Judges Pack

2025 Entries

The Horners Award for Plastics Innovation & Design &

The Horners Bottlemakers Award for Plastic Packaging &

The Horners David Williams Award

Horners Award For Plastics Innovation & Design

Horners Bottlemakers Award for Plastic Packaging

*Please note: all entries are open for consideration into the David Williams Award.

Entries for the Horners Award for Plastics Innovation & Design 2025

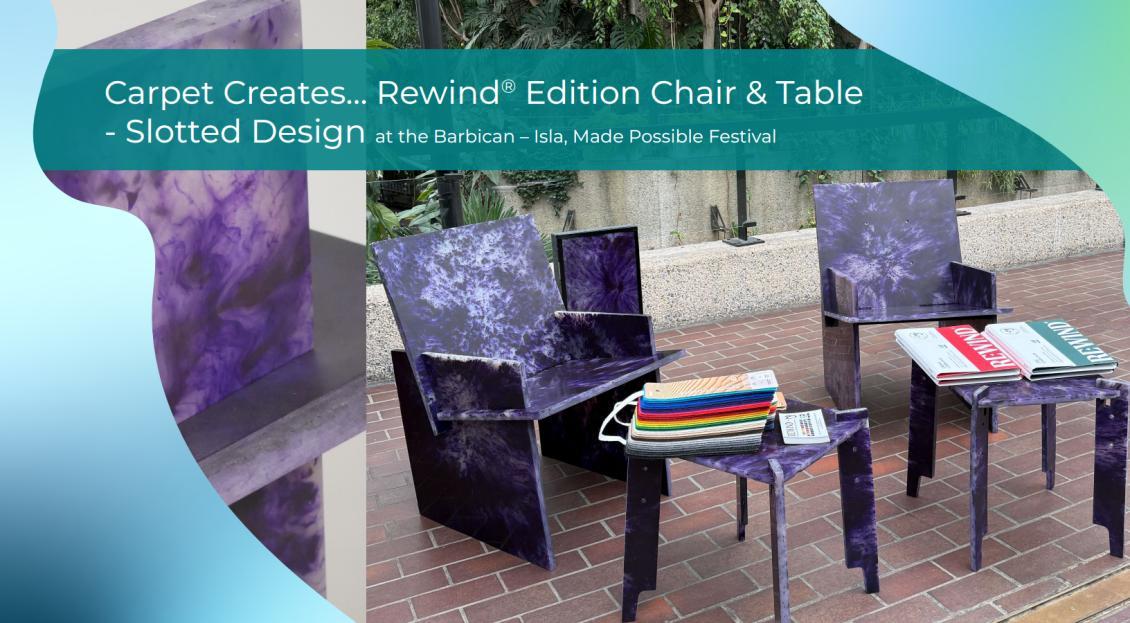

Carpet

Creates:

A Circular Collaboration between

Future

Makers, MJ’s Event Services and Blu Sky Technical Services by Future Makers

Future Makers, in partnership with MJ’s Event Services Ltd and Blu Sky Technical Services Ltd, has developed the Rewind® Edition slotted chair and side table - a UK-first, ultra-circular furniture system made entirely from recycled polypropylene event carpet.

Rewind® carpet was designed with recyclability in mind, but until now, had no scalable circular reuse route. Our team has created a complete system to recover, shred, pelletise, sheet-form and CNC-cut used carpet into interlocking, fixings-free furniture - made from mono-material polypropylene, fully recyclable at end of life.

The Rewind® Edition chair and table were officially launched on 26th February 2025 at Confex at ExCeL London, as a design-forward, ultra-circular furniture system made from recycled Rewind® carpet. The designs were subsequently validated through showcase events at the We Are Isla conference at the Barbican, RAI Amsterdam and Fira Barcelona, attracting strong interest from event organisers, designers and sustainability professionals.

Manufactured entirely in the UK using local, low-emissions processes, the Rewind® Edition helps divert post-use material from landfill and redefines the potential of eventgrade polypropylene through design-led circularity. Its compelling form, structural integrity and sustainable credentials make it ideal for zero-waste event fit-outs and commercial reuse.

This innovation combines design excellence, polymer engineering and industrial collaboration to transform a high-volume waste stream into a beautiful, functional productfully aligned with the Horners Award’s legacy of innovation in plastics and commitment to a circular economy future.

More Information

Carpet Creates: A Circular Collaboration between Future Makers, MJ’s Event Services and Blu Sky Technical Services.

