LATHE CHUCKS

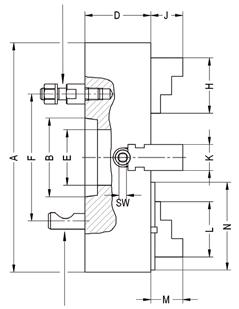

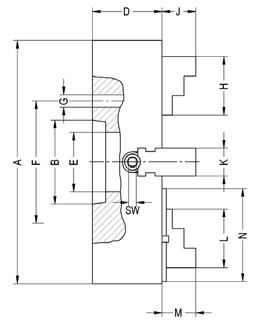

ABCDEF

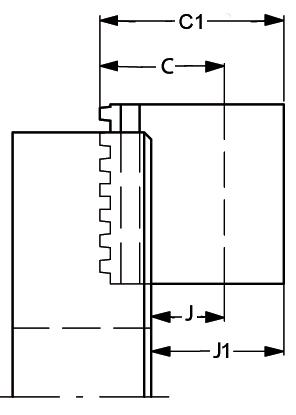

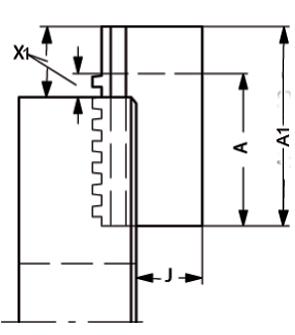

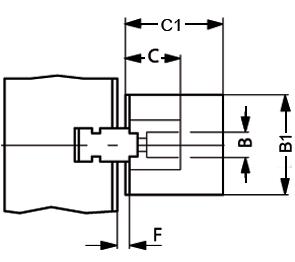

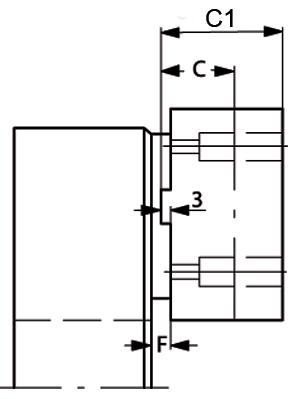

392,153,98511,131,83x15,170,66 4117,563,52511,133,33x16,782,55 514682,57512,738,16x19,8104,8 6181106,39014,344,56x23133,4 8225,4139,73515,950,86x26,2171,4 11298,5196,88517,560,36x31235 15403285,8001969,96x35,7330,2 20546412,8002182,56x42,1463,6

Typ

withdriver.

Holes on outer

Spindle nose size

A2 (corresponds ISO 702-1) 392,153,98511,115,93x7/16-14UNC70,66 410863,52511,11911x7/16-14UNC82,55 5133,482,57512,722,211x7/16-14UNC104,8 6165,1106,39014,325,411x1/2-13UNC133,4 8209,5139,73515,928,611x5/8-11UNC171,4 11279,4196,88517,534,911x3/14-10UNC235 15381285,8001941,312x7/8-9UNC330,2 20520412,80020,647,612x1-8UNC463,6

B1 5133,482,57514,28822,211x11,9104,88x7/16-14UNC61,9 6165,1106,39015,87525,411x13,5133,48x1/2-13UNC82,6 8209,5139,73517,46228,611x16,7171,48x5

-11UNC111,1

4-10UNC165,1

8-9UNC247,6

DIN 55021

Minimum CDEF M2021306,31020 M24253681224 M33345091430 M394056101635 M454667111840 M525580122045 M606290142250 M76x678112163063 M105x6106150204080

ABCDF1(F2) E2F2E1G 310253,98511163xM103x10,575-411263,52511203xM103x10,585-513582,57513227xM104x10,5104,88xM1061,9 6170106,39014257xM124x13133,48xM1282,6 8220139,73516287xM164x17171,48xM16111,1 11290196,885183512xM206x2123511xM20165,1 15380285,800204212xM246x25330,211xM24247,6 20520412,800214812xM246x25463,611xM24368,3

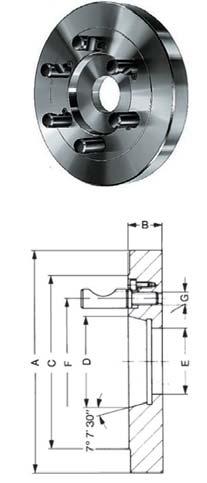

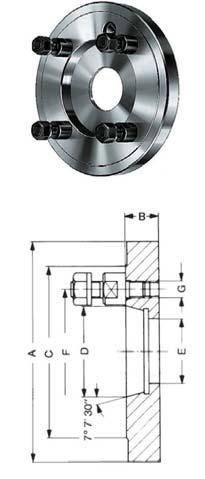

Form A: Tappedholesandthrough-holes inflange(without innerboltcircle)

Spindle nose size

Form B: Tappedholesandthrough-holesin flange(outerboltcircle) and tapped holesininnerboltcircle

Holes on outer bolt circle

Outer bolt circle Holes on inner bolt circle

Inner bolt circle

ABCC1 DF1(F2) E2F2E1 39253,98311-163xM1070,6-410863,52111-2011xM1082,6-513382,5731314,2882211xM10104,88xM1061,9 6165106,3851415,8752511xM12133,48xM1282,6 8210139,7311617,4622811xM16171,48xM16111,1 11280196,8831819,053511xM202358xM20165,1 15380285,7911920,6384212xM24330,211xM24247,6 20520412,7952122,2254812xM24463,611xM24368,3

