Bruce Westgate

Industrial Design Portfolio

Bruce D. Westgate

Bruce D. Westgate

B-Racer: Men’s Lacrosse Glove 2 - 8

Barano: Swimming Prosthetic 9 - 13

Westgate

Libero: Repairable and Adaptable Coffee Table 14 - 20

Miscellaneous Rendering 21 - 24

1

Bruce D.

2

Bruce D. Westgate

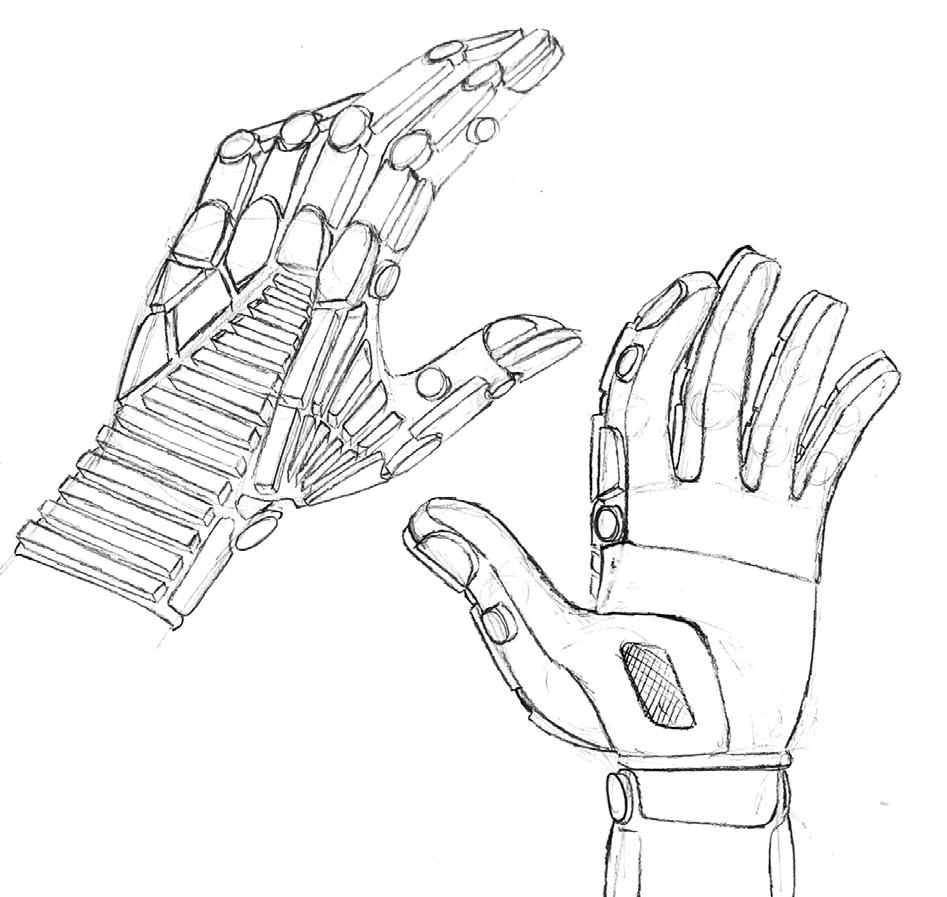

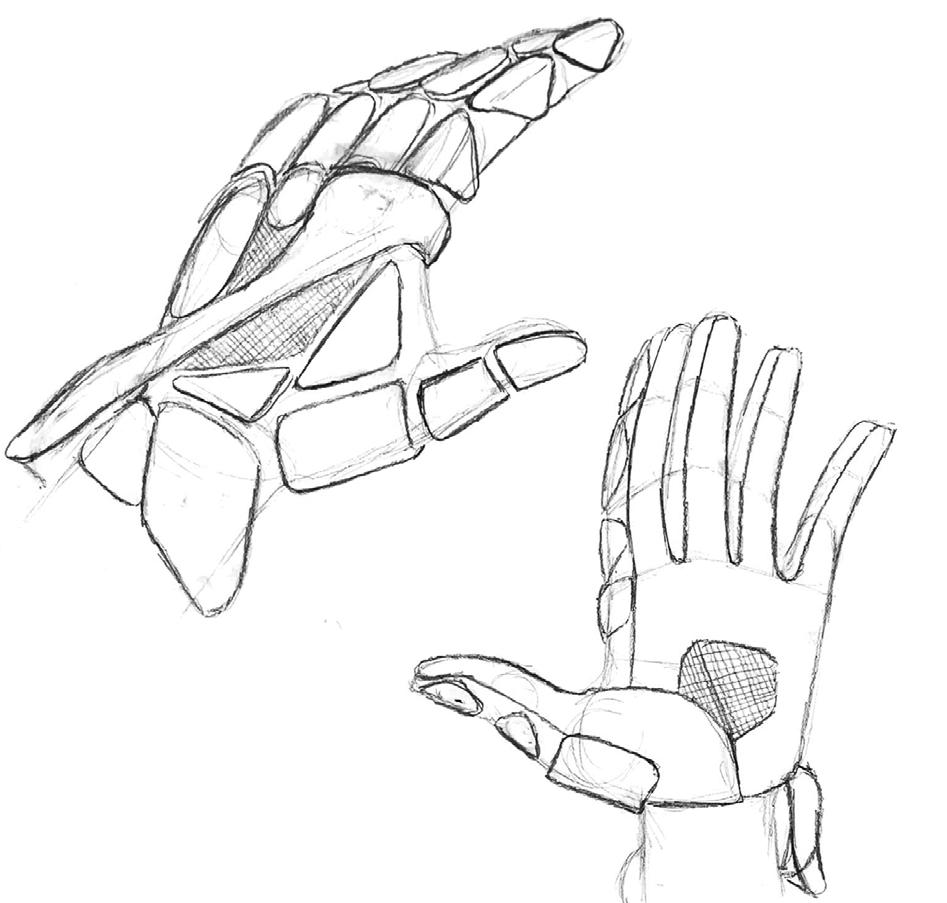

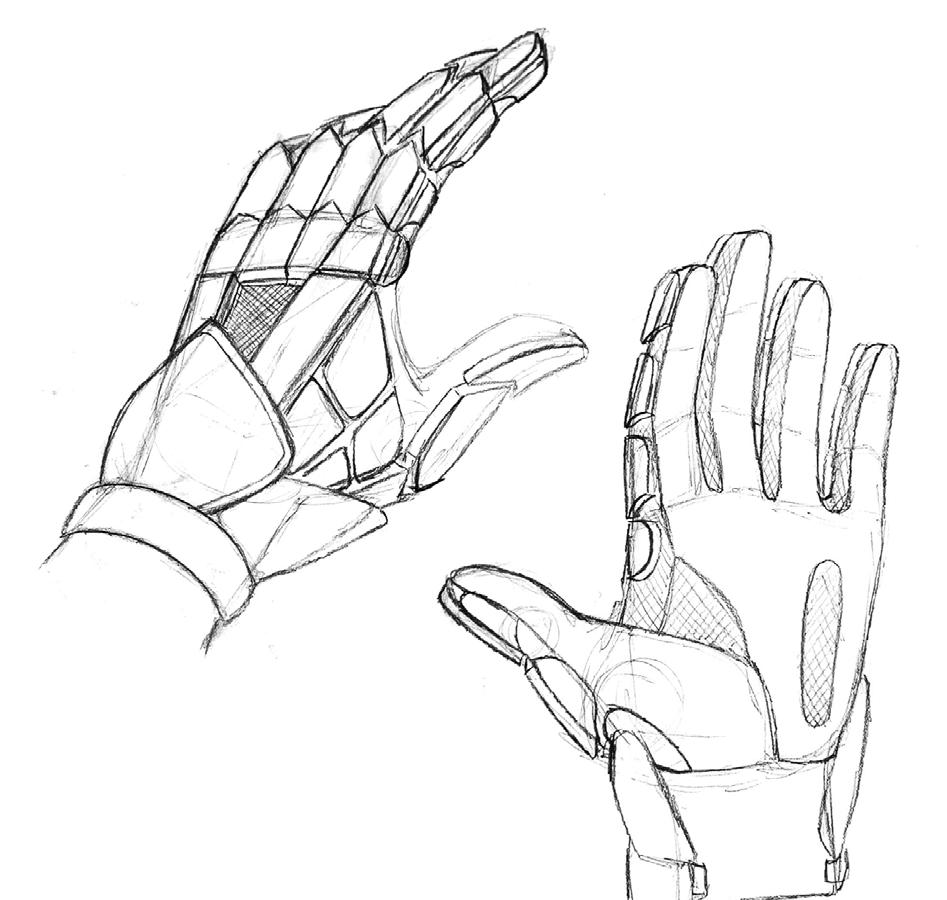

Men’s Lacrosse Glove B-Racer

Problem Identification

Through market research and interviews with lacrosse players from all ranges of play (high school to college divsion I) there was a common trend of problems with protection and comfort. Those being...

- Protection along wrist and thumbs leading to swelling and bruising

- Breathability of materials making players hands sweat and gloves get crusty (ventilations)