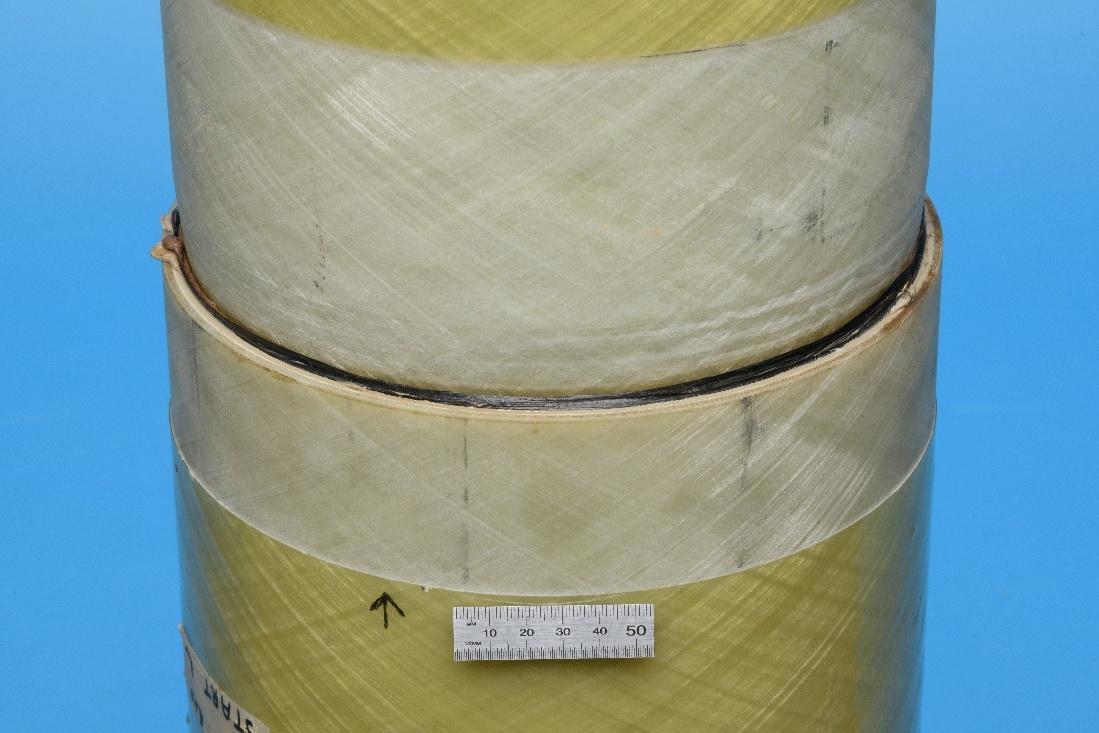

A Novel Approach To Joining in Non-Metallic Pipe Systems by TWI Ltd

Our innovation is to use ‘plastic welding’ to join thermoset composite pipes;improving the reliability of the joints compared to conventional adhesively bonded solutions. Of course, this is impossible as only thermoplastic composites can be truly welded. However, by coating each thermoset composite part with a layer of thermoplastic polymer these two polymer-coated parts can be joined using a conventional polymer welding approach. This has been tried in the past by modifying the surface or surface layers of the thermoset composite materials, adding thermoplastic fibres, using toughened epoxy systems etc, and whereas this approach has shown some potential to join advanced aerospace carbon composites it is unsuitable for joining glass reinforced thermoset resin (RTR) pipes for the oil and gas industry.

Our innovative joining process ‘W-RTR’ combines two welding techniques: induction welding (IW) and rotary friction welding (RFW). Induction welding is a relatively established technique, but the cutting-edge technology responsible for the uniqueness of this innovation is the adaption of the rotary friction welding process to join non-metallic materials.

The success of this innovation depended on being able to establish the correct friction welding process parameters to yield a strong joint between the thermoset and thermoplastic, with fibres crossing and reinforcing the interface, while at the same time ensuring that there was no significant thermal damage to the epoxy matrix. This was a serious challenge, as during the joining process the molten thermoplastic (at 450°C) was in contact with and epoxy resin that was uncomfortable at anything above 180°C.

More Information

Supplementary Presentation (run slide show to view animation)

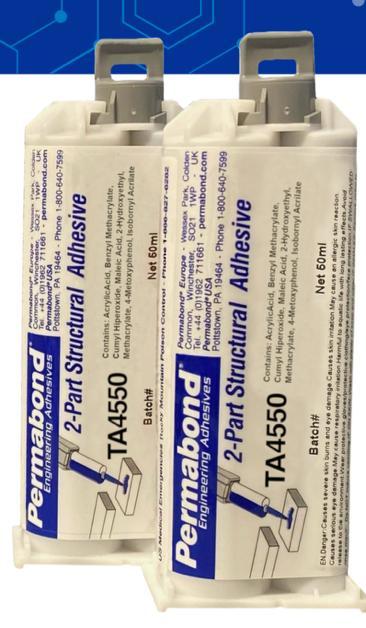

Permabond TA4550 - Nylon Bonding Adhesive by Permabond Engineering Adhesives Ltd

Permabond TA4550 is an acrylic adhesive that has been specifically developed for the structural bonding of nylon (polyamide / PA) 6, 6.6 & 12 without the need for primers or surface treatments. It has a non-slump rheology and cures at room temperature, making it ideal for vertical and large-scale applications, as it is easy to dispense and then align parts.

Capable of bonding other plastics as well as composites and metals, this adhesive’s high level of toughening creates outstanding resistance to impact and vibrations as well as performing well for peel and shear strength. TA4550 is non-flammable and therefore easy to ship and store, plus it has the added benefit of being a low-odour formulation, meaning it is ideal for increased worker comfort and high-end finishing.

This breakthrough product from Permabond has overcome some of the inherent challenges that working with nylon presents, such as its hydrophobic nature and low chemical reactivity causing a reduction in typical adhesive effectiveness. TA4550 provides superior strength performance over other market offerings - demonstrating this capability is data showing the nylon failing before the bond! (Please see supporting literature)

We don’t need to tell the BPF what types of industries use Nylon, we’re sure you already know plenty about your members and the types of plastics they use. We would, however, happily recommend this adhesive for use in Aerospace, 3D Printing, Automotive, Defence, EV Battery packs, and electronic applications, to name but a few.

Watch Video. (20m 39s)

The NonCrete™ Bio-Polymer Bollard by Traffic Mangement Products Ltd

The NonCrete™ bollard, developed by Traffic Management Products Ltd (TMP), redefines how we think about street furniture. Traditionally made from concrete, bollards are heavy, carbon-intensive, and difficult to recycle. NonCrete™ changes that.

Made from a plant-based sugar cane bio-polymer, NonCrete™ is lightweight (just 3.5 kg), 100% recyclable, and carries a negative carbon score of -1.0 kg CO₂e/kg - compared to concrete’s +8.6 kg CO₂e/kg. This dramatic reduction in embedded carbon represents a genuine opportunity for highways teams to make measurable progress towards sustainability targets.

Despite the material change, NonCrete™ delivers the same visual appearance, durability, and performance as its concrete equivalent, meeting highways standards and fitting seamlessly into existing infrastructure. It’s also compatible with retention sockets, enabling safer, faster, and more efficient installations - while reducing strain on operatives.