20540412,80021486x43463,6

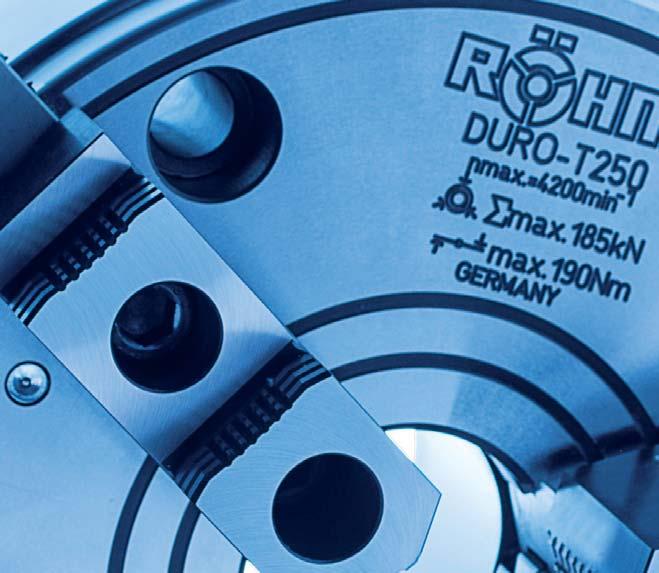

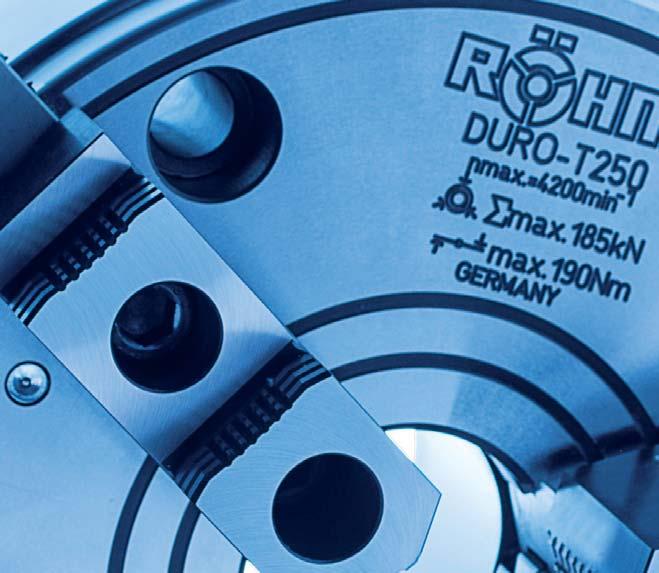

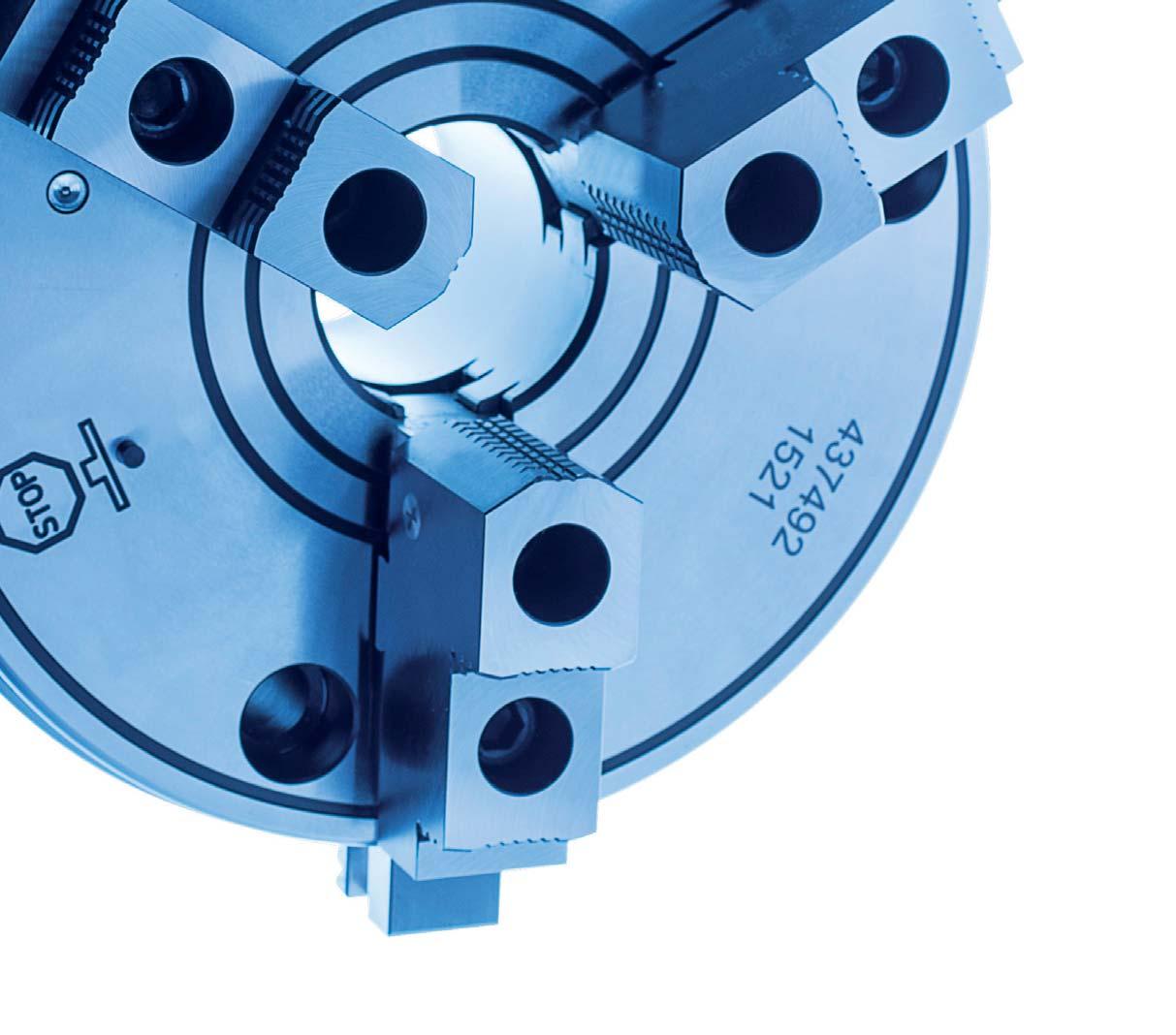

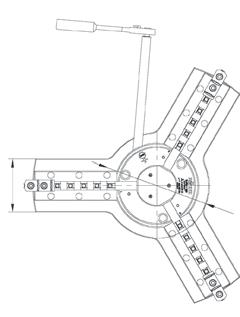

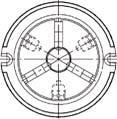

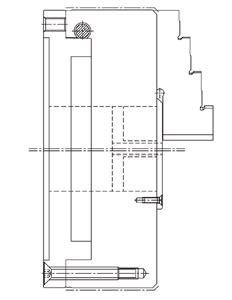

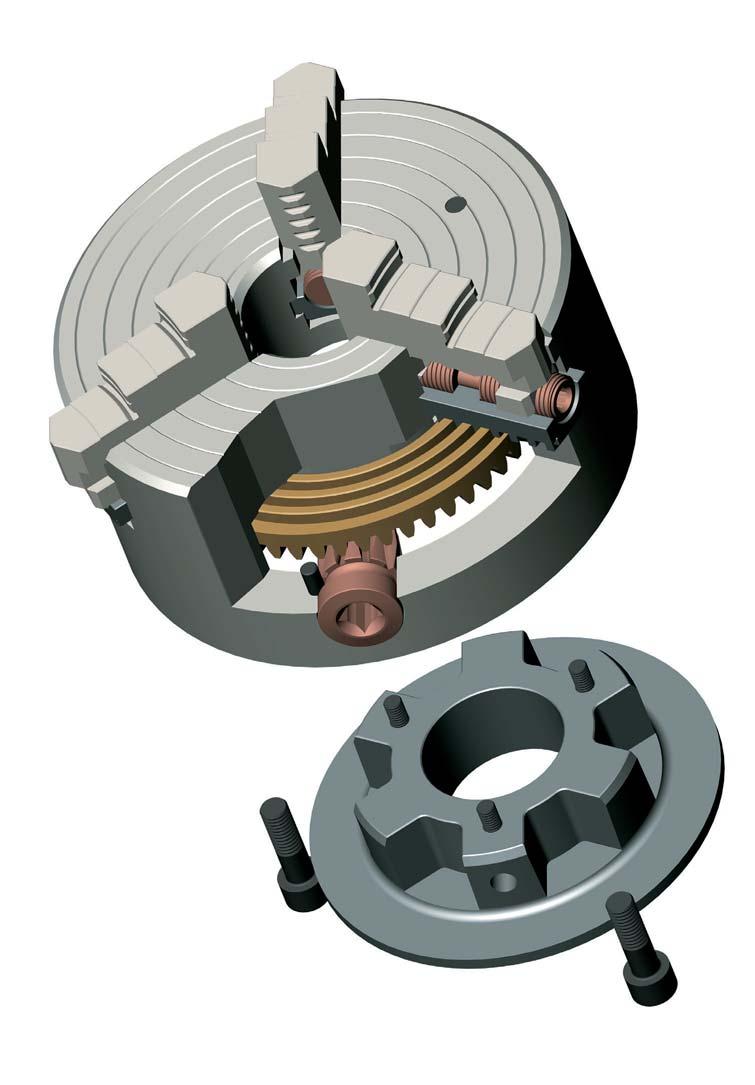

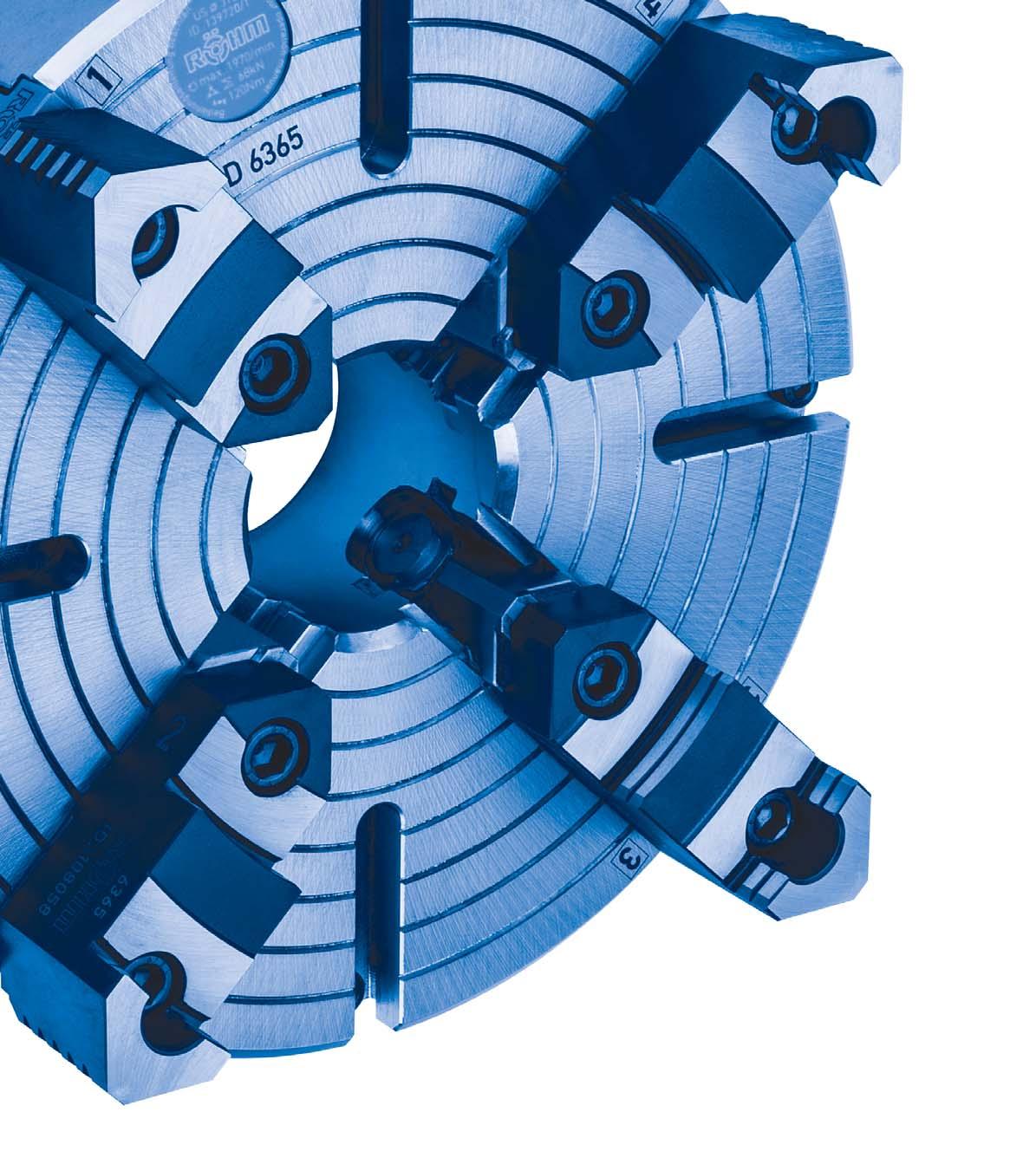

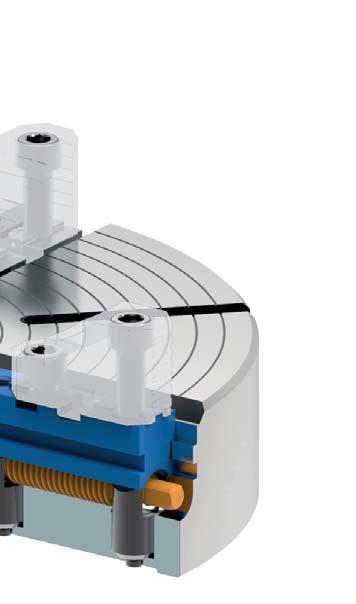

TheRÖHMkeybarchuckswithquickjawchangesystemareusedsuccessfullyinareaswhere extremelyhighclampingforces,highconcentricityandreliablelong-termrepeatabilityarerequired.

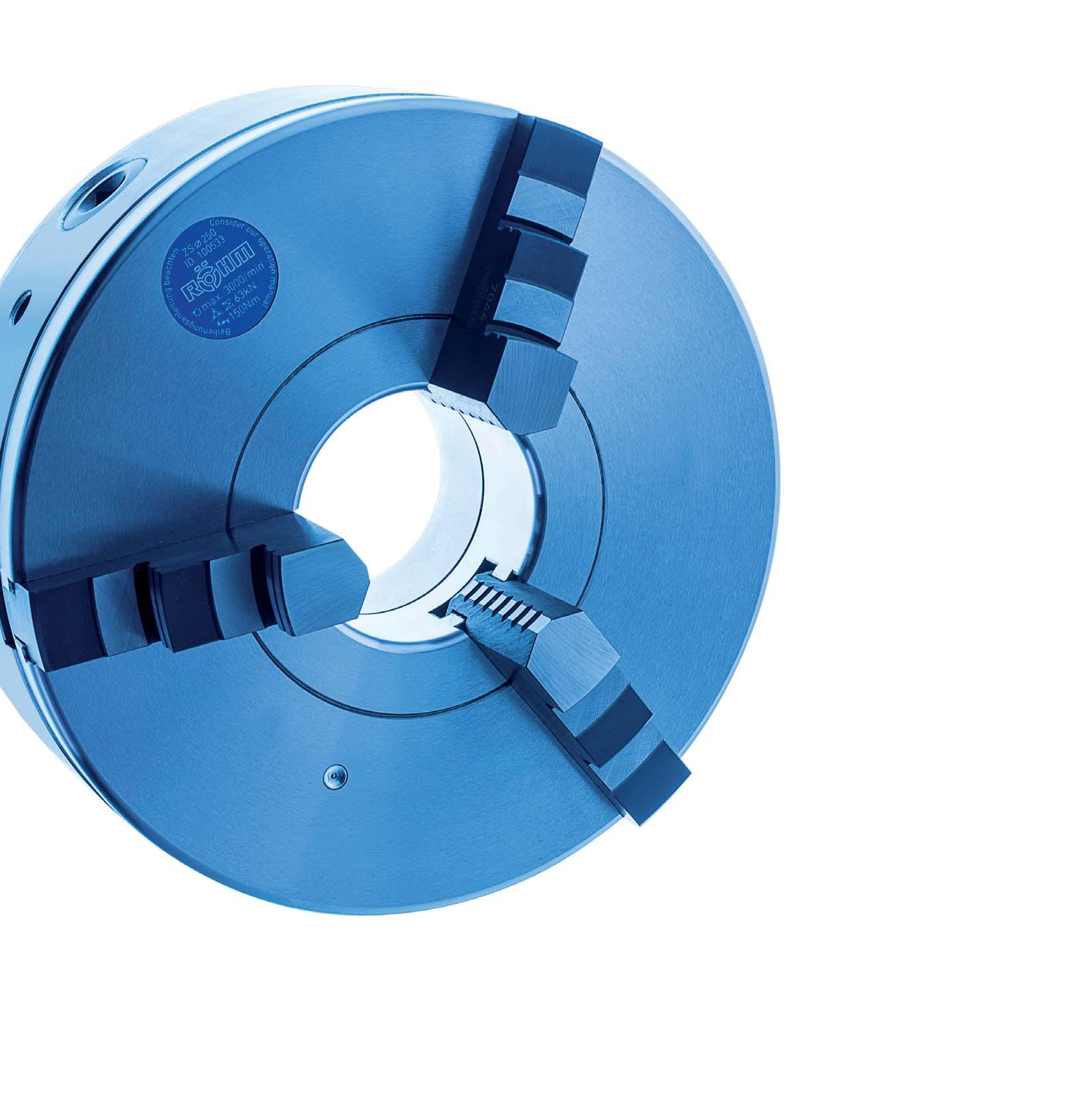

The DURO-T key bar chuck guarantees maximum precision, maximum clamping force and is completely balanced ex works.

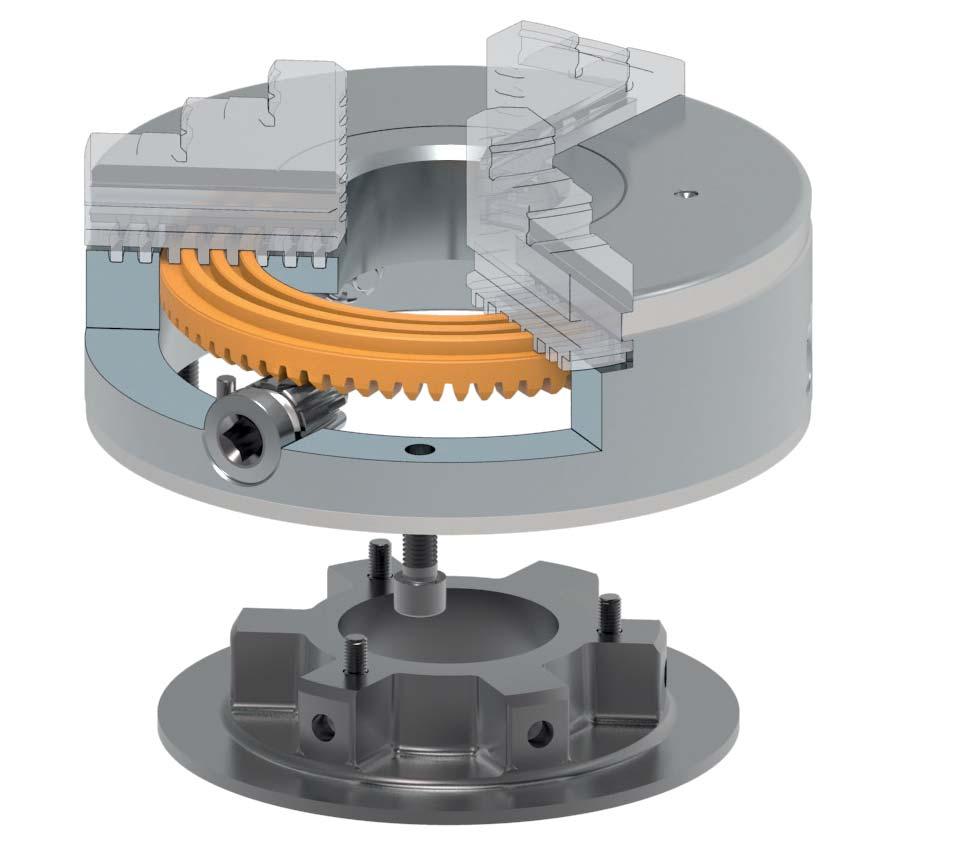

Thankstothetangentiallyarrangedthreadedspindle(1),the forceistransferredviaakeybar(2)havinganinternalthread. Thekeybarmovesthedriveringviaaslide(3).Twootherslidesin thedrivering(4)transfertheforcestotheothertwokeybars.The keybarshavinganinclinedprofileengageinthebasejaws(5), therebyguaranteeingexact,centricclamping.Thejawscanbe quicklyandeasilyturned,changedoroffsetovertheentireclampingrangewithinafewseconds.Todothis,thekeybarsmustbe disengagedbyturningthekeytotheleft;theindicatorpin(6)will projecthere.Inthisposition,thejawsaresecuredagainstbeing hurledoutintheeventthemachinespindleisstartedupunintentionally.Therefore,thegatevalve(7)ofeachjawmustbeunlocked viathecorrespondingpressurebolt(8)ontheouterdiameterof thechuck.

Large,straight-lineforcetransfersurfacesbetweenthekey barandjawtoothingyieldaveryhighclampingforceover alongservicelifeandprecisionwhichistwiceashighas prescribedbyDIN6386.Thehighclampingforceisachieved withoutexertinganyspecialamountofforcebymanually turningthekey.

Tomaintaintheclampingforce,keybarchucksmustbelubricatedregularly.Youwillfindcorrespondinginformationinthe operatinginstructionswhichareenclosedwitheverychuck. Foreasymaintenance,DURO-Tchucksareequippedwith threeadditionalgreasenipplesonthefrontside.

Optimizedforturningapplications,whichrequireextremelyhighclampingforces, maximumconcentricity,aswellasreliablelong-termrepeatability. Incombinationwithabaseplate,stationaryuseonmillingmachines,dividing unitsandmachiningcenters.

Keybarchuckwithquickjawchangesystem.

Guaranteedmaximumjawprecisionasfarastheseareonlyusedonthesame chuck,andbaseandtopjawsarekeptscrewedonforrecurringwork.

Maximumclampingforcethankstokeybarsystem Concentricityandaxialrun-outtolerancetwiceasexactasrequiredinDIN precisionclass1

Veryhighjawchangerepeatability

Balancedandjawsinchuckgroundoutforconcentricity

-Withjawsafeguard -Chuckbodycompletelysurface-hardened -Visualmarkingforquickjawadjustment -Externalshapeincl.splash-wateredge -Fasteningoptionsforstronglystressedslidingsurfaces -Incl.safetykey -Highcorrosionprotection

A08

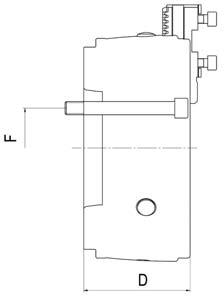

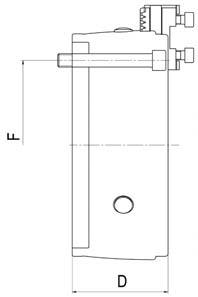

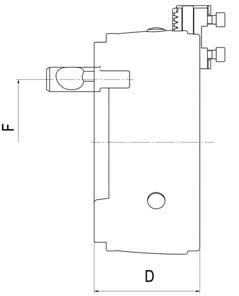

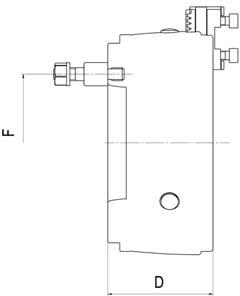

Cylindrical centre mount

SizeInchThrough-

437475

With

DmmFmmSpeedmax.

