JOHN AMOS: MR. BREAKBULK

From Bechtel to Breakbulk, a Life in Logistics

KIEWIT: BUILT FOR WHAT’S NEXT

With the Kiewit Supply Network and Advanced Logistics Tools, the Company Is Preparing for the Next Generation of Infrastructure

Credit:

Rob Greer

44 Global How High Rollers Play for Critical Minerals

At This Global Table, Power, Policy and Resources Are All in Play

50 Profile Kiewit: Built for What’s Next With the Kiewit Supply Network and Advanced Logistics Tools, the Company Is Preparing for the Next Generation of

63 Profile Navigating Project Cargo’s Complex Evolution Geanean Ordonez Sees Opportunity Amid Regulatory Shifts and Energy Market Volatility

68 Americas Readiness, Resources and Timing for Project Logistics

Logistics and Air Charter Specialist Fayçal Boumerkhoufa In Conversation With Pat Roche

72 Americas How to Break Into Government Contracts

The Realities Behind Winning and Keeping Government Work

76 Americas DHL Industrial Projects Puts Diversity to Work How to Turn Differences Into Deals

80 Americas Geothermal on the Rise Unlocking a Natural Battery for Global Energy

Be a part of Breakbulk in 2026

4-5

Breakbulk Middle East

Feb. 4-5

Dubai World Trade Centre Dubai, UAE

Breakbulk Europe

Jun 16-18

Rotterdam Ahoy Rotterdam, Netherlands

Breakbulk Asia

Nov. 18 - 19

Sands Expo and Convention Centre, Singapore

Breakbulk Americas

Sept. 22-24

George R. Brown Convention Center Houston, USA

91 Anniversary Special

Breakbulk Americas

35 Years Together

The Places, People, Cargoes, Achievements and Game Changers That Shaped the Project Cargo Industry We Know Today

104 Middle East

Saudi Sets Stage for 2034

FIFA World Cup Opens Massive Opportunity for Breakbulk and Project Cargo

111 Middle East

The Dealmakers in Dubai

LPX Partners Targets Early-Stage Logistics

Tech and Strategic Infrastructure

117 Middle East

Inside deugro’s High-Stakes

Cable Move

From Japan and Norway to Abu Dhabi: Forwarder Keeps HVDC Project on Track

122 Europe

Baltic Security Boost Creates Project Cargo Boom

Grid Synchronization Sparks Regional Logistics Revival

127 Asia

Vietnam, Verified Southeast Asian Nation’s Transition From Fallback to Frontline Sourcing Hub

104 Saudi Sets Stage for 2034

LET’S CELEBRATE

Thirty-five years ago, Breakbulk Events & Media began in Atlanta with a gathering of about 100 industry professionals.

Since then, Breakbulk has grown into three global events, soon to be four with Asia joining next year, plus a magazine published six times a year and a monthly newsletter that keeps our community connected.

Through all this growth, two things have remained constant: our commitment to providing a collaborative platform where the industry can address challenges together, and our focus on bringing people from every sector face to face to do business for the world’s industrial projects. As part of our 35th anniversary, take a look at the timeline in this issue, which captures milestone achievements of Breakbulk Americas and the people and companies that continue to make this industry one of the most fascinating in the world.

Many of you may know the man on the cover, John Amos, a co-founder of the original Breakbulk event and my dad. He has been involved in conference programming over the years and has never missed a Breakbulk Americas. In fact, he is the one who introduced me to Breakbulk in 2006. Read his story on page 86. Sometimes a complicated topic needs a new perspective. We explore the global critical minerals supply chain, imagined as a highstakes poker game among five

players: China, the United States, Australia, the European Union and Indonesia. Their strategies and alliances will set the course for the sector far beyond 2025. For our readers, this means insight into where projects will be sourced, how cargo flows may shift, and what opportunities or risks to watch as competition for minerals intensifies. We also take you inside the U.S. military logistics sector with advice from Pat Roche of Expeditors, Eric Giangiordano of Stratagem Aviation and Ted Graze of Bennett International. Each has extensive experience working on government contracts, and they share practical guidance on what logistics companies need to know to compete and win in this sector. Special thanks to Fayçal Boumerkhoufa for bringing this project together.

Simon West gives us a first look at Saudi Arabia’s plans for the FIFA World Cup in 2034 and the enormous opportunities tied to the construction of new stadiums and supporting infrastructure, comparing them to the scale and logistics demands of Qatar’s 2022 World Cup projects. This is a story for logistics professionals and soccer fans alike. And closer to home, we dive into EPC Kiewit’s out-of-the-ordinary business model with insights from long-time Breakbulk supporter Jesus Mejias.

There will always be challenges in the industry, but you can count on Breakbulk for the information and connections you need to find solutions. I hope you enjoy this issue, and I look forward to seeing you here in Houston.