The product has already been successfully trialled with Hampshire County Council and Milestone Infrastructure, and is now in use on UK roads. It was recognised with a Green Apple Environment Award for ‘Helping the Environment’ and was recently featured in Construction Industry News Magazine.

NonCrete™ is a practical, scalable example of low-carbon innovation in the public realm. It combines smart material science with everyday functionality - bringing environmental, operational, and societal benefits to local authorities across the UK.

This isn’t a concept. It’s a solution that’s already making a difference.

More Information

https://tmp.solutions/the-noncrete-bio-polymer-bollard-wins-at-green-appleenvironment-awards/

https://tmp.solutions/tmps-noncrete-bio-polymer-bollard-featured-by-constructionindustry-news-magazine/

Mi240 Hydraulic: Driving Down Costs, Accelerating Sustainability by M&I Materials

Our submission for the BPF Horners Award for Plastics Innovation and Design 2025, is Mi240 HYDRAULIC saturated synthetic ester hydraulic fluid – a readily biodegradable and non-hazardous fluid with proven capabilities to improve sustainable manufacturing processes and offer commercial advantages within the plastics industry.

It is a purpose designed advanced hydraulic fluid for plastic moulding, specifically high temperature injection and blow moulding systems. Mi240 HYDRAULIC has undergone extensive field trials for several years and thousands of operational hours. The fluid is proven to be compatible with a wide range of OEM moulding machines and is independently tested at Oil Analysis Laboratories on a regular basis, both for on-going trial purposes and new customer quality assessments.

Each trial revealed significant operational improvements compared to prior mineral oil alternatives. This is achieved through Mi240’s chemical base and formulation, which makes it naturally resistant to varnishing (oxidation) in hydraulic systems - a common problem experienced in the industry with mineral oil-based hydraulic fluids.

By mitigating varnish, early adopters using Mi240 HYDRAULIC reported:

• Reduced energy consumption of around 9%

• Significant reduction in fluid volume used long-term, reducing costs

• No fluid disposal or associated costs

• No unscheduled maintenance or off-line fluid filtration has been necessary

• No degradation of Mi240 HYDRAULIC in first trail machine from 2019 to today!

• ISO 4406 cleanliness level improve rather than degrade (common with mineral oils)

Mi240 HYDRAULIC is produced by M&I Materials Ltd, a UK company with a successful history in manufacturing and patenting advanced synthetic esters since the 1970s.

More Information

Short Video (24 seconds)

Independent Laboratory Testing – Mi240

Case Study (with White Horse Plastics)

SharpTek Technology by SharpTek

SharpTek Technology provides a revolutionary fully recyclable mono material tray designed to protect and cushion delicate berries without the use of glued absorbent pads. This advancement represents a major stride in sustainability, eradicating hundreds of tonnes of packaging from the supply chain and reflecting Sharpak’s dedication to the circular economy.

For decades, the berry industry has relied on glued pads to protect fragile fruits. However, these traditional solutions pose recycling challenges, as adhesives complicate the recycling process, and pads are not consistently recyclable. SharpTek revolutionises this approach with a mono material PET packaging solution that eliminates glued pads, boasting up to 80% recycled PET (rPET) content and full recyclability through kerbside collections.

Main Benefits:

• •Weight Reduction: SHARPTEK delivers a 17% weight reduction compared to the equivalent tray with an absorbent pad.

• •Packaging Unit Reduction: SHARPTEK eliminates glue and pads from the packaging.

• •Recyclability: SHARPTEK is used in mono-material trays and easily recycled through kerbside recycling.

• •Product Quality: SharpTek holds juices away from berries, maintaining product quality and helping to reduce food waste.

SharpTek is the culmination of years of meticulous development and rigorous testing. The primary technical challenge was crafting a soft base from mono material PET a typically rigid material that could replace the need for absorbent pads. Achieving a consistent, cushioning base involved significant innovations in tooling design and tray manufacturing processes. The result is a tray that meets all functional and recyclable criteria but is also 17% lighter than the current equivalent tray with an absorbent pad.

More Information

Collaborating With UK Grower WB Chambers To Bring Sharptek, Padless Berry Packaging To Retailer Shelves

Overview of Features

Weight Comparison of SharpTek vs Punnets with Pads of equivalent size

KOOLIQ®: Pioneering Innovation in Cold Chain Pharmaceutical Logistics by Engineered Foam Products

KOOLIQ® solves these challenges with a new generation of reusable expanded polystyrene (EPS) shippers, combining high thermal performance with a simplified enduser model. Developed and manufactured in the UK, KOOLIQ® is precision-designed to delivering up to 96 hours of thermal protection with KOOLIQ® XD and 48 hours with the Standard version against industry recognised ISTA 7D thermal stress profiles.

What makes KOOLIQ® unique is its operational efficiency, with world class payload efficiency both product thermal performance levels share the same external and internal geometry, coolant types, and packing method. This standardisation reduces warehouse complexity, training requirements, and pallet load variation, simplifying logistics and lowering emissions.

Addressing the industries growing demand for reusable packaging, KOOLIQ® eliminates costly and rigid service agreements, enabling customers to self-manage, requalify and reuse the shippers without unnecessary overheads and added transport emissions of sending shippers to external facilities for requalification.

Made from expanded polystyrene (EPS), KOOLIQ® offers outstanding thermal insulation with a polymer that’s 98% air, lightweight, durable, and fully recyclable. EPS is proven in temperature-sensitive industries like food, pharmaceutical distribution and HVAC, providing sustainable and affordable insulation systems.

With a clear focus on sustainability, affordability, and ease of use, KOOLIQ® represents a new way for pharmaceutical supply chains to manage cold chain packaging.

More Information

Video Overview (2m 46s)

KOOLIQ® Comparions

TyfuClir Grow Tray by Green Up Farm Limited

The TyfuClir Grow Tray is an innovative reusable and sustainable grow tray. It is made from recycled PET clear plastic;it has been uniquely designed to grow deliciously healthy Microgreens & Micro Herbs. The tray has slits instead of holes to help prevent overwatering, it is highly durable and easy to clean, meaning it can reuse year after year.