46,510060004023

437476 437483 437490 63125540012073

437477 437484 437491 811604600155114 2501062 437478 437485 437492 922004200190185

437479 437486 437493 1112503300210240

437480 437487

1183152200260260

A08 ISO 702-3 (DIN55027),withstudsandlocknuts

SizeMountshort

DmmFmmSpeedmax.

437499 437523 - 67104,860004023

437501 437525 437548 78104,8540012073 160642 437502 437526 437549 85133,4540012073 200552 437504 437528 437551 96104,84600155114 200652 437505 437529 437552 97133,44600155114 250662 437509 437533 437556 108133,44200190185 250862 437510 437534 437557 110171,44200190185

437512 437536 437559 129171,43300210240 3151187 437513 437537 437560 1312353300210240 4008102 437515 437539 437562 138171,42200260260 40011102 437516 437540 437563 1382352200260260 50011162 437519 437543 437566 1562351900320290 50015162 437520 437544 437567 163330,21900320290

- 4375451) 437568 1652351100350320

- 4375461) 437569 167330,21100350320

A08 ISO 702-2 (DIN55029),studforCamlock

SizeMountshort

437602 437625

6770,6660004023 125432 437603 437626 - 6882,660004023 160442 437604 437627 437650 83,582,6540012073 160542 437605 437628 437651 87104,8540012073 160642 437606 437629 437652 104133,4540012073 200452 437607 437630 437653 97,582,64600155114 200552 437608 437631 437654 101104,84600155114 200652 437609 437632 437655 106133,44600155114 200852 437610 437633 437656 125171,44600155114 250460 437611 437634 437657 118,582,64200190185 250562 437612 437635 437658 112104,84200190185 250662 437613 437636 437659 117133,44200190185 250862 437614 437637 437660 120171,44200190185 315687 437615 437638 437661 145133,43300210240 315887 437616 437639 437662 136171,43300210240 3151187 437617 437640 437663 1432353300210240 4006102 437618 437641 437664 153133,42200260260 4008102 437619 437642 437665 141171,42200260260 40011102 437620 437643 437666 1482352200260260 40015102 437621 437644 437667 168330,22200260260 5008135 437622 437645 437668 143171,41900320290 50011162 437623 437646 437669 1482351900320290 50015162 437624 437647 437670 153330,21900320290 63011192 - 4376481) 437671 1702351100350320 63015252 - 4376491) 437672 175330,21100350320

A28

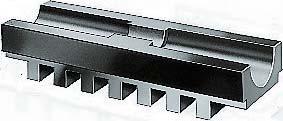

One-piece jaw EB, 3-jaw set, diagonally toothing, hardened

Item no.

1253set503414

1603set77,74520

2003set94,76022

2503set1147026

3153set1307932

400/5003set1679345

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Forjawswhichareappliedlater,sendinthechuck.

A28

Unstepped jaw BL, 3-jaw set, diagonally toothing, unstepped,soft,material16MnCr5

Item no.

1253set533414

1603set84,44520

2003set98,46022

2503set118,77026

3153set136,67932

400/5003set173,69345

A28

Reversible top jaw UB, 3-jaw set, hardened tongue and groove for external and internal clamping, material16MnCr5

Item no.

C21

C21

C21

C21

C21

Reversible

C21

C21

Draw-down

C21

160101201/2“

200121321/2“

250141861/2“

315171921/2“

400/500192201/2“ 1162787 630242501/2“

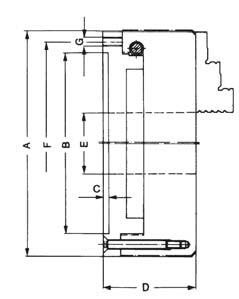

Chuck size A125160200250315400500630

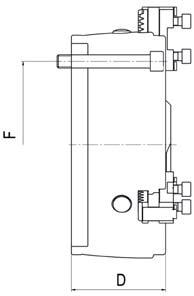

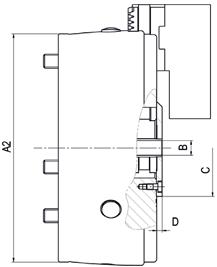

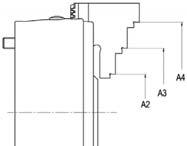

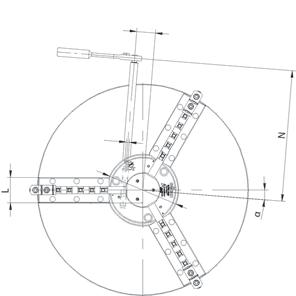

OuterdiameterA1128164206256322407507630 JawmovementB4,86,26,8810,212,512,514 BoreC3242526287102162252 BorecabbeenlargedCmax.35455575102130180270 D46,5638192111118118143 EH6115145185235300380460580 F45566666 G100125160200250315400520 H3xM83xM103xM123xM163xM203xM243xM243xM24 J1215182530373737 K22,531,543475957,757,572 L32,54253,566,586110152,5196 MSW8SW10SW12SW14SW17SW19SW19SW24 N117182211284309359356570 O180210270450500600600600 P8,513141721252529 Min.thicknessofflangeQ1730303535404555 MomentofinertiaGD21)kgm 20,010,030,100,290,872,375,7817,04 21o35´22o18o19o17o20o42o69o30´ approx.kgkg4,09,318,634,564112166300

1)Themomentofinertiawasmeasuredwithbasejawsbutwithouttopjawsorbackplate

Theborecouldbeenlarged(measureC,atsurcharge) Enlargedboremax.

Max. permissible speed

Themaximumpermissiblespeedhasbeenfixedsothat1/3ofthegrippingforceisstillavailableasresidualgrippingforceif themaximumgripppingisappliedandthechuckisfittedwithitsheaviestjaws.Thejawsmaynotprojectbeyondtheoutside diameterofthechuck.Thechuckmustbeinperfectcondition.ThespecificationDIN6386Part1shallbeobserved.

Chuck size125160200250315400500630

Max.speedmin-160005400460042003300220019001100

Gripping force

Thegrippingforceisthesumtotalofalljawforcesactingradiallyonthestationaryworkpiece.

Reversibleone-piecejaw EB, hardenedandground, jawstepsnotground

Chuck size125160200250315400+500

Blockjaw BL,unstepped,soft,thread andjawguideshardenedandground

A5077,794,7114130167 B142022263245 C344560707993 D10,720,62341,540,250,5 E1618,919,540,35471 F162228--G2937,550566473 H243040--J1922,530424953 K-810131320 L-161519,519,530 Jawapprox.kg0,4000,5000,6351,1351,8353,665

Chuck size125160200250315400+500

A5384,498,4118,7136,6173,6 B142022263245 C344560707993 Jawapprox.kg0,4350,5000,9001,5352,4005

Reversibletopjaw UB, completelyhardened,crosstenonground, jawstepsnotground

Chuck size160200250315400+500630

A61,570,592107130185 B20,424,434,435,750,468 C3743556279110 D81012121824 E33,53,53,54,54,5 F32,538505672102 G22,525,53035,541,459 H182020263040 J71010141521 K324040546082 L26,528,541405180 M131440,5547180 N17,51822263242 O252836415272 P23,52939405782 Q9914141822 R151520202633 T1)38,5455763,680,6114

Jawapprox.kg0,2000,3350,8001,1352,5356,350

Unsteppedsofttopjaw AB, forturningoutspecialchuckingdiameters

Chuck size125160200250315400+500630

A5585

145 180260 B20,720,3

50,568 C31,341

80110 D148

1824 E3,33

4,54,5 F25,536,5

73102 G2542

Basejaws GB, hardenedandground

Reversible claw-type top jaws KB, standarddesign

Reversible claw-type top jaw, large clamping range Chucksize160400500630

Item no. 137060137119137119151289

CapacitiesexternalØ min.-max.142,5-187,5314-446311-534391-670

CapacitiesinternalØ min.-max.22,5-67,599-23195-317176-456 Interferingcontour224528592800

Reversible claw-type top jaw, small clamping range Chucksize160200250315400500

Item no. 137061137064137108137114137120137120

CapacitiesexternalØ min.-max.37,5-82,556-11690-17082-210142-274139-360

CapacitiesinternalØ min.-max.133-178160-220177-257242-370301-433266-488 Interferingcontour209264330446535592

Reversible claw-type top jaw, medium clamping range Chucksize160200250315400500

Item no. 136062137065137109137115137121137121

CapacitiesexternalØ min.-max.103-148117-181167-248178-306270-402267-489

CapacitiesinternalØ min.-max.71-11691-155100-18497-225142-274139-361 Interferingcontour209264330396504592

Speciallyforgrindingmachines. Optimizedforextremelyhighclampingforces,maximumconcentricity,aswellas reliablelong-termrepeatability.

Keybarchuckwithquickjawchangesystem. Guaranteedmaximumjawprecisionasfarastheseareonlyusedonthesame chuck,andbaseandtopjawsarekeptscrewedonforrecurringwork.

Maximumclampingforcethankstokeybarsystem Withcoverforprotectionagainstdustontheface Veryhighjawchangerepeatability

TECHNICALFEATURES -Withjawsafeguard -Chuckbodycompletelysurface-hardened -Visualmarkingforquickjawadjustment -Externalshapeincl.splash-wateredge -Fasteningoptionsforstronglystressedslidingsurfaces -Incl.safetykey -Highcorrosionprotection

439606 439605 63540012073 2008 439608 439607 814600155114 25010 439610 439609 924200190185

A28

Outside

A28

Inside jaw

Item

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Item

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

A28

Unstepped

jaw

3-jaw

soft,material16MnCr5

Item

329044

A28

Item

Chuck size160200250

OuterdiameterA160206255 JawmovementB6,26,88 BoreC425262 BorecanbeenlargedCmax.455575 D638192 EH6145185235 F556 G125160200 H3xM103xM123xM16 J151825 K31,54347 L4253,566,5 MSW10SW12SW14 N182211284 O210270450 P131417 Min.thicknessofflangeQ303035 Momentofinertia1)kgm20,030,100,29 22°18°19° Weightapproxkg9,520°35

1)Themomentofinertiawasmeasuredwithbasejawsbutwithouttopjawsorbackplate

Theborecouldbeenlarged(measureC,atsurcharge)

Enlargedboremax.

Max. permissible speed

Themaximumpermissiblespeedhasbeenfixedsothat1/3ofthegrippingforceisstillavailableasresidualgrippingforceif themaximumgripppingisappliedandthechuckisfittedwithitsheaviestjaws.Thejawsmaynotprojectbeyondtheoutside diameterofthechuck.Thechuckmustbeinperfectcondition.ThespecificationDIN6386Part1shallbeobserved.

Chuck size160200250

Max.speedmin-1540046004200

Gripping force

Thegrippingforceisthesumtotalofalljawforcesactingradiallyonthestationaryworkpiece.Thespecifiedgrippingforcesare standardvalues.TheyapplytochucksinaperfectconditionwhichhavebeenlubricatedwithRÖHMgreaseF79andF80.

Chuck size160200250

Torqueappliedonkeyin1)Nm203035 Totalgrippingforce1)kN152433

TorqueappliedonkeyinNm120155190 Max.totalgrippingforcekN73114185

1)Maintainingtheaccuracy

Chuck size 160200250

Externalchucking

Jaw dimensions and

Outwardstepped jaw BB

Chuck size160200250 A465560 B202226 Cmax.95120143,5 Cmin.7291113 D576 E668 Jawapprox.kg0,4650,6431,065

Inwardstepped jaw DB

Chuck size160200250 A435050 B202226 Cmax.95120143,5 Cmin.7291113 D576 E668 Jawapprox.kg0,4350,6001,065

Unsteppedsofttop jaw AB

Chuck size 160200250 A90100125 B20,32230 C414555 D81012 E33,53,5 F36,54050 G556170 H182020 J6610 K303240 P27,53139 Q9914 R151520 SM8x1M8x1M12x1,5 U19,52327 Jawapprox.kg0,4350,8001,500

Basejaw GB

Chuck size160200250 A7490110 B202226 C171926 D182020 E55,55,5 F81012 G2,577 H62020 J7610 KM8x1M8x1M12x1,5 L323240 Mmax.105127148,5 Mmin.91103125 Jawapprox.kg0,3350,3650,700

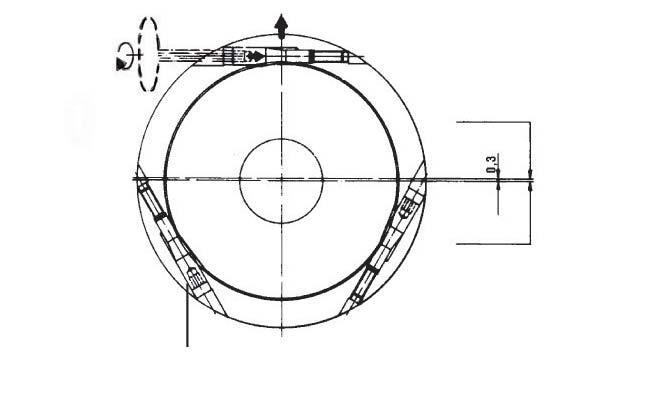

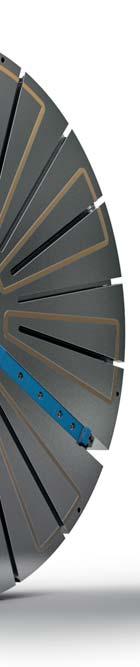

Equipped with extended and easy to assemble guideways the new lightweight DURO-TA XT is convincing with a flexible clamping area for machining large and small workpieces. Weight-reducing by up to 75 % makes maximum utilisation of the machine‘s potential possible.

ThenewDURO-TAXThasaninnovativeconceptforguideways thatguaranteesflexibleandweight-reducinguse.Incontrastto otherlargechucks,theDURO-TAXTisupto75%lighterand thatwaymakesmaximumutilisationofthemachine‘spotential possibleandclampingofhigherworkpieceweights.Through theextendedandeasytoassembleguideways,theclamping areacanbesetflexiblyandhenceconvertedquicklytolargeand smallworkpieces.Throughthedirectmountonthebasebody, theguidewaysguaranteeextremelyhighrigidity,stabilityand protectionagainstpenetrationbydirtanddust.

Thankstothetangentiallyarrangedthreadedspindle,theforce istransferredviaakeybarhavinganinternalthread.Thekeybar movesthedriveringviaaslide.Twootherslidesinthedrivering transfertheforcestotheothertwokeybars.Thekeybarshaving aninclinedprofileengageinthebasejaws,therebyguaranteeing exact,centricclamping.

ProvenDURO-TAbase

A28

One-piece jaw

A28

A28

Base jaw GB, 3-jaw set, diagonally toothing, withmountingbolts

Item no. ChuckSizeNumberofjawsContentsofdeliveryJawlengthmmJawwidthmm

094006 750(250)3set11026 094007 1000(315)3set12532 094044 1250(500)3set16045 Jawsonlyusableinbasicchuck.

