3 minute read

Do it Bcst Opens Southwcst

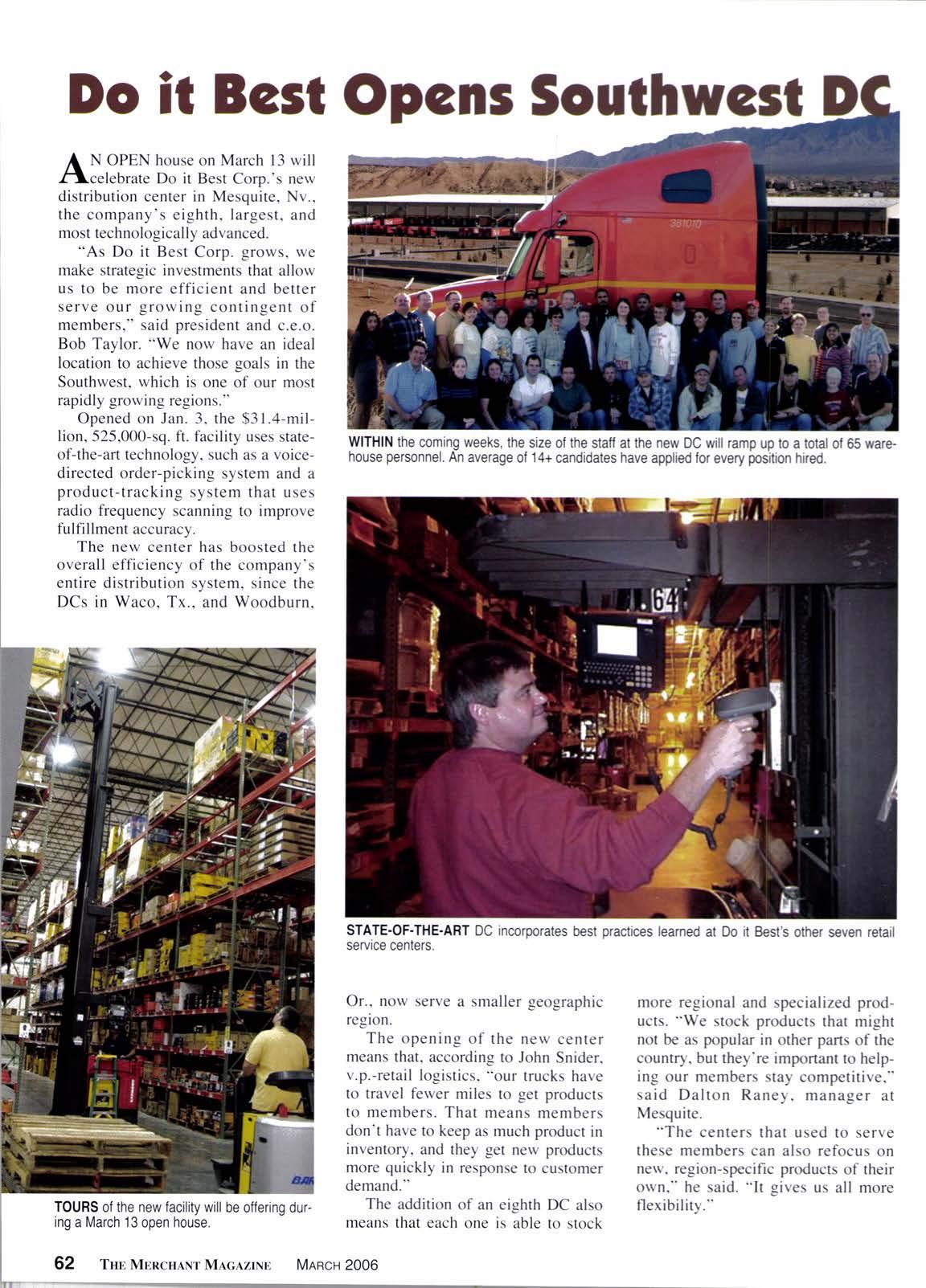

A N OPEN house on March l3 will .Cl,celebrate Do it Best Corp.'s nerv distribution center in Mesquite, Nv., the company's eighth, largest, and most technologically advanced.

"As Do it Best Corp. grows, we make strategic investments that allow us to be more efficient and better serve our growing contingent of members," said president and c.e.o. Bob Taylor. "We now have an ideal location to achieve those goals in the Southwest. which is one of our most rapidly growing regions."

Opened on Jan. 3, the $3 1.4-million, 525,000-sq. ft. facility uses stateof-the-art technology, such as a voicedirected order-picking system and a product-tracking system that uses radio frequency scanning to improve fulfillment accuracy.

The new center has boosted the overall efficiency of the company's entire distribution system, since the DCs in Waco, Tx., and Woodburn.

Or.. norv serve a smaller geographic region.

The opening of the new center means that. according to John Snider. v.p.-retail logistics. "our trucks have to travel ferver miles to get products to members. That means members don't have to keep as much product in inventory. and they get new products more quickly in response to customer demand."

