1 minute read

mark firm

Bean remarks, "if you need posts, for example, we'll flrnd them and ship 'em to you." Their marketing area is everything east of the Rockies.

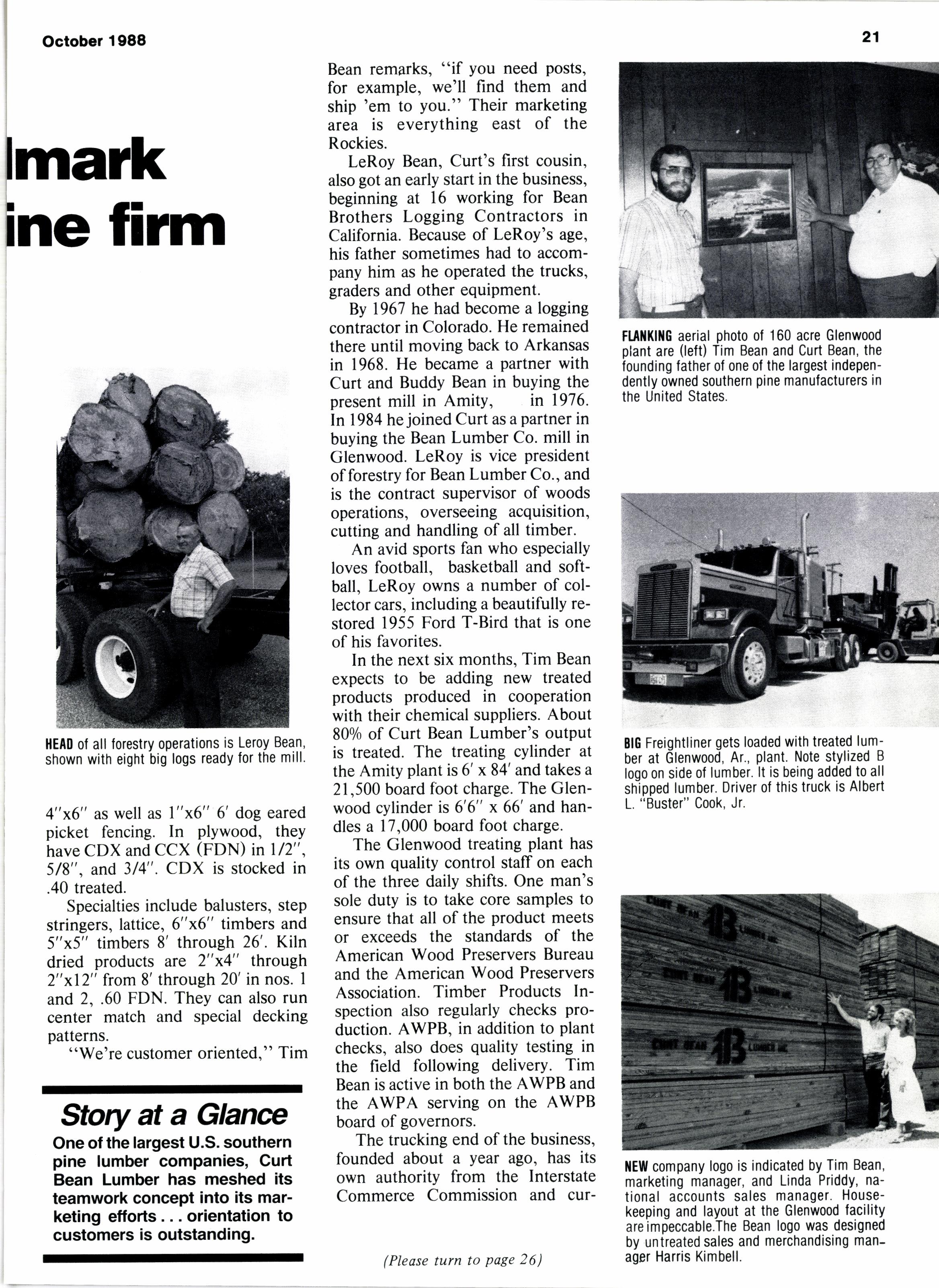

LeRoy Bean, Curt's first cousin, also got an early start in the business, beginning at 16 working for Bean Brothers Logging Contractors in California. Because of LeRoy's age, his father sometimes had to aocompany him as he operated the trucks, graders and other equipment.

By 1967 he had become a logging contractor in Colorado. He remained there until moving back to Arkansas in 1968. He became a partner with Curt and Buddy Bean in buying the present mill in Amity, in 1976. In 1984 he joined Curt as a partner in buying the Bean Lumber Co. mill in Glenwood. LeRoy is vice president of forestry for Bean Lumber Co., and is the contract supervisor of woods operations, overseeing acquisition, cutting and handling of all timber.

An avid sports fan who especially loves football, basketball and softball, LeRoy owns a number of collector cars, including a beautifully restored 1955 Ford T-Bird that is one of his favorites.

4"x6" as well as 1"x6" 6'dog eared picket fencing. In plywood, they have CDX and CCX (FDN) in l/2", 5/8", and 3/4". CDX is stocked in .40 treated.

Specialties include balusters, step stringers, lattice, 6"x6" timbers and 5"x5" timbers 8' through 26'. Kiln dried products are 2"x4" through 2"x12" from 8'through 20'in nos. I and 2, .60 FDN. They can also run center match and special decking patterns.

"We're customer oriented." Tim

S,tory at a Glane

One of the largest U.S. southern pine lumber companies, Gurt Bean Lumber has meshed its teamwork concept into its marketing efforts.. orientation to customers is outstanding.

In the next six months, Tim Bean expects to be adding new treated products produced in cooperation with their chemical suppliers. About 800/o of Curt Bean Lumber's output is treated. The treating cylinder at the Amity plant is 6' x 84'and takes a 2l,500 board foot charge. The Glenwood cylinder is 6'6" x 66' and handles a 17,000 board foot charge.

The Glenwood treating plant has its own quality control staff on each of the three daily shifts. One man's sole duty is to take core samples to ensure that all of the product meets or exceeds the standards of the American Wood Preservers Bureau and the American Wood Preservers Association. Timber Products Inspection also regularly checks production. AWPB, in addition to plant checks, also does quality testing in the flield following delivery. Tim Bean is active in both the AWPB and the AWPA serving on the AWPB board of governors.

The trucking end of the business, founded about a year ago, has its own authority from the Interstate Commerce Commission and cur-

(Please turn to page 26)