- Lack of articulation of materials hindering player’s performance

Bruce D. Westgate

Bruce D. Westgate

3

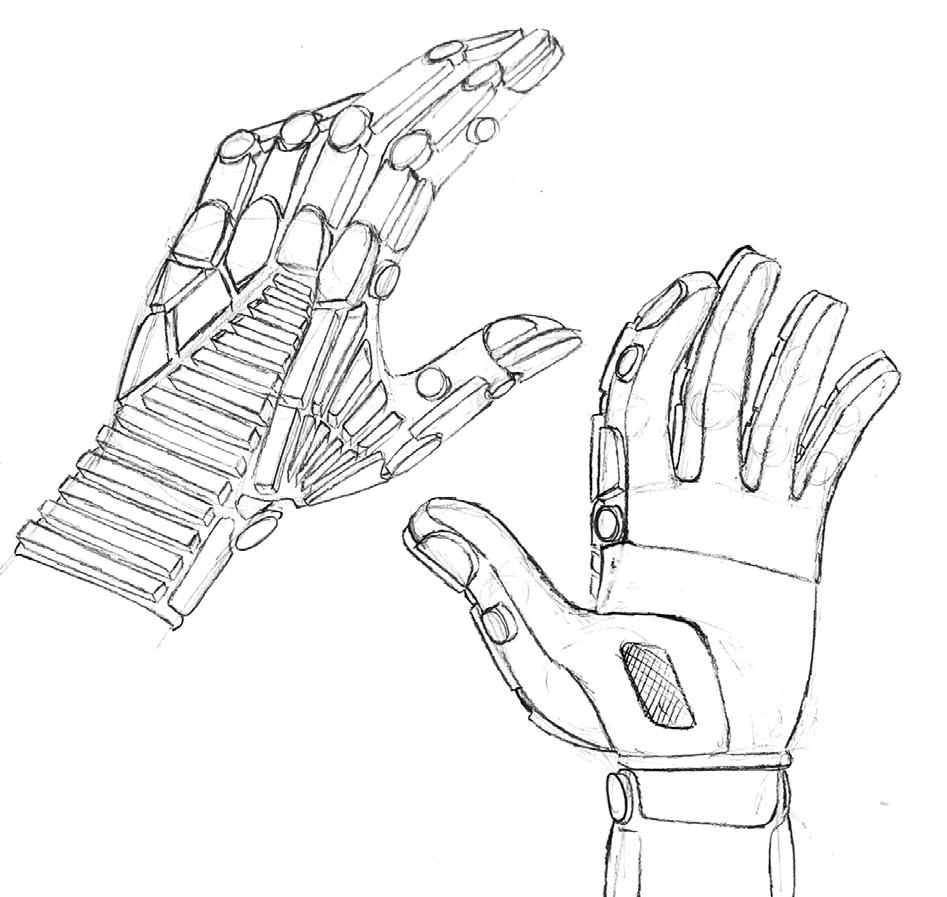

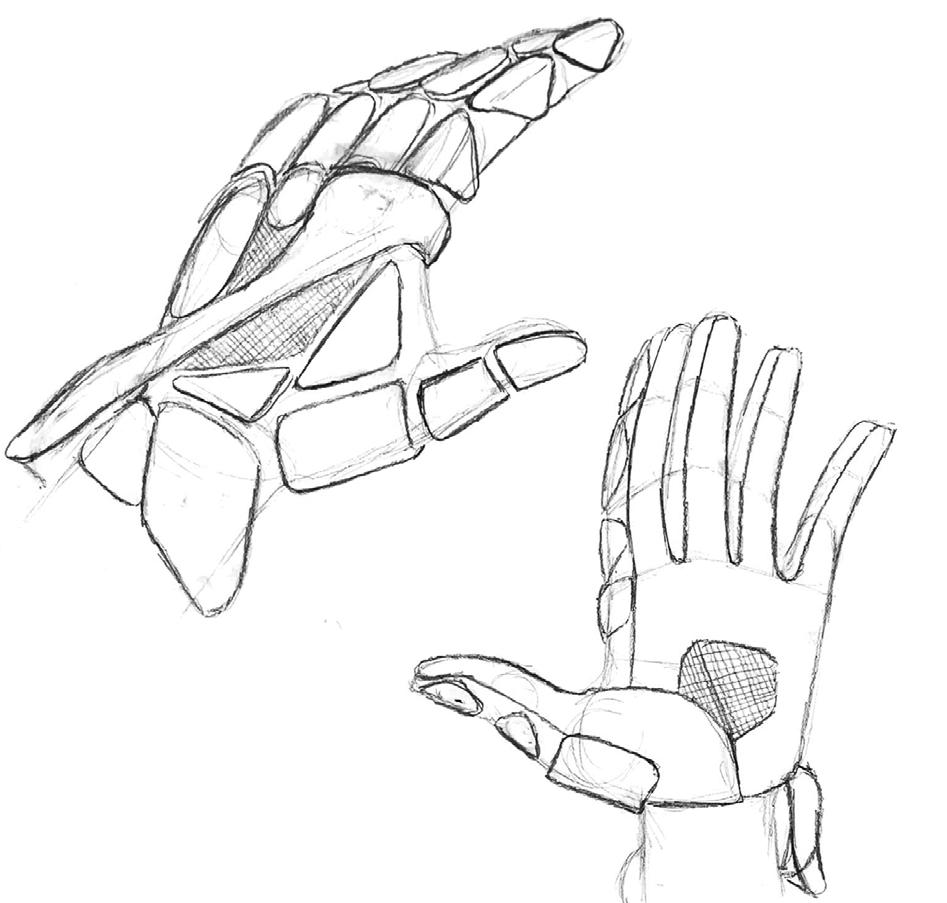

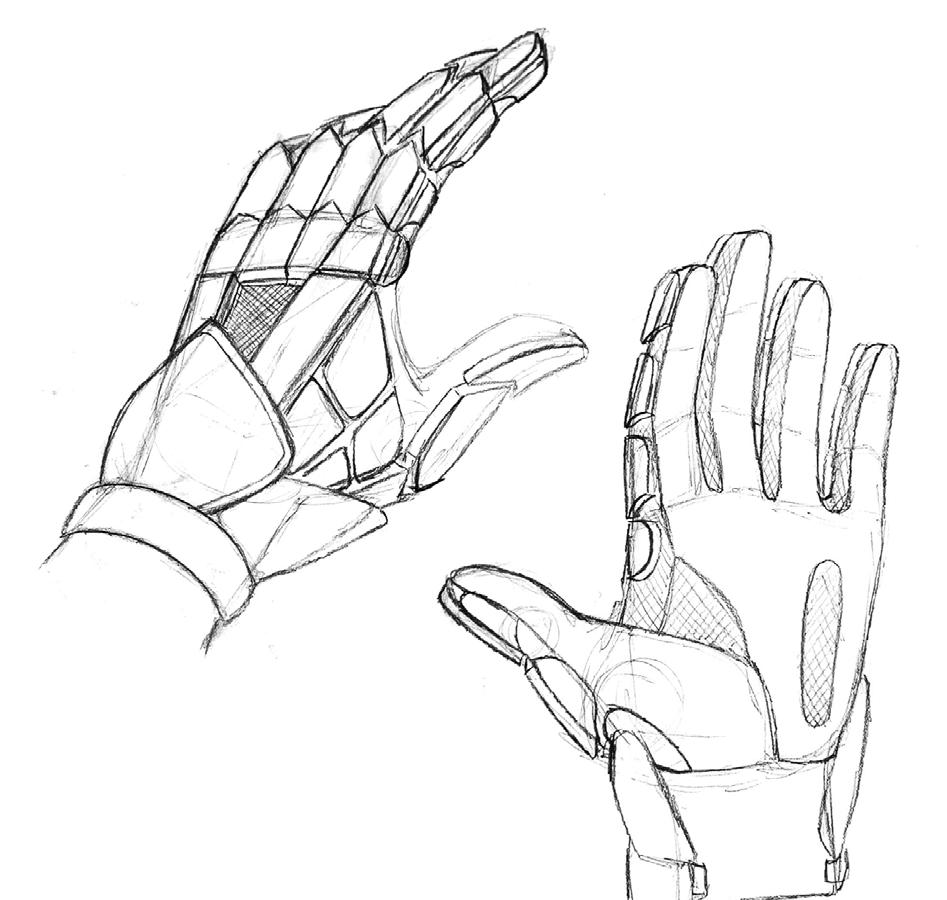

Design Exploration

4

Bruce D. Westgate

First Prototype

Takeaways:

