2 minute read

lndustrial uses of trcated wood incrcase

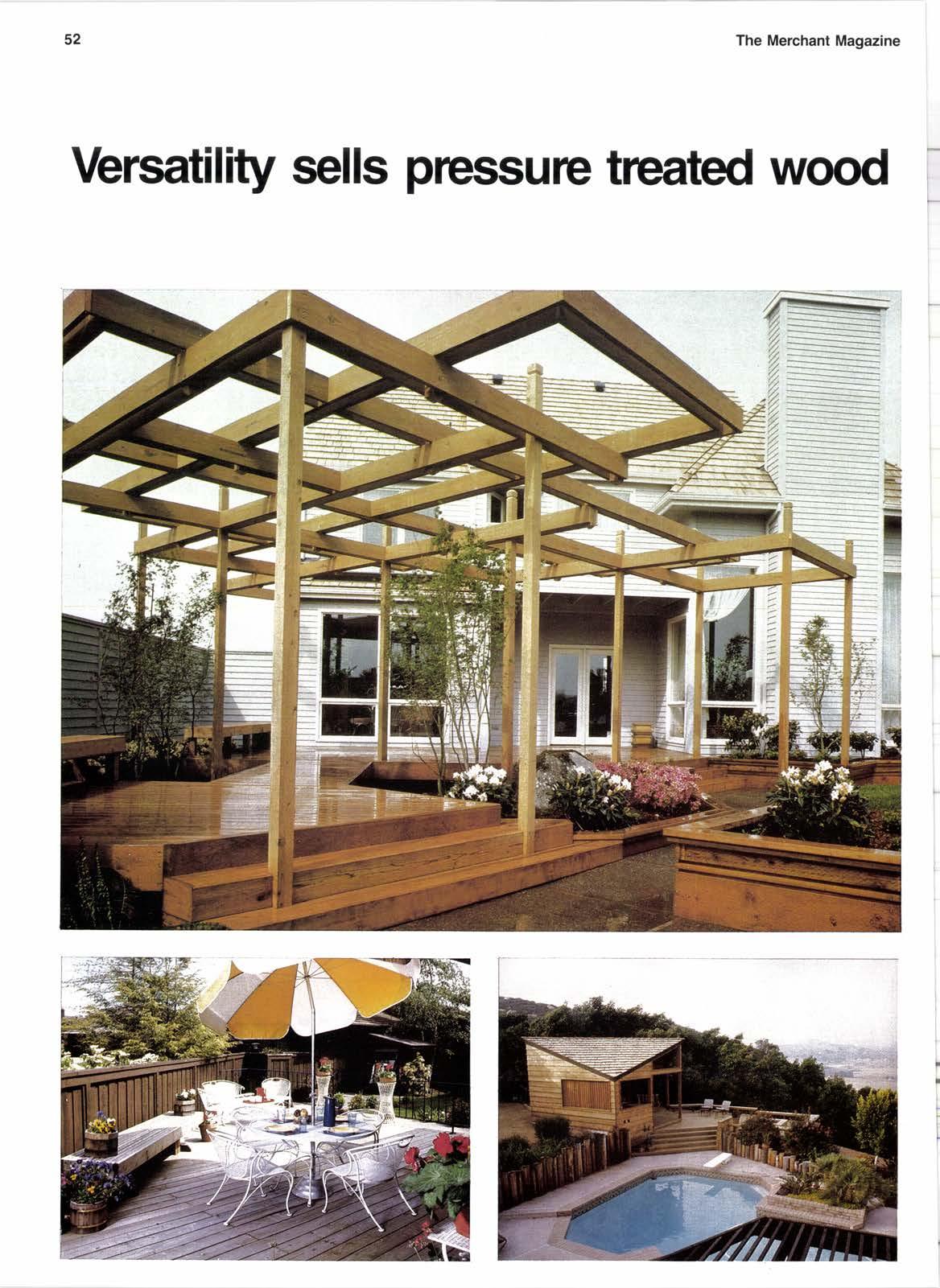

PRESSURE treated wood is being used in an increasing variety of commercial and landscape projects. Decks, fences, planters, retaining walls, board walks and gazebos are all markets for this long lasting wood.

Because cost is a consideration, along with durability and availability of materials, more and more industrial projects are using pressure treated wood. Often pressure treated wood costs less than alternative building materials.

Gene Coulon Memorial Beach Park in Renton, Wa., a major watersport center, is an excellent example of how pressure treated wood contributes to a better environment. The 57 acre park spreads over a mile of beach, reclaims the land's northern strip of natural marsh with a nature walk and has dock facilities constructed of pressure treated wood. Tieated piling and pressure treated wood were used in the decking and structural supports.

At a park in Kent, Wa., a series of three stairways and landings built of pressure treated wood lead pedestrian traffic from a parking lot to the deep canyon grounds of Mill Creek Canyon Park. It not only has an extensive series of walkways with hand rails, but also a three story viewing tower and a 2O x 25 foot gazebo for a performance shelter. Built on stringers of pressure treated glulam beams, the walkways and stairs will last decades with no corrosion and will keep the natural beaury of the park intact.

At Anacortes, Wa.,350 pressure treated piles were driven to build 50,000 square feet of dock at a 400 boat marina. The floats have treated whalers and are connected with pressure treated wood above the water line.

Public utilities increasingly are using pressure treated wood, too. The Cheland County PUD in Manson, Wa., used pressure treated wood to build an extensive dock for fisherman and boaters. Tieated pilings were used to support the fishing pier, which stands eight feet above the

Story at a Glance

Recreation and highway uses of pressure treated wood expand market . durabillty and economy plus appearance make it easy to sell . numerous examples of successful use.

water. The "T" shaped boating dock can hold up to six boats and has a footbridge leading up to the fishing pier. Concern about heavy water traffic at Lake Chelan prompted the PUD to decide to use durable, long lasting pressure treated wood.

A 2000 foot sound barrier was completed last spring along Interstate 5 south of Seattle, Wa. The fence is made of pressure treated laminated panels consisting of three layers of I x 8's. Height of the wall above grade ranges from 6 to 12 feet. The State of Washington says the barrier reduced the noise level by at least seven decibels, maybe as high as ten.

Builtjust over two years ago the I-280 retaining wall near Palo Alto, Ca., was the first of its kind using pressure treated wood instead of concrete. Cal Tians (California Tiansportation Dept.) believes that the treated retaining wall delivers all the performance of concrete but is more cost-efficient. Not only does pressure treated wood wear better due to its resiliency as the earth shifts, it also is easier and less expensive to repair than concrete and looks more natural.

Contractors continue using pressure treated wood because of its durability and lasting benefits. Confidence in the product will sell industrial users over and over as they become aware of the advantages.

Mixing

A hand powered cemenVmulti-purpose mixer weighing 20 lbs., with a capacity of 160 lbs. of mix or l8 gallons of liquid, is new from Bishop-Klein Industries.