C21

Draw-down jaws, forinterchangeableclampinginserts, diagonally toothing, 1piece,withoutclampinginserts

Item

141043 1000(315)136,463,932 141045 1250(500)173,673,445 Jawsonlyusableinbasicchuck.

C21

Draw-down jaws, additional clamping range, forinterchangeableclampinginserts, diagonally toothing, 1piece,withoutclampinginserts

Item

750(250)118,758,526 141044 1000(315)136,463,932 141048 1250(500)173,673,445 Jawsonlyusableinbasicchuck.

Chuck size A75010001250

OuterdiameterChuckA1256322507

OuterdiameterBaseplateA2320400590 JawmovementB810,212,5 Bore1)C6287162

D127152160 D1283435 EH6100100100 F666 G454545 H111111 K79,598,097,5 L66,586152,5 MSW14SW17SW19 N464565724 R90100130 R1160180210 S370495615

MomentofinertiaGD22)kgm210,5237,9298,70 MomentofinertiaGD22)3)kgm25,6618,1048,93 4,6o4,6o4,5o approx.kgkg183365640 approx.kg3)kg127233436

1)Withdirtcover

2)Themomentofinertiawasmeasuredwithbasejawsbutwithouttopjaws

3)Withmax.lightweightbaseplate

Max. permissible speed

Themaximumpermissiblespeedhasbeenfixedsothat1/3ofthegrippingforceisstillavailableasresidualgrippingforceif themaximumgripppingisappliedandthechuckisfittedwithitsheaviestjaws.Thejawsmaynotprojectbeyondtheoutside diameterofthechuck.Thechuckmustbeinperfectcondition.ThespecificationDIN6386Part1shallbeobserved.

Chuck size75010001250

Max.speedmin-1800570450

Gripping force

Thegrippingforceisthesumtotalofalljawforcesactingradiallyonthestationaryworkpiece.Thespecifiedgrippingforcesare standardvalues.TheyapplytochucksinaperfectconditionwhichhavebeenlubricatedwithRÖHMgreaseF79andF80.

75010001250

Chuck size

Torqueappliedonkey1)Nm7080100

Totalgrippingforce1)kN6680102

TorqueappliedonkeyNm190210320 Max.totalgrippingforcekN185240290

Chuck capacities of

Chuck

Reversibletopjaw UB, completelyhardened,crosstenonground, jawstepsnotground

Jaws only usable in basic chuck.

Chuck size75010001250

A92107130 B34,435,750,4 C556279 D121218 E3,53,54,5 F505672 G3035,541,4 H202630 J101415 K405460 L414051 M40,55471 N222632 O364152 P394057 Q141418 R202026 T1)5763,680,6 Jawapprox.kg0,8001,1352,535

1)Dimensionmarkedonbasejaw

Unsteppedsofttopjaw AB, forturningoutspecialchuckingdiameters

Chuck size75010001250

Dimensions for

design

Reversibleone-piecejaw EB hardenedandground,jawstepsnotground Jaws only usable in basic chuck.

A125 125 145 145 180 B30,4 50,5 34,3 50,5 50,5 C55 80 56 80 80 D12 12 12 12 18 E3,5 3,5 3,5 3,5 4,5 F50 75 50 74 73 G70 70 74 74 100 H20 20 26 26 30 J10 10 14 14 15 K40 40 54 54 60 P39 54 34 48 58 Q14 14 14 14 18 R20 20 20 20 26 SM12x1,5 M12x1,5 M12x1,5 M12x1,5 M16x1,5 T1)57 72 57,6 71,6 81,6 U27 42 22 36 42 Jawapprox.kg1,500 3,700 2,265 4,800 4,500

1)Dimensionmarkedonbasejaw

Blockbacken BL,ungestuft,ungehärtet, VerzahnungundFührunggehärtetund geschliffen. Jaws only usable in basic chuck.

Chuck size 75010001250 A114130167 B263245 C707993 D41,540,250,5 E40,35471 F--G566473 H--J424953 K131320 L19,519,530 Jawapprox.kg1,1351,8353,665

Chuck size 75010001250 A118,7136,6173,6 B263245 C707993 Jawapprox.kg1,5352,4005

Basejaws GB, hardenedandground

Jaws only usable in basic chuck.

Chuck size

A110125160 B263245 C263035 D202630 E5,56,57,5 F121218 G334 H77,68,6 J101415 KM12x1,5M12x1,5M16x1,5 L405460 M163196250294 Jawapprox.kg0,7001,0652,350

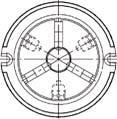

TheRÖHMgearedscrollchuckshavealreadybeeninusefordecadesandhaveproventhemselvesathousandtimes

TheRÖHMgearedscrollchuckshaveproventhemselvesathousandtimesoverandhavealready

Provengearedscrollchuckforuseinareasrequiringhighclampingforces,high concentricityaswellasreliablelong-termrepeatability.

Gearedscrollchucksinsteeldesign.

Highclampingforce

Specialflatdesignforminimuminterferingcontours Thejawscanbeadjustedovertheentireclampingrangebyturningthe

clamped

-Withone-piecejawsorwithbaseandtopjaws

-Series-balancedandhardened

ZS

ZSU

SizeZAThrough-hole

805619 102513 102505 - - 70003013 1007020 101782 102130 101788 102136 63006027 1259532 101672 106075 101678 106081 55008031 16012542 100717 101164 100725 101170 460011047 20016055 100186 100466 100189 100484 400014055 25020076 100533 101030 100541 101036 300015063 315260103 101344 101598 101350 101901 230018069 400330136 102062 102330 102068 102336 180024092 500420190 102555 103340 102585 103346 1300260100 630545240 102720 102856 102726 102862 850280105 800710380 104913 104917 700300110 1000910460 --104925 104929 560450115 1250910550 --104941 104945 450450115

Furthersizesandmountingsavailableonrequest

SizeZAThrough-holemm

55008031

125802 460011047 20016055 113158 113160 400014055 25020076 114304 114306 300015063

120270 129946 230018069 400330136 123475 134401 180024092 500420190 127616 123465 1300260100

128545 135061 850280105

A09

SizeMountshort

TorqueNmTotalclampingforcekN

160542 1007531) 101196 100757 101199 460011047

1001681) 101446 100172 101452 400014055

1001731) 101454 100177 101460 400014055 250576 100571 101064 100580 101073 300015063 250655 1005671) 101062 100578 101071 300015063 250876 1005691) 101063 100579 101072 300015063 3156103 101376 101931 101385 101937 230018069 315876 1013771) 101939 101386 101945 230018069 3506103 114643 127557 127848 127850 190021074 350876 1173191) 117320 127847 127849 190021074 4008136 102226 102353 102232 102359 180024092 40011125 1022341) 102361 102240 102367 180024092 50011190 102562 102979 102568 102985 1300260100 63011190 102768 102896 102774 103002 850280105 63015190 1027841) 103012 102790 103018 850280105

A09 ISO 702-2 (DIN55029),ASAB5.9,typeD,withstudsforCamlock

125432 108895 109208 105870 105872 55008031 160442 108897 109210 105882 105886 460011047 160542 109150 109213 105898 106302 460011047 200555 109151 109214 106330 106334 400014055 200655 109154 109217 106346 106350 400014055 250676 109155 109218 106386 106390 300015063 250876 109159 109222 106402 106406 300015063 3156103 109156 109219 106442 106446 230018069 3158103 109160 109223 106458 106462 230018069 31511103 109165 109228 106474 106478 230018069 4008136 109161 109224 106498 106602 180024092 40011136 109166 109229 106614 106618 180024092 50011190 109167 109230 103274 106646 1300260100 50015190 109170 109233 103275 103271 1300260100 63011192,7 109168 109231 106658 106662 850280105 63015240 109171 109234 103328 106251 850280105

1300260100

1300260100

A09

Inside jaw BB, DIN 6350, outwardsteppedjaw,hardened

ChuckSize 3-jaw set4-jaw set

JawlengthmmJawheightmmJawwidthmm

80 110155 110063 372612

110156 110064 4833,514

110157 110065 5241,518

110159 110067 6147,518

110160 110068 6953,520

110161 110069 9067,524

315 110162 110070 13079,534

350/400 110163110071 13079,534

500/630 110164110072 1909542

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Forjawswhichareappliedlater,sendinthechuck.

A09

Outside jaw DB, DIN 6350, inwardsteppedjaw,hardened

ChuckSize 3-jaw set4-jaw set

JawlengthmmJawheightmmJawwidthmm

80 110165 110073 372612

110166 110074 4833,514

125 110167 110075 5241,518 160 110169 110077 6147,518

110170 110078 6953,520

250 110171 110079 9067,524

315 110016 110080 13079,534

350/400 110017 110081 13079,534

110018 110082 1909542

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Forjawswhichareappliedlater,sendinthechuck.

A09

Unstepped jaw BL, DIN 6350, unstepped,soft,material16MnCr5

ChuckSize 3-jaw set4-jaw set

80 107588 107598 372612

107589 107599 4833,514

107590 107600 5241,518

107592 107602 6147,518

107593 107603 6953,520

107594 107604 9067,524

107595 107605 13079,534

107596 107644 13079,534

107597 107645 1909542

A09

Base jaw GB, DIN 6350, withfixingscrew

ChuckSize 3-jaw set4-jaw set

107500 107542 4614

107501 107543 5518

107503 107545 6518

107504 107546 7820

107505 107547 9224

107506 107548 10834

107507 107549 12734

107508 107550 16542

107509 107551 20342

105272 141616 29155

105274 141611 32955

105275 141614 36755

A09

Reversible top jaws UB, DIN 6350, hardened tongue and groove for external and internal clamping, material16MnCr5

ChuckSize 3-jaw set4-jaw set JawlengthmmJawheightmmJawwidthmm

108045 108053 4729,522

108046 108054 5637,526

107936 107938 66,741,528

107937 107939 79,542,530

108049 108057 95,352,536

108050 108058 109,557,542

108051 108059 12764,542

108052 108060 12779,550

105081 105085 2108968

105098 105101 21011068

A09

Unstepped top jaw AB, DIN 6350, soft,material16MnCr5

ChuckSize 3-jaw set4-jaw set JawlengthmmJawheightmmJawwidthmm

107633 107641 533022,5

107634 107642 623826,5

108581 108583 744228,5

108582 108584 874330,5

107637 107579 1035336,5

107638 107580 1205842,5

107639 107581 1376542,5

107640 107582 1408050,5

105103 105105 2108968

105107 105109 21011068

A09

Unstepped jaw BL, special length, soft,material16MnCr5,DIN6350

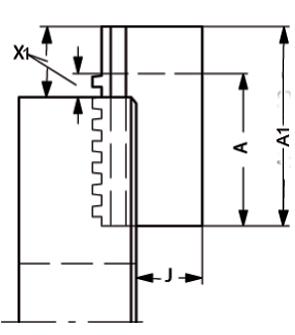

ChuckSize 3-jaw set4-jaw set A1mmX1max.AmmJmmXmax.mm

200 130031 137073 100506932,519

250 132658 137074 12056904126

315 132184 129894 160701304640

350/400 137075 130442 160701304240

500/630 131540 137076 220801905550

200 130033 137077 120706932,519

250 128880 130610 14076904126

315 118908 137078 2001101304640

350/400 137079 137080 2001101304240

500/630 137081 137082 2801401905550

315 121367 133691 2501601304640

350/400 137087 137088 2501601304240

A09

Unstepped jaw BL, special height, soft,material16MnCr5,DIN6350

ChuckSize 3-jaw set4-jaw set C1mmJ1mmCmmJmm

200 125710 132972 8058,55432,5

250 122188 134796 100736841

315 132186 137091 110768046

350/400 137092 131655 110728042

500/630 137093 137094 1501109555

200 125712 137095 12098,55432,5

250 122189 130630 1301036841

315 137096 137097 1401068046

350/400 137098 137099 1401028042

500/630 125117 137100 2001609555

200 125714 137101 150128,55432,5

250 137102 137103 1501236841

315 137104 130340 1601268046

350/400 132879 110109 1601228042

A09

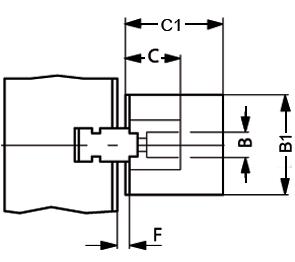

Top jaw AB, special length, soft,material16MnCr5,DIN6350

ChuckSize 3-jaw set4-jaw set A1mmX1max.FmmAmmXmax.mm

200 110086 148139 100436,88730

250 112122 129289 13063810336

315 110624 143764 160765,512036

350/400 110626 141277 160538,513730

500/630 103014 103393 170758,514045

200 112120 148657 120636,88730

250 125428 128700 15083810336

315 112091 147754 2001165,512036

350/400 112118 141263 200938,513730

500/630 110632 148234 2201258,514045

250 104710 146013 180113810336

315 112089 147860 2501665,512036

350/400 103654 149974 2601538,513730

500/630 112127 148235 2801858,514045

A09

Top jaw AB, special height, soft,material16MnCr5,DIN6350

ChuckSize 3-jaw set4-jaw set C1mmCmmFmm

200 132155 132181 60436,8

250 119645 135867 70538

315 110435 149975 80585,5 350/400 126385 118373 90658,5

500/630 128590 149985 100808,5

200 128564 149976 80436,8

250 128571 134999 100538

315 110437 129691 110585,5

350/400 110628 135426 120658,5 500/630 110630 149977 130808,5

250 128573 149978 150538

315 128569 141671 150585,5

350/400 128567 139591 160658,5 500/630 128588 140427 160808,5

A09

Top jaw AB, special width and height, soft,material16MnCr5,DIN6350

ChuckSize 3-jaw set4-jaw set B1mmC1mmBmmCmm

200 105057 105061 407030.543

137090 141338 508036.553

315 143053 149979 60904258

350/400 131567 149980 609042.565

137084 149981 8011050.580

200 133259 149982 508030.543

250 133653 137526 609036.553

315 143057 149983 801104258

350/400 137086 149984 8011042.565

803¼9256471520

100412080582025

125513580582025

1405½15080582025

1606¼17080582030

200821092662240

25010260105922550

31512½3301651003050

350143651801203060

A09

80/85piece

100/110piece

125piece 108503 140/160piece

200piece

250piece

315/350/400piece

500/630piece

A09

102521 74 102183 80/85 101754 100 112660 110 101721 125 105827 140 100303 160 100003 200 100203 250 101552 315 105228 350 102497 400 162973 500 162964 630

Item

746 102184 806 113198 856 101755 1008 112662 1108 101722 1259 105828 1409 100304 16010 100005 20011 100204 25012 112267 27012 101553 31514 105229 35014 102498 40017 162974 50019 162965 63019

A09

A09

A09

154370 80/856110

100/1108130

125/1409130

16010160

200/23011160

250/27012160

31514200

35014200

40017250

500/63019250

A09

Item

125/1409170

16010180

200/23011200

250/27012200

31514250

Item

80/8563/8

100/11081/2

125/14091/2

160101/2

200/230111/2

250/270121/2

315/350141/2

400171/2

500/630/700/800193/4

1000/1250243/4

74-85M6x20piece

100-140M8x30piece

160-230M10x35piece

250-270M12x40piece

315-350M16x50piece

400-630M16x60piece

20-12043512,7=1/2“3%

74M10x55piece1605

80M10x65piece2005

85M12x65piece2006

100M10x90piece2505

110M12x70piece2506

125M16x70piece2508

140M12x100piece3156

160M16x85piece3158

200/230M12x130piece3506

315M16x110piece4008

350M20x95piece40011

400M20x130piece50011

500M20x145piece63011

630M24x125piece63015

M20x1,586

M24x1,5156

M10x34piece33

M10x39piece43

M10x43piece54

M12x50piece64

M16x60piece84

M20x75piece116

M24x90piece156

M24x100piece206

7/16-20x3533 107466 7/16-20x3743 107467 ½-20x4356 107468 5/8-18x4966 107469 ¾-16x55,586 107470 7/8-14x67116 127621 1-14x76156 130637 1½-12x89206

Provengearedscrollchuckmadeofspecialcastironforuseinareasrequiring highclampingforces,highconcentricityaswellasreliablelong-termrepeatability. Foruniversaluseonlathes,rotarytables,dividingunits,etc.

