10 minute read

Dreaming Up Bedwood llesigns

that water and pressure are fundamental enemies of wood and that improp er powerwashing can do more harm than good. For best results, hire a professional painting contractor experienced with powenvashing.

The equipment should be capable of 2000 psi operating pressure and should deliver a minimum of four gallons of water per minute. Under normal conditions, pressures of l0O0 to 1200 psi should not be exceeded as this can result in erosion of the softer earlywood. resulting in an uneven. rough surface. Carefully check flashing and caulking before powerwashing to prevent moisture from entering the wall cavity of the house. Wait several sunny, dry days after washing before applying a protective finish.

Redwood lumber comes from Sequoia sempemirens, also known as the Coast Redwood. It is one of trvo species of redwood found in California. Sequoia sempervirens is the fastest growing conifer (softwood species) in North America. A coast redwood can grow to be 130 ft. tall in just 30 years.

$ ro* of eve4r five acres of commercial redwood forest are independently ceftified as well managed and harvested on a sustainable basis. The major redwood lumber mills and landowners have completed independent third-party certification of their redwood forestlands. As a result, over I million acres, approximately 80Vo of redwood commercial forests, are certified under one of the two most widely recognized certification programs: the Forest Stewardship Council or the Sustainable Forestry Initiative.

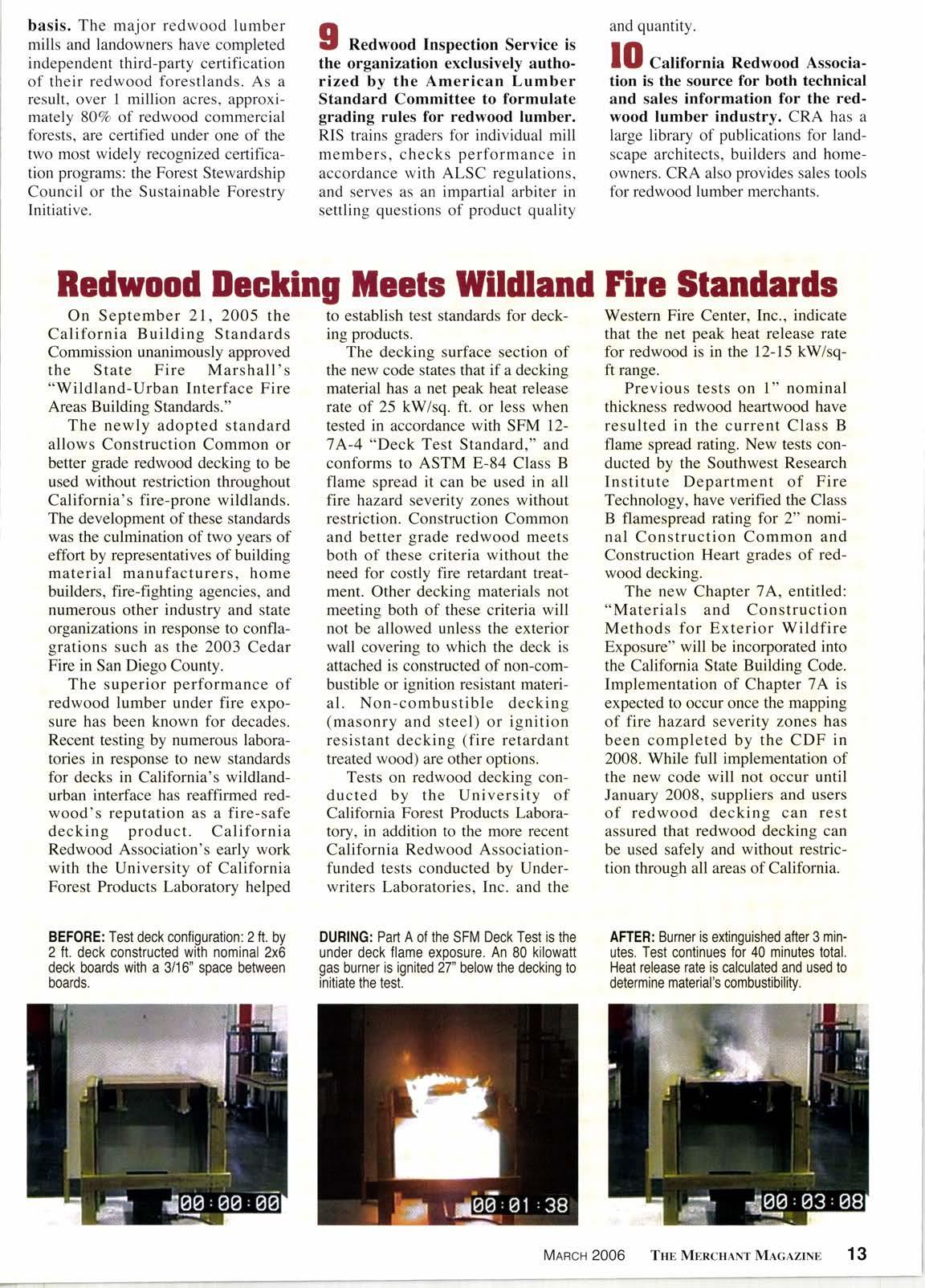

On September 21, 2005 the California Building Standards Commission unanimously approved the State Fire Marshall's "Wildland-Urban Interface Fire Areas Building Standards."

The newly adopted standard allows Construction Common or better grade redwood decking to be used without restriction throughout California's fire-prone wildlands. The development of these standards was the culmination of two years of effort by representatives of building material manufacturers, home builders, fire-fighting agencies, and numerous other industry and state organizations in response to conflagrations such as the 2003 Cedar Fire in San Diego County.