Over the past year we have been on an incredible journey discovering the life cycle of plastics here in the UK. Supported by the Applied Research for Circular Solutions at Swansea University our tray has been designed for reuse which supports our closed-loop recycling scheme. The tray will be used with our own supply chain but also available to other commercial growers so that they too can set up their return & reuse scheme.

Our aim is to disrupt the horticultural sector UK and beyond, growing in clear RPET plastic is not only a benefit for crop health but also for the environment. We hope to influence other growers to move away from PLA plastics and single use to embrace reuse.

Our trays after use can be donated to friends, schools and local growing projects, helping to spread the joy of growing delicious microgreens while protecting the planet.

Over the past year I have spoken with many horticulturalists asking them why do we grow in black or coloured plastics? The answer is always I don’t know we just have. It is time to change this and to embrace reuse.

The Wray Cup – A Sustainable Evolution of an Iconic Design by Great Central Plastics Ltd

The Wray Cup is a reusable, injection-moulded drinking vessel created for Harr + Bass and their client Wray & Nephew, designed to replicate the iconic look of the brand’s disposable paper cups. With over 200,000 paper units previously produced, growing pressure from the on-trade sector for a sustainable alternative sparked the innovation.

The challenge was to retain the exact visual character of the original including a deliberately distressed print while transforming it into a durable, reusable product. Great Central Plastics (GCP) provided a full end-to-end solution using UK-based expertise in sustainable injection moulding and toolmaking.

Our in-house team reverse-engineered the paper cup to develop a bespoke tool that could accurately recreate its texture and shape, while being optimised for scale and repeatability. The final product is manufactured using a custom material blend of LIMEX and BDP biodegradable, lower-impact alternatives that maintain a premium feel. These materials were sourced through LXD and selected for their sustainability, durability, and aesthetic quality.

Working collaboratively, GCP overcame complex print reproduction challenges, successfully applying the original graphics onto the new surface. The result is a commercially viable product that stays true to brand identity while significantly reducing environmental impact.

10,000 Wray Cups have now been produced, replacing single-use alternatives and demonstrating how polymer innovation, design precision, and sustainability can align in UK manufacturing. The project is a compelling example of how collaboration and material science can drive forward eco-conscious product design.

2 in 1 Insulated Beehive for Breeding and Queen Rearing by BS Honey Bees Ltd

This innovative beekeeping product is a 2 in 1 insulated hive used for breeding small honey bee colonies ("nucs") and rearing queen bees both vital to maintaining healthy pollinator populations in the UK.

Manufactured in the UK from high-density Expanded Polystyrene (EPS) at 120g/l, it offers excellent insulation to protect bees from extreme temperatures, helping colonies thrive through both cold winters and hot summers. EPS is lightweight yet robust, making the hive easy to handle, long-lasting, and fully recyclable at end of life.

The clever dual-chamber design allows beekeepers to house two separate colonies in one compact unit, or remove the central divider to create a larger single hive. This spacesaving flexibility improves efficiency and reduces equipment costs, especially important for small-scale and commercial beekeepers alike.

Designed by beekeepers for beekeepers, it features practical touches such as separate coloured entrances and integrated feeder compartments offering everything needed to manage bees effectively in one durable product.

This British-made hive combines responsible plastic use with modern functionality and has already sold over 28,000 units, becoming a staple in UK beekeeping. It’s a practical, sustainable solution that supports food security by helping beekeepers rear strong colonies and high-quality queen bees.

https://bshoneybees.co.uk/products/national-2-in-1-poly-nuc-box

Waste free chemical recycling of polyester plastic waste by Ionicycle

During my PhD at Imperial College London, I have spent the last 4-years developing a process for waste-free chemical recycling of polyester plastic waste, using low-cost ionic liquids to break the polyester down into it's monomer building blocks and recovering the monomers without generating additional chemical waste. Thus, the recovered monomers can be purified and recycled to prepare new ‘virgin’ quality plastics without relying on fossil-fuel resources for monomer feedstocks and closing the loop on the plastic life-cycle, preventing plastic waste from polluting the environment.

Due to the successful demonstration that this technology is feasible at lab-scale, we have filed a patent application and the invention is currently patent-pending. Following this, our goal is to transform this innovative research into an impactful commercial venture. We are currently carrying out market research and seeking funding opportunities so that we can grow our team and continue to develop the technology such that it can one day be adopted at large-scale.

The patent-pending status of this work highlights its commercial potential, especially as interest in advanced recycling technologies grows in response to the increasing demands to incorporate more recycled content into plastic products due to new plastic regulations. Plastic pollution is one of the greatest challenges that humanity must face in the coming years, and this technology provides a novel solution to a global problem.

Kelpy Bone by Plastek UK Ltd

The Kelpy Bone offers the performance and longevity of plastic dog toys but is moulded from 100% natural, biodegradeable Notpla Rigid.

Notpla Rigid is a highly-innovative material pioneered in the UK. Created from sustainable, natural seaweed, it has remarkable physical properties allowing it to be used in many different formats, initially to develop alternatives to cardboard and plastic single-use packaging such as take-away food containers.

In 2024 Plastek UK’s engineers achieved a global first by producing successful injection mouldings using Notpla Rigid, guiding the company’s materials scientists to modify their formulation (still using natural ingredients) to create the Pentaward-winning, seaweed-based, biodegradable Chip Fork.

Building on this success, Plastek UK has produced injection moulding tooling for another mass-market product with considerable potential for beneficial environmental impact. The customer, although based in Australia has enlisted Plastek UK as their chosen manufacturer due to our successes

Traditionally, dog toys are destroyed quickly (requiring continual replacement and therefore bearing the carbon footprint of continual remanufacture and transport). Nylon toys have much greater longevity, but when discarded or lost can take 50 years or more to decay, depositing plastic particles into the ground as they go.

