March • April •May Issue 27 Spring 2023 ISSN 2398-2489 Plus all the latest pr oducts & ser vices news fr om the UK drinks industr y’s suppl y chain PREVIEW SHOWC ASE In The Mix BeerX 2023 The Products & Services Magazine for the UK’s Drinks Production Industry Incorporating

Brewing & Beverage Industries Business is a quarterly ‘Supply Chain’ magazine targeting the UK drinks production industry. If your company supplies products and services to brewers, distillers, cider makers, etc, then this is the platform for you

Subscription is free and printed copies are mailed out throughout Great Britain and Northern Ireland If you are one of the very few UK brewers, distillers, or cider manufacturers, not receiving a regular copy, then please contact us today

ALWAYS IN PRINT & ONLINE - Now into

WHO WE ARE

Chris Freer

Digital Editor

Simon Butler

For editorial or advertising enquiries, call the Editor on 0115 8 549 349 or e-mail: chris@brewingbusiness co uk

WHO WRITES FOR U S

RUTH EVANS MBE

Ruth is CEO of BFBi, whose membership represents the supply chain for the brewing and beverage industries

JULIAN GROCOCK

Julian Grocock is a former chief executive of SIBA with extensive experience in beer, brewery and pub politics

ALAN POWELL

Alan Powell is a specialist excise duties consultant, who heads up the British Distillers Alliance.

Members of

Whilst every effort is made to ensure that the information in this publication is accurate and up-to-date, freerbutler limited does not take any responsibility for errors or omissions Opinions expressed in editorial contributions to this publication are those of their respective authors and not necessarily shared by freerbutler limited © freerbutler limited 2023

We are delighted to be the new home of News from the Brewing, Food & Beverage Industr y Suppliers Association 5 freerbutler limited is a Supplier Associate member of WELCOME TO Published by freerbutler limited PO Box 9666 • Nottingham • NG10 9BY United Kingdom Tel: 0115 8 549 349 brewingbusiness.co.uk Our print circulation is audited and certified Representing the entire value chain supplying the Brewing, Food & Beverage Industry Brewing & Beverage Industries Business magazine is an independent publication delighted to be a MEDIA PARTNER to All rights reserved No part of this publication may be stored in a retrieval system or transmitted in any form or by any other means, electronic or mechanical, photocopying, recording or otherwise,

of

without the prior permission

freerbutler limited

Products & Services Magazine

the UK Drinks Production Industry

The

for

ISSN 2398-2489

our

7th year! Magazine Editor

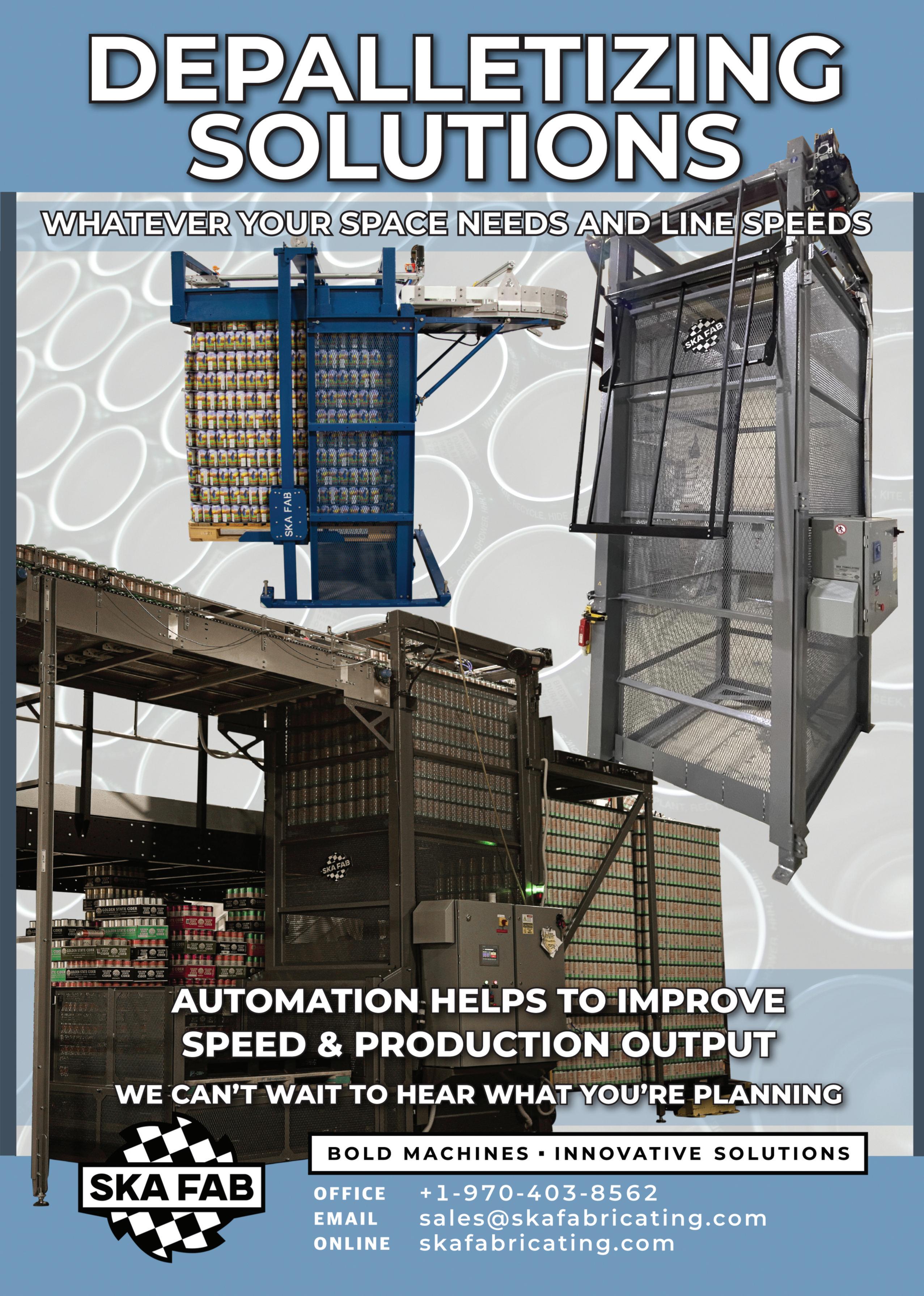

Cover illustration - Courtesy of SKA Fabricating

Word from the BFBi

Welcome to 2023!!

A new year, with new energy to address the existing and new opportunities and challenges. A new yet not so new New Year Resolution – to match the expectation of our members and industry.

BFBi took part in a global Association survey late last year, comprising input from 51 trade associations across the world and 12,700 respondents The outcome of the survey was not surprising but it did endorse what Associations (we) know they need to do to remain engaged with their members:

• Associations must leverage technology solutions like AI to ease access and help tailor communications and content to meet audience needs and expectations

It is no longer about virtual vs. in-person - it is about the right channel, for the right activity Access to products and programmes that meet members’ needs and interests, be that committee meetings, task forces and special interest groups

• Retired (aged 70+), and most likely honorary members, showed a higher relationship strength The older a member is, the more likely he/she is to recommend; the younger the member, the least likely. To be future-proof, we must consider the interests, preferred style of engagement and ease of access desired by younger, working members of the community

We NEED to better understand what drives and motivates Millennials and Gen Z to secure their involvement, active engagement, and brand loyalty.

Relevance of content is vital Fostering innovation and ease of access to products/programmes and content are key drivers.

• For all age groups, the survey clearly shows that associations must improve the personalisation and

customisation of their members’ and customers’ experience and access. Members want easy access to benefits and services that correspond to “my or my company’s needs”

A deep dive into performance engagement showed that only 21% of 12,700 respondents felt their trade associations “excellent” at providing benefits and services that meet “my needs” Or, in the case of trade associations, less than one quarter (24%) consider their association “excellent” in representing “my company’s interests.”

Conversely reputation and subject matter expertise rank highly – with more than half of the respondents awarding excellence to their association’s reputation

So, that is the market research and jargon To put it bluntly, a trade association cannot rely on reputation alone and the quicker and more easily a member can access the benefits, products and programmes that are relevant “to him/her/they”, the more the member or customer will likely engage and the more he/she/they will become an advocate

In order to remain relevant we need to:

• Review our engagement strategies against this benchmark

• Build on the agility, ways of working, and connectivity implemented during the pandemic

• Develop specific engagement

Gen Z

• Be sure to offer choice and multiple channels – both offline and online

• Involve young professionals in designing future strategy and relevance

• Leverage technology (data, help customise (personalise) members’ access to content, programmes etc

• Adapt in line with members’ evolving needs and preferences

That job starts now But, it can only be successful with your input and help

Ruth Evans MBE, BFBi C.E.O.