The superior performance of redwood lumber under fire exposure has been known for decades. Recent testing by numerous laboratories in response to new standards for decks in California's wildlandurban interface has reaffirmed redwood's reputation as a fire-safe decking product. California Redwood Association's early work with the University of California Forest Products Laboratory helped iU Redwood Inspection Service is the organization exclusively authorized by the American Lumber Standard Committee to formulate grading rules for redwood lumber. RIS trains graders for individual mill members, checks performance in accordance with ALSC regulations, and serves as an impartial arbiter in settling questions of product quality to establish test standards for decking products.

Redwood Association is the source for both technical and sales information for the redwood lumber industry. CRA has a large library of publications for landscape architects, builders and homeowners. CRA also provides sales tools for redwood lumber merchants.

Redwood llecking ileets Wildland Filo Standards

The decking surface section of the new code states that if a decking material has a net peak heat release rate of 25 kWsq. ft. or less when tested in accordance with SFM 127A-4 "Deck Test Standard." and conforms to ASTM E-84 Class B flame spread it can be used in all fire hazard severity zones without restriction. Construction Common and better grade redwood meets both of these criteria without the need for costly fire retardant treatment. Other decking materials not meeting both of these criteria will not be allowed unless the exterior wall covering to which the deck is attached is constructed of non-combustible or ignition resistant material. Non-combustible decking (masonry and steel) or ignition resistant decking (fire retardant treated wood) are other options.

Tests on redwood decking conducted by the University of California Forest Products Laboratory, in addition to the more recent California Redwood Associationfunded tests conducted by Underwriters Laboratories, Inc. and the

DURING: Part A of the SFM Deck Test is the under deck flame exposure. An 80 kilowatt gas bumer is ignited 27'below the decking to initiate the test.

Western Fire Center, Inc., indicate that the net peak heat release rate for redwood is in the 12-15 kWsqft range.

Previous tests on 1" nominal thickness redwood heartwood have resulted in the current Class B flame spread rating. New tests conducted by the Southwest Research Institute Department of Fire Technology. have verified the Class B flamespread rating for 2" nominal Construction Common and Construction Heart grades of redwood decking.

