3 minute read

TREATERS

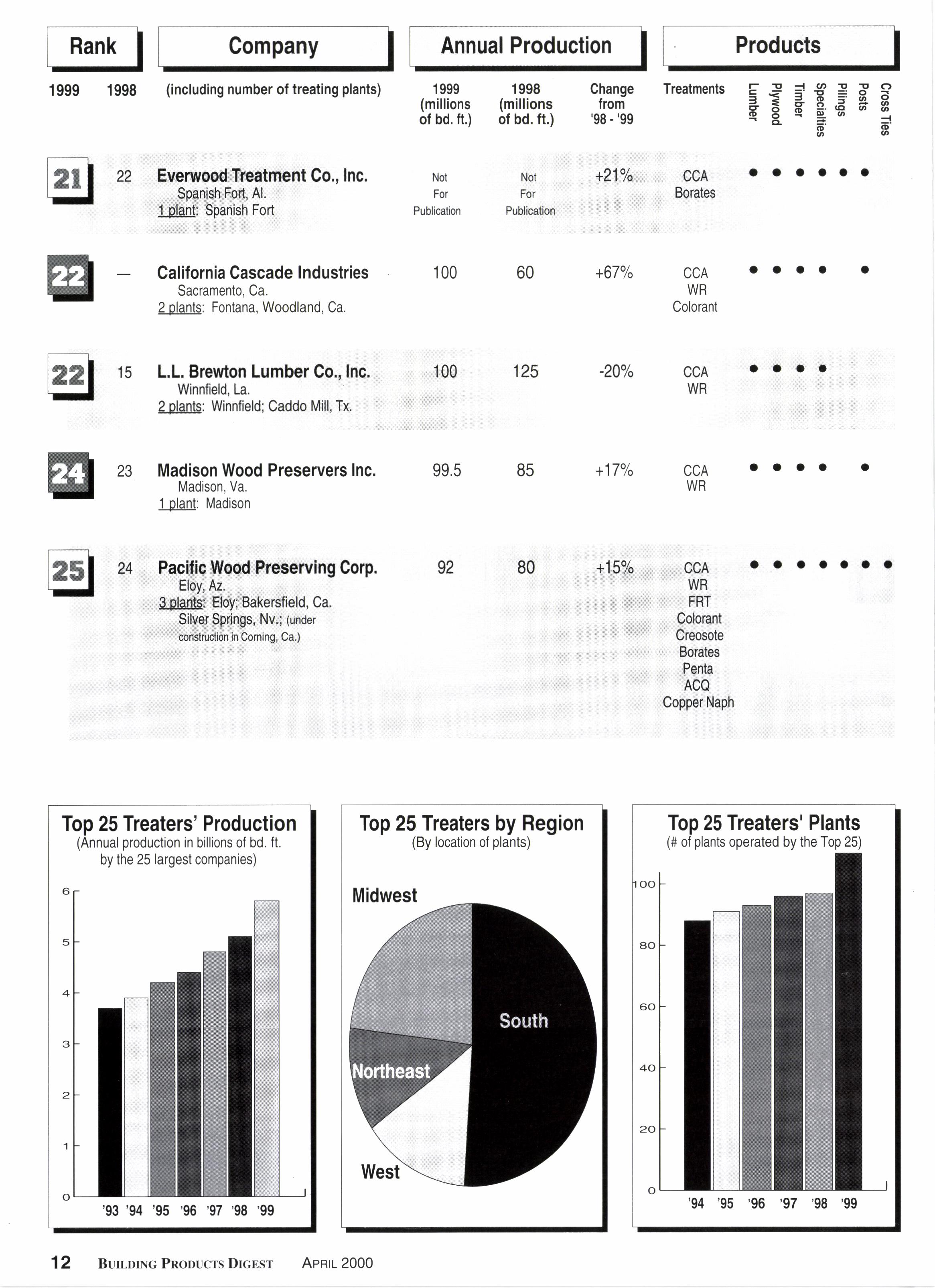

nother year of change shook up the treating industry, as 22 of the Top 25 swapped positions in this year's ranking of the nation's largest. While Universal Forest Products remained well ahead of the pack, Great Southern Wood Preserving regained the #2 position by leapfrogging GeorgiaPacific-despite G-P's acquisition last year of former #15 Mellco.

Another big storyline was the rise of western treaters. The region's two largest treaters each surged five spots, McFarland Cascade increasing production 25Vo to reach #12 and Allweather Wood Treaters upping output 277o

Company

(including number of treating plants)

Univereal Forest Products

Grand Rapids, Mi,

19 nlants: Windsor, Co,lAuburndale, Fl^; Moultrie, Union City, Ga.;Granger, In.; to #14. California Cascade cracked the Top 25 for the first time, with its 677o prodtction gain landing the company at #22. Pacific Wood Preserving increased production l5Vo to remain on the list at #25. Several others. notably Exterior Wood, just missed the cut.

Belcherhuvn, Ma.; Harrisonville, Mo.; Elizabeth Oity, $alisbury, N.C.; Hamilton, Lodi, 0h.; Gordon, Stoc*ertown, Pa.; New Waverly, Saginaw, Schefiz, Silsbee, Tx.; Janesville, Wi.; Ranson, W.V.

Great Southern Wood Preserving Abbeville, Al.

5 plants: Abbeville, Mobile, Muscle Shoals, Al.; Sumter County, Fl.; Conyers, Ga.

Companies are ranked by production of lumber, timbers and specialty products. Firms exclusively treating poles, pilings, railroad ties, etc., are not included. Abbreviations include FRT (fire retardant treated) and WR (water repellent).