Established in 1907, BFBi’s membership represents the entire value chain supplying the brewing and beverage industry – from seed geneticists through raw materials, brewhouse and process equipment to dispense, point-of-sale and brewers/distillers. The Association’s objective is to be the foremost trade association providing opportunities for its Members to develop within the brewing, food & beverage industry

As well as offering many benefits and services to suppliers of raw materials, process and packaging machinery, dispense and point of sale products, BFBi is a Trade Challenge Partner for various overseas exhibitions and owner and organiser of the oldest international brewing and cider Awards in the world

6

Ruth Evans MBE

Photo by Gerardo Jaconelli

BFBi

SEE PAGE 66 FOR MORE INFO ON HOW TO JOIN

The View Through My Glass Bottom

Julian Grocock

Counting the Cost

Fifty years ago, I was a Leeds University undergraduate drinking the local beer Last weekend, I was a regular in my village local drinking the guest beer

Needless to say, these two experiences share precious little in common Except, of course, for my starring role – and the brand name of my chosen tipple… Tetley’s.

I know I have asserted an unequivocal intention never again to go near a pint of the imposter now masquerading as the love of my formative ale-swilling youth But please bear with me – this is not about either the subtleties of flavour variation or my inability to stick to my word

(And I will throw in this brief, bracketed and italicised note: there was a touch more familiarity about this latest alien incarnation It wasn’t proper Tetley’s, but it was a good pint, with definite hints of my old ‘Hunslet hero’ )

What I am asking you to think about – with further and extreme emphasis on the chasm between then and now – is price.

~

In my first year as a student, a pint of Tetley Bitter cost as little as 12p Half a century later, the Tetley’s Cask in the Nags Head is £4 30

I hear your derisive snort: Haven’t you heard of inflation, you bloody idiot?! So let’s add some context

I began a teaching career in 1976 By this time the price of a pint of bitter had of course risen Online research reveals a UK average of 23p – but in the Midlands and the North I was still paying around 20p. And my starting annual salary was about £4,000, which invites a moment of comparative analysis across the ages Today, government websites suggest a minimum secondary school starting salary of £28,000 – an inflationary factor of 7 from where I began. However, because my pub pint example has risen by a factor of 21, you might just be beginning to see why I’m drawing attention to this marked disparity

Based on these figures, three pints in the pub then cost 0.8 percent of a

week’s gross pay; now, that modest amount of leisure activity can consume 2 4 percent – three times as much And though I accept these selective statistics cannot automatically be applied comprehensively across the board, they are certainly accurate, relevant on a personal level, and likely to reflect a general broad truth Which prompts a question: where does that leave the social media debate I’ve recently encountered, which is taking the pub trade to task for trying to drive down beer input prices? ~

What really tasks me is the way financial hardship across the hospitality industry – from manufacture to supply to retail – is generating division between its constituent parts. The severe economic climate is forcing breweries and pubs out of business and, ironically, the close (some would say symbiotic) relationship between the two is pitting them against each other on the fundamental issue of core product cost

Yet, at the same time, we can still buy the small-pack versions of Tetley’s in supermarkets for less than £1/pint (£1 70/ltr) This is an on-/off-trade price differential that didn’t exist in my student days And it begs another question: to what extent is on-trade pricing being used to subsidise cheap off-trade booze?

You may well retort that such a scenario could only apply to the massive brewery conglomerates, and thus seek to exonerate the smallerscale craft industry from any complicity in such devious dealings Except that I’ve sounded off before in this column about craft bar

‘schooners’ retailing at well over a fiver (£8+/pint) – which is far more than the same beers cost on those take-home shelves A quick scan of the Tesco website finds craft beer pint-equivalent prices as low as £1 55, up to £4 85, with a median at around £2 50

~

Off-trade prices introduce a ‘Catch-22’ element, undermining any campaign for real unity across our beer-oriented and beer-loving hospitality sector. An evening out can be prohibitively expensive, and even I succumb to the temptation to buy cheaply and drink at home – sometimes when I’m writing articles seeking to bring together beer and pub champions

But the mounting pressures on the on trade mean the ‘Catch-22’ also works in the opposite direction, against those persisting with its exploitation As pubs are increasingly being priced into submission, the subsidy they provide is shrinking, which will inevitably force up prices in the off trade

The final – and biggest – question is: how many more pubs have to die first?

8

Julian Grocock

Julian Grocock is a former pub landlord, managing director of Tynemill/Castle Rock, and chief executive of SIBA.

Extensive experience in beer and pub politics, brewery and pubco operations, and on the front line in the pub trade...‘from cellar to ceiling’.

Showcasing the British spirit

Alan Powell

WOWGR and spirits duty stampstwo steps forward, one step back!

In to my previous column (Ding Dong the WOWGR’s dead) I reported on HMRC’s findings of their review of the Warehousekeepers and Owners of Warehoused Goods Regulations 1999 (WOWGR). Their preferred option is to repeal that law, with a target of this year (following an administrative and legal process). The problem is that in fact HMRC has not formally committed to the repeal of WOWGR without ministerial sign-off and, inter alia, resources being available to make the changes to the law which could now take effect next year

In a meeting with Policy officials this month (January 2023), I stated that if HMRC had discounted all other options in their review to amend WOWGR, there seemed no logic not to proceed with their preferred option Moreover, ministers may well have the final say but it would require some special insight by ministers to go against the findings of HMRC’s administrative staff and lawyers. Besides, the industry can, and will, be writing to the HMRC minister (Exchequer Secretary to the Treasury) to make the case that WOWGR never had any legitimacy, is disproportionate, discriminatory and in breach of retained (sensible) EU principles about there being no liability to duty of spirits or beer sitting safely and securely in an excise warehouse even if aspects of the WOWGR provisions had been breached. In summary, this would support HMRC’s preferred option Nothing else would make sense

Some warehousekeepers had expressed concern about having to carry out enhanced due diligence on owners of goods if registration of owners is repealed from the law, particularly in sales of spirits in cask I think this misses the point and is a red herring I see no difference whether beer and spirits are subject to WOWGR or not. An owner of spirits in warehouse may be WOWGR registered but that does not mean the standard due diligence condition is modified. The Due Diligence condition does not constitute tick box checks It is a risk-based “probability” process to identify risk of alcohol duty fraud in the specific supply chain and mitigate any risk identified, the process commencing with “discovering how the fraud occurs”, as the courts have told us In terms of cask sales,

say, there is not even a supply chain per se, so one has to assess if there is even a risk to mitigate Sensible and reasonable commercial due diligence augmented by excise duty fraud awareness would be a responsible approach to assess such fraud risk and whether there is any risk to be mitigated This is regardless of WOWGR registration of the owners of the goods (For comparison, wine is not even subject to the due diligence condition per se in the warehousing system (but is for AWRS))

To shortcut extended legal deliberations, I proposed that the simplest step would be an amending Statutory Instrument (SI) to WOWGR to retain the necessary warehousekeeper authorisation and registration and repeal the provisions pertaining to registration of owners and duty representatives. There is no need to change primary law (Part VIIIB of the Customs and Excise Management Act 1979). An amending SI would simply be laid to indicate the amendments to be made and by negative assent of the House This procedure happens all the time More on WOWGR as things develop, but in the meantime

HMRC review of the spirits duty stamps regime

In early December 2022, HMRC invited industry members to provide input to a questionnaire in connection with HMRC’s review into the efficacy and, indeed, need for the spirits duty stamps scheme as an anti-alcohol duty fraud measure HMRC acknowledged that this subject had been raised by respondents to the Call For Evidence exercise in 2020 in relation to the government’s Alcohol Duty Review

The British Distillers Alliance (BDA) is a non-profit making body which provides a professional service for independent and craft businesses in the spirits production industry and supply chain The BDA represents distillers, rectifiers and compounders and those in related sectors New members always welcome

(ADR) but it was felt better (and more appropriate) to treat this matter under parallel modernisation exercises being carried out by HMRC for alcohol excise duty I had, in fact, written to ministers in 2020 and 2021 to set out the case for repeal of spirits duty stamps as well as part of my in response to the ADR and for the British Distillers Alliance (BDA) Just as for the origin of WOWGR, HMCE erred in believing there was any statistically significant duty fraud in spirits after 1998 but rather than acknowledge they had erred, ploughed on with measures that have placed immense and pointless burdens upon the legitimate trade More recent problems have arisen with what has to be done by industry to comply with the law when re-cycling empty spirits retail containers that have been stamped and re-filled The response of members of the British Distillers Alliance to the consultation has been uniform in supporting repeal of the duty stamps legislation Such repeal could be achieved very simply by Parliament not carrying over the duty stamps provisions in the Alcoholic Liquor Duties Act 1979 when it is repealed to make way for the new Alcohol Act currently in the form of a Bill Phew!

Alan Powell

Alan Powell is a specialist excise duties consultant, formerly a Policy official within HMCE’s HQ teams. He is excise duties advisor to the Chartered Institute of Taxation, honorary advisor to the UK Warehousing Association and founded the British Distillers Alliance as a conduit for consultation with, and representation to, Government bodies and to assist and advise on technical matters.