Best,

Leslie Meredith Product and Editorial Director

Editorial Director

Leslie Meredith Leslie.Meredith@breakbulk.com

Senior Reporter

Simon West simon.west@breakbulk.com

Designer Mark Clubb

Reporters

Luke King

Amy McLellan

Liesl Venter Iain MacIntyre

Breakbulk Magazine Editorial Board

John Amos Amos Logistics

Tina Benjamin-Lea Northvolt Drei Project GmbH

Fayçal Boumerkhoufa Ascent Global Logistics

Dea Chincuanco dship Carriers

Elisabeth Cosmatos Cosmatos Group of Companies/ The Heavy Lift Group

Dennis Devlin DT Project America

Payne Fischer Kuehne+Nagel

Dharmendra Gangrade Larsen & Toubro

John Hark Bertling North America / Texas A&M University

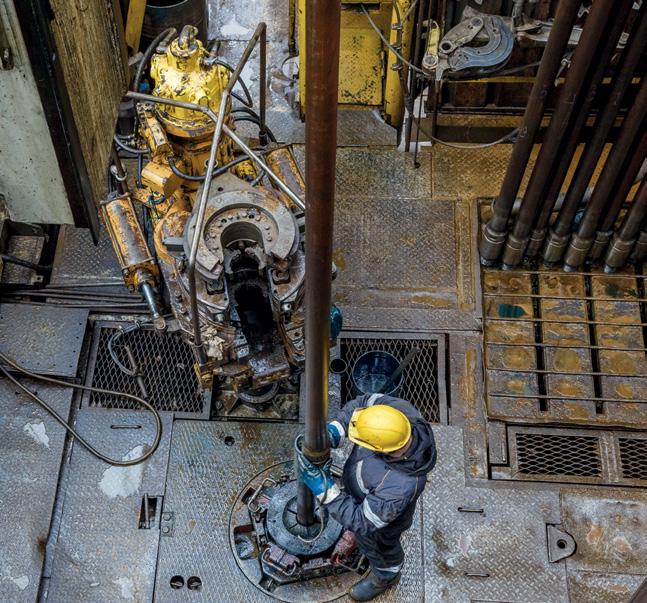

Itoro Ibanga Air Liquide

Margaret Kidd Houston Maritime Center & Museum

Jake Swanson DHL Global Forwarding

Edward Talbot Roll Group

Grant Wattman Jade Management Group, Inc.

Andrew Young Bechtel Corporation

Portfolio Director

Jessica Dawnay Jessica.Dawnay@breakbulk.com

To advertise in Breakbulk Media products, visit: http://breakbulk.com/page/advertise

Subscriptions

To subscribe, go to https://breakbulk.com/page/ breakbulk-magazine

A publication of Hyve Group plc.

The Studios, 2 Kingdom Street Paddington, London W2 6JG, UK

Leslie Meredith

Exhibitors and Breakbulk Global Shipper Network members in this issue:

Movers & Shakers (p. 12)

GEODIS, Blue Water Shipping, WR Logistics, LPX Partners, LS Cargo, Airbus, Air Charter Service, QTerminals, HHLA

Waves of Cargo (p. 14)

Berard Transportation Inc.

PCC’s Strategy for a Shifting Supply Chain (p. 18)

PCC Logistics

Lifting the Industry: MYCRANE’s US$50M Expansion (p. 36) MYCRANE

Inside the Critical Minerals Race (p. 44)

DHL Global Forwarding

Tracking a Future for Project Cargo (p. 54)

UTC Overseas, BNSF

Navigating Project Cargo’s Complex Evolution (p. 63)

UTC Overseas, Technip Energies

Readiness, Resources and Timing for Project Logistics (p. 68)

Expeditors International

DHL Industrial Projects Puts Diversity to Work (p. 76)

DHL Global Forwarding

Geothermal on the Rise (p. 80)

Chevron, BHP, NOV, Shell Energy, Nabors

The Dealmakers in Dubai (p. 111)

LPX Partners

Saudi Sets Stage for 2034 (p. 104)

JSL Global, Red Sea Gateway Terminal, GAC Qatar, The Heavy Lift Group, Roll Group, CEVA-Almajdouie Logistics, DENZAI, Saudi Ports Authority, NEOM, BESIX Group, Aramco

Inside deugro’s High Stakes Move (p. 117)

deugro, United Heavy Lift, BBC Chartering, AD Ports Group, Samsung C&T

Baltic Security Boost Creates Project Cargo Boom (p. 122)

BigLift, The Heavy Lift Group, Goldhofer, CF&S Group, Siemens Energy

Vietnam, Verified (p. 127)

DHL Global Forwarding, Blue Water Shipping, Rhenus Air & Ocean, NMT Projects

Key: Exhibitor

Breakbulk Global Shipper Network Member

INSIDE

Movers & Shakers

Waves of Cargo - Berard Transportation Inc.

PowerTrips Photo Contest Winners

West Coast Ports Update With PCC Logistics

News Bites

New Exhibitors at Breakbulk Americas

Project Power Awards Shortlist

MYCRANE’s Trading Expansion

Meet the Breakbulk Editorial Board

Margaret Kidd on Tariff Tensions

Women Steering America’s Waterways

One of North America’s first all-electric mobile cranes ready for operations at the Port of San Diego.

Credit: Port of San Diego

MOVERS AND SHAKERS

Highlighting Recent Industry Hires, Promotions and Departures

GEODIS

Laura Ritchey has begun her new role as president and CEO of GEODIS in the Americas, succeeding Mike Honious, who is retiring from the supply chain industry after 20 years with the company. Ritchey will lead a workforce of nearly 20,000 employees across eight countries, overseeing the management and growth of multiple business units in North and South America, including contract logistics, freight forwarding and transportation.

Ritchey joins GEODIS with over 30 years of experience, including 15 years in supply chain management for both retail and third-party logistics. Most recently she served as CEO of e-commerce fulfillment provider Radial, Inc. “With the U.S. being one of the top markets in our global network, Laura has the robust industry and leadership experience needed to continue strengthening GEODIS’ position in this critical region,” said Marie-Christine Lombard, CEO of GEODIS.

Blue Water Shipping

Following his departure as CEO of DHL Industrial Projects, Ryan Foley is set to join Blue Water Shipping as senior vice president of projects, effective from January 2026. “Blue Water’s reputation for tailored, safe and scalable project logistics aligns perfectly with my background in global industrial forwarding and project execution,” Foley said. “Together, I am confident we will exceed client expectations and drive sustainable value across major capital-intensive projects.”

In his new position, London-based Foley will lead Blue Water’s global project logistics strategy across sectors including energy, infrastructure, mining and industrial development, working closely with regional teams in Europe, the Americas, the Middle East and Africa, Asia and Oceania.

WR Logistics

WR Logistics has appointed Enejan Novruzova as CEO of its branch in Ashgabat, Turkmenistan, recently launched as part of the company’s ongoing expansion in the CIS region. In her new role, Novruzova will focus on building strong local partnerships and driving strategic growth.

Fluent in Turkmen, English, Russian and Turkish, Novruzova previously served as country manager at Suvari Shipping & Trading, where she led business development and operations across the Turkmenistan and CIS markets. She also worked at Turkmenbashi International Sea Port, where she managed marketing strategy and inter-port cooperation in the Caspian region.