The skills of Plastek’s technical development team have allowed the creation of the Kelpy Bone - a high-performance product with excellent structural integrity (to keep that essential dog-bone shape!) and longevity, but with the ability to disappear into the earth leaving ZERO harmful trace, made from 100% Notpla Rigid, using injection moulding. Safe for dogs, safe for the planet!

Wells Performance - PFAS Free Process Aid by Wells Performance Materials Ltd

PFAS Materials are a class of materials which are Poly-and Perfluoroalkyl Substances, as a material set, are currently undergoing a regulatory review in a number of constituencies, primarily the EU, UK and US. They are used in thousands of applications and there are some applications within the polymer industry. It is advantageous to formulate away from these materials, however finding suitable solutions or alternative chemistries is extremely difficult due to the intrinsic properties of the PFAS materials.

The compounding behaviour and PPA performance was first characterised on a laboratory scale both at Wells PM and at a University laboratory, which enabled a refinement of the potential material candidates to be chosen for further evaluation. Then a more detailed review for performance with regards to processing characteristics (melt pressure, energy usage) and performance such as melt fracture elimination (time and additive concentration requirements) on a larger pilot scale film tower.

This work led to a further refinement of candidate materials, which were assessed for commercial scale masterbatch production and evaluation on commercial equipment in various film extrusion techniques, before the launch of commercial products. So far, we have received significant commercial interest and a number of customers both in the UK and Europe have approved the Wells PM masterbatches as alternatives to existing PFAS containing products and commercial quantities have now been supplied.

The development work continues to offer a broad range of PFAS free solutions for the industry.

More Information

Wells Performance Materials PFAS and PPWR Regulatory Statement - Wells Performance Materials

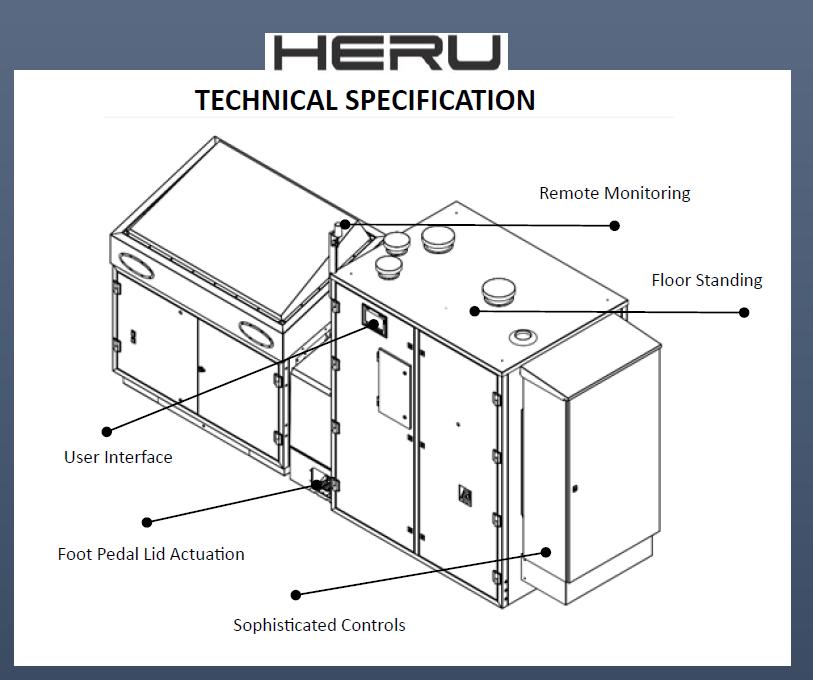

HERU the Hybrid Water Heating Device that eliminates plastic waste by HERU Technologies Ltd

HERU (Hybrid Energy Resource Unit) is a unique, innovative water heating device for business, homes and organisations with global patents granted.

The HERU (located where your wheelie bins used to sit) receives the 91% of plastic that cannot be recycled, uneaten food, nappies, garden trimmings, contaminated paper and card and turns this material in to a valuable energy source providing hot water for the property. The HERU produces twice as much energy as it uses by releasing the 8 meja joules of energy within the resources currently discarded as ‘waste’ whilst significantly reducing global warming gasses produced by the waste industry by up to 2 tonnes per home per year when powered by renewables (Ricardo life Assessment located on HERU Home Page) whilst reducing the 227 million tonnes of plastic waste causing pollution. Only metal, glass and ceramics to be collected for recycling.

The HERU has been designed in 3 receptacle sizes to suit its environment. 35, 125 and 250 litres. The heat pipe is designed for volume production with1 required for the 35, 3 for the 125 and 6 for the 250.

The HERU is a modular design for easy install to a pre prepared location in a day and pays the energy created directly to the hot water system up to 60°C via a thermal store (in the same way as other renewable energy sources)

Easy to use with a HMI screen and SCADA for the engineers to access remotely to provide support for our clients.

See website: www.myheru.com More information: Video Link – Click Here

More information and video about collaboration with Siemens

125G Specification Sheet - Draft V 2.0

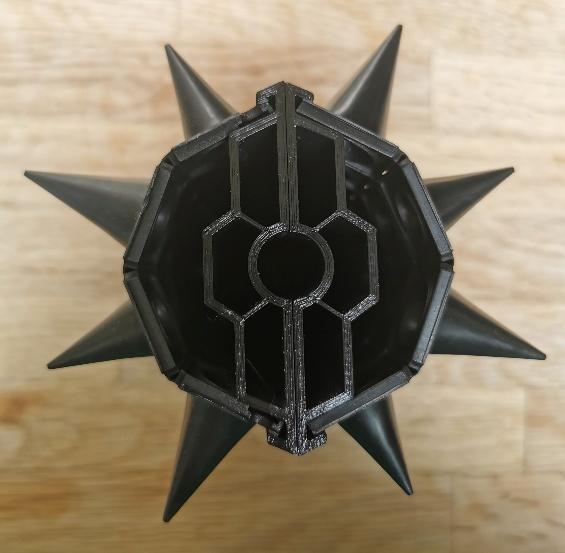

Condale Plastics x DefendaStrip® – Innovation in AntiClimb Protection by

PRG Communications

Born from a real-world safety concern, the Rise and the Spin anti-climb barriers were developed to address a tragic incident involving an unprotected pipeline crossing. Under HSE pressure, utility companies urgently needed cost-effective, easy-to-install deterrents to protect exposed infrastructure. DefendaStrip® identified this gap and set out to evolve their original flexible strip into a robust, modular system, turning to Condale Plastics to help realise that vision.

