2 minute read

Wood products seminar

llt OULD YOU believe a four-day U U conference that included a firsthand view of a logging operation high in the Pacific Northwest woods, a tour through a plywood nrill and sawmill, a look at a modern lumberyard and just about every other aspect ofwood production in between?

Well, building material dealers from across the country will tell you that's exactly what happened at the first "Wood Products Seminar" held in April in Tacoma, Wa.

The conference was designed to give dealers and key employees a complete, close-up look at the wood products industry. The goal: to provide an expanded background in plywood and lumber to enable dealers to better serve customers and improve sales.

The seminar, sponsored by the American Plywood Association, the National Lumber and BuildingMaterial Dealers Association and the Western Wood Products Association, was considered so successful by all involved that similar conferences are now being planned for other areas of the country. A second dealer's seminar was held in Houston in May.

"Every one of the comments I heard from the dealers who attended was positive," said Tom King, NLBMDA v.p. "l felt the entire program was very good, and the emphasis on learning how to supply the proper material at the lowest cost was excellent."

"I've worked selling wood products to contractors for l3 years," said one dealer who attended, "and even I learned something."

In Tacoma, the dealers, ranging in experience from just starting to over 20 years, spent the first two days attending classroom sessions on plywood and lumber products.

Story at a Glance

Four day seminar coverseverything from logging to a modern retail yard to give dealers a better lumber and plywood background to help them sell better.

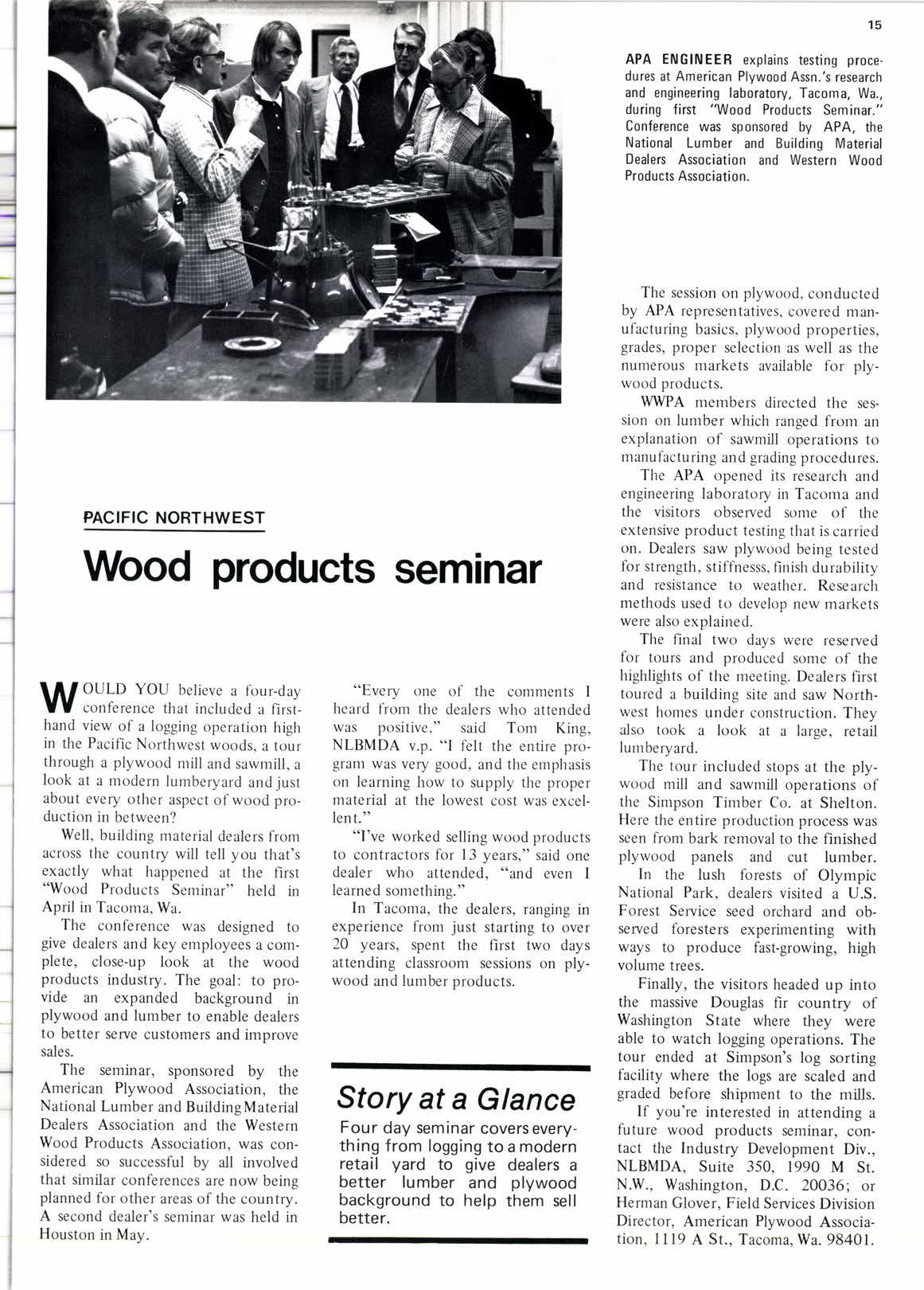

APA ENGINEER explains testing proce. dures at American Plywood Assn.'s research and engineering laboratory, Tacoma, Wa., during first "VVood Products Seminar." Conference was sponsored by APA, the National Lumber and Building Material Dealers Association and Western Wood Products Association.

The session on plywood, conducted by APA representatives, covered manufacturing basics, plywood properties, grades, proper selection as well as the numerous markets available for plywood products.

WWPA members directed the session on lumber which ranged from an explanation of sawmill operations to manufacturing and grading procedures.

The APA opened its research and engineering laboratory in Tacoma and the visitors observed some of the extensive product testing that is carried on. Dealers saw plywood being tested for strength, stiffnesss, finish durability and resistance to weather. Research methods used to develop new markets were also explained.

The final two days were reserved for tours and produced some of the highlights of the meeting. Dealers first toured a building site and saw Northwest homes under construction. They also took a look at a large, retail lunrberyard.

The tour included stops at the plywood mill and sawmill operations of the Simpson Timber Co. at Shelton. Here the entire production process was seen from bark removal to the finished plywood panels and cut lumber.

In the lush forests of Olympic National Park, dealers visited a U.S. Forest Service seed orchard and observed foresters experimenting with ways to produce fast-growing, high volume trees.

Finally, the visitors headed up into the massive Douglas fir country of Washington State where they were able to watch logging operations. The tour ended at Simpson's log sorting facility where the logs are scaled and graded before shipment to the mills.

If you're interested in attending a future wood products seminar, contact the Industry Development Div., NLBMDA, Suite 350, 1990 M St. N.W., Washington, D.C. 20O36; or Herman Glover, Field Services Division Director, American Plywood Association, l119 A St., Tacoma, Wa. 98401.