LPX Partners

Global logistics and supply chain investment firm LPX Partners has welcomed Thomas Skellingsted as its new managing director. Based in Dubai, Skellingsted will lead the buildout of LPX’s consulting practice, focusing on control tower implementation, bonded warehouse and logistics innovation across sectors such as energy, renewables, mining and infrastructure. He will also support the development of LPX’s core logistics operations across the region.

A frequent speaker at Breakbulk events, Skellingsted boasts more than three decades of experience in transport and logistics, with executive stints at companies including Hitachi and ABB. Prior to LPX Partners, he was president of Texas-based 4D Supply Chain Consulting, part of the deugro group.

Laura Ritchey

Ryan Foley

Thomas Skellingsted

Enejan Novruzova

Blue Water Shipping

Thomas Bek has been appointed CEO of Blue Water Shipping, taking over from Søren Nørgaard Thomsen, who is leaving the transport and logistics group after seven years. Bek joined BWS as a freight forwarding trainee nearly three decades ago. He most recently served as chief operating officer of the company’s energy, ports and projects division.

“Thomas Bek has a deep understanding of and knowledge about the entire Blue Water business: commercially, operationally and financially — and he is one of the strongest ambassadors for Blue Water’s unique values and culture. We believe that now is the right time to put Thomas at the helm of Blue Water as we set out to achieve the goals of our ambitious 2030 strategy,” said Jørgen Wisborg, chairman of the board.

LS Cargo

Drew Roberts has started his new role as president of North American operations at LS Cargo. Boasting more than 20 years of experience in the project logistics sector, Roberts brings “deep expertise” in handling complex industrial shipments in areas such as heavy-lift, over-dimensional cargo and U.S. rail transportation, LS Cargo said.

Prior to joining LS Cargo, Roberts headed North American operations at Trans Global Projects (TGP). He has also held executive positions at Martin Bencher Group (now part of Maersk Projects), DSV and deugro.

Airbus

Airbus has stuck with a familiar face after naming Jürgen Westermeier as president and managing director for India and South Asia. Westermeier joined Airbus as chief procurement officer in 2020 following more than two decades at BMW.

In his new role, Westermeier will lead Airbus’ operations in India and South Asia across commercial aircraft, defense and space, and helicopters. He will oversee commercial aircraft sales and drive regional expansion in the areas of services, engineering, digital solutions, innovation and training. The executive will also support Airbus’ commitment to ‘Make in India’ by advancing key company campaigns aligned with this national vision.

Air Charter Service

Air Charter Service has named Kerry Holder as its new chief financial officer, succeeding Stewart Pitt, who steps down after 19 years in the role to become a non-executive director. Holder brings to the company nearly three decades of financial experience, having begun her career at KPMG in 1997 and most recently serving as group finance director at Oxford International Education Group.

“ACS is unique in its field, with large volumes of business going through its global network across 18 countries. ACS is in a strong financial position, and I look forward to continuing the incredible work that Stewart achieved during his tenure,” Holder said.

QTerminals

Marco Neelsen has been appointed group CEO of Qatar-headquartered port operator QTerminals. Neelsen takes over from Charles Meaby, who, since April, has been acting CEO following the departure of Neville Bissett earlier this year. Meaby will return to his former role as managing director of Hamad Port, QTerminals’ flagship facility in Doha.

“His proven expertise in operational excellence, strategic transformation and port development positions him strongly to lead QTerminals into its next phase of growth, transformation and global expansion,” the company said.

Hamburger Hafen und Logistik

Jeroen Eijsink has become CEO of Hamburg-based logistics provider Hamburger Hafen und Logistik (HHLA), effective from October 1. Eijsink brings more than 25 years of international experience in the logistics and transport industry. The executive previously worked for road transport company Girteka Group, where he also served as CEO and led the strategic realignment of the company.

“HHLA is gaining an internationally experienced leader with a deep understanding of the challenges and opportunities of global logistics,” said Rüdiger Grube, chairman of the supervisory board. “We are confident that Jeroen Eijsink will provide the right impetus to ensure that HHLA remains successful, future-proof and competitive.”

Kerry Holder

Marco Neelsen

Jeroen Eijsink

Drew Roberts

Thomas Bek

Jürgen Westermeier

SHINE DOWN HITS THE WATER: BERARD LAUNCHES WORLD’S LARGEST HOUSEBOAT

When the world’s largest houseboat was ready to launch into Louisiana’s Bayou Teche waterway, heavy transport specialist Berard was there to take the helm. Built in Loreauville by the skilled craftsmen at Breaux Brothers Enterprises, the 330-ton, 120-foot Shine Down demanded precision planning and expert handling before its onward journey to sunny Florida. We spoke with Berard’s owner and COO, Braedon Berard, to hear how his team pulled off this mammoth splash.

Q: What were the biggest logistical challenges you had to prepare for before the move?

BB: Our team has assisted Breaux Brothers with nearly all their builds over the years, but this one was a milestone for the shipyard as it was the tallest, widest and heaviest vessel built to date. Several site visits, engineering and planning were considered to ensure all went well for the launch. When

the vessel was ready for transport to the launch ramp, the team had only about one foot of clearance between the vessel’s second deck roof and the shop roof to lift the vessel to begin the transport. Once at the launch ramp, the vessel was lowered onto an airbag system for the final launch phase. Heavy-duty prime mover winch trucks with cable lines attached to the vessel were used for a precise and controlled descent rate into the Bayou Teche.

Q: What equipment did you choose to manage the vessel’s weight and size?

BB: We deployed 16 lines of self-propelled modular transporters (SPMTs) to move the vessel to the launch ramp, two power pack units (PPUs), four prime mover trucks to slowly lower the vessel down the ramp and six air bags.

Q: Were there any unexpected issues during the move or launch?

BB: With all the pre-planning and preparation exercised prior to launch, we experienced no unexpected issues, proving

Waves of Cargo

Braedon Berard

The Shine Down is safely launched and ready for its onward voyage to Florida.