The new Chapter 7A, entitled: "Materials and Construction Methods for Exterior Wildfire Exposure" will be incorporated into the California State Building Code. Implementation of Chapter 7A is expected to occur once the mapping of fire hazard severity zones has been completed by the CDF in 2008. While full implementation of the new code will not occur until January 2008, suppliers and users of redwood decking can rest assured that redwood decking can be used safely and without restriction through all areas of California.

AFIER: Burner is extinguished after 3 minutes. Test continues tor 40 minutes total. Heat release rate is calculaled and used to determine material's combustibility.

DOTH dealers and distributors

Llknow that demonstrating an intimate awareness of quality materials is essential when establishing an ongoing relationship r,vith customers-and one that pays future dividends with additional projects and referrals.

However, rvith an overwhelming number of available materials. it can be tough to decipher fact from fiction when it comes to product features, performance and value.

One example of a versatile, quality material is western red cedar. With centuries of proven performance, the benefits of selling cedar are many: durability, environmentally friendly. versatility, beauty, etc. Yet many individuals may not fully understand the porver of using a quality material like rvestern red cedar to improve profitability and customer satisfaction.

So rvhat are the latest trends you should be arvare of rvhen suggesting value-adding buildin_e materials like western red cedar? Belorv are some key things to remember rvhen helpin-e your customers choose the proper material:

Environrnentall)' Frienclll'

These days. many consumers are concerned rvith incorporating materials that are safer for the environment- and are rvillin-s to pay extra torvards this ideal. Knorvledse about this trend and horv western red cedar is one of the most environmentallyfriendly buildin-e products is paramount rvhen discussing this aspect rvith your customers.

When you compare the life cycle of cedar to that of other materials. the environmental benefits of cedar can't be matched. For starters, as the rvorld's only renervable buildin-e material. rvood can not only be recycled. but re-eenerated as rvell. In fact. North America has more forestland now than it did one hundred )'ears ago. Other resources that contain plastic. steel or cement use up natural resources that can't be replaced.

In addition. althou-eh rvood products make up 47% of all ras' materials manufactured in the U.S.. their share of manuflacturing energy consumption is only four percent. Steel for example. requires 2l times the energy to produce and releases more than fifteen times the amount of sulfur dioxide rvhen compared to rvood.

Grorvn rvithin natural forests to preserve native ecosystems. western red cedar trees provide habitat and therefore the opportunity for the lar-eest number of species to live throu_ehout the landscape. Using more cedar trees-both as a substitute for non-renervable fossil fuels and materials such as steel. concrete and plastic-provides the added benefit of pulling carbon out of the atmosphere and reducin,s the amount of greenhouse emissions.

Better yet. western red cedar is entirely biodegradable. and at the end of its life cycle. can be absorbed by the earth rvithout negative impact. Some alternative products can sit in landfills for years and years rvithout breaking down-making western red cedar ultimately more earth friendly.

Durability & Value

There's a reason why western red cedar is found on some of the oldest homes in North America. All the advances in technology have not been able to duplicate wood's unique characteristics and performance capabilities. For hundreds of years, builders have relied on cedar to offer longterm performance. Western red cedar has a natural resistance to decay and insects, meaning projects made with cedar will perform outdoors without the need for toxic chemical treatments. And when you consider the wide range of styles and grades available, cedar provides financial flexibility unmatched by alternative products.

In addition, advancements in cedar manufacturing mean consumers can spend time relaxing and enjoying their homes, rather then maintaining them. Today, many manufacturers offer western red cedar siding pre-finished on all sides. This finishing technology is important as it ensures the highest level of quality, thus greatly increasing consistent coating, longevity, and overall resistance to moisture.

This allows a builder or subcontractor to choose the preferred finishing color and simply install. Properly finished and installed. western red cedar will offer decades of low maintenance protection.

