4 minute read

Fire retardant treated wood sales rising

I N A WORLD of increased awareI ness of fire safety, many builders are "feeling the heat." More and more stories appear in the media about buildings that were built without regard for fire safety. Building codes are feeling the public's ever watchful eye toward the safety of buildings.

Fire retardant treated wood (FRTW) is a material that often offers the best alternative to make a building less vulnerable to the dangers of fire. A building code requirement for "non-combustible" building construction usually means that FRTW can be used, while providing possible significant cost savings for the building owner.

Bill Hambrick, Clement Lumber Co., recalls a recent success story with fire-retardant treated wood. The Spartanburg, S.C., company was a stocking dealer of FRTW when the first prototypes of the 210 Quincy Steak Houses were being built in the South.

"All the contractor needed were 3" x 8" FRTW timbers. We wound up supplying more than 24,000 of them. We see FRTW as in the growth stage."

Story at a Glance

Fire safety aspect of FRTW has created a growing market for commercial, industrial, even residential buildings... second generation products perform better. higher margins mean more dealer profits.

tion of products has allayed the fears of many builders and contractors. And FRTW has become a growth business once again.

"We're pushing it, because it's a high-margin product that's been growing lWh - 200/o a year," observes Chaney Nicholson of Capital City Lumber Co., Raleigh, N.C. "Building is up, codes are more strict. We're selling a lot for shopping centers and commercial buildings."

"We're just beginning to scralch the surface," says Pete Pappas, sales manager for Commercial Lumber Co.. Houston, Tx.

Pappas says his FRTW business doubled in the past two to four years. One big order, totaling 92,000 board-feet, went into Fame City, a 300,000 sq.-ft. indoor fun palace for children, which roofs a miniature golf course, movie theater, restaurants, skating rink and "any game you can imagine."

Still, he says, "Our FRTW business is only a small fraction of what it could be. It's an educational process. Architects need to understand the kind of design freedoms FRTW can offer. Then you've got to go out and get the order. We're selling it into schools, hospitals, nursing homes, and a few churches and restaurants."

For most dealers, 10,000 boardfeet of stock is all that's needed to service the contractor customers. H & S Lumber Co.. lnc.. Charlotte, N.C., has about 20,000 board-feet on hand, according to sales manager Bob Hening. "We're selling it into commercial applications. We had a couple of real big jobsCharlotte Hospital and the South Park Mall."

"When the 'second generation' of FRTW products were born, around the beginning of the decade, a big market was waiting to be filled," notes product specialist Bob Lattanzi, Koppers Company, Inc.

Often, though, building codes would only allow FRTW. And, before the second-generation products were developed, FRTW meant wet treated wood that would warp, twist, crack as it dried after it was installed into the walls. The "oldstyle" treated wood was also exceedingly "hygroscopic"or having a strong tendency to absorb moisture from the air.

Experience with the new genera- lJ ASSLES over product quality

The FRTW market seemed to have grown up to the residential market and, for now, can't seem to get past the fire stop. Wood treaters and dealers are cautiously offering it to builders of multi-family dwellings.