Credit Berard

that doing your homework certainly makes for a flawless job.

Q: What was the most rewarding aspect of the project for you and your team?

BB: The most rewarding aspect of the job was that both Breaux Brothers and Berard Transportation are from the same one red light town, and employees from both companies grew up together. Another rewarding aspect would be assisting them with another milestone project. This vessel received quite a bit of publicity as it finally made its way down the Bayou Teche and onward to its home in Florida. We’re proud to be a part of such a fantastic project.

The 330-ton houseboat is slowly lowered into the water using prime movers and airbags. Credit: Berard

The project team deployed four prime mover winch trucks to control the launch. Credit: Berard

Berard had just one foot of clearance between the vessel’s second deck roof and the shop roof. Credit: Berard

16 lines of SPMTs move the Shine Down slowly to the launch ramp. Credit: Berard

Winning Photo

Bragg Companies

Bragg Companies is hard at work at the Gonzaga Ridge Wind Farm, using their Goldhofer FTV 850 blade transporter and AdDrive modular system to safely haul massive wind turbine blades across challenging terrain.

Visit the Bragg team at Breakbulk Americas, Stand M36

Original photo (drone image taken at lower resolution). Credit: Cara Reece

Winning video Racing Cargo

Visit us at Stand B16

From Kandla to Galveston, 2025:

This Breakbulk operation moved 1,800 tonnes of solar steel structures from India to Galveston, navigating thousands of nautical miles across global shipping lanes. Every stage from port handling to secure stowage was coordinated with precision, ensuring the cargo arrived safely on June 29.

Watch on YouTube https://www.youtube.com/watch?v=2Svpk2jt1UA

Top Photos

2nd Place: Racing Cargo, Galveston, Texas, Stand B16 Credit: David James

4th Place: Unimar, Amazonas, Brazil

3rd Place: Fracht Group, Houston, Texas Credit: Digiworld Media

5th Place: Port of San Diego, San Diego, California, Stand T07 Credit: Clarisse Meyer

PCC’S STRATEGY FOR A SHIFTING SUPPLY CHAIN

As Tariffs Redirect Trade, PCC Helps Project Cargo Shippers Rethink the West Coast

By Leo Lopez

Founded in 1988 by Mike McDonnell, Pacific Coast Container began as a 10,000-square-foot cross-dock facility specializing in frozen protein. Over the past 37 years, PCC Logistics has grown into an industry leader with 12 business units across five major U.S. West Coast ports.

Today, PCC Logistics offers a comprehensive suite of services, including warehousing, distribution, project cargo and transportation, customized to meet the operational needs of both domestic and international clients. Our strategic locations in Seattle, Tacoma, Oakland, Los Angeles and Long Beach enable us to serve every major West Coast port with precision and reliability.

With over 2 million square feet of warehouse space and rail service in every region, PCC delivers scalable logistics solutions backed by deep operational expertise.

At the heart of our company is a customer-first philosophy rooted in honesty, loyalty and integrity. This commitment has fostered long-standing partnerships, some spanning more than three decades, built on trust, performance and shared growth.

West Coast Ports Rise as Project Cargo Gateways in the Tariff Era

The U.S.-Asia tariff shakeup has disrupted traditional cargo flows, leading to a drop in container volumes at West Coast ports. But with reduced congestion comes opportunity. These ports are now emerging as high-performance gateways for project cargo, especially as shippers re-evaluate routing and customs strategies.

PCC Logistics Leads the Response

With warehousing and project cargo facilities across Los Angeles/Long Beach, Oakland and Seattle/Tacoma, PCC has accelerated its expansion to meet the moment. The company recently added bonded capacity throughout its West Coast network — empowering importers to mitigate tariff exposure through duty-deferral strategies, align cargo release with delivery schedules and stage oversized and sensitive cargo with precision.

Tariffs Change the Game

Over the past year, tariffs have introduced major uncertainty. While freight rates stabilized in August following a surge of pretariff imports, volatility remains a constant.

“Surprises in shipping, like last-minute surcharges or vessel skips, don’t faze us,” said Leo Lopez, director of operations at PCC. “We adjust routing, cross-dock if needed and shift delivery plans to keep cargo moving.”

As global sourcing shifts and customs strategies evolve, PCC’s bonded infrastructure and operational agility are helping shippers navigate complexity with confidence.

Why West Coast Ports Are Emerging as Project Cargo Powerhouses

Despite tariff volatility, global countries remain a key source for industrial equipment and modular components used in North American infrastructure projects. Many suppliers continue to

Owner Mike McDonnell circa 1988, the beginning of PCC Logistics. Credit: PCC

offer cost-competitive solutions, making direct ocean routes from Asia to the U.S. West Coast both practical and efficient.

West Coast ports, including Los Angeles/Long Beach, Oakland and Seattle/Tacoma, offer distinct advantages: faster customs clearance through established bonded facilities, direct inland connectivity via rail and trucking corridors, and strategic proximity to high-growth regions like California, the Pacific Northwest, Alaska and Western Canada.

These regions are experiencing a surge in energy, mining and infrastructure investment, and West Coast ports are uniquely positioned to support complex project cargo flows. PCC Logistics, with bonded and project cargo facilities in all three gateways, is helping importers navigate tariff exposure while maintaining delivery precision.

Recent shifts in trade policy have only amplified this opportunity. As container volumes decline due to tariff-driven sourcing changes, shippers are turning to West Coast gateways for alternate routings, duty-deferral strategies and controllable project delivery.

Regional Perspectives: West Coast Gateways in Action

Los Angeles/Long Beach

No U.S. port has felt the impact of shifting tariffs more acutely

than LA. Brandon McDonnell, executive vice president at PCC noted: “We’ve expanded bonded warehouse capacity to support duty-deferral, smooth customs clearance and provide flexible staging for oversized and sensitive cargo.” As importers frontload shipments ahead of tariff deadlines, PCC’s infrastructure ensures agility and compliance in one of the nation’s busiest trade corridors.