Gearedscrollchucksincastirondesign. Specialflatdesignwithdirectmounting.

3-jawand4-jawversion.

Optimalprice/performanceratio Specialflatdesignforminimuminterferingcontours Thejawscanbeadjustedovertheentireclampingrangebyturningthe key.Thisallowsworkpieceswithdifferentclampingdiameterstobequickly clamped Jawsinchuckgroundoutforconcentricity

TECHNICALFEATURES -Withoneseteachofone-pieceoutward-andinwardsteppedjaws -Vibration-dampingbodymadeofspecialcastiron -Spiralringdie-forgedaswellasbalancedandhardened

A09

45006027

A09

Inside jaw BB, DIN 6350, outwardsteppedjaw,hardened

110156

110157

110159

110160

110161

110162

A09

Outside jaw DB, DIN 6350, inwardsteppedjaw,hardened

110166

110167

110169

110170

110171

5241,518

6147,518

6953,520

9067,524

13079,534

4833,514

5241,518

6147,518

6953,520

9067,524

13079,534

A09

Unstepped jaw BL, DIN 6350, unstepped,soft,material16MnCr5

A09

Unstepped top jaw AB, DIN 6350 soft,material16MnCr5

ChuckSize 3-jaw set4-jaw set JawlengthmmJawheightmmJawwidthmm

107633 107641 533022,5

107634 107642 623826,5

108581 108583 744228,5

108582 108584 874330,5

107637 107579 1035336,5

107638 107580 1205842,5

A09

Unstepped jaw BL, special length, soft,material16MnCr5,DIN6350

3-jaw set4-jaw set A1mmX1max.AmmJmmXmax.mm

130031 137073 100506932,519

132658 137074 12056904126

132184 129894 160701304640

130033 137077 120706932,519

128880 130610 14076904126

118908 137078 2001101304640

121367 133691 2501601304640

A09

Unstepped jaw BL, special height, soft,material16MnCr5,DIN6350

3-jaw set4-jaw set C1mmJ1CmmJmm

125710 132972 8058,55432,5

122188 134796 100736841

132186 137091 110768046

125712 137095 12098,55432,5

122189 130630 1301036841

137096 137097 1401068046

125714 137101 150128,55432,5

137102 137103 1501236841

137104 130340 1601268046

A09

Top jaw AB, special length, soft,material16MnCr5,DIN6350

ChuckSize 3-jaw set4-jaw set A1mmX1max.FmmAmmXmax.mm

110086 148139 100436,88730

112122 129289 13063810336

110624 143764 160765,512036

112120 148657 120636,88730

125428 128700 15083810336

112091 147754 2001165,512036

104710 146013 180113810336

112089 147860 2501665,512036

A09

Top jaw AB, special height, soft,material16MnCr5,DIN6350

3-jaw set4-jaw set C1mmCmmFmm

132155 132181 60436,8

119645 135867 70538

110435 149975 80585,5

128564 149976 80436,8

128571 134999 100538

110437 129691 110585,5

128573 149978 150538

128569 141671 150585,5

A09

Top jaw AB, special width and height, soft,material16MnCr5,DIN6350

3-jaw

105057 105061

137090 141338 508036.553

143053 149979

133259 149982

133653 137526

143057 149983

C15

C15

100303

1008

16010

20011

25012

250/270121/2

100-140M8x30piece

250-270M12x40piece

100M10x90piece2505

110M12x70piece2506

125M16x70piece2508

140M12x100piece3156

160M16x85piece3158

200/230M12x130piece3506

315M16x110piece4008

M10x133

M10x143

M12x156

M16x1,566

M20x1,586

M22x1,5116

Optimizedformachiningworkpieceswhichmustbeproducedwith maximum

Canbeuniversallyused,butisespeciallyadvantageousonturningandgrinding machinesaswellasdividingunits.

Latheandgrindingchuckinsteeldesignwithwhichtheworkpiececanbe

Radialfineadjustmentformaximumconcentricity

Repeatability0.015mm

ZS

ZS Hi-Tru, with

8031/456350,5673xM641,7 100470363833xM853,6 1255954721083xM855,6 16061/41254811403xM10610 2008160489,51763xM10617,2 2501020051022243xM12834,5 315121/226051222863xM16857,5

ZS Hi-Tru,

8031/456350,5673xM641,7 100470363833xM853,6 1255954721083xM855,6 16061/41254811403xM10610 2008160489,51763xM10617,2 2501020051022243xM12834,5 315121/226051222863xM16857,5

A09

Inside jaw BB, DIN 6350, outwardsteppedjaw,hardened

Item no. ChuckSizeNumberofjawsContentsofdeliveryJawlengthmmJawheightmmJawwidthmm

110155 803set372612 110156 1003set4833,514 110157 1253set5241,518 110159 1603set6147,518

110160 2003set6953,520 110161 2503set9067,524 110162 3153set13079,534

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Forjawswhichareappliedlater,sendinthechuck.

A09

Outside jaw DB, DIN 6350, inwardsteppedjaw,hardened

Item no. ChuckSizeNumberofjawsContentsofdeliveryJawlengthmmJawheightmmJawwidthmm

110165 803set372612 110166 1003set4833,514 110167 1253set5241,518 110169 1603set6147,518 110170 2003set6953,520 110171 2503set9067,524 110016 3153set13079,534

Additionallyorlaterapplied,hardenedsteppedjawsmustbegroundoutinthechuck.

Forjawswhichareappliedlater,sendinthechuck.

A09

jaw BL, DIN 6350, unstepped,soft,material16MnCr5

803set372612 107589 1003set4833,514 107590 1253set5241,518 107592 1603set6147,518 107593 2003set6953,520 107594 2503set9067,524 107595 3153set13079,534

A09

Unstepped top jaw AB DIN 6350, soft,material16MnCr5

Item no. ChuckSizeNumberofjawsContentsofdeliveryJawlengthmmJawheightmmJawwidthmm 107633 1003set533022,5 107634 1253set623826,5 108581 1603set744228,5 108582 2003set874330,5 107637 2503set1035336,5 107638 3153set1205842,5

A09

Unstepped jaw BL, special length, soft,material16MnCr5,DIN6350

Item

130031 200100506932,519 132658 25012056904126 132184 315160701304640 130033 200120706932,519 128880 25014076904126 118908 3152001101304640 121367 3152501601304640

A09

Unstepped jaw BL, special height, soft,material16MnCr5,DIN6350

Item no. ChuckSizeC1J1CJ 125710 2008058,55432,5 122188 250100736841 132186 315110768046 125712 20012098,55432,5 122189 2501301036841 137096 3151401068046 125714 200150128,55432,5 137102 2501501236841 137104 3151601268046

A09

Top jaw AB, special length, soft,material16MnCr5,DIN6350

Item no. ChuckSizeA1mmX1max.FAXmax.

200100436,88730 112122 25013063810336 110624 315160765,512036 112120 200120636,88730 125428 25015083810336 112091 3152001165,512036 104710 250180113810336 112089 3152501665,512036

A09

Top jaw AB, special height, soft,material16MnCr5,DIN6350

Item no. ChuckSizeC1CF

20060436,8 119645 25070538 110435 31580585,5 128564 20080436,8 128571 250100538 110437 315110585,5 128573 250150538 128569 315150585,5

A09

Top jaw AB, special

and height, soft,material16MnCr5,DIN6350

200407030.543 137090 250508036.553

31560904258

200508030.543

250609036.553

315801104258

C15

80/8563/8

100/11081/2

125/14091/2

160101/2

200/230111/2

250/270121/2

315/350141/2

74-85M6x20piece

100-140M8x30piece

160-230M10x35piece

250-270M12x40piece

315-350M16x50piece

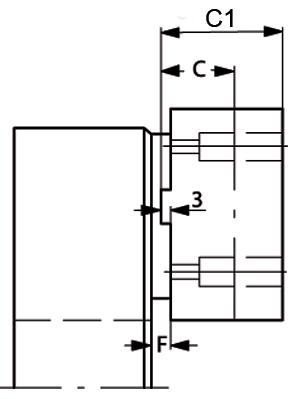

Formountingondividingheadsandotherattachmentsfromthefront,thelathechuckswithacylindricalcentremountcan alsobesuppliedpre-drilled(atsurcharge)G1,itisalsopossibletoenlargethebore(measureE,atsurcharge). Cylindrical centre mount DIN 6350 Enlargedboremax. G1=Mountingfromfront*4-jaw=4xØ9

Size A748085100110125140160200250315350400500630

BH6565660708095105125160200260290330420545 C2,533334444556557 D32,539,539,5505056606573,58295100105120135 E15191920273240425576103115136190240

Emax---21-3343507092114120150210253 F6367728395108120140176224286318362458586 G3xM63xM63xM63xM83xM83xM83xM83xM103xM103xM123xM163xM163xM166xM166xM16

G1-----3xØ9*-3xØ10,53xØ113xØ143xØ14-3xØ186xØ186xØ18 H32373748485261616990130130130190190 J141414181822,522,52632,54046454354,554,5 K61)6688991011121414171919

L---80,5-95,5106108119,6139,6155168,5171,5201,5216,5 M---47475666,766,779,595109,5127127127127 V---53,653,66167,769,780,289,9100,4110,4113,4128,4143,3 W1314,514,51818202122,4525,726,53034353848 approxkg.11,31,92,93,44,55,88,214,625,744,25680126208

SIze ØA70080010001250 B610710910910 C2)7+0,037+0,037+0,037+0,03 D147147157157 E310380460550 Emax.330420580580 F660760950950

3-Jaw G 6xØ226xØ226xØ266xØ26

Size A250315350400 Tapersize45685681168116811 B63,582,5106,4139,782,5106,4139,7196,9106,4139,7196,9106,4139,7196,6 D83838383969696104122122122106106106 E60,776767679,6103103103103115115103136136

F DIN85 Caml.82,5104,8133,4171,4104,8133,4171,4235133,4171,4235133,4171,4235 P60,7---79,6---103--103-Q40,5---49---81--54-V90,990,990,990,9101,4101,4101,4109,4127,4127,4127,4114,4114,4114,4 W27,527,527,527,531313139565656363636

Tapersize8111511151115152015201520 B139,7196,9285,8196,9285,8196,9285,8285,8412,8285,8412,8285,8412,8 D122122122137137149149149149159159159159 E136190190192,7240310310380380460460550550 F171,4235330,2235330,2235330,2330,2463,6330,2463,6330,2463,6 P136--192,7-192,7281,2281,2-281,2407,5281,2407,5 Q61--63-767676-85858585 V130,4130,4130,4145,3145,3160160160160168168168168 W40404050505050505055555555

Mounting holes DIN4666666666666 Caml.6666666666666 approx.kg150225280350590850

Allotherdimensionsshouldbetakenfromthetableaboutchuckswithcylindricalcentremount Size A160200250315350400

Tapersize5565686868811 B82,582,5106,482,5106,4139,7106,4139,7106,4139,7139,7196,9 D6674,574,58383839696122122106106 E4242557655761037610376136125

2)---104,8--133,4-133,4-171,4G---111)--14-14-18N3)61,961,982,6-82,6111,1-111,1-111,1-165,1 O111)111)14-1418-18-18-22 V70,781,281,290,990,990,9101,4101,4127,4127,4114,4114,4 W23,4526,726,7275275275313156563636

Mounting holes *336366666666 **444444444444 approx.kg814,52544,57182

B196,9196,9285,9196,9285,9196,9285,9412,8285,9412,8285,9412,8 D122137137149149149149149159159159159

External chucking

Chucking capacities of jaw steps (standardvalues)

Size 748085100110125140160200250

A1(BB)2-242-302-303-383-423-533-534-724-1005-122 A2(DB)2-242-302-303-383-423-533-533-724-1005-122 A3(DB)23-4627-5527-5538-7139-7739-8947-9747-11656-15273-190 A4(DB)45-6852-8052-8070-10070-10075-12591-14091-160104-200131-250 max.swingdia.88104104128138157174194238302 Jawmovement11141415192525344858

A16-13520-18020-20035-26050-350110-350150-450250-600320-600 A26-13520-18020-20035-26050-350280-672325-853425-1070490-1150 A396-225110-270110-300140-360190-490356-748400-928500-1150564-1224 A4186-315200-350200-400280-500330-630---max.swingdia.3954404806007301000117013901476 Jawmovement6480100110150120150175140

J245-6850-7850-7865-9465-10473-12383-13283-15292-186119-236

J3-----526-922566-1094660-1314740-1400

values.Theyarevalidfor3-and4-jawchucksandlathechuckswithreversiblejaws.

not exceed maximum chucking ranges.

Max. permissible speeds for ZS - ZSU, Orange Line, ZS Hi-Tru to DIN 6350

Themaximumpermissiblespeedhasbeenfixedsothat 1/3ofthegrippingforceisstillavailableasresidualgripping forceifthemaximumgrippingisappliedandthechuckis fittedwithitsheaviestjaws.Thejawsmaynotprojectbeyondtheoutsidediameterofthechuck.Thechuckmustbe inperfectcondition.Thespeedlimitforchuckswithcastiron bodiesisbasedonthepermissibleperipheralspeedforcast iron.ThespecificationDIN6386Part1shallbeobserved.