Condale Plastics engineered a bespoke extruded base profile that could securely house the existing Flex product while enhancing performance and versatility. Designed and manufactured in the UK using recycled ABS, the extrusion features a unique honeycomb structure, offering lightweight rigidity with minimal material use, optimising both sustainability and cost.

The resulting products, the Rise, a static barrier, and the Spin, a rotating deterrent, share a common profile, enabling a first-of-its-kind mix-and-match system to protect a wide range of boundary surfaces. Together, they mark a significant advance in scalable, adaptable perimeter protection.

This collaboration involved multiple design iterations, custom tooling and creative problemsolving, including subtle geometric changes to overcome complex tolerance issues. With both products now in production and trials underway with Network Rail, the innovation is already gaining traction in sectors with critical security needs.

By turning a bespoke safety response into a commercial, sustainable and technically ambitious product range, Condale Plastics and DefendaStrip have set a new benchmark for UK-based polymer innovation.

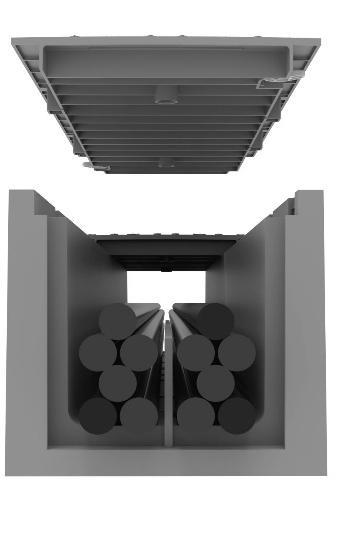

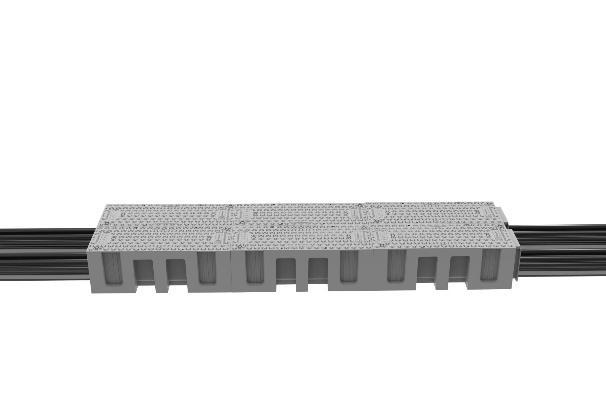

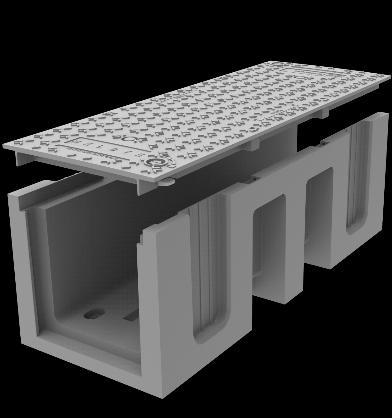

PROtrough 350: Reinventing Cable Protection with Polymer Innovation by Cubis Systems

The PROtrough 350 from Cubis Systems is a cutting-edge, UK-manufactured cable trough system that redefines performance in polymer-based infrastructure design.

Manufactured using flame-retardant, UV-stable Glass Reinforced Polyester Resin (GRP), the PROtrough 350 offers a lightweight yet highly durable solution for cable protection across transport, energy, and utility sectors. With a market-leading internal capacity of 310mm, it allows for greater cable volume within a compact footprint reducing the need for additional civil works.

Designed with installation efficiency in mind, its modular interlocking units are manually handleable, eliminating heavy plant and improving on-site safety. Its integrated dual walkable lid system supports operational access and personnel safety during maintenance. An enhanced locking mechanism and end-to-end interlocking joints improve system integrity and resilience once installed.

The environmental advantages are equally significant. Compared to traditional concrete systems, PROtrough 350 achieves up to 80.7% carbon reduction, supporting major infrastructure clients in meeting Net Zero goals. Reusability, recyclability, and localised UK manufacture further reduce embodied emissions and transport impact.

Already adopted in major rail and road schemes, the product demonstrates strong commercial uptake and has rapidly expanded Cubis’ reach within the sustainable cable management space.

With its polymer innovation, clear environmental benefits, and high UK content across design, manufacturing, and supply chain, the PROtrough 350 exemplifies the design excellence this award celebrates.