Oakland

Northern California’s clean energy boom and industrial reinvestment are driving new volumes through the Port of Oakland. Luis Corral, facility manager at PCC Oakland emphasized: “Oakland is well placed for cargoes feeding the region’s renewables and manufacturing sectors. Strong inland access makes it a natural hub for project cargo.” With EPAbacked zero-emissions initiatives underway, Oakland is fast becoming a sustainability leader in the logistics space.

Looking Ahead

With sourcing decisions in flux, West Coast ports are taking on a larger role in project cargo movement. PCC’s bonded capabilities and regional coverage give importers the flexibility to plan smarter under pressure. To learn more about PCC Logistics’ plans, visit them at Breakbulk Americas, Stand Q36

Leo Lopez is the director of national accounts and operations at PCC.

One of PCC’s state-of-the-art facilities serving the West Coast and beyond. Credit: PCC

NEWS BITES FROM AROUND THE WORLD: QUICK HITS, BIG IMPACT!

A roundup of Breakbulk shippers and exhibitors in the news

FLUOR-JGC JV WINS FEED WORK AT LNG CANADA FACILITY

A JV between Fluor and JGC has been awarded a contract to update the front-end engineering and design (FEED) for a proposed Phase 2 expansion of the LNG Canada facility in Kitimat, British Columbia. LNG Canada itself is a JV between Shell, Petronas, PetroChina, Mitsubishi Corporation and KOGAS.

DP WORLD EXPANDS AUTOMOTIVE CAPACITY AT JEBEL ALI

DP World has increased automotive capacity at Jebel Ali Port in Dubai with the opening of a 2.6 million square foot vehicle storage yard at Terminal 4. The expansion, which includes an 800-meter quay capable of handling up to three roll on-roll off vessels at once, has added 13,000 car equivalent units, boosting total capacity by 21% to 75,000 CEUs.

The upgrade has seen the transfer of ro-ro operations from Terminal 1 to the new purpose-built zone at T4, a move that will improve berth availability, shorten turnaround times and free up space to meet rising demand. The upgrade comes amid robust growth in vehicle volumes, with the Middle East’s busiest port handling 545,000 vehicles in the first half of 2025, up by 28% from a year earlier.

Since 2018, the Fluor-JGC JV has worked on the project’s Phase 1 by providing critical engineering, procurement, fabrication management, construction and commissioning services to build the facility and support safe startup. The 14-milliontonnes-per-year plant recently celebrated its first shipment of LNG.

PRISM BOOSTS GULF FLEET WITH ABU DHABI BARGE LAUNCH

Prism Logistics has launched its first 250-class barge into service in Abu Dhabi, strengthening its marine transport capabilities across the Gulf Cooperation Council (GCC). Built for transporting heavy loads across international sea routes, the vessel marks a significant step in the company’s offshore logistics expansion.

The barge will support industries including oil and gas, renewables, power and other industrial markets. While primarily intended for operations within GCC waters, it will also be deployed for worldwide missions if needed, the company said. The company confirmed that three more barges – a 230-class, 300-class and 330-class – will join the Abu Dhabi fleet in the coming months.

BOSKALIS-ALLSEAS JV WINS TAIWAN GAS PIPELINE CONTRACT

A JV between offshore contractors Boskalis and Allseas has secured a €1.2 billion contract from Taiwan’s state-owned oil and gas firm CPC Corporation to build a major offshore natural gas pipeline. The 50/50 consortium will design, construct and install the 232-kilometer YT2 pipeline, which will run parallel to an existing line linking the Yongan LNG terminal in southern Taiwan to the Tongxiao transfer station in the north.

The project, aimed at boosting energy security and supporting Taiwan’s energy transition, is slated to begin in 2026 and conclude in 2028. Taiwan is ramping up LNG infrastructure as it shifts away from coal and nuclear energy, with gas expected to play a central role in its future energy mix.

POLAND ENERGY MINISTER: SMRs TO JOIN GRID BY 2040

Poland is preparing to integrate small modular reactors (SMRs) into its power grid by 2040, Energy Minister Milosz Motyka said. The minister told an audience in Warsaw that work is under way on a roadmap to develop the SMRs, advanced reactors with a generating capacity of up to 300 MW. Plans are already in place in Poland

EXXONMOBIL FIRES UP FOURTH OFFSHORE GUYANA PROJECT

ExxonMobil has begun production at Yellowtail, its fourth oil development at Guyana’s prolific offshore Stabroek block. Yellowtail’s One Guyana floating production storage and offloading vessel joins the Destiny, Unity, and Prosperity FPSOs, bringing total installed capacity in Guyana to more than 900,000 barrels of oil per day (bopd).

One Guyana is the largest FPSO on the Stabroek block with an initial annual average production of 250,000 bopd and a storage capacity of two million barrels. By 2030, ExxonMobil Guyana expects to have a total production capacity of 1.7 million barrels of oil equivalent per day from eight developments.

for its first large-scale nuclear power plant at Lubiatowo-Kopalino on the Baltic Sea coast near Gdansk. Bechtel has been brought on board to build the facility, which will use Westinghouse AP1000 reactors to provide three GW of clean energy. Construction is slated to start in 2028, with the first of three reactors coming online in 2036.

ACS KEEPS CARGO MOVING AFTER SOUTHEAST ASIA BORDER SNARL

Air Charter Service (ACS) has arranged dozens of charter flights transporting thousands of tons of cargo between Thailand and Cambodia, following the sudden closure of the countries’ shared land border. The cargo is being shipped as manufacturers have scrambled to secure alternative logistics solutions after the border shutdown halted all road transport, severely disrupting supply chains.

The aircraft charter specialist said the initial spike in demand came from the automotive industry, with flights carrying as much as 100 tons of cargo. Requests quickly expanded to consolidated shipments involving goods from multiple industries. The charters have run between Bangkok and the Cambodian cities of Siem Reap and Phnom Penh, with cargo moving in both directions.