10

www.britishdistillersalliance.com For further information:

Being staged at Liverpool Exhibition Centre from 15th-16th March 2023, BeerX is back once more. Over the following pages we give exhibitors an opportunity to let brewers, delegates and other visitors to the show, know a little of what they can expect to see and hear on their stands at the show

An 8th BeerX for Beer Box Shop, part of Drinks Packaging Ltd

It’s been a very busy year for us as we continue to develop all aspects of our business. We’re excited to meet new and old friends from the brewing industry at BeerX 2023 and have the opportunity to present and talk about our new products and services

The Drinks Packaging Ltd (DPL) side of our business is focused on high volume, high quality, low cost packaging solutions that range from auto-pack retail packaging, bottle trays, and trade boxes to bespoke shelf-ready packaging and shipping solutions, all supported by our in-house box design services

With our move to a new purpose-built 18,000 sq/ft warehouse last summer, we’re now providing customers with free storage for their bulk packaging orders, with immediate call off as and when needed

We’ve developed new Point-of-Sale and Free Standing Display Unit concepts for the DPL range and we’re looking forward to talking to customers about options that will help to ensure that their products are best represented in retail locations

Beer Box Shop has had a great year since BeerX 2022; we’ve relocated, grown our customer base and expanded our product range!

We’re continuing to provide our customers with a fast and efficient next day delivery service for our in-stock packaging range Our new warehouse has allowed us to hold more stock and accelerate the expansion of our range of trade, shipping and gift boxes We’ve also added Bag-in-Box solutions, liquid pouches, 750ml bottle packaging and some exciting new gift packaging concepts to our range!

All of our products are fully customisable

so customers can add their logos and branding, and we also provide highly competitive and comprehensive bespoke printing options

We’ll be displaying examples of our favourite gift box creations together with our new exciting packaging and point-ofsale concepts Come and see us at BeerX on Stand 166!

For further information:

Automated solutions from Vitikit on show

Vitikit is proud to be an official exhibitor of this year's BeerX UK exhibition which takes place from 15-16th March in Liverpool We are providers of the latest wine, cider, distilling and brewing equipment in the UK. At Vitikit, we are constantly adding new products to our range and also holding more and more items in stock to meet our customers' needs.

We are excited to demonstrate at the show:

Smart Analysis

SMART ANALYSIS is a portable, highly accurate and reliable enzyme analyser for the beverage industry. The system uses innovative, patented fibre-optic and LED source technologies, which makes Smart Analysis a compact and rugged

spectrophotometer that requires little to no maintenance It allows your brewery to have more control than ever before The system records all of the key parameters and implement a robust quality control regime to ensure the product is just as you wanted, time and time again

Automated Brewery Control System

Vitikit works with Fermecraft to create the best automated brewing solutions for breweries, distilleries and wineries to make the processes easier, more timeefficient and cost-effective We do this by using revolutionary industry 4 0 software, which utilises automation to ensure consistency and quality, with every batch, using an intelligent automated system that integrates everything into one user-friendly control point

Keg Washer

Vitikit installs and supplies keg washers up to 30 kegs/hour The BiboKeg series of keg washers are built to meet our

customer's needs of washing and cleaning kegs with 1-2- or 3-stations

The machine is made of 304 stainless steel and is fully automatic except for the loading and unloading of the kegs The intelligent cycles adjust the cycle time to real conditions and purge old beer left inside the kegs, and this operation is also automatic

Contact us

If we have sparked your interest, then It would be great if we could set up a personal meeting with you at the show, which would give you a better understanding of our equipment If you have any questions, please contact us on stand

For further information:

STAND 166 info@vitikit.com

12

PREVIEW BeerX 2023

beerboxshop.co.uk Tel: 01538 528181

STAND 53

Fulton to promote solutions for brewery decarbonisation strategies

Heat transfer specialist Fulton will be using BeerX to promote how its class-leading fuel-fired and electric steam boilers and portfolio of aftercare solutions can help with a brewery’s or distillery’s decarbonisation strategy and put your company on the Road to Net Zero

While Fulton will continue to promote the many features and benefits of its Classic and award-winning VSRT vertical steam boilers the company will, at a time when fuel costs are soaring and efficiency is vital to an organisation’s on-going strategy, also be promoting its range of electric steam boilers

Some believe that electric steam boilers are superior to fuel-fired steam boilers in many ways, believing that using electric boilers may be less expensive than using a fuel-fired boiler in the long term, whilst also possibly being more environmentally-friendly

Using Fulton’s portfolio of electric steam

boilers as an example, including Compack, Electropack and Europack models, less ancillary equipment is required than a traditional steam boiler, therefore helping to reduce the installation costs that come with a fuel-fired boiler Electric boilers also generally have a smaller footprint and can therefore fit into smaller areas, thanks to the way they are constructed and the lack of ancillaries that a fuelfired boiler needs to operate

Additionally, because no flue system nor fuel supply is required, electric steam boilers can sometimes be located closer to the process, which reduces pipe work losses and improves steam system efficiencies

However, this doesn’t mean the end for fuel-fired boilers which, given the correct infrastructure and process requirements, will play a huge role in a company’s decarbonisation strategy

Beyond its product portfolio, the company will also be showcasing the many solutions on offer from its

aftercare division, which can support Fulton’s own installations and those from other boiler manufacturers

As well as offering boiler spares and repair service for all makes and types of heat transfer equipment, Fulton’s aftercare portfolio also includes accredited boiler operator training to INDG436 and BG01-R2, technical boiler house risk assessments, boiler and water treatment service contracts, water treatment training to BG04 and EN12953, steam trap surveys, site mass balance assessments and system design, etc

Multifaceted approach from Lallemand

Many brewers will know Lallemand as the company behind stalwart brewing yeasts such as Nottingham®, Windsor® and London®.

What they may not know is the amount of work that goes on behind the scenes to develop and market new yeasts to the brewing industry

Lallemand is a global leader in the field of biotechnology, operating not only in the world of brewing, but also in wine making, distilling, human and animal probiotics, plant care and baking The vast knowledge amassed by Lallemand is a product of the R&D done by the brilliant and creative scientists that we employ, as well as collaborative work conducted with universities and private biotechnology companies around the world

When bringing new products to the market we can draw on the combined experience of the many specialists present within our team, to create

genuinely innovative solutions for brewers

Recent innovations by Lallemand Brewing included WildBrew Philly Sour™- a lactic acid producing yeast which negates the need for kettle souring, LalBrew Farmhouse™- an STA negative saison strain, and LalBrew NovaLager™ - a temperature tolerant lager yeast, allowing brewers to save both time and money

Our approach to a new strain launch is multifaceted Unlike some yeast producers, we do not just reproduce the strains of others freely available on the open market, but work alone, and collaborate directly with research partners to produce strains that are genuinely new, interesting and innovative

Further, production is not outsourced but takes place in our own bespoke plants, allowing Lallemand Brewing to control all stages of the production and QC process New strain development is not

quick, and the entire process can take between two and three years

When you choose Lallemand you can rest safe in the knowledge that our strains are new, original, and have been thoroughly researched and tested before being launched to the marketmeaning you know exactly what you are going to get Premium, well characterized yeast, in an easy-to-use dried format

14

STAND 85 www fulton co uk Tel: 0117 972 3322 For further information: www.lallemand.com brewing@lallemand.com For further information: STAND 113 PREVIEW BeerX 2023

15

PREVIEW BeerX 2023

Evolution uncovered

Innovative bottling and packaging equipment for beer

With nearly twenty years experience in delivering bespoke packaging line solutions, Evolution BPS is recognised for its expertise in providing state-of-the-art equipment combined with first class customer service

Evolution BPS understands your passion for the unique qualities of your beer In particular, bottling represents a critical stage in the life cycle of beer, and for this reason it must be managed with competence and accuracy Evolution provides quality, innovative machinery for all parts of beer bottling lines, maintaining product integrity at every stage, and in particular during the delicate stage of filling

Evolution works in partnership with MBF for rinsing, filling and capping machines

MBF (machine pictured) is a renowned expert in the careful management of delicate products through the filling process In addition the portfolio includes TMG for depalletisers, palletisers, case-packing machines and all end-of-line machinery; Robino & Galandrino for capsuling machines; P E LABELLERS for types of labelling machines; Logics & Controls highly advanced inspection systems for fill level, label, empty bottle and closure inspection

In partnership with its suppliers,

Evolution provides quality, innovative equipment to secure the correct solution for any project, creating a proposition that can offer full line turnkey solutions or individual machines for all your bottling and packaging needs Its equipment is installed, commissioned and maintained by a UK-based team of Field Service Engineers, complemented and supported by its manufacturers every step of the way

Providing bespoke solutions via its premium product range is only one aspect of the Evolution BPS proposition Evolution also prides itself in delivering outstanding Customer Service by developing a partnership relationship with its customers which is based on delivering a solution-driven working relationship

For further information:

evolutionbps.co.uk

See Muntons at BeerX 2023

STAND 145

Muntons, widely regarded as one of the world’s most sustainable maltsters, will be exhibiting at BeerX in Liverpool this year

Muntons has received a number of accolades including Global Brewing Supplier 2022 for its practical work in sustainability, championing pioneering programmes in malt production and demystifying the world of carbon for the wider food and drinks industry

Find out more by visiting the Muntons stand at BeerX.

For further information:

www.muntons.com

Brewing Services Ltd promoting excellence

Brewing Services Ltd has worked with over 200 breweries in the UK and abroad, offering training, advice and technical support.