- Too small

- Cuff doesn’t stay up

- Leather covers aren’t tight enough

5

Bruce D. Westgate

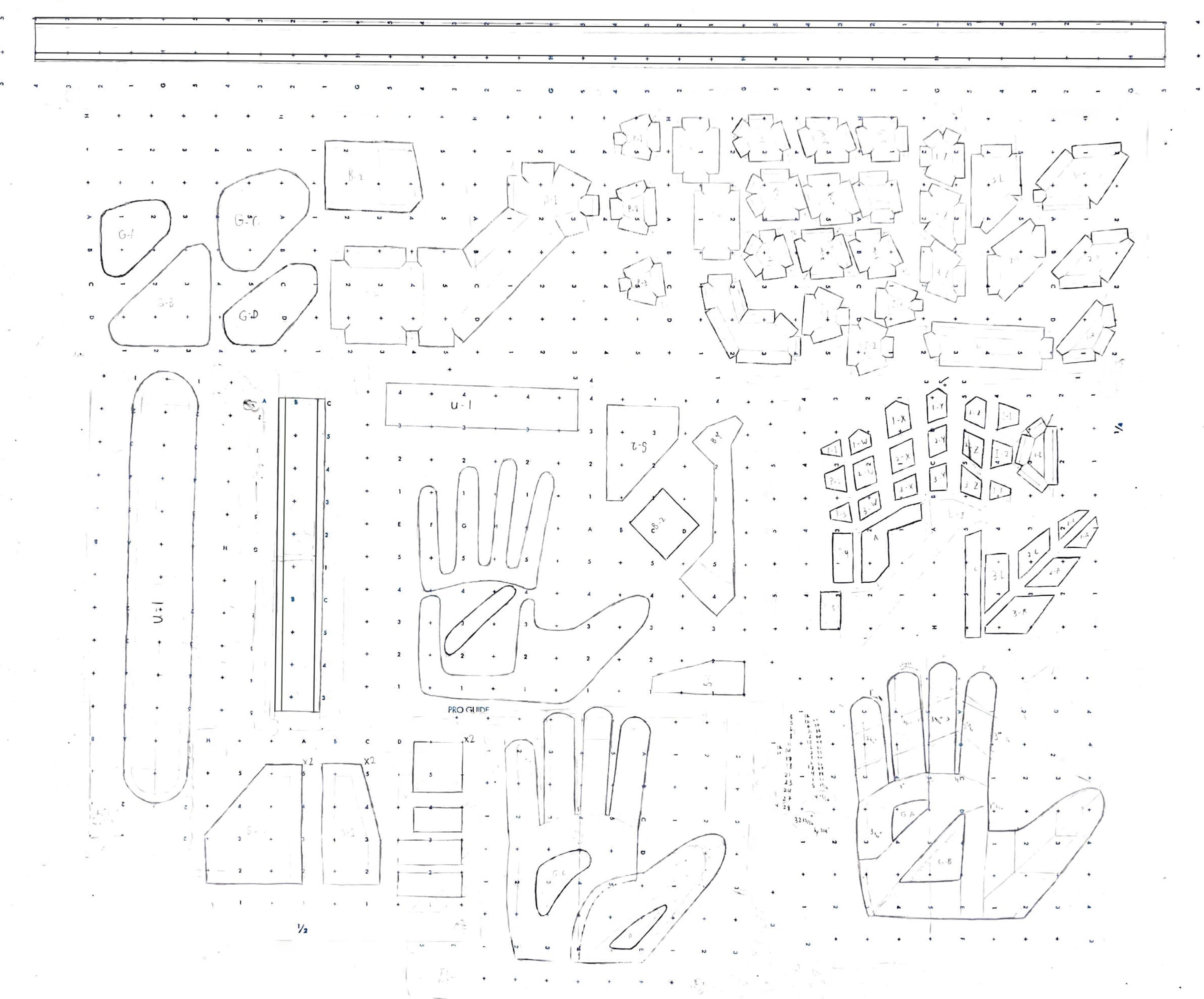

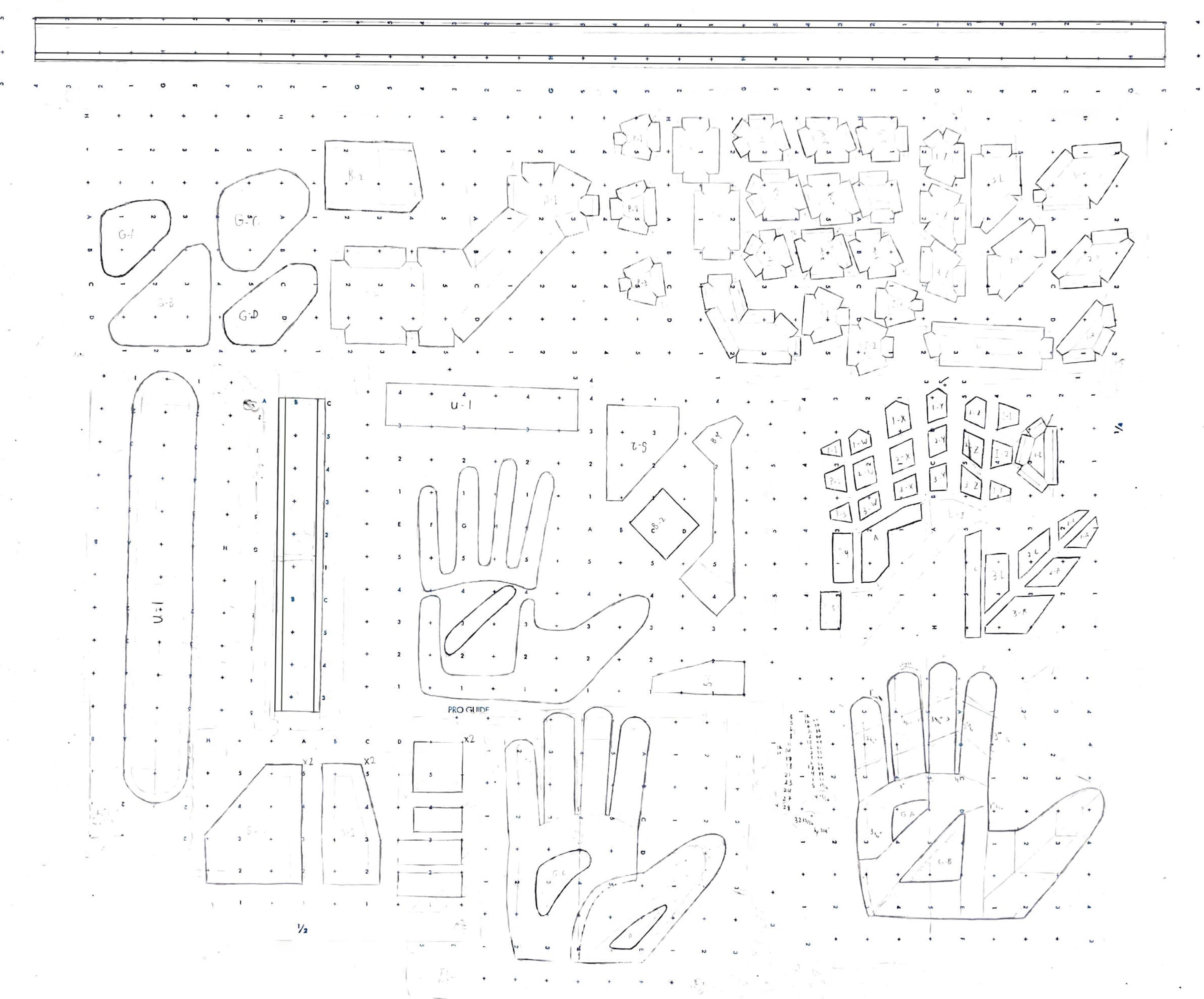

Final Pattern

83 individual pieces

6

Bruce D. Westgate

Final Prototype

Using visco-elastic polymer foam I was able to design a brace to block most impact to the hand while also being flexible. Not only did this increase articulation and protection it aslo made extra room for vents to keep the players hands cool.

7

Bruce D. Westgate

Final Prototype

8

Bruce D. Westgate

9

Bruce D. Westgate

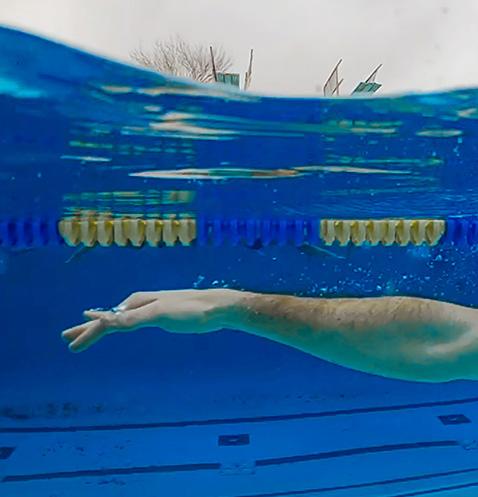

Barano

Swimming Prosthetic

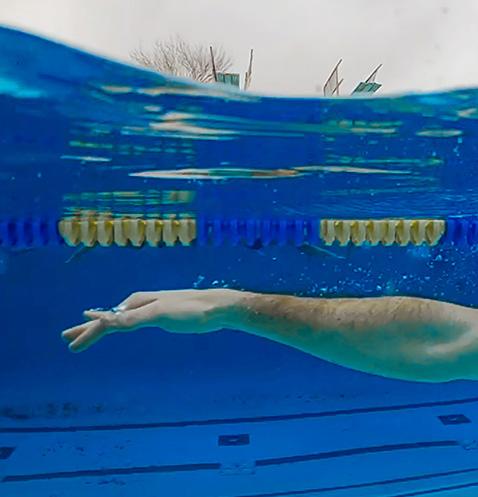

Problem Identification

Allowing amputees to reclaim parts of their lives lost before their amputation can help combat depression in amputees whether those be hobbies, activities, or sports. In the case of swimming for transradial amputees there are many challenges that they face. Some of these challenges include that swimming with a prosthetic that’s not the right size or without one entirely can cause one’s stroke to be unbalanced which can lead to injury in the dominant arm. Not only that but many materials usually used in prosthetics don’t lend themselves well to prolonged use in water.

10

Bruce D. Westgate

Research

Research was primarily based around the element of water. being deceptively destructive it was to not only find mechanical locks that would work underwater but also what materials could survive the elemnt and be formed to mimic a human’s hand. in the end a pin lock mechanism was chosen and materials were based on paddles used for training.