ACWA POWER, GIC TO DEVELOP KUWAIT’S LARGEST IWPP

ACWA Power and consortium partner Gulf Investment Cooperation have signed a letter of agreement with authorities to develop the Az-Zour North Phase 2 & 3 Independent Water and Power Project (IWPP) in southern Kuwait. The US$4 billion project is set to be the nation’s largest integrated power and water plant, with a net

power generation capacity of at least 2,700 MW and a net desalinated water production capacity of 120 million imperial gallons per day.

According to ACWA Power, the facility will be developed under a 25-year buildoperate-transfer (BOT) agreement, with the consortium designing, financing, building, operating and maintaining the

plant before transferring ownership to the government. Operations are slated to begin in 2029.

MEET NEW EXHIBITORS AND SPONSORS AT BREAKBULK AMERICAS

We asked some of our standout exhibitors a few questions, including what they have to offer and what the biggest industry challenges are today, to help you start the conversations on the show floor.

ONE Dan Sheehy Senior Vice President of Marketing & Commercial Virginia, USA Maritime Transport www.one-line.com Sponsor

What is the most important thing about your company that you’d like the Breakbulk community to know about?

We want the breakbulk community to know that Ocean Network Express (ONE) is fully committed to being a reliable, flexible and innovative partner for oversized and project cargo solutions. While ONE is globally recognized for its extensive container shipping network, we’re not just a container carrier, we’re a partner you can trust for your most challenging logistics needs. Our global reach and local expertise ensure that we can efficiently and safely support breakbulk and project cargo movements across key trade lanes.

What made you decide to exhibit /sponsor at Breakbulk Americas this year?

Breakbulk Americas provides an exceptional platform to connect directly with key players across the supply chain. As the largest gathering of industry professionals in the Americas, the event allows us to showcase our specialized services, particularly in handling heavy-lift, oversized and complex cargo moves, and to highlight our expanding capabilities across North America.

More than that, we see Breakbulk Americas as a golden opportunity to engage with current and potential partners, understand emerging market needs, and reinforce our customer-first approach by listening and learning from our peers.

What are the biggest challenges facing industry professionals, and how can coming together in Houston benefit you and your colleagues?

Navigating continued supply chain volatility is a monumental challenge, especially in relation to project cargo planning, port congestion, equipment availability and geopolitical uncertainty. Every move within the breakbulk and heavy-lift space is complex and high-stakes, making collaboration and real-time information sharing more critical than ever.

The beauty of our time at Breakbulk is that it’s not just a trade show: it’s a forum for open dialogue, relationship building and solution sharing. By connecting face-to-face with shippers, trucking companies, forwarders and port authorities, we gain clearer insights into shared challenges and can collaborate to create more resilient, innovative supply chain strategies. As ONE, We Can!

GCS Industrial Group

Chad Downs Vice President

Texas, USA Maritime Transport www.gcsind.com Stand F51

What is the most important thing about your company that you’d like the Breakbulk community to know about? We want the Breakbulk community to know that GCS Industrial is a Houston area-based stevedore company that operates in Texas and Louisiana. GCS Industrial leads with safety and quality, coming through on our commitments to clients and our employees is paramount.

What made you decide to exhibit at Breakbulk Americas this year?

Attending Breakbulk will aid GCS Industrial in showcasing our brand, broadening our network and growing our company. Connecting with potential future clients and building relationships is essential to GCS’s growth.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

The biggest strains industry professionals face today in our opinion are global trade uncertainties, port congestion and delays, geopolitical instability, and technology adoption and integration. With great minds from thousands of premier companies coming together at Breakbulk Americas, ideas and solutions to significant industry issues can be communicated and remedied.

Heavy Duty Transaxle

Peter Thomas Chief Operating Officer

Washington, USA

Equipment hdtransaxle.com

Stand R16

What is the most important thing about your company that you’d like the Breakbulk community to know about?

Heavy Duty Transaxle is the largest independent distributor of Meritor industrial and off-highway components in the USA. We specialize in providing high-quality drivetrain components for off-highway, load-intense applications like port operations, ensuring durability, efficiency and superior performance. Since 1995, we’ve kept America’s fleets up and running.

What made you decide to exhibit at Breakbulk Americas this year?

The attendees at Breakbulk Americas are the leaders in energy, construction and logistics. Their operations depend on a reliable fleet, which requires a reliable supply of genuine drivetrain components. Heavy Duty Transaxle and Meritor have combined to deliver a unique offering, providing high-quality drivetrain solutions tailored for specialized applications. This partnership ensures unmatched durability, efficiency and performance.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

Mergers, acquisitions and planned obsolescence have created significant challenges for maintenance managers striving to keep their fleets operational. Extended lead times and inflated costs often leave equipment idle, resulting in substantial losses in both time and revenue. Heavy Duty Transaxle, in partnership with Meritor, offers a powerful solution. Our innovative programs deliver high-quality drivetrain components, ensuring reliable fleet performance without excessive costs. With a focus on durability, efficiency and exceptional customer support, we empower maintenance managers to minimize downtime and maximize operational success.

Racing Cargo

Agustín Ravelo Chief Commercial Officer Texas, USA

Freight Forwarder

racingcargo.com

Stand B16

What is the most important thing about your company that you’d like the Breakbulk community to know about?

Racing Cargo is a logistics company with a strong global presence. We combine global reach with local expertise, ensuring seamless coordination and execution across borders. Our team is deeply committed to delivering solutions that go beyond transportation, we build trust and long-term partnerships.

What made you decide to exhibit at Breakbulk Americas this year?

This year is a milestone for Racing Cargo as we launch several groundbreaking breakbulk cargo projects in the U.S., especially in strategic hubs like Galveston, Houston and California.

Exhibiting at Breakbulk Americas is a natural step because it allows us to formally introduce our capabilities to the North American market and connect with industry leaders. We’re here to show that Racing Cargo is not just entering the U.S. market, we’re here to make an impact.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

The biggest challenges today include navigating global supply chain disruptions, ensuring cargo security and bonding with strong, reliable partnerships in a fast-paced

environment. Coming together in Houston creates an essential space for collaboration, knowledge exchange and relationship-building. For us at Racing Cargo, it’s an opportunity to strengthen our network, deepen key partnerships and build the trust that drives successful project execution, both in the U.S. and globally.