Our mission is to help establish breweries with a complete commitment to quality, promote excellence throughout the brewing process, assist brewers in producing beers of the highest possible standard and train brewers to achieve their full potential

Technical Support and Brewing & QA Surveys

At Brewing Services, we believe that good technique, consistency and efficiency are the foundations of great beer Through a combination of on-site

surveys and remote technical support, we provide a service tailored to your needs, looking at your brewing process and procedures, from raw materials to the quality of the beer on the bar, along with microbiological checks, analytical testing of products and hygiene monitoring

Training

Providing on-site training, exam mentoring and brewing courses, Brewing Services has helped increase the knowledge of hundreds of brewers ‘Brewing: The Fundamentals’, a four-day residential training course held in March and November each year, covers the basics of brewing theory and good brewing practice through a combination

STAND 72

of lectures, workshops and visits, with participants gaining greater insight into the art, science and craft of brewing

Start-Up Services

We aim to help you make a better beer before you’ve even brewed your first pint Our Start-Up Consultancy service covers initial feasibility studies, through site and equipment planning, to training, recipe development and commissioning We provide full support over those first critical brews

See you on Stand 72 at BeerX

For further information:

www.brewingservices.co.uk

enquiries@brewingservices.co.uk

16

STAND 90

17

Keg

l A Genuine Alternative to Cask and Keg Replacement l Repairs to casks and kegs of all sizes l We can supply refurbished casks too l Fast On-Site Turnaround l Competitive R ates l Over 60 years of Industr y Experience Please contact us for details of our other onsite ser vices. Head Office: 01283 740807 • Mob: 07952 152 099 Email: repairs@dhmbreweryservices.co.uk • Contact: Jason Miller Web: www dhmbreweryservices co uk • Twitter: @DHMBreweryServ

Cask and

Repair & Refurbishment Specialists

Close Brothers Rentals puts Ekeg Plus on show

The latest addition to the Close Brothers Brewery Rentals product portfolio is EkegPlus, which allows customers to collect and refill from our vast fleet of and ECasks and deliver them directly to venues as well as through approved wholesalers

This flexibility gives our customers increased control, with the added benefit of only paying for containers when they’re being used The technology driven combination of bulk scanning equipment and the PlusPortal

management platform offers brewers live cycle data, transparent billing, and informative insights to reduce costs and streamline operations

This year at BeerX we will be offering demos of our newly launched Handheld Scanner App which provides handy process walkthroughs helping to streamline brewery operations.

Close Brothers Brewery Rentals provides a wide range of services in addition to longer term container rental, including our well-known fee-per-fill short term rental containers ECasks and EKegs, as well as repair and refurbishment services and equipment

finance By providing these financial solutions to the UK drinks industry, we have become extremely familiar with the equipment commonly used and have good relationships with many of the main suppliers

Come and see us on stand 80 at SIBA’s BeerX (15-16th March) to discuss our range of products and services We’re sure that we will be able to find the right means to help your business grow this year

For

We are once again looking forward to being back at BeerX, seeing customers and friends face to face

With a 150-year heritage of supplying into the UK beer industry, supporting SIBA through our Gold Sponsorship is just one thing we do to ensure that we are investing in our customers and the fabulous beer industry

Glass is endlessly recyclable and the obvious material for sustainability If you want to know more about how Croxsons and glass can help meet your own sustainability goals, come and speak to one of our team at BeerX

We put our resources where our heart is: a climate positive workforce, and a commitment to be carbon neutral in 2023 We can't do everything, but we must do something Come and be part of the journey

For further information:

croxsons com

Smaller breweries needing a cost-effective, reliable dissolved oxygen (DO) content measurement device, could find the answer in Pentair Haffmans’ Oxy-2Go

Pentair Haffmans Oxy-2Go is a portable device that measures the complete range of DO content in beer wort, beer, and other carbonated beverages

Developed using Pentair Haffmans known and trusted optical technology (incorporated into our long-established O2 Gehaltemeter, in-line, and laboratory quality control devices), the Oxy-2Go ensures you don’t run the risk of your DO content becoming too high or too low

Pentair Haffmans Oxy-2Go enables smaller breweries to measure their DO content without significant hardware investment The device’s lightweight portability allows measurement throughout the entire brewing process line, reducing overall batch losses due to more regular monitoring Maintaining the correct levels of DO during the complete brewing process is crucial to the taste and stability of your beer ’s shelf life The built-in optical technology of the Pentair Oxy-2Go provides reproducible & reliable DO content level readings

Features & Benefits:

• Built with Pentair ’s proven optical technology

• Portable and wirelessly rechargeable

• Multiple language options

• Lightweight & compact

• Wide-ranging, cost-effective DO measurement

• Ensures beer quality

• Reduces beer loss

For further information:

18

Croxsons at BeerX again STAND 80 STAND 81

www.closebreweryrentals.co.uk Tel: 01425 485 421

PREVIEW BeerX 2023

further information:

Pentair showing Oxy-2Go STAND 178 www foodandbeverage@pentair com

News from the Rawlings Group

Just over a year ago, Rawlings, leading independent packaging specialists, announced a merger with Vigo Limited, renowned production equipment suppliers since 1984

Now, as key brands of the Rawlings Group, the consolidation has allowed for increased capacity, efficiency and a complete (end-to-end) processing and packaging solution for all clients. The Group warmly invites you to visit them at BEERX 2023

Here's a preview of our offering:

Vigo - New Canning Line Additions

Vigo is pleased to be launching two new additions to our range of canning systems:

New! CraftCan Go: The CraftCan Go is ABE's latest innovation, offering the flexibility to fill either via counter pressure filler or at open atmospheric pressure without having to purchase a new canning line This gives craft breweries the versatility to fill low carbonated beverages or those with a high volume of CO₂ The CraftCan Go is compact, mobile and can be operated by just one operator As with all the equipment Vigo supplies, servicing, maintenance and breakdown support, is offered by our team of 9 engineers You can see the CraftCan Go at BEERX 2023

CIMEC Rotary Canning Lines: Vigo has added CIMEC rotary canning lines to its range, which are not only counter pressure fillers, but can at speeds of up to 6,000 cans per hour Having supplied, installed and commissioned CIMEC bottling lines for 19 years now, Vigo's natural transition to CIMEC canning lines enables breweries to achieve higher outputs of carbonated beers As always, servicing, maintenance and ongoing support is offered by the Vigo engineering team

Rawlings - helping you find the right container for your brand!

Rawlings has been supporting the beer industry for decades, working in partnership with both newly formed start-up brewers and established highvolume multi-brand breweries to create standout, on-brand packaging, whether bespoke or off-the-shelf With an informed collaborative approach to the development of packaging, Rawlings' experts foster both creativity and innovation, while building long-standing relationships Offering a complete bespoke container design service as well as an extensive range of standard off-the-shelf bottles (many unique and proprietary to Rawlings), clients benefit from Rawlings independent and strategic partnerships with manufacturers all over the world

Collaborative partnership

Working alongside a dedicated technical team, Rawlings manages the design and production process on the client's behalf, advising on relevant design options that fully encompass a brand's persona, whether traditional or contemporary

Decoration & Labelling

Rawlings offers an array of decorative techniques and labelling to achieve a unique and distinctive product which grabs attention and recognition at point of sale, helping clients' brands stand out with the use of decorative embossing, screen printing, full body sleeving, or textural and highly visual labels, to mention a few

The finishing touches

Whether the bottle requires a crown cap, cork, swing-top or other closure, Rawlings can help Further customisation and branding can be achieved by embossing or printing on the closure

Using sophisticated forecasting to monitor both client and manufacturer activities, Rawlings can make sure you have the right stock in the right place, when and where you need it

Come and have a chat with Vigo and Rawlings on stands 46 - 48 at BEERX

Whether you are interested in the new CraftCan Go, CIMEC rotary canning lines, CIMEC bottling lines, Malek kegging equipment, Quantor temperature control equipment, filtration, brewhouses, bottles and decoration, the Rawlings Group looks forward to seeing you.

For further information:

www

www.rawlingsbristol.co.uk

Part of the Rawlings Group

Ninkasi at BeerX

STANDS 51 & 52

Ninkasi Rentals & Finance is an ideal partner for fast growing and pioneering breweries From our range of high-quality equipment to our competitive finance packages, Ninkasi is uniquely placed to provide support to you and your business from our team of industry experts.

Our innovative FV rental product allows for an almost instant capacity boost and is delivered and installed by us Along with FVs, we have a wide range of products in stock and available for immediate delivery. Drop by our stand to find out more about how we can help you and learn more about our new CO₂ Capture Technology – available on rental or finance

For further information:

www ninkasirentals co uk

20

PREVIEW BeerX 2023

STANDS 46 - 48

vigoltd

com

Full range of equipment and services from Enterprise Tondelli

Over 45 years Enterprise Tondelli have been supplying bottling, canning and kegging lines from single machines to complete turnkey projects and has taken three stand spaces 174, 176 and 176 at BeerX 2023.

On our stand will be a Eurosistemi TF 1 self-contained bottle and can drier This stops under crown mould, makes selfadhesive labelling easier and reduces moisture in the final pack preventing soggy trays/boxes!