More information:

https://www.cubis-systems.com/uk/products/cable-protection/cable-trough/protrough-350/ https://www.cubis-systems.com/uk/news-and-events/2025/june/introducing-the-protrough350/

Watch Video- Click Here

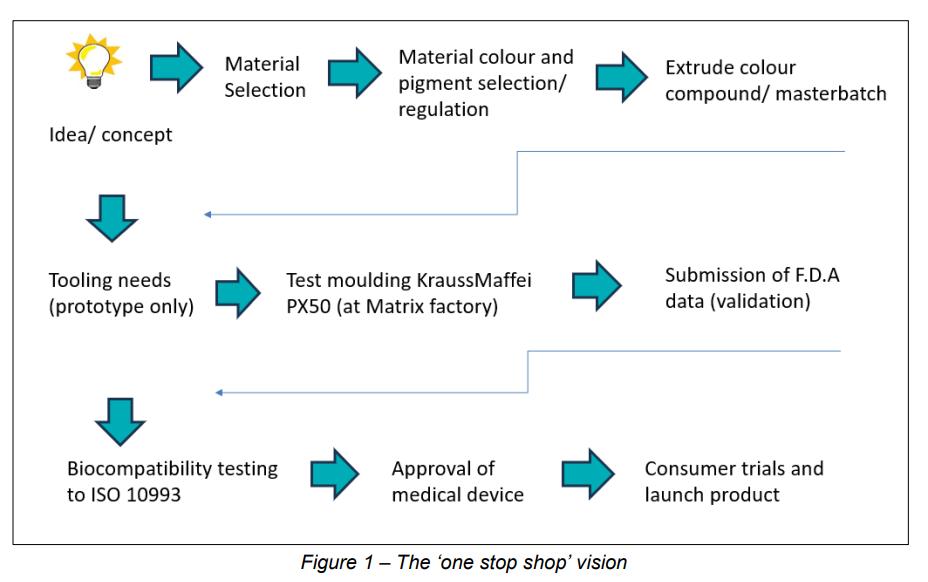

KraussMaffei partnership with Matrix Plastics for Sustainable product development by krauss maffei

This document clearly demonstrates a partnership between Material Manufacturer Matrix and KraussMaffei with furthering their investment into renewable and sustainable ventures whilst at the same time increasing customer trials for more sustainable solutions and local employment.

Example of text from document

“Investment Success

This investment meant we were able to offer a ‘one stop’ solution for designers and innovators to develop the next generation of medical devices.

It gave Matrix Plastics the ability to produce parts that enabled the customer to develop their new product all under one roof and in a cleanroom facility achieving particle counts down to ISO Class 7 standards. Initially, we used our diverse sets of skills and knowledge working with established customers and concentrating on the UK and Ireland’s Medtech sector. To be able to provide this service, we established Matrix Medical Materials and set about setting up a fully compliant facility to meet the rigorous needs of our medical customers. In November 2023, we received ISO 13485:2016 (see appendix 2) that demonstrates we were able to provide medical devices and related services that would consistently meet customer and applicable regulatory requirements. This meant Matrix Medical Materials was the UK's first 'cleanroom' plastic compounding facility with a sterile manufacturing environment and impeccable hygiene standards. This enabled us to become the medical compounding partner of choice for many manufacturers and OEMs across Europe. Nigel Batt stated "We know that quality and compliance is imperative when manufacturing medical devices, and so securing this ISO certification is a fantastic achievement for our medical compounding business. In addition to this new certification we have gained, we're proud to add to our medical compounding quality standards by ensuring that all medical products are processed and tested according to ISO Class 9 cleanroom regulations and all ingredients used on site in the production of medical products meet the requirements of ISO 10993-1:2018 and USP Class VI." We were then able to offer our customers a unique service as detailed in figure 1 below”

Entries

Maison Guerlain Aqua Allegoria by Amcor

The bottle for the Maison Guerlain Aqua Allegoria hand creams demonstrates how the availability of a premium recycled polymer, which can match the characteristics of virgin material, is able to reconcile what were once considered the opposing requirements of luxury and sustainability.

The hand creams contain over 97% natural-origin ingredients (In accordance with the ISO 16128, calculation including water). The packaging had to be consistent with the brand’s premium identity, while demonstrating Maison Guerlain’s ongoing commitment to the planet.

CleanStream® technology provides a closed-loop system that mechanically recycles household polypropylene (PP) waste into high-purity recycled plastic suitable for contactsensitive applications. The process goes beyond simple material-based sorting by employing multiple AI-driven sorting steps, including automated identification, sorting and decontamination, to achieve high polymer purity.

This allows the recycled polymer to be included in the Aqua Allegoria bottle with no compromise on the performance of the pack in terms of its aesthetics, product protection, or functionality. Each bottle includes around 30% CleanStream®.

The bottle’s eye-catching design is inspired by the hexagonal shape of a honeycomb, reflecting the bee which has been the emblem of Maison Guerlain since 1853. It is produced in PP in a choice of three colours, and its multilayer construction protects and maintains the quality and effectiveness of the creams. The bottle is screen printed, and both it and the cap are finished with a matt colourless varnish. Because it is produced solely in PP, the bottle can be recycled where the appropriate recycling infrastructure is in place

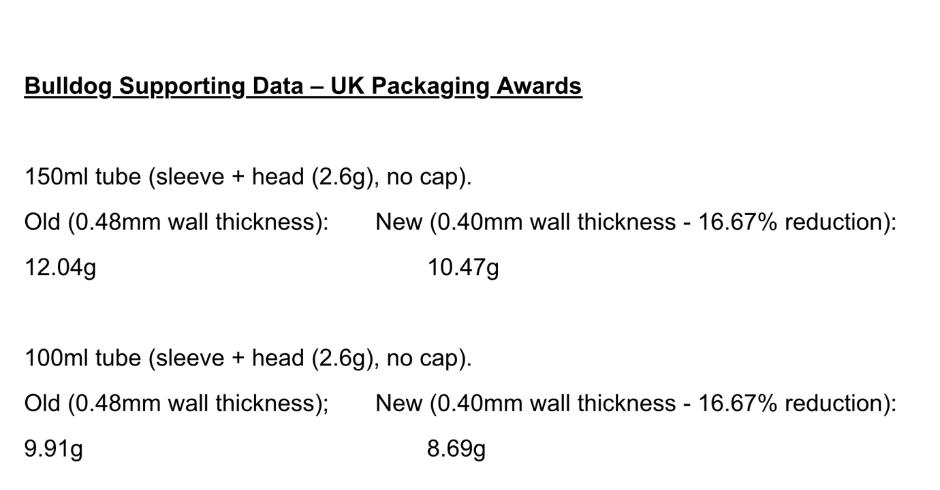

Lightweight of flexible tube for Bulldog by Amcor

The latest iteration of Bulldog’s 100 ml and 150 ml flexible tubes demonstrates how material innovation and design optimisation can deliver measurable sustainability gains without sacrificing performance, aesthetics or production efficiency.

