment can eliminate expensive Pallets, cutting the cost per load bY $2 or $3, when loads leave Your Plant for a customer.

(2) Do you want to stack loads or simply transPort them? If You stack loads in racks or in Piles, a lifting mechanism is required. This is a mast which will lift high enough to place the toP load on a stack. If you do stack, consider these factors:

(a) The maximum fork height which you need should be at least 6" above the suPPorting surface of your highest load. This Provides for clearance and for the sPace required for the pallet under the forks.

(b) Determine the overall mast height when lowered. When the load is down, the truck must clear all overhead obstructions it will encounter, such as PiPes, building trusses and lights'

(c) Determine the overall height of trailers which transport your products. These are'usuallY over ?' high, but some are less. If you plan to double stack loads in low overhead areas, be sure to determine the "free lift" of the mosf Tf vnrr relate f,railer heisht to