This is being supplied as part of a complete beer bottle and canning line rated at 9,000 container per hour for the UK market The line includes all our equipment from depalletiser, labeller, bottle and can filler, packer, multipacker, conveyors and palletiser etc

Examples of new bottling and canning line projects completed by Enterprise this year will be demonstrated from a 1,500 bph kombucha bottling line to a turnkey 13,000 cph widget beer canning line with tunnel pasteuriser project We supply beer bottling and canning lines from 600 containers per hour to 72,000 containers per hour and all sizes in between

Enterprise Tondelli has a full design service so we can check the space required and also ergonomics to give the most efficient project as possible

We welcome the opportunity to discuss your requirements from single machines to complete lines If you are unable to visit then check out our website to see the full range and recent case studies

For further information:

Tel: 01525 718288

www.enterprisetondelli.co.uk

Arlington for beer transport and storage

Arlington’s innovative beer combo system and associated products are leading the way in the transport and short-term storage of real ale, craft lagers, and other types of beer The system consists of a heavy-duty, all-plastic collapsible 1000L container that is used with a range of product-specific airless liner bags.

Each fill requires a new bag to ensure maximum cleanliness and hygiene The bags unfold as the product is filled into them and, when used correctly, contain nothing but the product, with no air or contaminants This results in less dissolved oxygen, less energy usage, fewer chemicals required for cleaning, and less time spent preparing transport containers The combo system boasts a 2 5:1 empty-to-full ratio, making it easy to store and transport

The four-way entry pallet base also allows for easy handling when full, and the containers can be stacked up to 5 high when full or 10 high when empty With over 25 years of experience in filling and transporting high-value liquid products, Arlington is a name that you

STANDS 174, 175 & 176 STAND 45

can trust From drinking water to pharmaceuticals, we have a wealth of knowledge and experience in handling products where hygiene is critical

In addition to the combo system, Arlington also offers a range of fittings and accessories specifically designed for the brewing sector Our goal is to ensure the highest quality and lowest “DO” fill possible Most hoses, fittings, and liners are available off the shelf, so you can get what you need when you need it At Arlington, we are proud to provide immediate, knowledgeable service that covers all aspects of what we do Whether you need assistance with equipment rentals, bag filling, or technical queries, we are here to help Our tailored, affordable packages ensure that you get the best value for your investment

True to our packaging roots, we also supply the Arlington 4pt flat pack beer carrier pouch, perfect for take-outs and

cellar door sales

Come visit us on stand number 45 at the exhibition and see for yourself why Arlington is the leader in the beer transport and storage industry

Pictured: Arlington containers at Stroud Brewery

For further information:

Tel: 01672 563723

www.arlingtonpackaging.com

22

PREVIEW BeerX 2023

23

Caskwasher returns to BeerX 2023

It’s great to be returning to Liverpool again this year and we are looking forward to seeing customers old and new on Stand 140.

Despite the challenging conditions over the last 12 months within the industry we have still seen a steady demand for our range as brewers strive for effective cleaning and operational efficiency

Our range of cask and keg washers is designed and built to order from our manufacturing facility at Acle in Norfolk. Rugged yet simple to operate, Cask Force machines accelerate the cleaning process, thus saving money, labour and time Using a state-of-the-art manufacturing processes we pride ourselves on providing our clients the best quality components and through innovation we are continuing to update and invest in the range helping us to maintain our position as one of the leading manufacturers in this sector

Cask Force has a great heritage It is a wholly-owned subsidiary of Hugh Crane (Cleaning Equipment) Ltd who have been manufacturing specialist cleaning equipment systems across a range of industries for 40 years and our machines are recommended by breweries everywhere

What makes Cask Force the cleaning system of choice?

• Simple to Operate and Maintain Casks/kegs are placed once, without the need of additional lifting

• Saves Time

Fully automated washing process

• Saves Water

Recycled water from the process is cleverly reused minimising usage costs and the environmental impact

• Reduced Problems

Eradicates the expensive issue of contaminated casks/kegs

• Reduces Bottlenecks

Quickly restores the supply of clean units to circulation

One cask washer that has proven popular over the years is the 200 K-series electrically heated machine It cleans up to 24 casks per hour Power is supplied though a 16amp; 3 phase supply although the steam version can be powered by a single phase supply. The cleaning process is simple and clients have seen massive savings in manual labour and time taken to thoroughly clean returned casks

The machines also provide other financial benefits They save water, as the recycled water from the cleaning process is cleverly reused for pre-rinsing minimising usage costs and the environmental impact It also

Multi-generational family

Thomas Fawcett & Sons Ltd was established in Castleford, West Yorkshire in 1809 and is now in its 214th year of trading

The Company manufactures over 30 styles of malt which it supplies to discerning brewers all over the world It remains a 100% family-owned business with 6th, 7th and 8th generation family members involved

In spite of its longevity the company remains small and specialised. It produces the finest ale malts from only the best malting barleys which include Maris Otter, Halcyon, Pearl of the winter varieties and Golden Promise and Laurette from the springs These are barleys that produce consistent and

140

flavourful malts which remain favourites with craft brewers as well as brand leaders Together with its offerings of fine malt, the Company manufactures the complete range of Crystal and Roasted malts allowing brewers to make excellent balanced beers of all styles

The Company retains its own fleet of vehicles which allows it to deliver malt on time and encompasses all practical packaging requirements from bulk tipper or blower deliveries to pre-milled and palletised options

The Company is proud to be trading with some of the biggest and some of the smallest breweries in the UK and abroad and is very much customerdriven A little old-fashioned perhaps, but great emphasis remains on building

significantly reduces the likelihood of not cleaning effectively potentially spoiling batches This improves the customer experience knowing that products are going to arrive with the client in first class condition

If you are looking to make an investment in our range visit Tim and Chris at BeerX on Stand 140 on March 15-16th We look forward to seeing you there

lasting and collaborative relationships with its customers to promote all the best things that can go into a pint

24 Tel: 0800 157 7198 sales@caskwasher.co.uk For further information:

STAND

PREVIEW BeerX 2023

sales@fawcett-maltsters.co.uk For further information:

maltster STAND

89

25

The ‘perfect partner ’ at BeerX

With its comprehensive range of keg washer/fillers specifically designed for the craft sector, Lambrechts is the perfect partner for craft brewers requirements, according to its UK spokesperson, Mike Hickman. With its global reputation for sterilising kegs, you can have total confidence in filling ‘’pay-per-fill’’ rented kegs or brewing the most individualistic beers of any style, whilst still saving energy without compromising quality

From individual standalone washing and filling heads, to the ubiquitous two-head semi-automatic Compact machine, these are ideal for those brewers requiring up to 35 kegs washed and filled per hour Alternatively 60 one-way PET kegs or pre-washed steel kegs

For these brewers looking at increasing efficiency in and around their kegging area, the Monobloc Slimline 50 is the

answer Taking up a footprint of only 4 x 4 m including conveyor, it maximizes the output of washed/filled kegs at 55 per hour for the minimum footprint

The larger Monoblocs are capable of washing and filling over 80 kegs per hour with built in external keg washer and check weigher We can also offer a range of keg handling solutions including robots, as they become virtually standard on continental and US installs

With remote internet monitoring of the machine when needed, Lambrechts can work out the optimum time for servicing along with full diagnostics, so solving potential problems before they arise This combined with superb build quality and supplying competitive off the shelf non-proprietary spares makes Lambrechts a great long-term partner

Manufacturing the largest range of returnable containers of any global keg producer, Schäfer will once again be at BeerX.

As well as the standard stainless steel 50-, 30- and 20-litre kegs produced in 304 material with a higher tensile steel for the chime ends, Schäfer has also pioneered designs of lighter weight kegs and improved branding recognition

The returnable ECOKEG will reduce the average weight of the empty keg by 2 5 kg on a 30-litre size and 3 4 kg on a 50litre size keg Utilising comfortable to handle, customer-designated coloured polypropylene hoops, when combined with silk screening they offer an attractive contemporary solution to bulk beer packaging

The well-known PLUS keg, like the ECOKEG, is fully stackable and reduces noise in the kegging hall and during offloading by 70% Also available in slim line designs, both the ECOKEG and PLUS help to promote your quality brands

The new 10-litre d beer system does require power to dispense or keep and offers pub qu beer without the n pythons, coolers Co2 cylinders It i for small volume and the more disc home drinker tryin create the pub experience.