Developed in close collaboration with Amcor, the tube sleeve incorporates a 16.67% reduction in wall thickness, delivering a material saving of approximately 8.5 metric tonnes of plastic annually. This lightweighting approach was carefully validated through extensive in-house testing to confirm durability, leak resistance and high print quality, ensuring a reliable, high-impact pack that retains the consumer experience expected of the Bulldog brand.

The tubes also contain over 62% post-consumer recycled (PCR) content throughout the entire assembly, thereby significantly reducing the reliance on virgin plastics. Importantly, the cap and shoulder components remain unchanged, facilitating seamless integration into existing filling lines and ensuring operational continuity.

The inclusion of sugarcane-derived biopolymer, sourced from certified renewable feedstock, contributes to reduced CO₂ emissions and supports Bulldog’s broader environmental goals. The mono-material structure, made entirely from HDPE, is recyclable via standard kerbside collection where infrastructure permits.

Compact and efficient to transport, the tube’s design further supports logistical sustainability. This pack exemplifies how responsible design and proven materials can deliver credible circular solutions for the personal care sector

ReBorn - UK-made, circular homewares by Reborn Homewares Ltd

Housewares is a huge category – worth £7 billion a year in the UK alone. However, most items are made from virgin materials in the Far East. Moreover they are typically nonrepairable or recyclable at end of life, so ultimately end in landfill.

ReBorn is a breakthrough in sustainable design and manufacturing, producing stylish homewares, all in Wiltshire - entirely from recycled plastic waste collected and sorted by Biffa. Every product is designed for circularity avoiding over-moulding and other multimaterial techniques to ensure they remain fully recyclable. Any damaged items and customer returns are reprocessed in-house, allowing them to be ReBorn again and again.

ReBorn eliminates the need for virgin plastics, international shipping and landfill at end of life. Independent lifecycle analysis by Brunel University London confirms a 79% reduction in carbon emissions compared to equivalent products made from virgin materials in the Far East.

Since launch in September 2023, ReBorn has saved 27 tonnes of plastic from landfill and prevented 450 tonnes of CO₂e emissions. With over 56,000 units sold, the range has rapidly gained commercial traction. ReBorn is now available in all John Lewis stores nationwide, generating over £17,000 in weekly sales. The range has also launched in NEXT, Dunelm, B&Q, Leekes & more: proving strong consumer demand for sustainable innovation.

ReBorn combines advanced material reuse, intelligent product design, and scalable UK manufacturing to deliver a real-world circular solution. ReBorn sets a new standard for how sustainable, closed-loop products can succeed in the mainstream market.

Foamo Coffee Cup- Redefining Reusable by First Editions Ltd

Foamo is a pioneering reusable coffee cup that redefines plastic packaging for the modern, sustainability-conscious consumer. Co-developed by First Editions Ltd and Bockatech (both previous Bottlemaker Award recipients), Foamo builds on next generation Eco-Core™ foaming technology to create a retail-quality cup with 50% less plastic and best-in-class thermal insulation.

What sets Foamo apart is its engineering-led design. First Editions developed a unique selective foaming technology which allows a non-foamed threaded core to be moulded within the body, making it the first Eco-Core™ product with a secure, screw-on lid. This innovation directly addresses the number one consumer requirement for reusable cups: leak prevention. The result is a product that performs, lasts, and feels at home in both retail and promotional environments.

Made entirely in the UK at Tyseley Energy Park using all-electric moulding machines powered by renewable energy, Foamo exemplifies local, low-impact manufacturing. It’s dishwasher safe, durable, and moulded from a plant-based monomaterial polypropyleneboth lid and body - ensuring recyclability at end of life.

An independent LCA confirms that Foamo emits just 5% of the carbon emissions of a standard double-walled reusable cup. Since its launch, Foamo has gained early commercial traction, particularly among eco-conscious brands and organisations looking to align their merchandise strategies with net zero commitments. With branding and education at its core, the Foamo range is not only viable at scale but positioned to lead the transition toward meaningful reuse in the beverage packaging market.

PPFTG Reusable Food to Go Plastic Packaging by Loughborough University

Our design is a first. A reusable food-to-go plastic packaging solution;from filling and sealing with recyclable plastic film, to customer purchase and consumption, then washing and re-filling to repeat the cycle.

Setting our packaging apart is its thermoformed manufacture from rPET, a more lightweight and less energy intensive solution than existing reusable injection moulded containers. Through intelligent design consideration, rPET sheet is used but at a higher gauge than existing single-use thermoformed trays and engineered to reduce residual thermal stresses. Manufactured on existing lines, a direct swap can be made from producing single-use to reusable packs, with minimal disruption.

We have proven it capable of being washed and subjected to rigorous performance testing with no negative impact to its structure or material, vitally staying within food safety standards for cleaning quality assurance. If reused just 10 times up to 90% of food-to-go plastic packaging waste could be avoided.

We have provided an innovative strategy for diversifying from single-use to reusable packaging manufacture;ultimately reducing material usage, decreasing plastics going to landfill, minimising plastic packaging tax and CAPEX costs for manufacturers, whilst keeping highly trained manufacturing personnel employed in the UK plastics industry.

It is one result of the Perpetual Plastic for Food to Go project led by Loughborough University, in collaboration with Klöckner Pentaplast and partners from across the UK foodto-go supply chain, supported by UK Research & Innovation's Smart Sustainable Plastic Packaging Challenge.

Additional details can be viewed on the PPFTG project website: ppftg.wordpress.com