The same is true of cedar decking. One of the biggest misconceptions about decking products is regarding the necessary amount of maintenance. Most consumers may believe that once installed, plastic or composite decking need never be touched again. Regardless of the material, all decks require some annual maintenance to remain looking their best. And unlike composites or other man-made materials, cedar can easily be restored to its original condition-an important benefit that's often overlooked.

Beaufy & Versatility

Cedar provides an all-natural beauty that can't be duplicated by plastic or composite materials. A range of natural hues, tight grain-patterns and soft textures continue to make western red cedar the building material of choice. And with cedar. customers aren't limited to the styles or material shapes set at the factory. From decking to siding, paneling to landscape structures, cedar is easy to work with, shape and finish. The wide variety of grades and styles means cedar can provide a building material solution where other materials may fall short.

This all-natural beauty has also made cedar the focus of one of the hottest trends in residential construction. Specifically, incorporating materials and designs embracing the natural environment. The ability of cedar to blend seamlessly with surrounding stone, woodwork or landscape features has made cedar increasingly popular with architects and builders looking to create unique homes of distinction. Despite the wide variety of building material choices available todayin many cases, Mother Nature still knows best.

Knowing the issues, explaining the true value of building materials and discussing the correct information is paramount to establishing a strong relationship with your customers. To learn more about the virtues of cedar, the Western Red Cedar Lumber Association has developed a collection of brochures about a variety of applications. To learn more, call (866) 788-9096 or visit www.realcedar.org.