11

Bruce D. Westgate

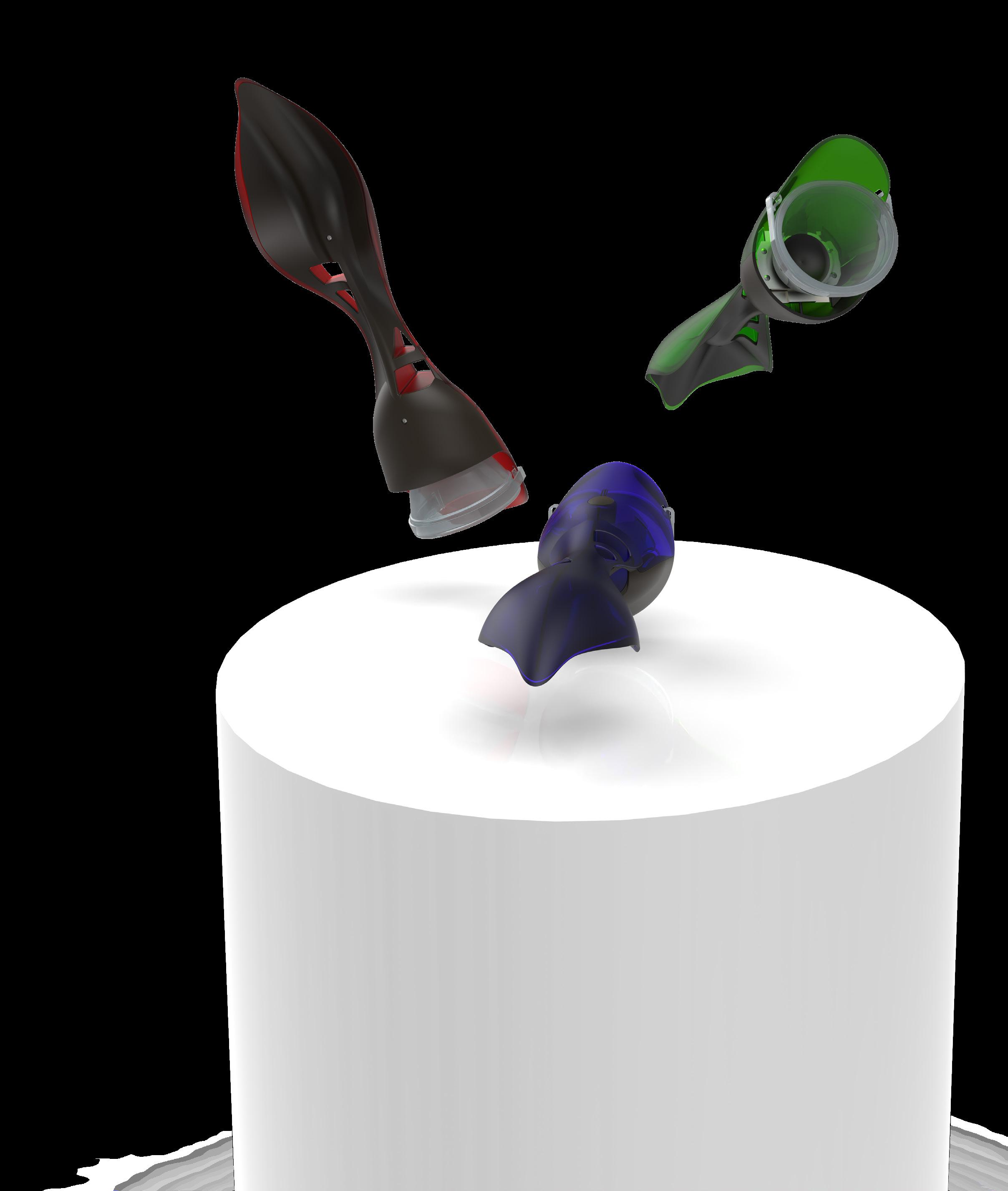

3D Exploration

Pink foam was chosen for the 3D exploration and appearance model as it was a fast way to rapid prototype different shapes for the design

12

Bruce D. Westgate

Final Prototype

Final prototype included:

- Window Cuts to visually lighten the form and al

low water to pass through the shaft

- Button for quick attachment and release

- Silicone Elastic for a stronger connection

13

Bruce D. Westgate

14

Libero

Bruce

D. Westgate

Repairable and Adaptable Coffee Table

Problem Identification Aesthetic Inspiration

Walking through the streets of Brooklyn you see mounds of furniture pile up at the start of every month. Either due to wear and tear or the unpractical and financial burden of having to move it to a new home. most knockdown furniture is not designed to be reconstructed after a single use easily like advertised leading to waste. I looked to incorporating insert threads and bolts as fasteners to achieve a knockdown furniture design that could be reconstructed countless times and changed with a changing home. I also looked to make it easy for a user to incorporate found object into my furniture piece.

By using elements of modularity and knockdown elements in the design, the coffee table will be able to make better use of both positive and negative space in order to add more options for storage. Also, the incorporation of easy to access fasteners and accessible construction will make the product welcoming to customize for the users ever changing space and tastes.

15

Bruce D. Westgate

2D Exploration

In my initial round of sketches I tried to explore different shapes of tables. After deciding on doing a coffee table I explored incorporating storage space in the negative space under the table. All this while keeping in mind how it would be constructed as making it simple for an unfamiliar user could put together. All while exploring different shaped table tops and storage opportunities in the negative space underneath

16

Bruce D. Westgate

3D Exploration

17

17

Bruce D. Westgate

Prototype

18

Bruce D. Westgate

19

Bruce D. Westgate

Proof of concept of using a reclaimed door as a coffee table and place of gathering.

Final renders and painted table show the same base in different materials. enhance the idea of the table changing with a users environment to match any homes aesthetic. As well as a demonstartion of the modular capabilities.

