5 minute read

AN OPEN LETTER TO PRESIDENT NIXON

President Richard M. Nixon

The White House

1600 Pennsylvania Avenue Washington, D.C.

Mr. President:

\ffE WERE honored to be asked to suggest names YY for sovernment service within your administration. Th"is we did in our letter of Ju.,u".y 2, naming a distinguished member of the forest products industry, who, at this writing, prefers to remain anonymous.

The reasoning behind this thought is that we believe the federal government has equal responsibility with the private sector to educate and inform the public on the true meaning of Conservation as opposed to Preservation.

Because increasing population is making more and more demands on a static land base, the need for a major liederal Land Use Policy study and implementation is now-before the preservationists have tied up all the productive land for single use.

Giant steps have been made between government and the forest products industry to understand each others' problems, but first steps are not enough. Our whole economy depends on proper use of our natural resources, particularly our only renewable natural resource-the forest lands. The time is past when this nation can permit continued withdrawal of productive land solely for recreation. We must learn how to integrate the two.

Thus we see a need for a presidential assistant with broad knowledge in all fields from the tree to the end use (housing), whose activities would include public education in the best use of land for the common good. We are pressed for housing needs at the same time as we are asked to assure sufficient timber supply under constant withdrawal pressures.

This problem can be solved by cooperation be' tween industry and government, but only if the public is educated to the true meaning of the words Conservation vs. Preservation.

Action in this area deserves high priority, both short and long range.

Sincerely yours,

A. D. Bmu Jn. Publisher The Merchant Maeazine

We intend to keep right on bringing you the finest of Certified Kiln Dried Redwood and other quality Redwood products that the industry can offer. You can rely on ARCO as a dependable source for your future Old-Growth Redwood requirements.

\T/HEN L.