Size

3 and 4 jaws

10045006300 12540005500 14037005000 16036004600 20030004000 25025003000

35017001900 40016001800 50010001300

700650800

Claming

Size 741) 80/85100/110125140160200250315350/400500/630 A3237485261616990130130190 B1012141818182024343442 C232633,541,541,547,553,567,579,579,595 D4,74,86,37,38,38,38,310,311,311,314,9 E44,56777810151515 F101215171818202741,541,550 G2124,531354040445786,586,5120 H56688101014151520 J-12141617171926404050 K-24,53034393943568585120 Jawapprox.kgBB0,030,050,10,20,220,250,30,71,81,83,8 BL0,050,080,150,270,320,380,5212,42,45,2

1)Reversiblejaws

Size 100/110125140160200250315350/400500630 A465565657892108127165203 B-0,057,947,947,947,947,9412,712,712,712,712,7 C2,53,13,13,13,13,13,13,13,13,1 D+0,019,512,6812,6812,6812,6819,0319,0319,0319,0319,03 E67,67,67,67,67,67,610,810,810,8 F3,44,87,84,86,885,510,52)8,58,5 G121315,815,81922,225,428,528,528,5 H243238,138,144,455463,576,238,138,1

J metr.M6M8M8M8M8M12M12M16M20M20 UNC1/4"-205/16"-183/8"-163/8"-163/8"-161/2"-131/2"-135/8"-113/4"-103/4"-10 K1214,51616162025293333 L19,2522,628,528,534,939,747,657,157,157,1 M--------38,138,1 N14181818202434344242 O19,5242727283540454949 Grooves1111111123 Tappedholes2222222245 Jawapprox.kg0,060,120,170,170,220,40,7811,722,1

-0,0512,712,712,712,7 C3,13,13,13,1

+0,0119,0319,0319,0319,03 E10,810,810,810,8 F111199 G28,528,528,528,5 H38,138,138,138,1

metr.M20M20M20M20

/4"-103/4

K37373737 L57,157,157,157,1 M38,138,138,138,1 N55555555 O62626262 Grooves4567 Tappedholes6789 Jawapprox.kg6,27,189

A1475666,779,595,3109,5127127210210 253627487103120137140210210

B 122262830364242506868 222,526,528,530,536,542,542,550,56868 C129,537,541,542,552,557,564,579,589110 2303842435358658089110

D5,57,67,67,67,67,610,810,810,810,8 E7,967,967,967,9612,7212,7212,7212,7212,7212,72

F2,53,13,13,13,13,16,356,356,356,35 G9,5012,6812,6812,6819,0319,0319,0319,0319,0319,03 H19,2522,628,534,939,747,657,157,157,157,1 J121315,81922,225,428,528,528,528,5 K243238,144,4553,9563,576,276,276,276,2 L6,699 1)10,52)91)10,52)141418222222 M1115151)16

1)162)202026333333 N79101013,513,5172121,521,5 O121315,81922,225,428,554,65151 P29,53542,851,560,267,47788,58989 R681010141515202225 S22,2525,632,238,743,552,962,163,67070

T151619,522,82630,733,553541,541,5 U19273030414347616571 V--------38,138,1

Jaw approx.kg UB0,120,190,270,390,661,021,2724,456,1 AB0,210,340,50,71,21,862,183,04810,8

This

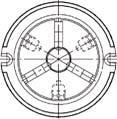

Througharadiallyarrangeddrive(1,hardened),theforce istransferredviaabevelgearingtoahardenedspiralring(2) andfurtherconductedviathespiraltothebasejaws(3,hardenedandground),spindle(4,hardened)andreversiblejaws(5, hardenedandground).Thepositionoftheworkpiececanbe adjustedbyturningthespindle.Steelbody(6),cover(7).

Thejawscanbeadjustedovertheentireclampingrangeby

Tomaintaintheclampingforce,gearedscrollchucksmust

Optimizedforthemachiningofirregularlyshapedworkpieces.

TYPE

Gearedscrollchuckinsteeldesignwithwhichirregularlyshapedworkpiecescan bealignedviaadjustingspindles. 3-jawand4-jawversion.

Exactalignmentofirregularlyshapedworkpieces

Jawscentricallyclampingandindividuallyadjustable Die-forgedspiralring,series-balancedandhardened Jawsinchuckgroundoutforconcentricity

-Withoneseteachofbaseandreversiblejaws -Clampingwrench -DimensionsandmountingstoDIN6351 -Hardenedspiralring -Die-forgedsteelbody

ES =independentlyadjustablejaws,steel

111360 111789 11047 20016055 111365 111793 14055 25020076 111370 111797 15063 315260103 111375 111801 18069 400330136 111380 111805 24092 500420190 111385 111809 260100 630545240 111390 111813 280105

Furthersizesandmountingsavailableonrequest

A09

Reversible

A09

110118

139666 139670

139667 139671

139668

139669

107669

139674 139678

139675 139679

139676 139680 13079,534

139677 139681

A09

jaw

hardened,

and internal

material16MnCr5

107654 107662 6215,326

139682 139686 7817,830

139683 139687 8617,830

139684 139688 11822,744

139685 139689 11822,744

107659 107667 1762554

20011

25012

27012

31514

35014

40017

50019

63019

35014140

500/63019150

A09

100/1108130

125/1409130

16010160

200/23011160

250/27012160

31514200

35014200

40017250

500/63019250

A09

80/8563/8

100/11081/2

125/14091/2

160101/2

200/230111/2

250/270121/2

315/350141/2

C15

Item no. ThreadFortaperQuantity

M10x3043 107455 M10x3554 107456 M12x4064 107457 M16x4584 107458 M20x55116 127618 M24x65156

80M10x85piece2005

85M12x85piece2006

100M10x110piece2505

110M12x90piece2506

125M16x90piece2508

140M12x120piece3156

160M16x105piece3158

315M16x130piece4008

350M20x115piece40011

400M20x155piece50011

500M20x170piece63011

630M24x150piece63015

A09 Stud and locknut ISO 702-3 (DIN55027)

M12x50piece64

M16x60piece84

M20x75piece116

M24x90piece156

A09 Stud for Camlock ASA B 5.9 (DIN55029) and cylindrical studs

7/16-20x3533

7/16-20x3743

½-20x4356 107468 5/8-18x4966 107469 ¾-16x55,586 107470 7/8-14x67116

1-14x76156

A09 Stud for Camlock ISO 702-2 (DIN55029) and cylindrical studs

M10x133

M10x143

M12x156

M16x1,566

M20x1,586

M22x1,5116

M24x1,5156

M27x2206

Cylindrical centre

Thebore(measureE)couldbeenlarged (atsurcharge)

Enlargedboremax.

Max. permissible speeds for chucks ES to DIN 6351

Thespecifiedvaluesareonlyapplicablefor workpieces notexceedingaspecificunbalanceof25 gmm/kg.

Size A100125160200250315400500630 BH67095125160200260330420545 C344455557 D67718095,5100117123145160 E2032425576103136190240 Emax.2133507092114150210253 F83108140176224286362458586 G3xM83xM83xM103xM103xM123xM163xM166xM166xM16 H5656698590130130190190 J22212832,540,646,5475555 K8910111214171919 R*5,55,55,588881212 W202022,4525,726,530353848 approx.kg461018295488145240

Reversiblejaw UB Left-handthread

Steel bodySteel body 100-125-16032002850 20026502350 25022001900 31514001220 40014001220 500880770 630750660

Size100125160200250315400500630 A5656698590130130190190 B181820242434344242 C41,541,55057,567,579,579,59595 D8,78,79,79,79,711,1511,151515 E778101015151515 F171719252640405050 G35354354568585120120 H8810121415152020 ThreadTr14x3Tr14x3Tr16x4Tr18x2Tr18x2Tr20x2Tr20x2Tr26x3Tr26x3 approx.kg0,180,180,30,530,71,71,73,73,7

H6CDF3-jaws4-jaws

A09

jaw BB, DIN 6350, outwardsteppedjaw,hardened

ChuckSize

1101541)

110156

110157

110159

110160

A09

jaw DB, DIN 6350, inwardsteppedjaw,hardened

ChuckSize

110166

110167

110169

110170

A09

Unstepped jaw BL, DIN 6350, unstepped,soft,material16MnCr5

5241,518

5241,518

A09

Short-taper

plate ISO

approx.kg

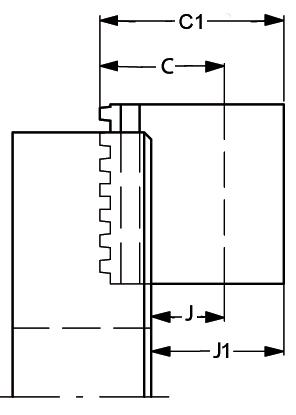

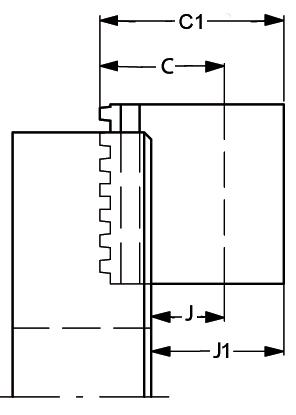

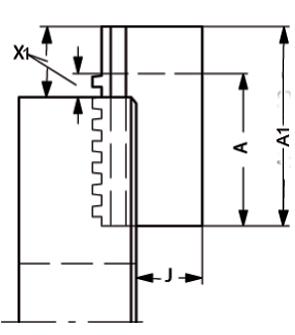

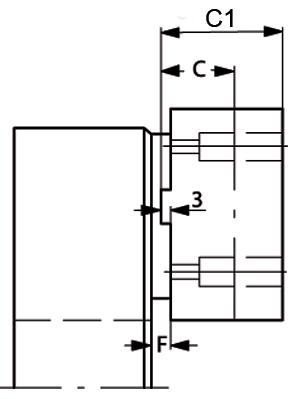

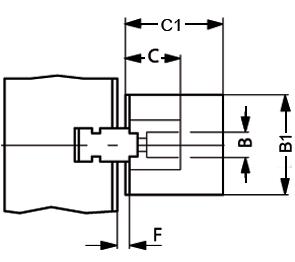

182900 1403179553,97551,2070,60M10108/1203x/6xM81,4 182902 1404219563,51361,0082,60M10108/1203x/6xM81,55 182904 1405219582,56379,60104,80M10108/1203x/6xM81,4 182906 16562595106,37580,00133,40M12108/1206xM82,7 182908 16041812563,51361,0082,60M101406xM102,5 182910 16051812582,56379,60104,80M101406xM102,2 182912 165625125106,375103,20133,40M121406xM102,5 182914 210832125139,719100,00171,40M161406xM105,8 182916 20041816063,51361,0082,60M101766xM105 182918 20051816082,56379,60104,80M101766xM103,9 182920 200622160106,375103,20133,40M121766xM104,1 182922 210832160139,719136,20171,40M161766xM105 182924 25052120082,56379,00104,80M102243xM127,7 182926 250626200106,375103,00133,40M122243xM128,7 182928 250830200139,719136,20171,40M162243xM127,3 182930 315624260106,375103,00133,40M122863xM1214,5 182932 315830260139,719136,00171,40M162863xM1216 182934 3151142260196,869192,90235,00M202863xM1216,2 182936 400632330106,375103,00133,40M123623xM1630,8 182938 400832330139,719136,00171,40M163623xM1629 182940 4001138330196,869192,90235,00M203623xM1629,7 182942 4001549330285,775281,50330,00M243623xM1624,5 182944 500836420139,719136,20171,40M164586xM1653,1 182946 5001136420196,869192,90235,00M204586xM1649 182948 5001546420285,775281,50330,00M244586xM1649,5 182950 6301142545196,869192,90235,00M205866xM16100 182952 6301543545285,775281,50330,00M245866xM1690 182954 6302042545412,775408,00463,60M245866xM1663

(DIN55029)and ASA B

D1, Camlock

Item no. ØAmmTaperInchBmmCmmDmmEmmFmmGWeight approx.kg 319673 125352792,153,9754070,667/16-202,3 319674 1254528117,563,5134082,557/16-202,2 319675 16036¼2792,153,9754070,667/16-203,9 319676 16046¼28117,563,5134082,557/16-203,9 319677 16056¼3114682,56340104,8½-204,6 319678 2004828117,563,5135082,557/16-206,4 319679 200583114682,56350104,8½-207,4 319680 2006836181106,37550133,45/8-188,4 319681 2504128117,563,5136182,557/16-2010,2 319682 2505103114682,56363104,8½-2011,6 319683 25061036181106,37563133,45/8-1813,3 319684 25081039225,4139,71963171,4¾-1613,8 319685 315512¼3114682,56363104,8½-2018,6 319686 315612¼36181106,37563133,45/8-1821,5 319687 315812¼39225,4139,71963171,4¾-1622,6 319688 3151112¼45298,4196,869632357/8-1425,2 319689 400615¾36181106,37563133,45/8-1835 319690 400815,7539225,4139,71963171,4¾-1637,2 319691 4001115,7545298,4196,869632357/8-1442 319692 4001515,7550403285,77563330,21-1442,1 319693 50082041225,4139,71980171,4¾-1662 319694 500112045298,4196,869802357/8-1467

500152050403285,77580330,21-1468

approx.kg

319650 125351910253,9754075M102,3 319651 125451911263,5134085M102,2 319652 16036¼2110253,9754075M103,9 319653 16046¼2111263,5134085M103,9 319654 16056¼2113582,56340104,8M104,6 319655 200482111263,5135085M106,4 319656 200582113582,56350104,8M107,4 319657 2006823170106,37550133,4M128,4 319658 250412111263,5136185M1010,2 319659 2505102113582,56363104,8M1011,6 319660 25061023170106,37563133,4M1213,3 319661 25081026220139,71963171,4M1613,8 319662 315512¼2613582,56363104,8M1018,6 319663 315612¼26170106,37563133,4M1221,5 319664 315812¼26220139,71963171,4M1622,6 319665 3151112¼33290196,86963235M2025,2 319666 400615¾31170106,37563133,4M1235 319667 400815,7531220139,71963171,4M1637,2 319668 4001115,7531290196,86963235M2042 319669 4001515,7533400285,77563330,2M2442,1 319670 50082041220139,71980171,4M1662 319671 500112041290196,86980235M2067 319672 500152041400285,77580330,2M2468

Furthersizesanddesigns,suchasISO702-1,availableonrequest!

IndependentchucksfromRÖHMareparticularlysuccessfulandeffectivewhenforcehastoppriority.

workpiecesareclamped.

threadedspindle(nocentraldrive).Startingfromsize315withT-slots.