20

Bruce D. Westgate

Final

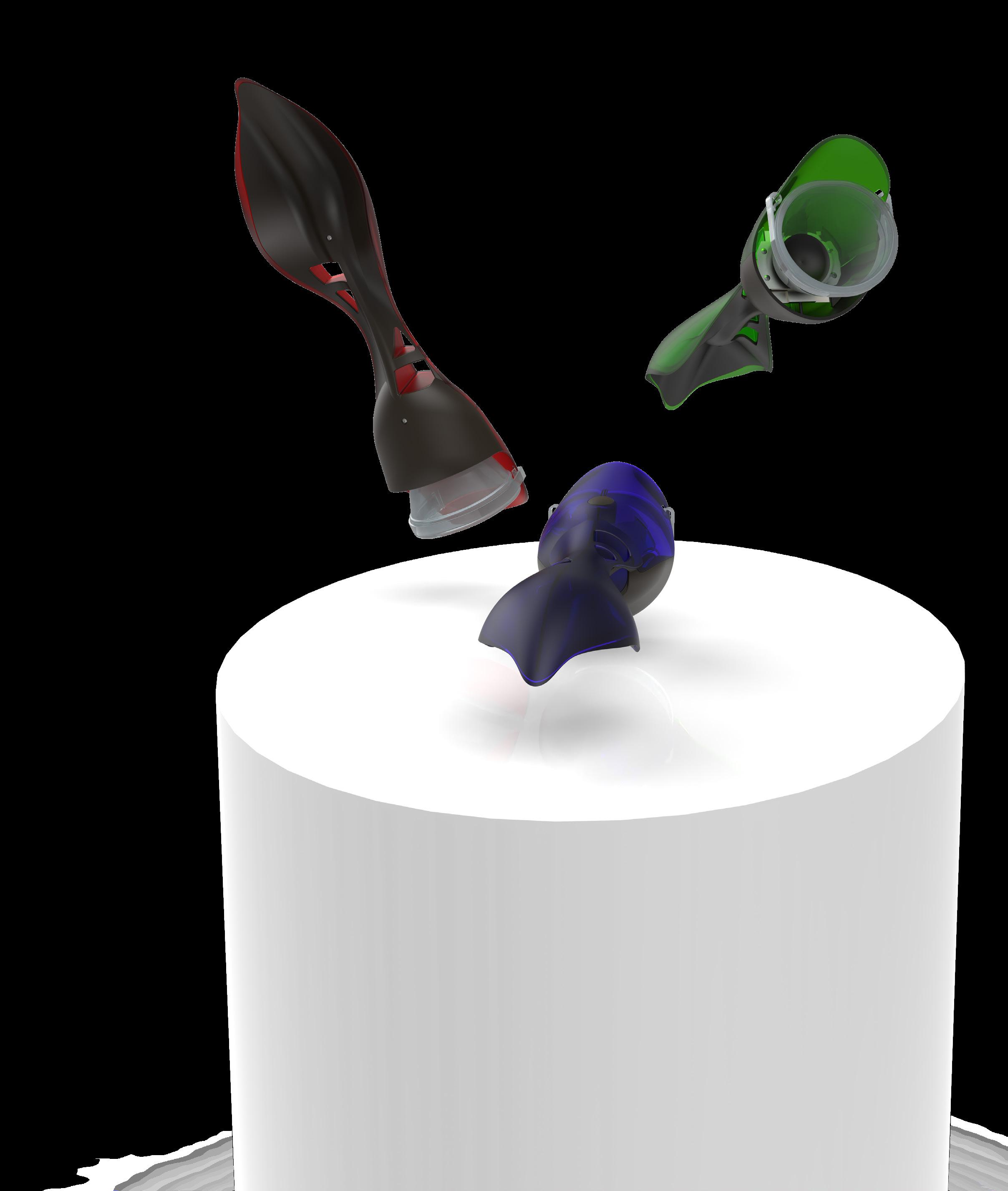

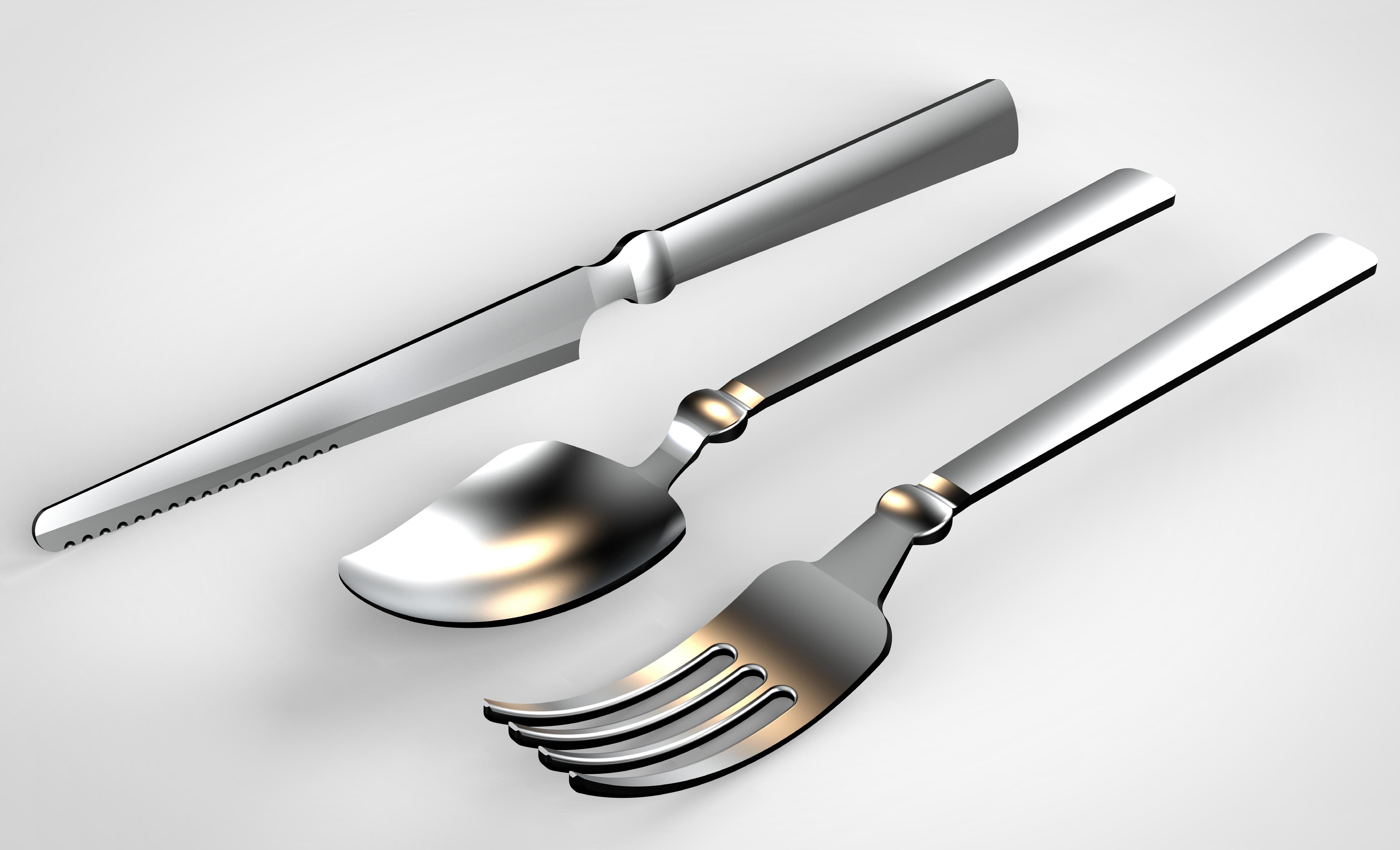

Miscellaneous Renders

21

Bruce D. Westgate

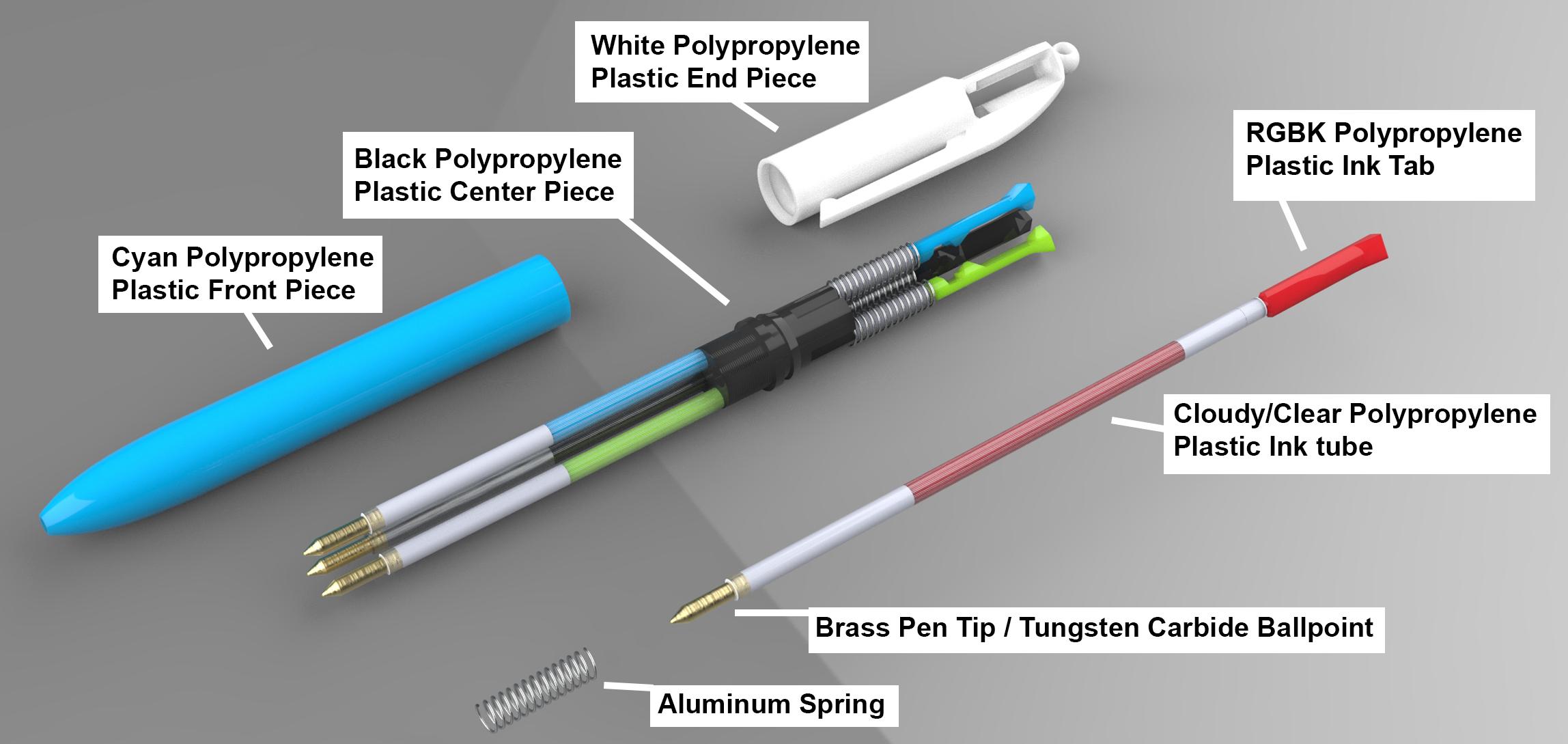