According to Mike Hickman from Sc the UK industry is to start gearing u smaller container desires a wider choice of fresh tasting products, but will not be increasing their overall consumption

“With health and economic considerations ‘quality over quantity’ will lead to meaningful change in the coming years, based on what we have seen in Europe The 20-litre is the ideal diameter to fit inside an under-counter fridge ”

26

Both Mike Hickman and Tobias Wirth will be attending the show

Pictured: The Lambrechts OMNI COMPACT

ECOKEG and PLUS keg on show on the Schäfer stand at BeerX STAND 169 www schaefer-container-systems com For further information: www.lambrechts-group.net mike.hickman56@outlook.com For further information: STAND 167 PREVIEW BeerX 2023

Schaefer light weight ECOKEGS

LemonTop can help your brand to stand out

Whether you need a refreshing change, or you just want to heat things up a little, LemonTop can help your brand or service stand out from the competition

We have built a reputation as specialists due to our ability to offer the whole package - branding, graphic design, illustration, packaging design, promotional material and advertising

Some of our clients are suppliers at the start of the production chain and want us to promote their service or equipment, while other clients are at the end of the process and have a product to sell Wherever you are in the sequence, you’ll benefit from the services we offer

We’ve helped many businesses get their products to market, and helped many other businesses navigate their way along the processing chain From brilliant beer brands and fabulous drinks packaging, through to compelling pointof-sale and stimulating promotional material, we offer everything you need to place your products, services and

business at the forefront of the brewing industry

How do we do this? Your products and services are the items that kickstart the journey but we start by listening to your story We look at how your business sits within the marketplace, who your competitors are, your target audience, and your ultimate objectives

Only then can we use our creative and conceptual thinking to position your brand and tell stories that draw customers closer to you

Product packaging design is one of our most dynamic and captivating design services It is an inescapable part of everyday life, yet it requires a high standard of skilled design. It motivates the consumer to try your product, ultimately creating a cycle of repeat purchasing and brand loyalty Get it right and it even has the potential to become a collectible piece of art

STANDS

143-144

BRITANX from Fabdec offers high quality hygienic stainless steel vessels to the food, beverage and processing industries

With over 60 years’ experience, all manufacturing is from our state-of-the-art 65,000sq ft facility in Shropshire, UK

As specialists in hygienic and pressure vessels, we design and manufacture all vessels for the brewery industry

From mash tuns to DPVs, to serving tanks, we have our own complete standard range and can also custom design to your specification

All vessels are expertly produced using the very latest technologies in welding, polishing and testing This includes our very own and the UK’s only laser

welded dimple plate machine This enables us to produce and test our own heating and cooling jackets in house

All claddings are fully welded and 85mm of injected polyurethane insulation comes as standard

All pressure vessels are designed to PD5500 and both the vessel and jackets come with all pressure test certification

To complement the brewing process, we manufacture a number of ancillary items, such as Plate Heat Exchangers, inline carbonation, hop dosing and more.

Find us at BeerX on stand 143-144

For further information:

sales@britanx com

28

Visit us on stand 60 (look out for the yellow balloons) and take a look at some of the projects we have on display

BRITANX’s range of vessels for the brewing industry PREVIEW BeerX 2023 STAND 60 www.lemontopcreative.com Tel: 01642 969 222 For further information:

Is it time to invest in CO2 recapture?

With CO2 prices rising and sustainability becoming increasingly important, so is the option of investing in technology to reduce waste and cost

By reusing the carbon dioxide rather than releasing it we have found many of our customers benefit from:

Core Equipment exhibiting at BeerX 2023

Following on from the major success of BeerX 2022, Core Equipment will again be showcasing its products and services at BeerX 2023. As a market-leading brewery equipment supplier, Core is looking forward to meeting with both existing and new customers as well as industry partners

Core supplies a wide range of brewery and packaging equipment, including counter-pressure canning lines, brewhouses, fermenters, kegging machines and much more The company specialises in providing brewers with the latest innovation to support business development and growth

The Core purchasing team ensures that the equipment supplied is manufactured by industry-leading companies and has been quality assessed The Core sales team will be available to discuss your brewery needs across the 2-day event, to answer any questions you may have and any queries relating to brewing and packaging equipment

Sales Director Dan Tomlin, explained: “We are delighted to be here at BeerX once again, supporting this great event As the UK craft beer market continues to experience growth, BeerX 2023 is set to be the biggest brewing event in the calendar and we therefore look forward to having a beer with our customers once again ”

For further information:

www.core-equip.com

• Cost savings

• Reduced emissions.

• Time savings

Lots of breweries are still reliant on CO2 delivered by 3rd parties while letting their own supplies bubble off into the atmosphere This is highly inefficient when you think you are releasing a by-product from your yeast and buying someone else’s

So is it time to get the full potential out of fermentation and close the loop? The biggest hurdle is process and upfront cost of the equipment It is possible to do it via adding a spending valve during fermentation, however for operations of a larger scale or looking to can A CO2 recapture system can offer an effective solution

The issue within the craft brewery industry has always been the upfront cost of most machinery Here at Moorgate Brewery Finance, we have been able to find cost effective solutions that are good for cashflow As we have seen an increase in demand for these types of kit, its become increasingly

important to introduce funders to the benefits and cost savings

The other concern with bringing in more electrical equipment is the cost of power, but these systems are modern and of low cost to run generally and many breweries are making the jump to solar power with the cost lowering, availability improving and batteries becoming common place Reducing your energy cost can help you reduce the price of producing a pint

We have been working with many breweries since 2015 to find solutions to advancing craft brewing and helping expansion The team will be at BeerX again this year and are always keen to have a chat over a pint

www.moorgatefinance.com

Full range of keg options from Keg Logistics

Keg logistics is the only company that can offer you rent-to-own, flexi rental, pay-per-fill, sale and lease back and steel export.

Rent-to-own - allowing the brewer to build up their keg and cask population with the option to purchase the containers

Flexi rent - with agreements starting from 3 months up to 72 months for a cheaper rental

Pay-per-fill - one time fills sent to wholesale

Sale and lease back - unlock £££ within your assets

Steel Export Keg - send steel containers worldwide including Europe, Canada and the USA

Keg Logistics gives breweries flexibility in uncertain times

To discuss one of our programs please call at our stand at BeerX or visit our website www.keglogistics.com

For further information:

30 PREVIEW BeerX 2023

STAND

97

For further information:

STAND

186

We asked companies supplying the following products and services to let us know something about themselves....

l Malts, hops, fruit, yeast and any other raw materials which contribute to the finished product

l Chemicals and other adjuncts used in the drinks production process

l Companies providing power and other resources, plus products and services to help meet hygiene regulations

Suffolk maltster, Muntons, shares the secret of its sustainability success

It is no secret that a lot of energy and water are used in producing malt, making it a major contributor to the carbon footprint of beer. We talk to Muntons, widely regarded as one of the world’s most sustainable maltsters, as the company shares its story of how it is reducing the environmental impact of malt, safeguarding it in centuries old heritage beer brands as brewers look for opportunities to form sustainable supply chains from grain to glass

“To us, sustainability is defined by the need to make meaningful long-term systemic changes To do that well, you must truly know your business,” explains Adrian Dyter, Head of Procurement & Technical for Muntons.

“Creating the first malting barley carbon calculator gave us the data and knowledge to meaningfully change our environmental and social governance and underpin lower carbon supply chains The time taken to measure and baseline our data back in 2007 has proven invaluable Not least of all because we can see where we can make the most impactful changes but also demonstrate how far we have come “Our biggest carbon reduction opportunities involve the growing of malting barley from our farmers and the energy we use Focusing on the areas is making the most significant difference to Green House Gas Emissions. Real action we can pass on to our customers.”

Global drinks giants, Heineken and Suntory are not only sourcing low carbon, 100% sustainable malt from Muntons but are working with the supplier and its partner farmers to radically change the way the barley is grown to reduce greenhouse gas emissions by 50%*

Muntons has received a number of accolades including Global Brewing Supplier 2022 for its practical work in sustainability, championing pioneering programmes in malt production and demystifying the world of carbon for the wider food and drinks industry The company has recently been awarded a Platinum Medal for the second year running by the world’s most trusted sustainability ratings organisation, EcoVadis This places the maltster in the top 1% of companies globally for its sustainability performance

The company has invested in novel applications of technology across its Suffolk and Yorkshire plants including green energy generated from waste water treatment that enables the company to recycle and be a valued contributor to the local river network

Muntons is already seeing decarbonisation of its UK maltings by around70% Having been in the earliest cohort of manufacturers and the only maltster to set Science Based Targets reducing its GHG emissions by 45% by 2025 and to be Net Zero by 2050, the progress it have made so far has given the firm confidence to challenge itself even further, bringing forward its net zero target by 2 decades to 2030

*Early trials are producing certified carbon negative barley and expecting to show reduced GHG emissions by 50% for the growing of malting barley Data source Sustainable Futures Ltd 2022

See Muntons at BeerX - stand 145

Above: Muntons Maltings and Malted Ingredients site in Stowmarket ”

Below left: Muntons’ anaerobic digestor has now generated over 17 million kWh of electricity for the plant

For further information:

muntons.com

Siebel Institute introduces Sensory Training Kit for Sour Beer

To assess brewers’ abilities to perceive the characteristics of each of these compounds and/or be able to detect off-flavour linked to souring, a Siebel Institute Sour Sensory Training Kit has been developed which allows the compounds to be mixed with beer to mimic their sensory impact

The Siebel Institute Sour Sensory Training Kit offers 6 vials with different compounds that cover a spectrum of organic acids, Diacetyl and one biogenic amine (cadaverine) commonly produced by microbiological acidifying agents such as bacteria Each vial allows for spiking 1 liter of beer As with the other kits, the Sour Sensory Training Kit is shipped in ready-touse liquid form, making them as easy to use as possible

For further information:

www siebelinstitute com/sensorykits

34

SHOWC ASE In The Mix

35

SHOWC ASE In The Mix

A Curious relationship for Christeyns Food Hygiene

As the craft beer market becomes increasingly competitive, it is even more important to stand out from the pack. This means consistently creating and producing outstanding product. We talk to Wesley Lynch, Head of Production at Ashford-based Curious Brewery as to how the company achieves this.