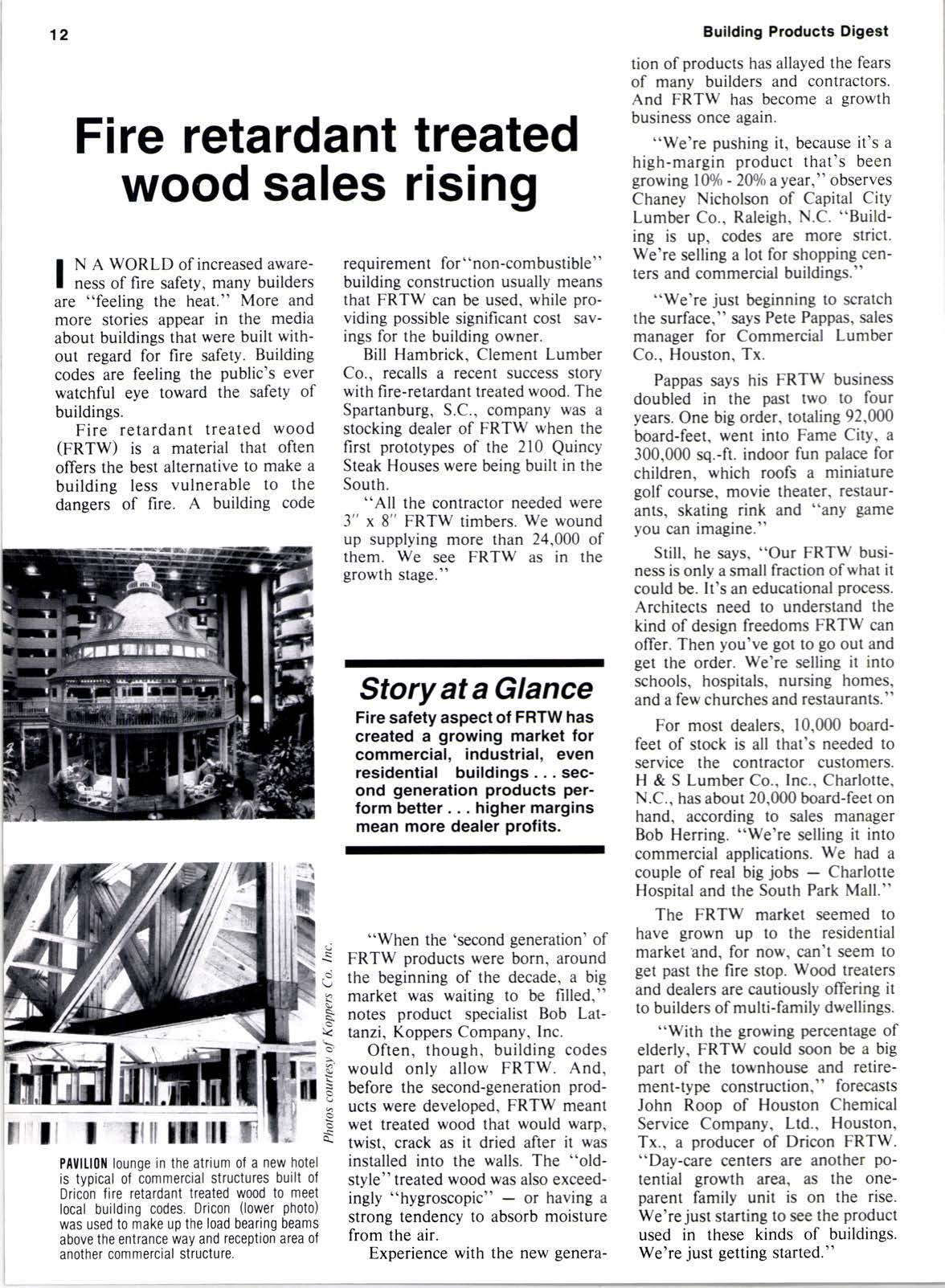

"With the growing percentage of elderly, FRTW could soon be a big part of the townhouse and retirement-type construction," forecasts John Roop of Houston Chemical Service Company, Ltd., Houston, Tx., a producer of Dricon FRTW. "Day-care centerc are another potential growth area, as the oneparent family unit is on the rise. We're just starting to see the product used in these kinds of buildings. We're just getting started."

I I are the dread of every rerailer, but when you're dealing with pressure treated wood, you can cut the possibility of such problems by being informed on approved quality marks.

All material produced under the monitoring of the American Wood Preservers Bureau and inspected by their I I approved inspection agencies is produced to nationally recognized and accepted consensus standards of the American Wood Preservers Association.The AWPB cloverleaf quality mark has been a recognized symbol of quality for over 20 years.

The d-i-y customer usually has limited knowledge of lumber grades and often judges treated wood by appearance only, buying wood that "looks good." Because he is oblivious to the approved grade marks, it is the responsibility of the retailer to provide him with properly treated wood suitable for the intended use. If he doesn't, the seller may face a product liability problem in addition to an unhappy customer.

"The advent of the treated lumber market has created a somewhat different buyer and user due to the volume of treated lumber which is sold directly to the retailer consumer for d-i-y projects," says B. W. Perkins, director of the Treating Division of the Southern Pine Inspection Bureau. "We need the help of retailers at the consumer level to assist the uninformed buyer and user of treated wood. The quality mark for treatment assurance is important but so is the grade mark since the lumber is the vehicle for the treatment."

Lon J. Sibert, manager of the lumber division of Timber Products Inspection, offers the following guidelines for those purchasing either untreated or treated lumber.

(1) Beware of any good deals that are significantly below the market price. Report any suspicious sales proposals to any appropriate ALSC approved grading agency.

(2) When appropriate, specify lumber with an ALSC approved gradestamp (and AWPB quality mark) on your purchase order. Notice how your supplier represents the product in his acknowledgement or invoice.