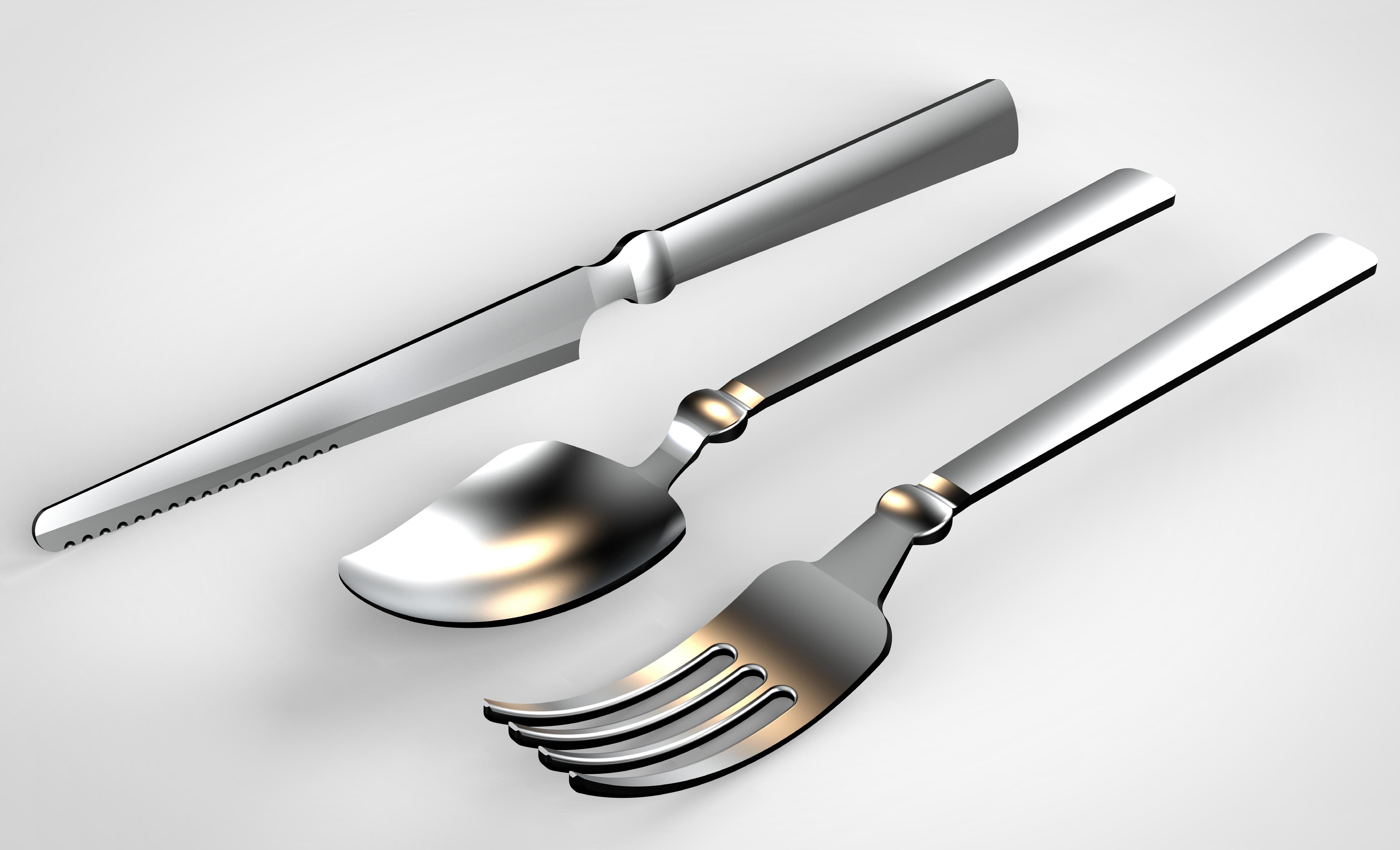

Miscellaneous Renders

22

Bruce D. Westgate

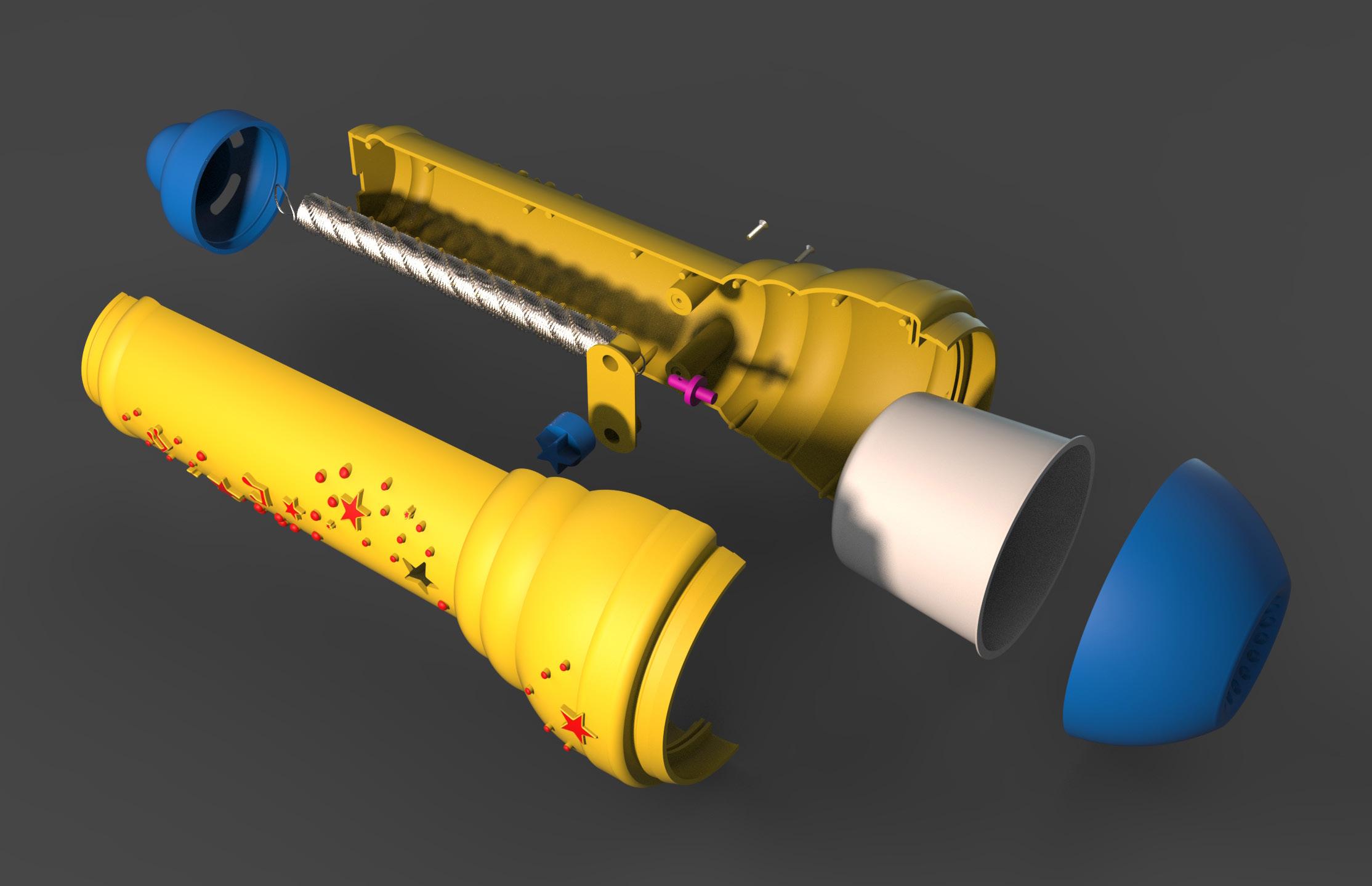

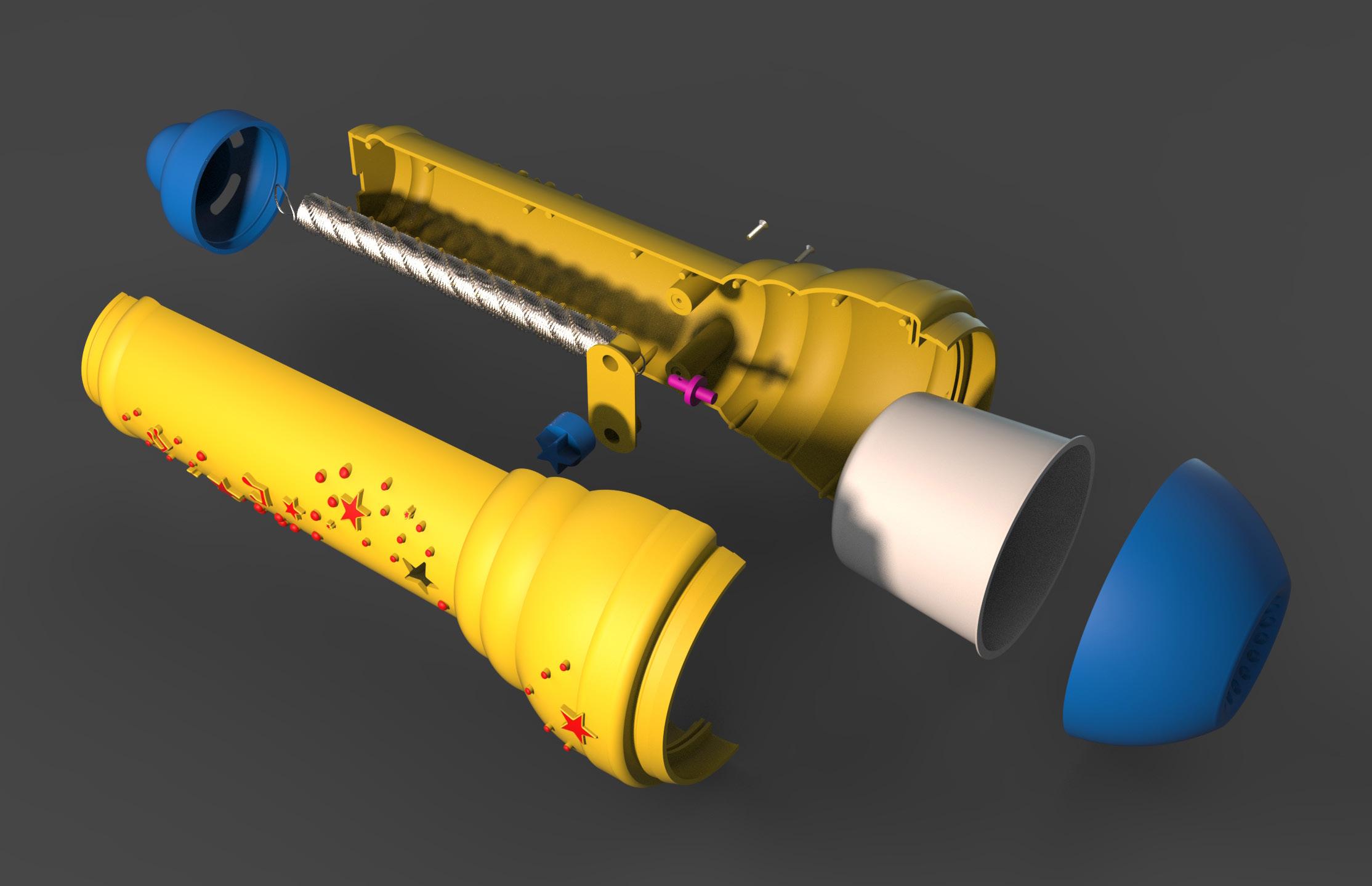

Toy mic solidworks/keyshot recreation