139781 137147 70235012017

139796 139720 75197012017

139827 135368 95153017023

139842 136944 95136017023

139857 135631 95122017023

139887 139723 13597024037

140800 141097 13586024037

19076530045

140801

70235012017

70235012017

SizeMountshorttaper

Through-holemmSpeedmax.min-1TorqueNmClampingforce/ jawkN

141094 141108 19276530045

19068030045

600641 19068030045 100011 141115 19061032047 100015 141116 19061032047

600645 19061032047

150500 19055532047

19055532047

600646 19055532047 120011 150501 19051045064 120015

19051045064

19051045064

A26 ISO 702-2 (DIN55029),ASAB5.9,typeD,withstudsforCamlock

SizeMountshorttaper

With one-piece

jaws

Through-holemmSpeedmax.min-1TorqueNmClampingforce/ jawkN 2604 139791 137166 60235012017 2605 139792 137254 70235012017 2606 139793 137255 70235012017 3105 139806 139733 75197012017 3106 139807 139734 75197012017 3108 139808 139735 75197012017 4006 139837 135375 95153017023 4008 139838 135376 95153017023 40011 139839 135359 95153017023 4506 139852 136951 95136017023 4508 139853 136952 95136017023 45011 139854 136955 95136017023 5006 139867 135703 95122017023 5008 139868 135704 95122017023 50011 139869 135705 95122017023 6308 139897 139776 13697024037 63011 139898 139777 13697024037 63015 139899 139778 13697024037 7108 140804 141102 13686024037 71011 140805 141103 13686024037 71015 -141418 13686024037 80011 140810 141418 19276530045 80015 140811 141112 19276530045 90011 600660 19068030045 90015 600661 19068030045 100011 141119 19061032047 100015 141120 19061032047 100020 600665 19061032047 110011 150504 19055532047 110015 600662 19055532047 110020 600666 19055532047 120011 150505 19051045064 120015 600663 19051045064 120020 600667 19051045064

A09

Reversible

A09

jaw GB,

400/450set12647,140

500set164,447,140

630set16551,145

710set20251,145

1200set35092,270

A09

Reversible top jaws

Item

2604set95,352,536

3104set109,557,542

400/4504set12764,542

500/630/7104set12779,550

800/9004set2108968

1000/1100/12004set21011068

A09

2604set1035336,5

3104set1205842,5

400/4504set1376542,5

500/630/7104set1408050,5

800/9004set2108968

1000/1100/12004set21011068

26010166565 31010162110 40013162121 45013161629 50013161611 63016161583 71016247826 80018150544 90018150545 100018150546 110018149776 1200-24

260/31010160097 40013160098 450/50013160099 630/71016160100 800/900/1000/110018150548 1200-24

Cylindrical centre mount

Size A260310400450500630710800

BH8130130210210210260260370 C88181818181818 DUSE-USU8595112,5112,5112,5122,5132,5145 EUSE-USU7075959595135135180 F105105175175175220220330 G4x13,54x13,54x174x174x174x20,54x20,58x22 H8594112112136172172185 J343541,5425055,555,580 K3535404040454560 L8087105114126140165210 M56,560,5545469696991 N100105125135145165185240 SW1010131313161618 approx.kg2332527691150190270

Short taper mount

DIN 55021 withsetscrewsandlocknuts

1)Outerhexagon Size A260310400450500630

Tapersize41)52)656868116811681181115 B63,582,5106,482,5106,4139,7106,4139,7196,9106,4139,7196,9106,4139,7196,9139,7196,9285,8 D7582112,5112,5112,5122,5 E61707075959595135

DIN 55027

DIN

DIN

1)NotforDIN55021orA1/A2inch

2)NotforA1/A2inch

F DIN85 Camlock104,8133,4104,8133,4171,4133,4171,4235133,4171,4235133,4171,4235171,4235330,2 82,6 G111114111418141822141822141822182226 H8594112112136172 J343542425055,5 KUSE353540404045 USU364242425050 L95,3109,5127127127127 M56,560,554546969 N91107126126164,4165 SW101013131316 approx.kg2332527691150

Size A710800

Tapersize8111581115 B139,7196,9285,8139,7196,9285,8 D132,5145 E135180

F171,4235330,2171,4235330,2 G182226182216 H172185 J55,580 KUSE4560 USU6868 L210210 M6991 N202240 SW1618 approx.kg190270

Reversible

Size260310400450500630710800 A8594112136172185 B353540404560 C64668088108130 D101010101214 E121214141418 F273036425255 G293238466065 H141519232630 approx.kg0,80,91,62,253,54,2

Base jaw GB Size260310400450630710800 A91107126165202240 B353540454560 C40,140,147,151,151,161,1 D101010121214 E121214141418 F12,712,712,712,712,712,7 G3,13,13,13,13,13,1 H5463,576,238,138,138,1 JM12M12M16M20M20M20 K7,67,610,810,810,810,8 L21,224,427,527,527,527,5 M19,0319,0319,0319,0319,0319,03 N38,746,656,156,156,156,1 Grooves111234 Tappedholes222456 approx.kg0,80,91,11,42,22,8

ReversibletopjawUBandunsteppedtopjaw

500630710800900100011001200 A262630303034344040404048 B92111145170170215255260310343393425 C141416161620202222222228 D141738384148484848484865 E27,53955706295105127177201251210 F161620202020202424242430 SW1010131313161618181818241)

Chucking

A2max.260295400450500585690800 l1min.758090100145145245170 l2max.260310360450520650730820 max.swing.dia.305355465510610675785870

PalletisingsystemssuchastheEASYLOCKzeropoint clampingsystemfromRÖHMachieveaconsiderable productivityincrease.Thismodularsystemmeetsthe requirementsofcustomer-specificsolutionswiththe best-possibleutilisationofmachinecapacity.Althoughthe machinetoolhadtostopfortheset-uptimeuntilnow,the workpiececannowbeclampedandpositionedonthe palletoutsidethemachinetool.Theset-uptimeisnow onlylimitedtoloadingandunloadingthepallet,which happensinseconds.Ifmultiplemanufacturingprocesses arenecessaryformachining,thenthepalletincludingthe workpiececanbeusedwithoutzeropointloss.Dueto therobustandrust-resistantconstruction,EASYLOCK zeropointclampingcanbeusedthroughout,startingwith machininguptothemeasuringmachines.

WiththeRÖHMEASYLOCKzeropointclampingsystem, theclampingpinistheinterfacebetweenthemachine tableandtheworkpieceorfixture.Theexactpositioning guaranteessecureclamping.Atthesametimetheresultingmachiningforcesaretransferredviatheclampingpin tothepressurecup.Thehigh-precisionpressurecupsof theEASYLOCKsystemensureanabsolutelysecureholdof theworkpieceorfixture.Thehighlockingandholdingforces makethesystemsuitableforallkindsofuse.

MachiningwithEASYLOCK?

EASYLOCKisideallysuitedtoallmachiningprocesseslike grinding,milling,drillingandmeasuring.

Whatismeantbyholdingforce? Holdingforceistheforceatwhichthepalletstillrests securelyontheclampingsystem.Thisforcemustnotbe exceededduringmachining.

Whatismeantbyrepeataccuracy? Therepeataccuracygivesthetolerancerangeforthe recordedworkpiecereferenceswhentheworkpieceisremovedandsubsequentlyreclamped.Therepeataccuracy oftheEASYLOCKsystemisaround<0.005mm.

Apreciselycenteredanddeformation-freesetupisofutmost importance,especiallyforeasilydeformableworkpieceswhich requireturningmachiningfromallthreesideswithinoneworking operation.Thankstothecombinationofmagneticclampingforce anddeformation-freecentering,workpieces,suchasringsorother hard-to-grippartshavingawiderangeofsizesandcontours,can bepreciselyclampedwithinsecondswiththehybridchuckMZMF.

Set-uptimesreducedbyupto50%

Machinedowntimesreducedtoaminimum

3-sidemachiningforturningandgrindingparts

16individuallyadjustableadhesionstages

Uniformanddeformation-freesetup

Combinedmagneticandcenteringchuckclampingarepossible

Highprocessreliabilityforrationalseriesproduction

Fastamortization

Forspecialcustomerdemands,RÖHMoffersanindividualrangeofspecialsolutions,whichgoes farbeyondthestandardproductrange.Fromthesmallest„MicroTechnology“clampingchuckfor watchesandjewelrymachiningtoimpressivechuckswithadiameterofover5.5metersandweight of25tonsforrailvehiclesortheenergysector.

Other special solutions

Machining of large bearings and rotary unions

Chuckforturningmachining

Constantclampingforceathighspeeds bymeansofcentrifugalforcecompensation Integratedquickjawchangesystemfor minimumsetuptimes

Machining of large bearings and rotary unions Chuckfordrillingmachining

Centricallyclampingwedgehookchuck Quicklyadjustableclampingjawsandstopsfor minimumset-uptimes

Clamping chucks for rail traffic

Clampingdiametersofupto1.3meterswithflexible set-upforindividuallychangingworkpiecesizes Automatedjawadjustmentforinnerandouter machining

Independent chucks for power plants and steel mills

Clampingdiameterofupto5meters

Safeclampingusingpowerspindlesallowsupto 50tonsofclampingforceperjaw

Forfurtherinformationsofourspecialsolutionsinanyareasvisitourhomepage: http://www.roehm.biz/downloads/

TheRÖHMmainplantislocatedinSontheim/Brenz.Inthisultra-modernproductionfacilitycomprising41,000m²optimumconditionshavebeenachievedinordertosolvetheextensiverange ofdiscerningconstructionandproductiontasksmakingthecompanyevenbetter,fasterandmore efficientinthefuture.

Sontheim/Brenz

Sontheim IAllnationalandinternationalactivitiesareplannedandcoordinatedattheadministrativeheadquartersin Sontheim.Thankstotheexcellentinfrastructureandtransportroutes,thislocationisidealforacompanyrelyingon

basisforthesuccessofourcompany:itisrichinqualityawarenessandmotivatedemployeeswiththeresultthatwe areideallypreparedforthechallengesofthefuture.Themainplantuniquelyunitesmassproduction,serialproduction andcustomisedindividualproductionunderasingleroof.

SuchstronggrowthonthepartoftheRÖHMGroupisalsoobviouslyassociatedwithhigher requirementsondevelopmentandproductioncapacities.Thedemandsoftodayandtomorrow canbecompliedwiththetwofacilitiesinDillingenandSt.Georgen.

Plant Dillingen/Danube |ThisbranchplantinDillingen wasputintooperationbytheRÖHMGroupasearlyas1953. Thankstoextremelypositivedevelopment,theplantissubject toconstantexpansionandmodernisation.Forthisreason, newmodernproductionfacilitieswerebuiltin1982and1991. In2007RÖHMbuiltanewproductionhallfortwoportal turningandmillingmachines.Thisenablesmachiningof workpiecesupto4metresinlengthwhichwillsecurea leadingmarketpositionforRÖHMinthefuture.Morethan 300employeesareprimarilyinvolvedinengineeringand manufacturinglathechucks,machinevicesandspecial clampingequipmentforturningandmillingmachineryas wellasformachiningcentres.

Engineering and sales department St. Georgen |

Apartfromstandardmandrels,tailor-madesolutionsfor awidevarietyofrequirementsarealsomanufactured hereinthissmallbutaccomplishedhigh-techforge.

RÖHMretainsmechanicalorpower-operatedmandrels,slidingjawmandrelsandhydraulicmandrelsforits customersfortensioningworkpiecesindrillholesor interiorcontours.

Germany:

RÖHMGmbH Heinrich-Röhm-Straße50 89567Sontheim/Brenz Tel00497325–160 Fax00497325–16510 info@roehm.biz www.roehm.biz

RÖHMGmbH Röhmstraße6 89407Dillingen Tel00499071–508-0 Fax00499071–508-174 infodlg@roehm.biz

RÖHMGmbH Feldbergstr.5 78112St.Georgen Tel0049–7724–946812 Fax0049–7724–5189 Mobil0152–22887050 stg.info@roehm.biz

Brazil: RÖHMIND.ECOM.DE

FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo

Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

China: ROEHMChinaCo.,Ltd. Room702,Building24, No.518XinzhuanRoad, SongjiangDistrict, 201612Shanghai Tel0086–21–37705395

Fax0086–21–37705376 roehmcn@roehm.biz

Czech Republic: RÖHMSLOVAKIAS.R.O. Partizanska73 95701BanovcenadBebravou Slovakia Tel00421–387600222 Fax00421–387600224 Mobil00421–902556777 info@roehm.sk

France: RÖHMS.A.R.L. 325ruePaulLangevin BP90204

F-60744SaintMaximincedex Tel0033–344641000 Fax0033–344640068

fr.roehm@roehm.biz www.rohm.fr

Great Britain: ROHM(GreatBritain)LTD. Unit12theashwaycentre ElmcresentKingston-upon-Thames SurreyKT26HH Tel0044–2085496647 Fax0044–2085411783 rohmgb@roehm.biz www.uk.roehm.biz

Italy:

RÖHMItaliaS.R.L. ViaReissRomoli17-19 20019SettimoMilanese(MI) PalazzoRothenberger Tel0039–02–92103531 Fax0039–02–92101753 rohmitalia@roehm.biz www.roehm-italia.it

Mexico: RÖHMProductsMéxicoS.deR.L. EmilioGarzaMeléndez#6606 Col.CampestreMederos Monterrey,N.L.,México,C.P.64970 Tel005281–9627–0686 info@rohm-products.com

Switzerland: RÖHMSpanntechnikAG Feldstraße39,3360Herzogenbuchsee Tel0041–629563020 Fax0041–629563029 roehmch@roehm-spanntechnik.ch www.ch.roehm.biz

Singapore:

RÖHMAsiaPacificPte.Ltd. 8UbiRoad2

#07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

Slovakia: RÖHMSLOVAKIAS.R.O. Partizanska73 95701BanovcenadBebravou Slovakia Tel00421–387600222 Fax00421–387600224 Mobil00421–914122932 info@roehm.sk

Spain: RÖHMIbericaS.A. C/Rejas,No.9Nave11D 28022Madrid Tel0034–91–3135790 Fax0034–91–3135793 rohmiberica@roehm.biz www.roehm-iberica.es

USA: ROHMProductsofAmerica 2500NorthlakeDrive 30024Suwanee,GA Tel001–770–963–8440 Fax001–770–963–8407 rohmusa@roehm.biz www.us.roehm.biz

Poland: RÖHMPolskaSp.zo.o. AlejeJerozolimskie424A 05-800Pruszków Tel0048–22–759–5990 Fax0048–22–759–5999 roehmpolska@roehm.biz

Portugal: RÖHMIbericaS.A. C/Rejas,No.9Nave11D 28022Madrid Tel00351926853881 es.pjfernandes@roehm.com www.roehm-iberica.es

Hungary: RÖHMHungariaKft. Gyáru.2.(BITEPIpariPark) H-2040Budaörs Tel0036–209–324597 jozsef.alker@roehm.biz

PresenceonallcontinentsfromAfor AustraliatoVforVietnam.Youcanreceive thecontactinformationofourworldwide representationseasilythrough www.roehm.biz.