Xenon Freight Solutions

Jessie (Alesi) Schueller

Head of Commercial Development

New Jersey, USA

Freight Forwarder

xenonfs.com

Stand H33

What is the most important thing about your company that you’d like the Breakbulk community to know about?

Xenon FS is a full-service final mile provider. We can assist in any location in the continental U.S., as well as Canada, Hawaii, American Samoa and Guam. We are able to assist with any OOG, flatbed, FTL/ LTL, breakbulk and/or specialized cargo moves. We like to consider ourselves a one-stop shop for all your final-mile needs!

What made you decide to exhibit at Breakbulk Americas this year?

We understand the demand for specialized trucking and feel Breakbulk Americas is a great way to get our name out to the breakbulk logistics community.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues? Creativity and innovation are key in this market. Not everyone is willing to brainstorm to come up with new solutions for transporting difficult breakbulk commodities and sizes. We are all industry experts in this field, and we can collectively come up with new ways to move our customers’ goods efficiently.

Doral Equipment Rental

Ken Meuler

Rental

Specialist

Wisconsin, USA Equipment

doralequipmentrental.com

Stand E58

What is the most important thing about your company that you’d like the Breakbulk community to know about?

Doral Equipment Rental offers the largest fleet of VersaLift forklifts in the nation for bare rental, along with other specialized heavy lifting equipment for rigging and machinery moving. We provide coast-to-coast delivery for both shortterm and long-term rentals, ensuring our customers get reliable, well-maintained equipment exactly when and where they need it. Our team understands the precision, safety and efficiency that critical lifts demand, and we back every rental with responsive, expert support.

What made you decide to exhibit at Breakbulk Americas this year?

This is our first year at Breakbulk Americas, and we see it as the premier gathering place for the project cargo, rigging and heavy-lift community. Our goal is to connect with industry leaders, share how our specialized fleet can help solve complex lifting challenges and forge partnerships with companies who value dependable equipment and service.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

One of the biggest challenges in our industry is coordinating specialized equipment availability with tight project timelines, especially when those projects require precise, heavy-lifts in diverse locations. By coming together at Breakbulk Americas, we can exchange solutions, learn from each other’s expertise and build the relationships that make these complex projects possible, no matter the distance or demands.

ICAT Logistics

Tyler Sullivan

Texas, USA

Freight Forwarder www.icatlogistics.com

Stand D48

What is the most important thing about your company that you’d like the Breakbulk community to know about?

ICAT Logistics has been in business for over three decades, delivering the most complex and critical

cargo to over 226 countries and territories through our global partnerships and deep industry knowledge. While we are well known for our government and defense work, we have expanded into the oil and energy sector by establishing a centralized project control tower for smarter decisions and faster results. We actively charter both aircraft and vessels and have implemented warehouse consolidation programs for leading oil and gas companies. By applying our proven government and defense logistics expertise, we provide mission-critical solutions with the speed, compliance and precision that the energy sector demands now more than ever.

What made you decide to exhibit at Breakbulk Americas this year?

We are investing across the Gulf Coast and key export corridors that support it. Our objective is to align early with EPCs, OEMs, and our carrier, warehouse and trucking partners, to solve global, high consequence challenges for our customers. Breakbulk Americas is the ideal platform for our team to connect with top decision-makers, formalize long-term partnerships and establish standard operating procedures that will be crucial for years to come.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

The oil and energy supply chain is under continuous pressure from multiple fronts. We are contending with volatile geopolitical chokepoints, such as the Strait of Hormuz and Suez Canal, infrastructure constraints at critical ports and inland corridors, tightening regulatory and ESG mandates, and cost inflation across ocean, air and trucking capacity.

Climate-related risks from sea level rise at export terminals to extreme weather disrupting production and transport are also forcing operators to reinvent resilience. The oil and gas industry continues to struggle with the constant shortage of skilled labor, both on the operational and compliance sides, while cybersecurity threats are escalating and impacting digital logistics networks.

The Gulf Coast region is a global energy and project cargo hub that is home to major EPCs, OEMs, operators and logistics providers. Gathering in Houston for Breakbulk Americas offers a strategic advantage, giving our team the opportunity to exchange real-time intelligence on evolving risks, align on contingency routing and infrastructure solutions, and strengthen partnerships that shorten decision cycles in high consequence moves. This concentrated forum in Houston is a great way to connect with the key stakeholders who collectively drive resilience, efficiency and innovation in the face of today’s logistics headwinds, and we look forward to making an impact.

BDS Heavy Haul

Ryan Simons President

North Dakota, USA and Alberta, Canada Road Transport

bdsheavyhaul.com

Stand T14

What is the most important thing about your company that you’d like the Breakbulk community to know about?

With a fleet of specialized heavy haul trailers, pilot trucks, picker trucks and crane units, BDS Heavy Haul navigates route planning, permits, regulatory compliance, customs clearance and safety requirements to expertly haul oversize and overweight loads to their required destinations. Whether moving oversize/overweight industrial equipment across Canada’s challenging terrain or navigating U.S. interstate regulations with multi-wheeled trailers, we provide seamless transportation solutions backed by a fleet of specialized, state-of-the-art heavy haul trailers capable of hauling up to 225,000 lbs. and a commitment to cross-border coordination.

What made you decide to exhibit at Breakbulk Americas this year?

We chose to exhibit at Breakbulk Americas because it aligns perfectly with our strategic growth goals and our commitment to serving the North American heavy haul market. This event is the ideal platform to showcase our expanded cross-border capabilities that have been strengthened by recent investments in additional heavy haul trailers and specialized equipment.