All information was provided by the companies themselves. While every ef'fort was made to ensure full accuracy and completeness, a handful of treaters elected not to participate in this tut

Annual Production

1999 1998 (millions (millions of bd. tt.) of bd. ft.)

6

(including number of treating plants)

Georyie-Paeific Corp.

Atlanla Ga.

12 planh: Alhsns, Nauvoo, Louisville, Al.; Rocldedge, Fl.; Steding, Ga,; Rochelle, It.; Bichmond, ln^; Pleasant Hill, Mo.; Middleburg, Roanoke Rapids, N.C.; Rock Hill, S.C.; Mineola, Tx.

Culpeper Wood Preservers

Culpeper, Va.

3 plants: Culpeper, Fredericksburg, Va,; Shelbyville, In.

Walker-Williams Lumhr Co., lnc.

Columbus, Ga.

5 plants: Hatchechumoe, Falkvills, Al.; Blanchester, Youngstown, 0h.; Westville, In.

Quality Wood Treating Co.,Inc.

Prairie du Chien, Wi.

6 plants: Prairie du Chien, Janesville, Wi.; Lansing, Mi.; St. Paul, Mn.; Columbus, Oh.: Fombell. Pa.

Commonwealth lilood

Hampton, Va.

9Sg0[$ Hampton; Fairless Hill, Pa.;Betrlehem, N.H.

Rocky Top Wood Preservers

Rocky Mount, Va.

3 olants: Rocky Mount; Streator, ll.; Hagerstown, Md.

Cox lndustries

Oangeburg, S.C.

LUlrolC: Augusta, Ga, ; Orangeburg, Eutawvifle, Norlh, Sumter, S,C.; Coleridge, Cove City, N.C.

John A. Biewer Lumber Co.

St. Clair, Mi.

5 olants: St. Clair, Lansing, Mi.; Seneca ll.; Washington Court House, Oh.; Prentice, Wi.

C.lS. Tucker Lumber

Pageland, S.C.

2 plants: Pageland; Henderson, N.C.

Annual Production

1998

(including number of treating plants)

7 Kerr-McQee0hemical0orp.

Oklahoma Citv, Ok.

6 phnts Madison, ll; Columbus, Ms.; Springfied, Mo.;The Dalles, Or.; Texarkana, Tx.

McFarland Cascade

Tacoma, Wa.

5 olants: Tacoma; Sandpoint, ld.; Eugene, Or.; Broken Bow, Ok.; Electric Mills, Ms.

Allweather Wood Treaters l*ew $outh Inc.

Washougal, Wa.

5 plants: Washougal, Femdale, Wa.; Fort Collins, Loveland, Co.;Medford, Or.

Robbins Manufacturing Co.

Tampa, Fl.

3 plants: Tampa, Fort Myers, Orlando, Fl.

Conway, S.C.

2 plants: Conway, Camden, S.0, giamond Wood Treaters, Inc.

Curt Bean Lumber Co. Glenwood, Ar.

3 olants: Glenwood, Amity, Ar.; Buckner, Mo.

Decatur, Al.

2 nlanls: Decatur; Bulls Gap, Tn.

Bestway Enterprises

Cortland, N.Y.

4 plants: Lancaster, Ma.; Cortland, Gouverneur, N.Y.; Stony Point, N.C.

1998

Company (including number of treating plants)

Everwood Treatment Co., lnc. Spanish Fort, At.

1 olant Spanish Fort

California Cascade Industries Sacramento, Ca.

2 olants: Fontana, Woodland, Ca.

L.L. Brewton Lumber Co.,Inc. Winnfield, La.

2 plants: Winnfield; Caddo Mill, Tx.

Madison Wood Preservers Inc. Madison, Va.

1 olant: Madison

Facitic Wood Preserving Corp. Eloy, Az.

3 planls: Eto$ Bakerstield, Ca. 9ilver Springs, Nv.; (under construciion in Coming, Ca.)

A

LTHOUGH CCA treated wood is .CLsometimes promoted as "maintenance free," treatment alone does little for appearance or dimensional stability. And, to consumers, the appearance of their deck is just as important as its long-term structural integrity.

While CCA treatment makes wood resistant to decay and insect attack, it also causes changes in the wood structure that affect its appearance, properties and finishability. Its appearance changes to a flat, greenish, less natural hue. The treating cycle of drying, saturating and redrying creates internal stresses that can result in cracking, checking, splintering and grain raising. Chemical interactions can weaken wood and make it more brittle, giving rise to splintering and cracking.

Originally, coatings manufacturers responded by shoe-horning "all-purpose" products into the deck category, with disappointing performance results. In the past few years, however, finishes have been developed that specifically address the special requirements of CCA treated wood.

In addition to the availability of user-applied surface coatings, manufacturers can now add water repellents, mildewcides and toners during the treating process. Yet, according to the Forest Products Laboratory-sponsored Joint Coatings/Forest Products Committee, such ingredients provide initial protection that may last only a few months to a few years. Eventually, surface coatings are required to provide ongoing protection.

Unlike most other wood preservatives, CCA does not adversely affect finishes. It not only readily accepts most coatings, but has been shown to enhance the service life of water repellents, paints and stains. In spite of CCA treated wood's general compatibility with most coatings, there are some potential problems:

Lack of Penetration. Many nonfilm-forming finishes such as stains and water repellents must penetrate the wood's surface to work effectively. If treated wood is not sufficiently dried, excessive moisture can impede penetration of finishes. Air dry lumber that is saturated with water before