Sales Agents in GermanyAgents worldwide

Baden-Wuerttemberg: ThomasHaas

Tel07725/914895 Mobile0152/22887120 thomas.haas@roehm.biz

DominikGotthelf Mobile0152/22887093 dominik.gotthelf@roehm.biz

RichardSedlak Tel07021/9498970 Mobile0152/22887030 richard.sedlak@roehm.biz

Baden-Wuerttemberg / Rhineland-Palatinate / Saarland: MichaelSchmitz Tel0033388720403 Mobile0152/22887018 michael.schmitz@roehm.biz

Baden-Wuerttemberg / Bavaria: DirkGaarz Mobil0152/22887116 dirk.gaarz@roehm.biz

Bavaria: JanBirkholz Mobile0152/22887014 jan.birkholz@roehm.biz

GerhardHäutle Tel09071/7299322 Mobile0152/22887015 gerhard.haeutle@roehm.biz ChristianHeigl Mobile0152/22887026 christian.heigl@roehm.biz

Bavaria / Thuringia: SteffenBlatz Mobile0152/22887016 steffen.blatz@roehm.biz

North Rhine-Westphalia / Rhineland-Palatinate RalfSchnichels Tel02152/8973547 Mobile0152/22887025 ralf.schnichels@roehm.biz

North Rhine-Westphalia: FriedhelmSchneider Tel02762/490728 Mobile0152/22887017 friedhelm.schneider@roehm.biz

North Rhine-Westphalia / Lower Saxony ThorstenNolte Tel02721/120182 Mobile0152/22887031 thorsten.nolte@roehm.biz

Lower Saxony / Saxony SusanneBormann Mobile0152/22887088 susanne.bormann@roehm.biz

Berlin, Mecklenburg-Western Pomerania, Brandenburg, Saxony-Anhalt: HendrikSeifert Tel030/70072459 Mobile0152/22887032 hendrik.seifert@roehm.biz

Hesse: KlausDieterHofmann Tel06406/906740 Mobile0152/22887029 k.d.hofmann@roehm.biz

Hamburg / Bremen / Schleswig-Holstein / Lower Saxony: WilliPhillipHövermann Mobile0152/22887148 WilliPhillip.Hoevermann@roehm.biz

Algeria: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/34640068 fr.roehm@roehm.biz www.rohm.fr

Argentina: HimaqS.R.L., Venezuela3652, 1603VillaMartelli Prov.BuenosAires Tel00541/147093505, Fax00541/147093472 himaq@himaq.com.ar

Australia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

FISHERLAMCOPTYLTD Tel00611300838572 mark.hughes@fisherlamco.com.au

Austria: RichardSchörkhuber Lichtenhof2b 8511St.StefanobStainz Tel0043/3463/81510 Fax0043/3463/81560 Mobil0043/664/9237710 richard.schoerkhuber@roehm.biz

SchachermayerGmbH, SchachermayerStr.2 Postfach3000,4021Linz Tel0043/732/6599-0 Fax0043/732/65991444 maschinenmetall@schachermayer.at

Lackneru.UrnitschGmbH Bahnhofgürtel37,8020Graz Tel0043/316/711480-0 Fax0043/316/71148039 lackner@urnitsch.at

HaberkornUlmerGmbH HoheBrücke,6961Wolfurt Tel0043/5574/695-0 Fax0043/5574/695-99 nfo.wolfurt@haberkorn.com

MetzlerGmbHu.Co.KG ObererPaspelsweg6-8,6830Rankweil Tel.0043/5522/77963-0 Fax0043/5522/77963-6 office@metzler.at

Belarus: RÖHMGmbH Heinrich-Röhm-Straße50 89567Sontheim(Germany) Tel00497325–160 info@roehm.biz www.roehm.ru

Belgium: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0032495727399 Fax003242866948 frederik.hamels@roehm.biz www.rohm.fr

BELTRACY Bergensesteenweg189 1600Sint-Pieters-Leeuw BELGIUM Tel.0032/25436890 Fax0032/25385910 info@beltracy.be www.beltracy.be

Canada: ROHMProductsofAmerica 2500NorthlakeDrive,30024Suwanee,GA Tel001–770-963-8440 Fax001–770-963-8407 rohmusa@roehm.biz www.us.roehm.biz

Chile: RobertKralemann SERVICOMPLtda. Av.Departamental1595 LaFlorida-Santiago Tel0056/2/8894700 rkralemann@gmail.com

Colombia: RÖHMIND.ECOM.DE

FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Costa Rica: RÖHMIND.ECOM.DE

FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Croatia:

PFEIFER-TTID.O.O. 40000Cakovec,Croatia Tel00385-9/8303522 Fax00385-1/3639530 marijan.pfeifer@pfeifer-tti.hr

Denmark: RyttergaardToolsA/S Falkevej13 3400Hillerød Dänemark +4536412266 info@ryttergaard.com

Ecuador: RÖHMIND.ECOM.DE

FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Egypt: DirkJaegemannTradeAgency GmbH&Co.KG 28279Bremen Tel0049/4218392130 Fax0049/4218398921 info@djta.de

Finland:

TeräskonttoriOy, Muuntotie3, 1510Vantaa Tel00358/102192200 Fax00358/102192245 info@teraskonttori.fi

OyInterfiiLtd. Teollisuuskatu35-39LH4 20520Turku,Y-tunnus2374026-3 Tel00358/201474500 Fax00358/201474501 info@interfii.com

Greece: K.S.PAPADOPOULOS&CO EthnikisAntistaseosStr.7-A 55134Thessaloniki-Greece Tel00302310488758 Fax00302310488753 stefanos@agent.com.gr ntinos@agent.com.gr

India:

RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

Indonesia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

PT.GermantaraToolingServiceIndonesia Jl.RayaBekasiKm.21 PulogadungTradeCentre(PTC)Blok8A/8 Jakarta13920-Indonesia Tel.+622146834110 Mobile+628119593027 kris@group.gts.co.id www.gts.co.id

PT.SOMAGEDEINDONESIA KomplekGriyaIntiSentosa Jl.GriyaAgungNo.3 SunterAgung,Jakarta14350-Indonesia Tel.+62216410730 avi@somagede.com www.somagede.com

Iran: SakhtAbzarParsCo.(SAP) No.19/4SaebTabriziSt., NorthAbbasShiraziAve, MollaSadraAve.,Tehranpostcode19917 Tel.0098/21/88031888 Fax0098/21/88037733 sales@sap-iran.com

Ireland: ROHM(GreatBritain)LTD. Unit12theashwaycentre ElmcresentKingston-upon-Thames SurreyKT26HH Tel0044-2085496647 Fax0044-2085411783 rohmgb@roehm.biz www.uk.roehm.biz

Iceland: FossbergLtd. Dugguvogi6,104Reykjavik Tel.00354/5757606 E-mail:fossberg@fossberg.is

Israel: ETMOSToolDistributingCo.Ltd. 34HAHOFERST.,5811702Holon Tel.00972-3/5581933 Fax00972-3/5581934 etmos@etmos.co.il

Japan: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

TakedaTradeCo.,Ltd. NAKANOSHIMADAI-BUILDING603,3-3-23, NAKANOSHIMA,KITA-KU 530-6106OSAKA Tel.0081368060757 hata@takeda-trade.co.jp

Luxemburg: RÖHMS.A.R.L. 325ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/344640068 fr.roehm@roehm.biz

Malaysia: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

KSPrecisionTools(M)SDN.BHD. A1-01-05,1stFloor,JalanSR1/9 TamanSerdangRaya,Section9, 43300SeriKembangan SelangorDarulEhsan,Malaysia Tel.603-89417168 michael@ks-precision.com

Marocco: RÖHMS.A.R.L. 325,ruePaulLangevin 60740St.Maximin,FRANCE Tel0033/344641000 Fax0033/34640068 fr.roehm@roehm.biz www.rohm.fr

New Zealand: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

TradeToolsLtd 23OliveRoad,Penrose POBox112114 Auckland1642,NewZealand Tel006495258882 sales@tradetools.co.nz

Netherlands: BoorwerkB.V., Flevolaan52A, IndustrieterrianNoord 1382JZWeesp Tel0031/294/432050 Fax0031/294/432152 mail@boorwerk.nl

RÖHMS.A.R.L. 325ruePaulLangevin BP90204 F-60744SaintMaximincedex Tel0033–344641000 Fax0033–344640068 fr.roehm@roehm.biz www.rohm.fr

Norway: Ing.YngveEgeA/S Ryenstubben5 0679Oslo11 Tel0047/23241000 Fax0047/23241001 ege@ege.no

Peru: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Philippines: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

NicklausMachineryCorporation 1795MalabonStreet Sta.Cruz,Manila1014Philippines Tel.+6327118414 Mobil+639178278812 nmcservice@yahoo.com www.nicklaus-machinery.com

Romania: KSNTechnikSrl Str.Tabacarilor15B/103 400139CLUJ-NAPOCA,Romania Tel0040/264/449-533 Fax0040/264/449-533 office@ksntechnik.ro

Russia: RÖHMGmbH Heinrich-Röhm-Straße50 89567Sontheim(Germany) Tel00497325–160 info@roehm.biz www.roehm.ru

Saudi Arabia, UAE, Bahrain, Kuwait, Oman, Quatar, Kazakhstan, Lebanon: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2

#07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

COBALTMEFZE SAIFZONE

QI-05-077/C Sharjah,VAE Tel.+971556834422 sales@cobalt-me.com

Sweden: TechpointSystemteknikAB Nyponvaegen4 19144Sollentuna Tel0046/86231330 Fax0046/86231345 info@techpoint.se

LunaAB Sandbergsvägen3, 44180Alingsâs Tel.0046/322606000 Fax0046/322606203 info@luna.se

Singapore: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

GPSystemSingapurPTELTD No.51,BukitBatokCrescent, #04-04/05UnityCentre, Singapur658077 Tel.0065/6861-2663 Fax0065/6861-3500 enquiry@gpsystem.com

Slovenia: BTSCOMPANYTRGOVINAIN ZASTOPANJE,D.O.O. Bratislavka5 1000Ljubljana Tel0038/615841440 masa.bitenc@bts-company.si

South Africa: SupraToolingandAccessoires(Pty)Ltd P.O.Box1892 1460Boksburg,Gauteng SouthAfrica Tel.002764674284 Fax0027119185492 supratoolig@mweb.co.za www.supratooling.co.za

ToolingPromotions P.O.Box3989 Vanderbijlpark1900,Gauteng SouthAfrica Tel00270169311266 Fax00270169311269 info@toolingpromotions.co.za www.toolingpromotions.co.za

South Korea: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

CHEONGDOMACHINETOOLCO.,LTD. RMA-6-103,604-1,KURO-DONG KURO-KU,SEOUL,KOREA Tel+82226784155 cdmt@chol.com www.cdmt.co.kr

KMCCo.,Ltd. Zipcode15090 42-404,204,Gongdan1-daero, Siheung-si,Gyeonggi-do,Korea Tel+82314306789 chelee@naver.com www.entkr.com

Thailand: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

KrasstecCompanyLimited 1205Rama9Soi55,Rama9Rd, SuanLuang,SuanLuang Bangkok10250Thailand Tel66(0)27321144 Mobile66(0)819410509 chaithat@krasstec.com

Tunisia: RÖHMS.A.R.L., 325ruePaulLangevin 60740St.Maximin,FRANCE Tel.0033/344641000 Fax0033/344640068 fr.roehm@roehm.biz

Turkey: SintekMühendislikMakinaSan. VeTic.Ltd.Sti TarabyaMahallesi YumakSok.No:3/A1 34457SARIYER–ISTANBUL Tel.0090/212/2996184 Fax0090/212/2995675 sinan.onurlu@sintekmuhendislik.com

Ukraine: DenisAlexandrov OfficialSalesConsultantRussia onbehalfofRÖHMGmbH Tel.+79851101234 denis.alexandrov.external@roehm.biz www.roehm.ru

Venezuela: RÖHMIND.ECOM.DE FERRAMENTASDEFIXAÇÃOLTDA. Rod.RaposoTavares,Km14-BlocoA 2ºandar-sala2-CEP05576-100 SãoPaulo Tel0055–11–37322222 Fax0055–11–37353097 vendas@rohm.com.br www.br.roehm.biz

Vietnam: RÖHMAsiaPacificPte.Ltd. 8UbiRoad2 #07-10Zervex Singapore408538 Tel0065–64437748 Mobil0065–83288980 info@sg.roehm.biz www.sg.roehm.biz

CUONGANHMACHINERYCO.,LTD 2/27HoangNhuTiep,BoDe. LongBien,Hanoi,Vietnam HanoiOffice:Suite1005-B.HH2B Building,GiaThuyStreet,LongBien District,Hanoi,Vietnam +842438723571

HoChiMinhCityOffice: Suite501,No67PhoQuangStreet,2Ward, TanBinhDistrict,HoChiMinhCity,Vietnam Tel02835470769 contact@cuonganhvn.com www.cuonganhvn.com

§ 1 Offer, conclusion of contract and contractual contents

1.OurTermsofSaleshallapplyexclusively;wedonotrecognisecontradictoryterms andconditionsortermsandconditionswhichdeviatefromourTermsofSaleunlesswe hadexplicitlyapprovedtheirvalidityinwriting.OurTermsofSaleshallalsoapplyifwe carryoutthedeliverytothebuyerwithoutreservationintheknowledgeofcontradictory termsandconditionsofthebuyerortermsandconditionswhichdeviatefromourTerms ofSale.

2.OurTermsofSaleshallonlyapplytowardsanentrepreneurwithinthemeaningof Section14BGB[GermanCivilCode].

3.OurGeneralServiceTermsshallapplywithprecedenceovertheseTermsofSalein therespectivevalidversionincases,whichcomprisetheserviceofferofRÖHMGmbH.

4.Ouroffersarealwaystobeunderstoodasinvitatioadofferendumandaretherefore withoutobligationinsofarastheyhavenotexplicitlybeendescribedasbinding.The contractshallonlybeconcludedwithourwrittenconfirmationandinlinewithitsconten tsand–ifawrittenconfirmationismissing–bytheservice/delivery.Ifadelivery/service iscarriedoutimmediatelywithoutaconfirmationthentheinvoiceshallatthesametime bedeemedasanorderconfirmation.

5.Costsfortheproductionofdrawingsforspecialconstructionsaretobeborneby theordererinsofarastheofferdoesnotleadtoanorderforreasons,forwhichweare notresponsible.

6.Alldetailsconcerningweights,dimensions,servicesandtechnicaldata,whichare containedinourprintedmaterial,catalogues,pricelistsorinothercontractualdocu ments,merelyserveforpurposesofinformationandareonlybindinginsofarastheyare explicitlydescribedasbinding.

7.Wereservetherighttomakeconstructionandformchangestotheobjectofcontract insofarasnochangesaremadehereto,whicharedeemedunreasonablefortheorderer.