M. "Larry"

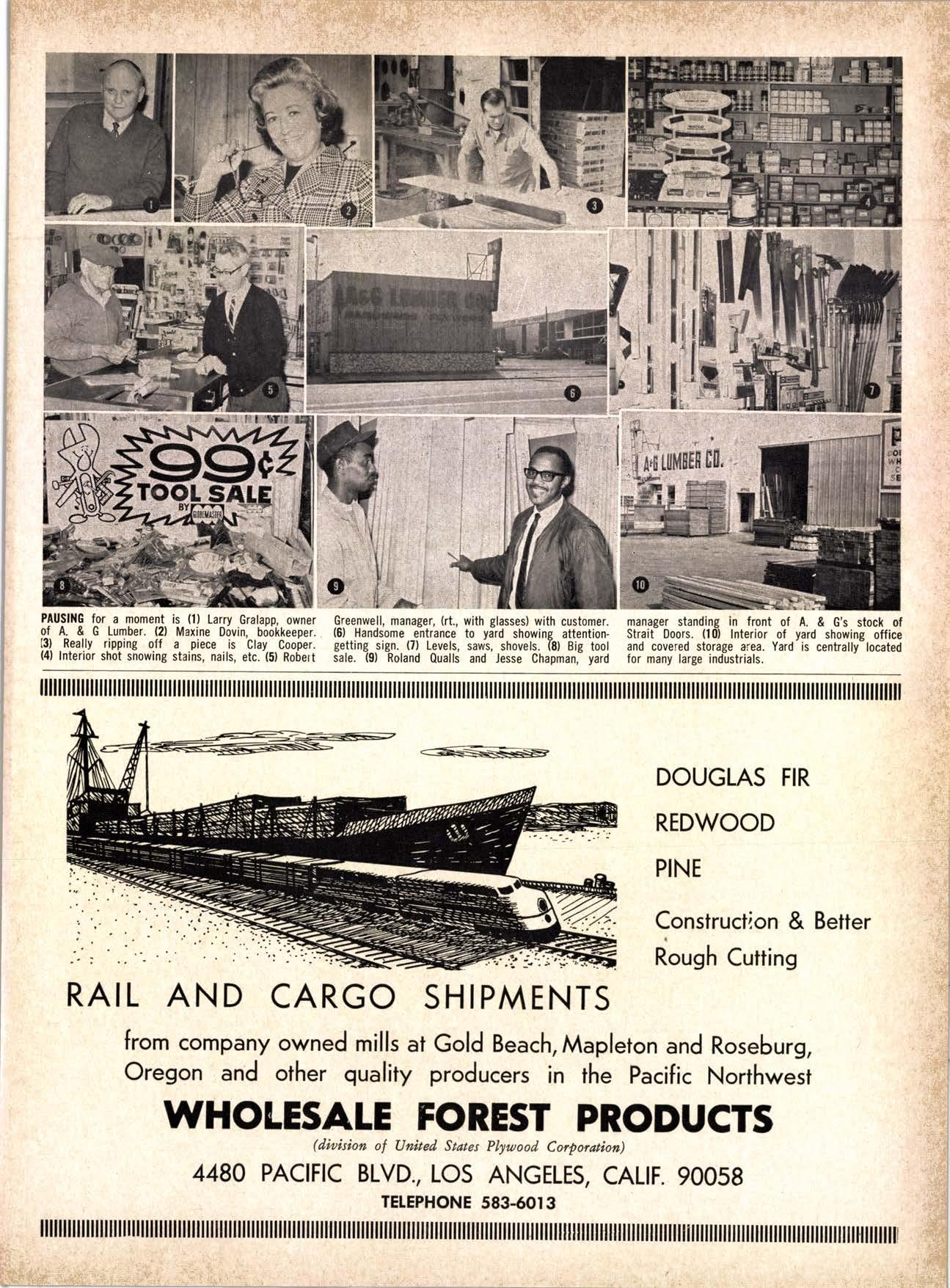

Gralapp and Carl VY Ahlgrin put their heads together to decide what to name their new yard, a local contractor jokingly told them, "With two names like that, why don't you call the place A & G." They did,andA & Glumber Co. in Culver City, Calif., has been growing ever since, with one switch: in 1964 Ahlgrin was bought out by Larry Gralapp.

Gralapp's yard is located on one of the many feeder streets to downtown Los Angeles with little or no walk by traffic.

Straight retail counts for only 5 percent of A & G's business. Power tools and paint, money makers at most yards, are the big losers when it comes to turn over, As Gralapp put it, there's "just not enough traffic." Their retail trade area covers approximately a five mile radius. Much retail business is sold by word of moutlr to employees of the big industrial concerns A& G does business with. Industrial-commercial accounts, which represent about 60 percent of A & G's business, come from as wide an area as El Segundo, Beverly Hills, the San Fernando Valley and the downtown area.

Gralapp feels his retail trade seems to have bottomed out over the past 25 years. Located in a largely industrial area, there are few homes in the A & G neighborhood. Many apartments have been torn down and the ooapartments left are at a minimum," noted Gralapp. Builder-contractor business, which accounts for 35 percent now, is increasing along with industrial business. "So intangible," was the way Gralapp re' ferred to industrial accounts because of the lulls between orders. Yearly grosso tho it o'fluctuates," runs approximately $340,000, said Gralapp.

A & G employs three yard men, three office personnel, a bookkeeper and a part time student, Gralapp's 2l year old son. The small crew efficiently handles large industrial orders, keeping costs down, one of the ways they keep up with the competition. Gralapp and Manager Robert Greenwell regard "anybody" as competition.

Another way they keep prices down is to buy in sufficient quantities to earn a discount from the wholesaler or manufac' turer.

The yard has no expansion plans presently as Gralapp sufiered a crippling accident seven years ago and runs his yard from a whrelchair.

No prefab work and no remodeling packages are done. He pointed out that if plumbers and electricians don't show uo to install a remodeling package, the yard is in a real bind.

Cutting lumber to order is done for in' dustrial customers. A & G charges $9.50 per hour, which will "go up if wages go up," said Gralapp. The yard carries an 'oawful lot of specialty items" for industrial customers, explained Gralapp. "Sales of framing lumber are not too great," he continued. Delivery charges start at $3.50 to defray costs and to protect the yard from people who "want a bedboard delivered to an apartment way over in Beverly Hills, a $3 or $4 order," said Gralapp.

Story dI d Glqnce

City traff ic patterns inf luence yard's slow switch from retail towards industrial knowledgeable staff concentrates on industrials . stocks many specialty items.

A & G hires personnel through classified ads. They find that often people are unreliable, working only when they feel like it, although their regular crew is top notch. o'Very little" is spent on advertising, said Gralapp. They use the phone directory Yellow Pages; ads in local papers for goodwill primarily; calendars, pens and pencils for ontact makers.

Industrial customer can be very careful when they select a yard to do business with, often coming out to look the yard over. Hughes Aircraft (owned by industrialist Howard Hughes) checked the yard through Dun & Bradstreet, among other things.

While A & G stocks no plumbing, theY do stock electrical replacement parts, switches. wire and so forth for industrials'

Accounting is not itemized into lumber and nonlumlrcr percentages but done "all together," said Gralapp. Credit policy, in addition to accepting major credit cards, gives a two percent discount on bills paid before the IOth.

Little of A & G business can be described as seasonal but sometimes business does fade down during the hot summer months, July and August.

In keeping with the industry as a whole, the men at A & G have had some trouble lately keeping up with lumber prices undergoing rapid fluctuations. But a depression in the housing market would give the yard few problems both Greenwell and Gralapp believe. Were the Viet Nam war to end, business would depend on how defense work and government contracts continue among their industrial customers.

Not located on a spur, the one acre yard is open {rom 7:30-4:3O, Monday-Friday, 8:0O-noon on Saturday. The office and showroom area, with mezzanine, includes approximately 1,500 sq. ft.

Larry Gralapp entered the lumber business with Patten-Blinn in Los Angeles, in 1935. His career was interrupted with a tour of duty in the Sea Bees during Wbrld War II. He is married with one son. Bob Greenwell was born in San Franciscq grew up in Los Angeles and settled in Ventura, Calif.. where he was in the hardware busi' ness. He went to work for Peoples Lumber on a tip from a friend after serving in the Korean War. Bob will have been with A & G two years this June. He has three daughters.

Both men believe success comes to the man who's o'in the right place at the right time.'n A & G's success is based on service, personnel and having a yard laid out to serve their customers efficiently.