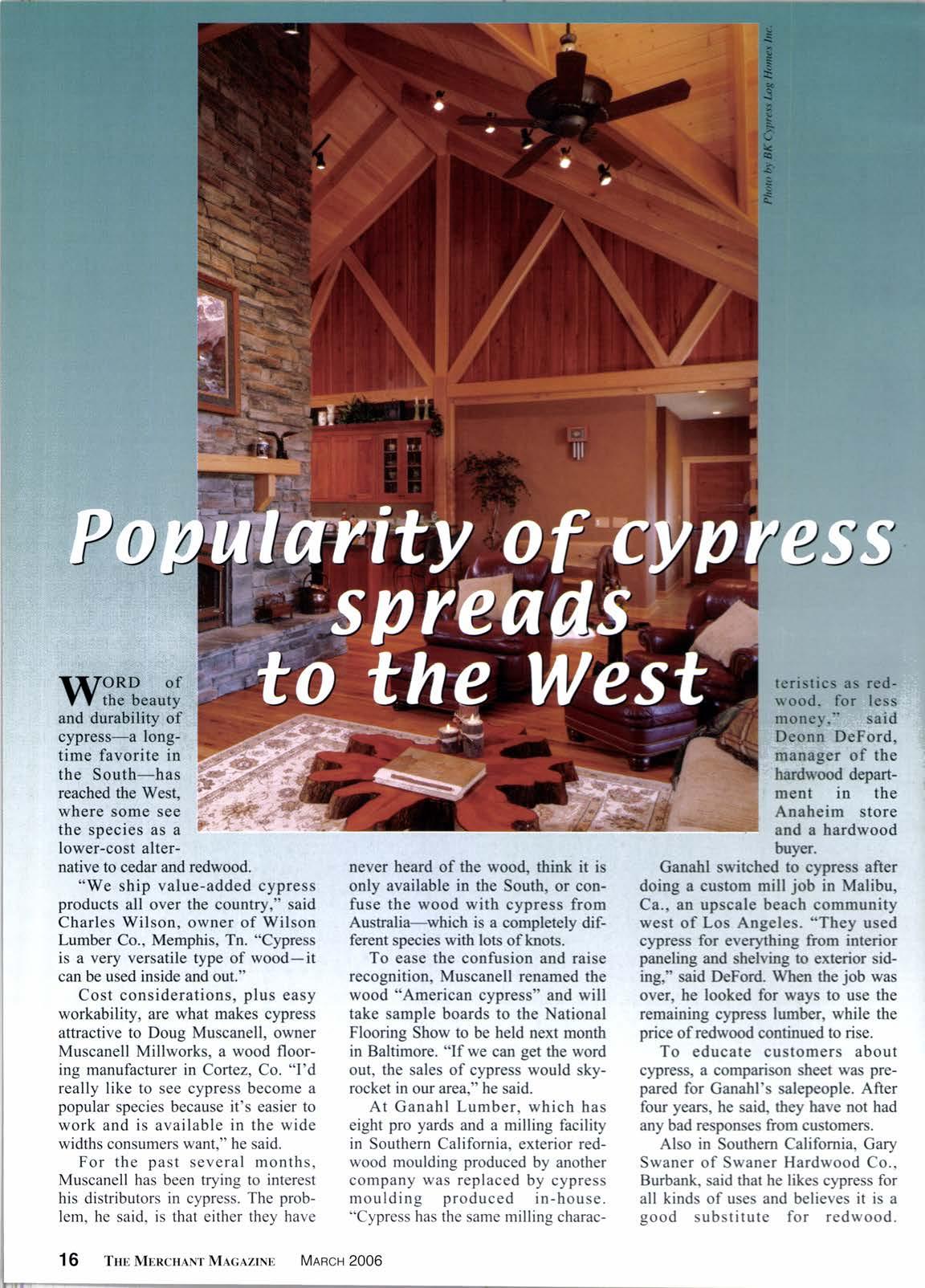

II IORD of

V V the beauty and durability of cypress-a longtime favorite in the South-has reached the West, where some see the species as a lower-cost alternative to cedar and redwood.

"We ship value-added cypress products all over the country'." said Charles Wilson. owner of Wilson Lumber Co.. Memphis. Tn. "Clpress is a very versatile type of rvood-it can be used inside and out."

Cost considerations, plus easy workability, are what makes cypress attractive to Doug Muscanell, ouner Muscanell Milluorks. a u'ood flooring rnanufacturer in Corte-2. Co. "l'd really like to sec cypress bccomc a popular species because it's casicr to rvork and is availablc in thc ri idc widths consumers \\'ant." he said.

For thc past scvcral rnonths. Mrrscancll lras bccrr tr\ ir'ru l(r irrlcrc:t his distributors ir.r cvprcss. Tlie problcrn. hc said, is that cithcr thcy harc never heard of the u'ood. think it is only arailable in the South. or confuse the rvood u'ith cypress from Australia rvhich is a completc.ly dit'ferent species u'ith lots of knots.

To ease the confusion and raise recognition. Muscant--ll rcnamL-d the *'ood "American c1'press" and *ill take sanrple boards to thc r\ational Flooring Shou to be hc-ld ne\t month in Baltinrore. "lf ue can gc't thc' nord out. thc salcs of cvprL'ss rlould skr'rocket in our arr-a." hc- said.

At Ganahl Lurrber. s hich has cight pro vards and a milling facrlity in Southcrn Califbnria. crtc'rior rcdnood moulding proclucc-cl br anothcr collrpanv n as rcplacccl b1 cy pr.'s. moulding producc-cl rn-housc.

"Clprcss has thc sarrc nrilling charac- teristics as red'*'ood. for less mone)'." said Deonn DeFord, manager of the harduood department in the Anaheirn store ;l =-:+t*-.'+ and a hardrvood buvcr.

Ganahl ssitchc'd to c)'pr!-ss after doing a custorn mill job in \lalibu. Ca.. an upscalc'bcach comnrunitl u est of Los Angr--lc-s. "Thc-r' use-d cvpress tbr evc'rvthing tiorn intc'rior paneling and shelr ing to cxterior sidin_tr." said DeFord. \\-hcn thc job uas over. he lookcd lbr sars to use the rcmaining c)prL'ss lunrbcr. uhile the pricc of r.'duood continuc-d to rise.

To c'ducatc cuslolncrs about c\ prc\\. i.t e (rnlnitri:()t] \hcct \\ lts nrcparcd tbr Glnahl's salcpcrrplc. Attcr tbur vcars. hc sard. thcv harc' not had anr bad rL'sponscs liorn ctrstonrcrs.