The addition of an eighth DC also means that each one is able to stock more regional and specialized products. "We stock products that might not be as popular in other parts of the country. but they're important to helping our members stay competitive." said Dalton Raney. manager at Mesquite.

"The centers that used to serve these members can also refocus on nerv. region-specific products of their orvn." he said. "lt gives us all more flexibility."

.\1 5u,lLt.tsrttt (,r()Lrlr. \\r' l)lirttt tlt()lrt lhlttl lt tlltllirlll s('oclllllgs il \c.il'. IjV ntil"l u|i nt.lll(i l'cllrt\\lllg ()tLl'l()l'a5t5. \\'c lllillic sLtfc ()ur' ( Lrst()nrcrs lrirVc .t t.r:lttlV SuIpl\ ()l lfillllillg itttlllct'. sttLcls .urcl pl;'u oot[.

\\t elso trtkc plttlt' in crccrclit'ig Lht rttiLtir'.1]]tnls of thc ()rcgon Irorcsl Pt-atLitr:s.\r't. rihtclt,t,1.'r.' 11ttr.;i SLIllliicllt:l.rle It,rrcslry, c()clc 1n tht' crrLtt.ttt'r:

\\'e'r'c grou,Ln{ TrtltLlrc--i builtling llrtcrlll ,\ucl. it'c u-rll bc lol gtr-rl'ations lr) r0llrc.

weKaffi)n/h

csrsJup JF

tlllt$ll llll ri4LrSll Ih-+l r j"lltSll ll+l

I'lrlotrrl i--lltSll ll'; ri-} 1l3ll llj+ \lLLtis t)+lrSll Ilrr rr+lI$ll Il()+

Boise Offers Automatic Sawing Systems

Boise Engineered Wood Products has introduced SawTek automated cutting systems to its dealers to achieve faster, safer, more accurate processing of Boise BCI Joists and

Versa-Lam laminated veneer lumber. SawTek systems are fast and accurate, typically cutting about 20.000 lineal ft. in an eight-hour shift rvith accuracy to 1132". The sarvs are used in conjunction rvith a package of other Boise value-added services that are all components of Boise's Simple Framing System. designed to help dealers and builders improve their profitability and reduce the cycle time required to build homes. itrr strongcr. crr,sie L-rr,-rrrsrrill cr,ui1.,.,srtt .lccking rur.l lcncilrg. PlLrs, Elk's LZ-LlLrtl.l Flstcnir-ig Srsicnr n'L,Lke. instlrll,rfiL,L.r trr:icr', lin.1 tlic hiJ.lcn fltstttrct's\'\tcnr cftirt.\ il nr!)rc l)tltutllill Jtck. (lr,trr'l itlll,et'.'llllirltte l'1crl.l,,l,,ilk lltltl poll|111111lcllc.,'llll'111.'f,' crcltte:l nrLrlt'Llrrlril.le, hrng!'r--lir\ting rL]t.'rnrrlir.'1rr lttltlt'rl ri',xt.l. lilr.k.',] i', ., fi.-l-\cltr lrntil..l \\illliItt\, (.r',''. I itrtl.etr i: lr tt'arttttltie]\lJli()ll \'()tl cltlt tltlti.r'\\i1ll eLrtlli' tlt'ltre. lrrrl'lt)()fr'jlli(rl'lrlillir)l), \i'il r)llf\\tlr\il( ;tl ittrrt.t'llittlllr.foltl.

"We think just supplying products alone to our channel partners won't get the job done anymore." said Denny Huston. sales & marketing manager of Boise Engineered Wood Products in Boise. Id.

"SarvTek and our other valueadded services help us rvork together rvith our distributors and dealers and their builders. so we all have the ability to solve supply-chain problems and run better. more profitable. more long-term businesses." he added.

SarvTek and its peripherals are fully compatible rvith Boise's new BC Framer 6.1 integrated framing software to efficiently process longlength engineered rvood products. Because of the accuracy of home plans created using BC Framer, SarvTek cutting systems can also deliver ready-to-install framing, reducing a builder's cycle time by eliminating most jobsite custom-cutting and cutting errors.

SarvTek automated cuning systems can also combine and optimize several orders simultaneously and keep track of each piece. SarvTek order optimization lets dealers intermix cut lists of several jobs to get the most out of every length and virtually eliminate waste. Besides reducing material costs, optimization simplifres inventory control, rvith engineered wood products usually ordered in the longest available lengths for greatest cutting flexibility.

Inkjet printers are another adjunct to SarvTek and are used to mark every piece for delivery to the jobsite, and relate back to the color-coded framing placement plan for proper installation in the structure. Because of the clarity of the color-coded framing placement plan from BC Framer, even framers rvho can't speak fluent English can frame the home rvithout errors.

Boise value-added services are designed to solve supply-chain problems and help Boise and its channel partners run more successful businesses. "We rvant to lead the charge in helping our supply-chain partners find rvays to run their businesses more smoothly and more profitably."

Huston said.