Curious is a fully independent brewery, run by brewers and focused on making the UK’s best lager, IPA and cider Its journey began through the Kent-based winemaker Chapel Down who introduced its first beer product in 2011, Curious Brew lager In April 2021 Risk Capital Partners, (RCP), purchased Curious in what set out as a passion-led project for its CEO, Luke Johnson

The site for the brewery in Kent was purchased in late 2017 and doors to the brand new brewery opened on May 10, 2019 The project cost around £16m with an addition of £6m equipment sourced from around the globe, including fermentation vessels from Austria and the Brew House from China

As of Summer 2022, the brewery has brewed approx 7 5 million pints The biggest seller and flagship beer is Curious Brew Lager which boasts a clean, fruity, and aromatic finish During the summer months Curious Apple, an aromatic cider fermented with Bacchus wine yeast, is not far behind

There is also a Curious Session IPA brewed with three complementary hops and the newest product, Kentish Pilsner brewed in celebration of Kent’s hop-growing heritage, was launched in 2022

So, what makes Curious Brew different and how does it keep output quality consistently high? Wes explains in more detail

“We may brew lagers, but they aren’t your standard lagers We want to brew characterful beer which celebrates the ingredients that go into it We use a lot of hops in our products which gives us a more flavourful product once it’s finished. We may no longer have the winemaking connection through Chapel Down, but what we want to celebrate is the

provenance of Kent and the hops grown here

“However, the addition of champagne yeast and Nelson Sauvin hops means we have a lot more hops to clean out at the end of our processes The physical debris is always a challenge and a good hygiene partner is crucial to help us stay on top of our game and ensure a pristine brewing environment

“What I discovered is that Christeyns Food Hygiene really goes the extra mile to encourage its account managers to work closely with clients They make time for proper visits and have a good reporting structure with audits to highlight areas that need attention from hygiene to chemical safety They visit monthly as a minimum and produce a detailed report about any findings or recommendations

“Since using CFH we have done a lot of work on our brewhouse CIP procedures We standardised and validated the process and ended up with a much better result As this is one area where malt and hops and heat make the equipment that much harder to clean, it has been an invaluable improvement for us

“We have also installed an automatic testing and dosing unit for the detergent on our keg washer/filler This has allowed us to have much more confidence in the cleanliness of our kegs before they are filled Dirty kegs have a huge impact on beer quality and can lead to sourness and haze, so this is one of our key areas for brewery hygiene

“Having a supplier that knows best practice (and particularly safe practice!) matters We work with Justin Adams at Christeyns and he has carried out numerous chemical

handling training sessions with my team as well, so they are knowledgeable about the risks they are taking on Health and safety is always at the top of our list – followed closely by quality ”

Not one to rest on its laurels, Curious is firmly set on the future and working on several initiatives

The brewery recently purchased Wild Beer Co. from administration and is now in the process of bringing those beers online at the Curious site From a hygiene perspective, the famous Wild, or sour beer, can only be produced in an environment with impeccable hygiene standards

Sustainability is a personal focus for Wes this year As well as looking at shortening raw material supply chains the brewery now sends spent grain to aerobic digestion rather than animal feed There are also discussions underway with a local hop farmer about taking the used hops as potential fertiliser and negotiations are underway with a new waste supplier to improve the brewery’s recycling programme.

Wes concludes: “CFH has always been supportive of using less chemical and optimising how we use it – this is counterintuitive for them as it means we would purchase less, but that’s a mark of a good supplier who looks after its customers and the environment as a whole rather than always selling more ”

In 2019 Curious won the UK Brewer of the Year award and Gold medal at the World Beer Awards for their product Curious Brew The brewery continues to go from strength to strength

www.christeyns.com/uk-en/

36

For further information:

Brew your own energy

Says Ian Gadsby, Managing Director, Ylem Energy

Here’s a sobering thought – the UK economy would probably have fallen into recession if the breweries hadn’t kept the taps flowing during the World Cup. Pubs and bars experienced a sales jump of 30-40 per cent on matchdays during the tournament, with around 50 million pints alone drunk during the weekend of the quarter finals

GDP Figures for November released in January showed unexpected growth of 0 1 per cent, again highlighting the importance of the hospitality industry to the UK economy This should have marked the beginning of a post-Covid recovery in the brewing sector, but high energy costs and inflation continue to cast a shadow over the industry.

With the cost of commodities and labour inextricably linked to inflation, they will continue to present a substantial challenge, although energy may be the most severe, even existential, threat

Unlike at home, breweries can’t just turn down the thermostat, reduce the boiler flow temperature or unplug appliances not being used If you’re energy intensive, you are cost intensive – beholden to an energy market which has the potential to spiral again and with no guarantee of long-term Government support

The Government announced in January that it will continue to support breweries and other energy intensive industries until March 2024 under their new Energy Bills Discount Scheme. Reports had suggested the scheme would be targeted at vulnerable businesses, so it was a welcome surprise for most businesses that the scheme will be universally extended for another 12 months However, the stark reality is that businesses still face huge energy cost increases

The application of the original price cap meant the net cost to business was circa 24p kWh However, with the replacement scheme halving support, the same businesses are expected to be paying around 30p kWh – around twice as much as most were paying twelve months ago

Adding other elements, the net cost to business could be somewhere between 35p and 40p kWh Beyond international market fluctuations, additional concerns have been raised about increasingly fractious relationships with suppliers, prompting the British Beer and Pub Association (BBPA) to raise the matter with Ofgem Accusations of profiteering are rife at the moment, with upfront deposits demanded and non-energy costs layered onto bills, leaving many publicans and breweries concerned about what they can do to secure their energy supply.

There is also a distinct lack of focus on improving efficiency, with most contracts encouraging breweries to use as much energy as possible With the wider focus on decarbonisation and meeting Net Zero, it seems counter-intuitive to seek operations that are more energy intensive While ‘cash is king’ for the time being, consumer interest in sustainably sourced products looks to only grow and it must be built into any long-term energy supply strategy

It is clear breweries must become more innovative in the way they operate At Ylem Energy we are seeing an increasing number turn to on-site energy generation, whether this is installing technologies such as solar panels, or hydrogen-ready gas power generation systems

Having a bespoke energy supply and storage system which is more sustainable provides security that energy tomorrow will cost no more than the energy today, rather than being at the mercy of global market headwinds Where more power is generated than needed, you can choose to engage with the grid on your own terms by selling that excess on With energy costs remaining stubbornly high and Government support being gradually reduced, the time to act is now The spike in brewing sales during the World Cup showed there is still life yet in the brewing industry and that our pubs and bars can survive in the post-Covid economic environment

However, what the past year has shown us, is that their long-term

survival hinges on being futureproofed against avoidable energy price spikes

There is no sure way of predicting when the next hike in energy prices will come, but by moving your energy generation on site you can take control and insulate your business against these fluctuating costs

This energy crisis we are experiencing may be new, but the solutions don’t have to be.

As Managing Director of Ylem Energy Limited, Ian is leading the UK based business growth across a diverse range of energy projects. These include expansion of the company’s O&M services, grid connected “peaking“ generation, grid scale battery energy storage and onsite power generation – utilising solar, battery storage and base load generation solutions for intensive energy businesses In addition to its UK business, Ian is also responsible for the oversight of the business’ activity in South Africa and Mexico

For further information:

www.ylemenergy.com

New Beer Recipe Development Course

The IBD has launched a short course aimed at brewers on a path of continuing professional development and those who just want to become better brewers!

The course provides essential knowledge for recipe development for experienced commercial brewers with a sound understanding of the basics of brewing, and it will also benefit more serious home brewers The course includes expert advice and guidance from brewers who have developed some of the world’s most iconic beer brands:

For further information:

www.ibd.org.uk

38

SHOWC ASE In The Mix

SHOWC ASE In The Mix

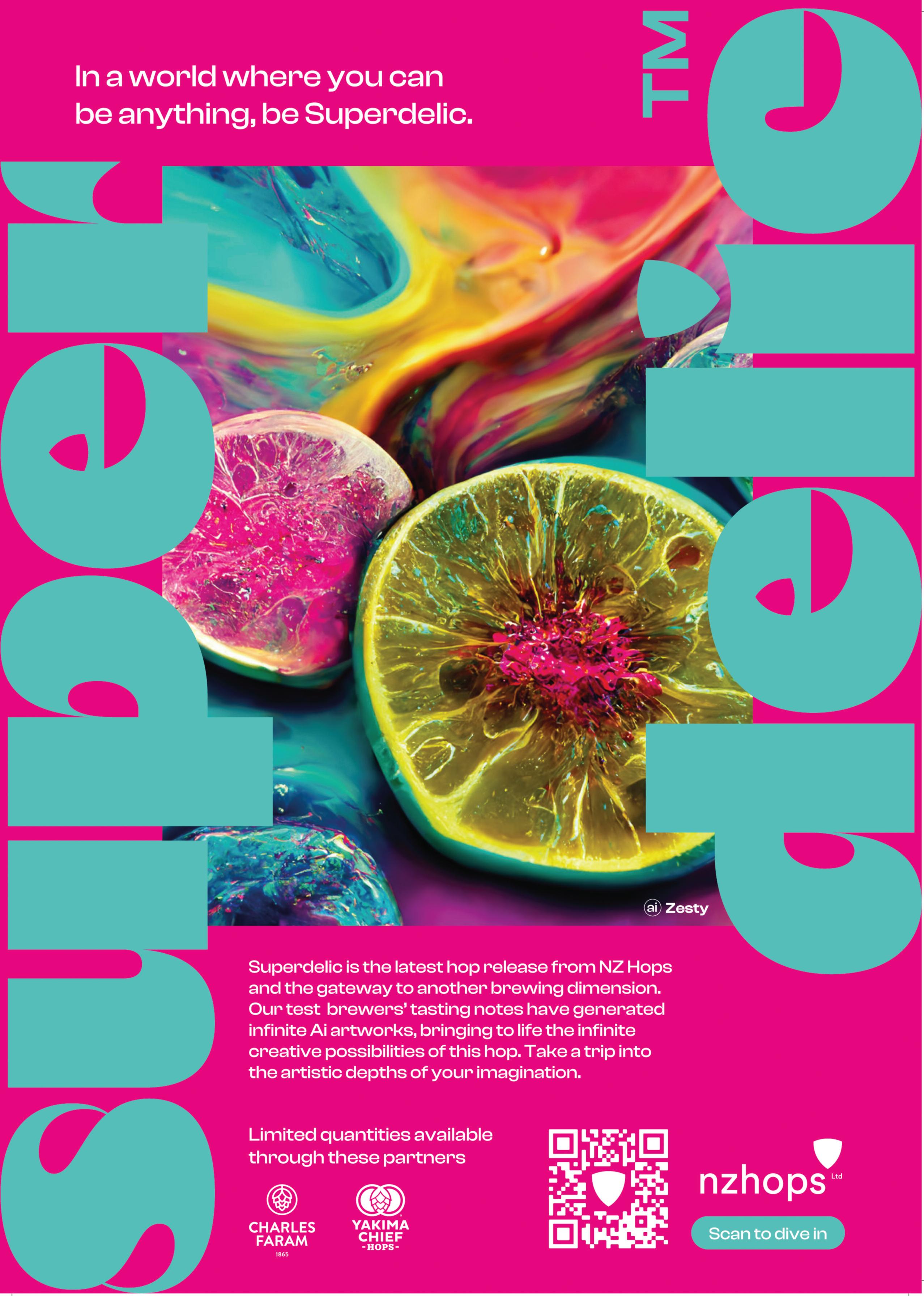

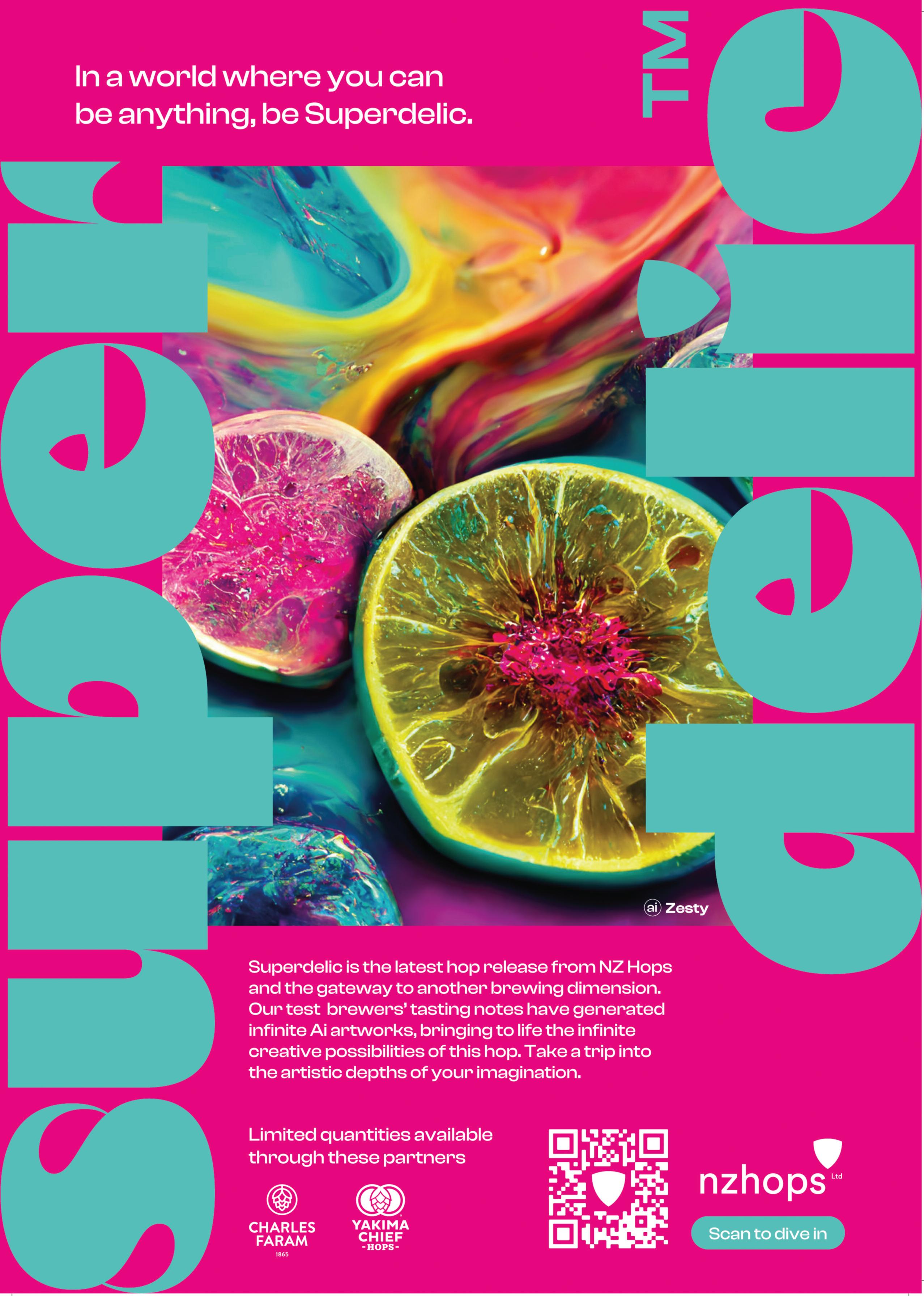

NZ Hops Ltd unveils Superdelic™

NZ Hops does it again, launching a new hop variety with the ‘wow’ factor, set to delight tastebuds of craft beer fans the world over.

Superdelic™ is the brand-new hop cultivar released into market this 2023 season by leading co-operative, NZ Hops Ltd After more than 10 years of breeding work, the early brewer trials suggest it will deliver like no other “This exceptional hop is a playful number, with red fruit, candy, citrus and tropical fruit characteristics, offering brewers something totally different to use in their craft We’re excited to release this unique hop and expect it will create a frenzy,” says Blair Stewart, general manager of NZ Hops

NZ Hops values its highly successful hop breeding partnership with Plant & Food Research where Superdelic™ was developed Scientist, Kerry Templeton, leads the hop breeding programme

“It’s an amazing milestone to see a new variety enter market after our years of breeding work and Superdelic™ has winning strengths Its excellent yield potential will allow growers to produce high-quality hops

more efficiently and sustainably. And in the brewers’ hands, new and interesting beers will come from Superdelic™’s unique flavour and aroma profile,” says Kerry

Dr Ron Beatson, who led the hop breeding programme at Plant & Food Research before his retirement in 2021 added, “The use of both European ancestry and New Zealand stocks when breeding Superdelic™ has resulted in flavours different from others in the portfolio, complimenting other varieties when used together It will be a significant player ”

Several of the co-op’s 27 Master Growers, have been involved in early grower trials for Superdelic™, including Wilson Matthewson of Glenrae Hops. “We’ve been impressed with Superdelic™ vigorous bine growth It promises to yield well, and it looks spectacular out in the field We’re hopeful for an excellent harvest and can’t wait to see it performing well for the brewers "

Through NZ Hops’ Bract Brewing Programme, select global brewers trialled Superdelic™ in special craft brews to explore the hops’ characteristics, aromas, and brewing performance

“From the very first brew we knew it was something special In a Hazy IPA it revealed its ripe mango, sweet berry, and citrus notes We also noticed its unique performance, with great biotransformation properties from dry hopping during active fermentation It is an incredible

addition to our brewery We were lucky to be one of the first to try it,” says Mike Sutherland, Director at Sawmill Brewery

Commercialisation of a new variety is a vital part of NZ Hops’ commitment to innovation as the leader in that country’s hop industry. Over 85% of New Zealand-grown hops are exported, with a turnover of around $40 million Superdelic™ follows Nectaron® in the growing NZ Hops Ltd brand family

“Nectaron® brought a whole new flavour profile to the market in 2020, with its full tropical notes Demand for Nectaron® grows every year and we expect the same with Superdelic™,” says Blair Stewart

The launch of Superdelic™ comes during the midst of the 2023 harvest and before NZ Hop’s two-day festival‘HarFest’ on 20 & 21 March During ‘HarFest’, NZ Hops will showcase hop growing and the breeding programme to visiting brewers from Australia, United States, United Kingdom and from around New Zealand – a tribute to the global demand for high-quality New Zealand hops

For further information:

www nzhops co nz

The flavour combinations tipped to drive growth in the flavoured beer market

Drawing on and enhancing the naturally

occurring flavours

in

beer

is a recipe for success