.\lso in Southcrn C'alitirrnia. Gan Ssuncr of Sriancr Harduood C'o.. Ilurbank. surtl that he lrkc: c\ prL'ss tbr rull kincl. ol' uscs antl bclicr cs it is ;.r gtrrltl :trb:tiltrtc l'trr rctlrlorrcl.

Ouhide, clprees's durability and strength makes it a good option for siding and shingles, shutters and trim, doors and windows, andlandscape.elements such as furni;; ;"d ;;;;. ;#"-""0*

*JiJ*"J,-";;;; ;;i""

a natural oil that provides resistance to insects and decay. Unlike western red cedar or redwood, however, cypress does not bleed tannins.

Although technically a softwood, cypress is graded as a hardwood according to rules set by the National Hardwood Lumber Association's rules. It has needle-like leaves like a so{irwood, but the trees shed in the fall like hardwoods. Under the right conditions, cypress can live for hundreds of years, reaching a height of 150 ft. and a diameter of 12 ft. Second- and third-growth trees, however, are usually harvested before the the tree reaches this size.

After harvesting, cypress sprouts from the trunk and reaches lumber size in 35 to 40 years. Although cypress can grow from seed dropped from its cones or from planted seedlings, regeneration is the quickest way as long as lots of water and sunlight is available. With careful harvesting, cypress supplies are expected to keep up with rising demand across the country.

"Consumers want to buy solid wood, natural products like cypress that are responsibly harvested," said Phil West, Coastal Lumber Co., Weldon, N.C., and the new president of the Southern Cypress Manufacturers Association. "We just have to get out and promote it."

'-t fi

BIG CREEK

;a es alrtl tne e ar '--"a a.: : 't -:: :t : lrr'()lrlf tl tll t lltirtr. 111.' 1r1 .i,1... 1.1,1 :,, l|ilrlt !Jt,ilt!! (,1 \l!!a\\ l'.1

'' I lter ..rt,1 .',. 'irlii:t i |.i r t.LIl lr11si11q'sr irt tltr..rrL.r lr.!.rr... li. lLrtt':l:',\!t! .ri tLtl. 'l tLl ] tlr|I.

'LLr,i \1.( lLlr T' 1.r..,1-ll ,l iri llir l)ltr cttpott. ( ii ir.i\.!l ! 1, t'li,r

'I ll.t.' :rlt lt lrjl tl L)l! t!rl\\.()(jlL\ t!t.' tl{)\\ lll,t,l ,.\ ll.'tr ".. .l:rtl.,l. ,liL.' ,, ,,1 i , i I r I r" .alfrli\ r' ltlttt i.lrl.. 'l-L,,llrr. liir ( r,'.1' l\ nr\(\ !!rr r .Lr \,r l!tl!t\ l)L: \ (rl\ l\ lll\( j lrtl I .Lt \.1 rri :lti L fr .a: lr .. it ,

1111"111. lrr1;1 ,' \ir !\..rt \i l.tr i- ,-

'' 'I. r' r1 ( r : lllirL .Ltll ttitt. :tt I Ir,i llt. llr.l I r.'ltt.. tl. .r',. i.i. t iil- ,,t t.'!l

\irrrnrrll |t ll|. l..iti ,,: I

Dealers, distributors, and conlra*ro1s trust Ell<,Rail\Vays As$ing Collecnans for the beauty and style of easy-to-install railing. Offering rwo beautiful collections, the Traditional Series boasts the elegant, timeless look of wood in a low maintenance design, while the Old World Series offers the look of "uth.rrti. wrought rron. And with:$,Jkls putun, peodirrg Uni.Ball- ,yrt"* foi:.: "no-drill" installadon and Z0-year limited warranty, RailVays is a recommendation you can make with confidence. For more inforrnation, visit our websiGat www.elkcotp.com. '" '.1t.

I ilt {$$ r$ llll a a'# nui