Table with glass center

Miscellaneous Renders

23

Bruce D. Westgate

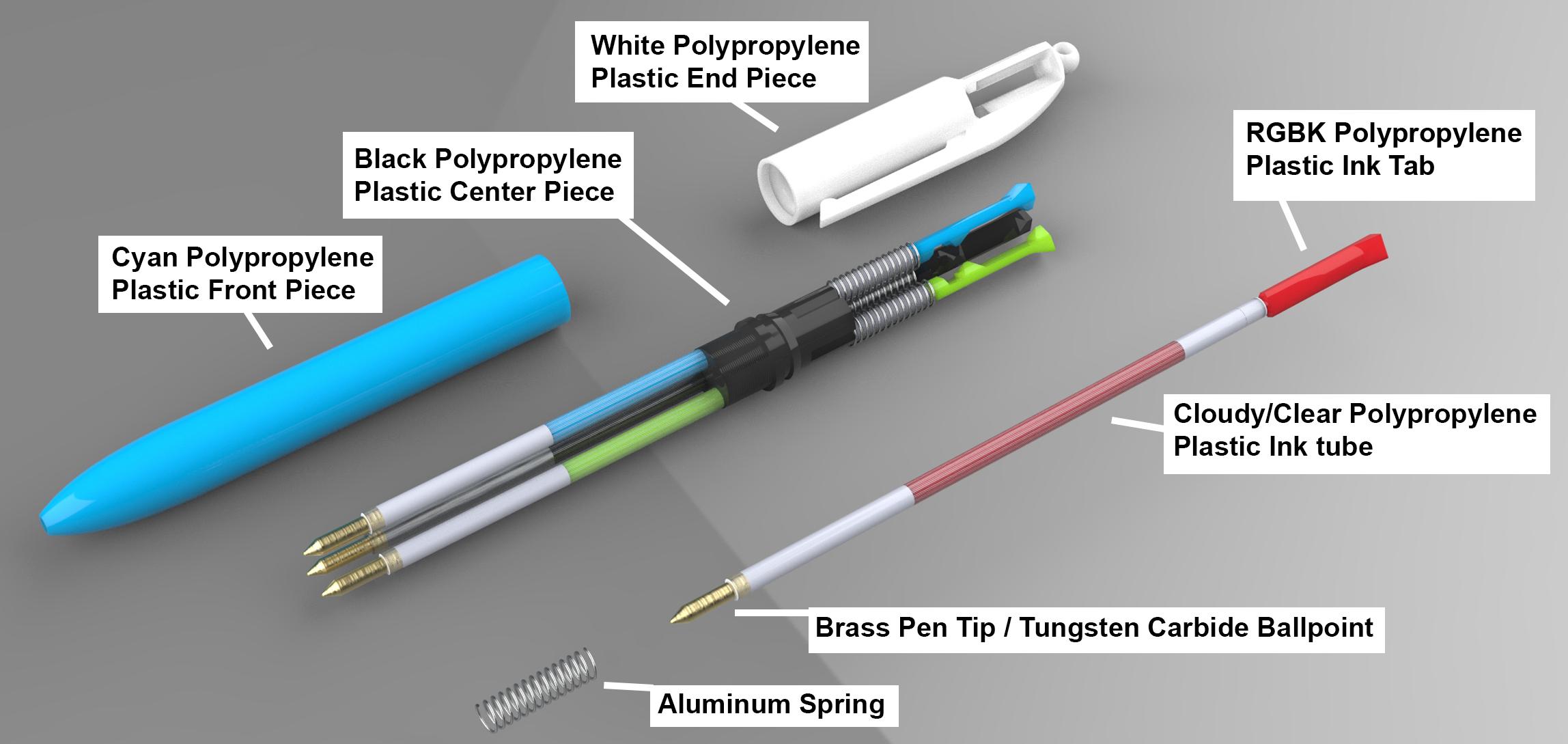

4-color BIC pen recreation

Any Chair: Transforming Chair/Handbag

Miscellaneous Renders

24

Bruce D. Westgate

Toy mic solidworks/keyshot recreation exploded view

Mouse shell

Thank you!

Bruce D. Westgate

Bruce D. Westgate

Bruce D. Westgate

Bruce D. Westgate