Design Portfolio LIN, PO-HAN

Lin, Po-Han +886 978729900 bruce.l0919@gmail.com

Education

2017 – 2021 Fu Jen Catholic University BA in Applied Arts, specializing in metalwork

Work Experience

∙ 22 Design Studio Part-time Concrete Product Maker

∙ Grid atelier–Bamboo Installation art Project Internship

Awards

∙ 2021 Oyster Action – Young Pin Design Award - Craft Category Winner

∙ 2020 Grandma (Rattan&wood Chair) – Taitung Craft Design - 2nd Place

∙ 2019 4th TJDMA Jewellery Design Contest - Selected

Extracurricular Experience

∙ 2021 Taiwan Design Expo RE: Chia Yi, Recyclable Area Exhibit

∙ 2012-17 Chia-Wu Art Association – Volunteer Teaching Assistant

Oyster Action

Graduation project | 28 weeks

Studio professor : Dr. Chen Kuo-Jen, Dr. Chen Li-Hao

Advisor : Mr. Wong Ming-Shong

Design Team : Lin Po-Han, Peng Shih-Syun

Concept

Due to the added stability and strength of oyster shell powder mixed with cement mortar, the raw material was widely used as a traditional building material in fishing villages in Taiwan.

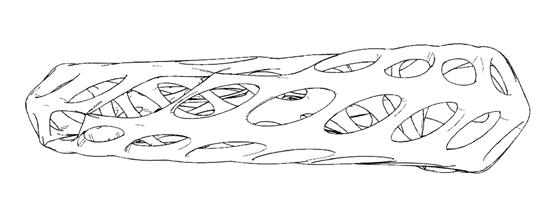

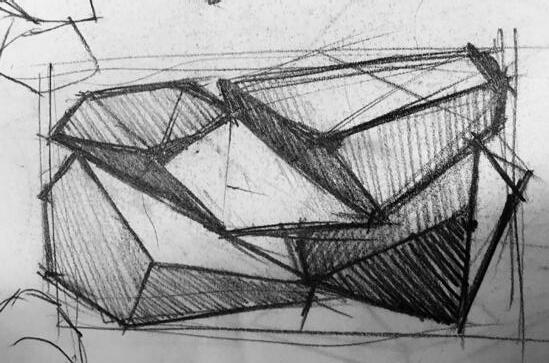

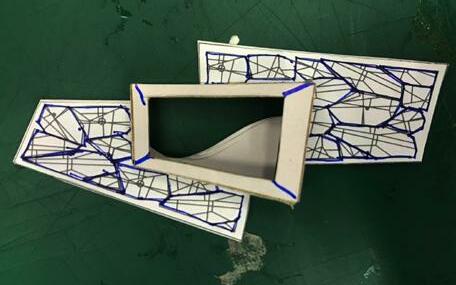

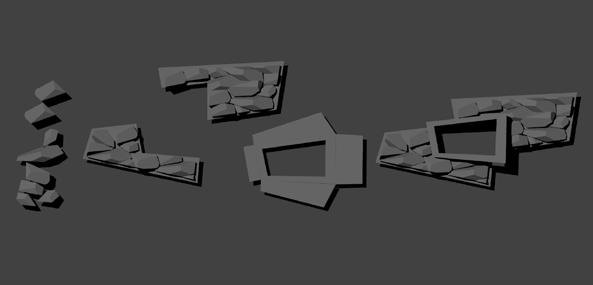

In this project, we created a collection of aromatherapy jewellery that reconnect people with nature and demonstrate the potential of turning non-biodegradable wastes into valuable resources once again.

Current situation

While oyster farming is a valuable sector of Taiwan’s aquaculture industry, the leftover shells have been a serious threat to the environment as there is no proper place for dum oyster shells. Over time, this casual disposal of the abandoned shells along the coast has polluted the environment and spoiled the sea coast with a rotten egg odor that discourages visitors.

Hence, our goal is to raise awareness of this environmental issue, promote the practice of upcycling, and change the negative perception of the smell of leftover oyster shells by transforming them into a piece of subtly fragranced jewellery.

Discovery

Upon further research, we discovered oyster shells were a common construction material used in the south of Taiwan back in 1623. However, it was eventually replaced by other materials with a more efficient and faster manufacturing process, such as concrete and plaster.

Materials

Traditional approach:

According to historical literature, the traditional processing of oyster concrete is complex. Before blending with sticky rice and cane sugar water, shells should be sundried and burned to ash through a massive kiln over 1100 °C.

Our approach:

Oyster concrete replaces the sand in traditional concrete with ash and the powder of oyster shells, and it is more environmentally friendly and much lighter than conventional concrete.

Tutor : Dr. Chen Li-Hao

Designer: Lin Po-Han, Peng Shih-Syun, Neo Liang

Tutor : Dr. Chen Li-Hao

Designer: Lin Po-Han, Peng Shih-Syun, Neo Liang