It also provides the opportunity to connect face-to-face with both new and existing clients across sectors. These conversations allow us to better understand project needs, share our expertise and explore how BDS can deliver safe, efficient and compliant transport solutions for some of the most complex loads across the U.S. and Canada.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

Oversized and overweight loads, particularly cross-border shipments like those BDS Heavy Haul specialize in, face a maze of changing regulatory requirements, trailer configuration acceptance, rising costs, skilled labor shortages and aging transportation infrastructure that impacts route planning. Managing these complexities requires significant resources, precise coordination, meticulous planning and the expertise of a seasoned heavy haul provider. When done incorrectly, clients face disruptions to their supply chains and project delays.

Breakbulk Americas is where these challenges meet solutions. Gathering in Houston enables industry leaders to connect with suppliers who have invested in showcasing their expertise, discussing emerging trends, and exploring practical solutions backed by real-world experience. For BDS and our clients, events like this go beyond networking, they foster relationships and collaborations that turn complex heavy haul projects into smooth, successful operations.

The Port of Hueneme

Stacy Lange Chief Commercial Officer

California, USA

Ports & Terminals

www.PortofH.org

Stand C57

What is the most important thing about your company that you’d like the Breakbulk community to know about?

How to pronounce Hueneme: Why-Nee-Me. All kidding aside, we want the breakbulk community to see the Port of Hueneme as their premier gateway in the West, known for our uncongested gate and out-of-the box thinking. As an operating port, we are able to choose our commercial business partners and offer unique solutions. This flexibility has allowed us to drive innovation and grow our cargo volume by 80% over the last ten years.

What made you decide to exhibit at Breakbulk Americas this year?

Exposure was a key driver in our decision to exhibit at Breakbulk Americas this year. The Port of Hueneme has made significant investments in infrastructure to support our continued growth, with major improvements already completed and more on the way. Our unique operating model offers flexibility and efficiency that we believe aligns well with the needs of the breakbulk community. We’re here not only to share what makes Hueneme a strong partner, but also to learn, collaborate and strengthen relationships across the industry.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

In today’s climate of uncertainty in international trade, one thing remains clear: relationships matter. The breakbulk industry is navigating shifting regulations, supply chain disruptions and evolving market demands. Coming together in Houston gives us the opportunity to build the right partnerships, share insights and collaborate on solutions. Now more than ever, the ability to weather changing tides depends on the strength of our connections.

Gulf of America Logistics

Keith Lincoln Vice President of Operations

Louisiana, USA

Freight Forwarder

www.goalogistics.com

Stand M01

What is the most important thing about your company that you’d like the Breakbulk community to know about?

Gulf of America Logistics (GOAL) is a veteran-owned, U.S.-based logistics provider built around engineered solutions for oversized, heavy-haul and project cargo. We pride ourselves on being hands-on problem solvers who understand the challenges of moving complex freight safely and efficiently. Our team combines decades of operational expertise with a homegrown, America-first approach to delivering reliable transport services across trucking, barge, and rail.

What made you decide to exhibit at Breakbulk Americas this year?

Breakbulk Americas is the heart of our industry, and Houston is the natural hub for project cargo in North America. As a growing company, we want to showcase our capabilities, connect with partners and demonstrate how GOAL can bring fresh energy and practical solutions to the marketplace. Exhibiting gives us the opportunity to meet face-to-face with decision-makers and reinforce our commitment to being a trusted logistics partner.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

Today’s logistics professionals face tightening capacity, volatile pricing and the need for seamless coordination across multiple transport modes. The best way to overcome these challenges is through collaboration and trusted partnerships. Breakbulk Americas creates that platform: It allows us to exchange ideas, build relationships and align on how to keep projects moving forward despite market headwinds. For GOAL, being in Houston means being at the center of those conversations.

PSC Crane & Rigging

John Boone Special Projects Manger

Ohio, USA Equipment www.pscind.com

Stand N20

What is the most important thing about your company that you’d like the breakbulk community to know about?

At PSC Crane and Rigging, we pride ourselves on being more than just a crane service provider. We are a trusted turnkey partner for complex lifting, heavy hauling and industrial rigging projects. From planning and engineering to execution, our team delivers safe, efficient and cost-effective solutions tailored to each client’s unique needs. With decades of experience and a commitment to safety and precision, we ensure every project moves forward without compromise.

What made you decide to exhibit at Breakbulk Americas this year?

Breakbulk Americas brings together the very industries we serve — energy, manufacturing, infrastructure, and beyond. We chose to exhibit this year to showcase our expanding capabilities, connect with partners and clients, and highlight the expertise we bring to large-scale and specialized projects.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

One of the biggest challenges in our industry today is navigating increasingly complex logistics while maintaining the highest standards of safety, efficiency and compliance. Rising project demands, tighter timelines and evolving regulations require greater collaboration across all segments of the supply chain. By coming together in Houston, we can exchange knowledge, strengthen relationships and align on innovative approaches that keep projects moving smoothly.

South Brooklyn Marine Terminal (SBMT)

Mike Taylor

Head of Ports, Equinor Renewables

New York, USA

Ports & Terminals

www.southbrooklynmarineterminal. com

Stand T21

What is the most important thing about your company that you’d like the breakbulk community to know about?

The South Brooklyn Marine Terminal (SBMT) is a premier port and maritime facility located in the heart of New York Harbor within the Sunset Park neighborhood of Brooklyn. The site features 63 acres of recently upgraded facilities, quayside and laydown areas, heavy-lift infrastructure, versatile berthing options, and large cargo operations dredge depth. SBMT offers unmatched resources for a variety of maritime applications, with a particular focus on offshore wind and renewable energy operations. Strategically situated to serve the Northeast, SBMT is designed to accommodate large-scale logistics, cargo handling and high-capacity staging requirements. The site is currently being upgraded for NY’s Empire Wind project after which it will be available for use in mid-2027.

What made you decide to exhibit at Breakbulk Americas this year?

The current regulatory landscape has changed the outlook for offshore wind in the short-term, and it is likely to be several years before the next wind project uses SBMT for staging and assembly. SBMT is now in a position to service non-offshore wind tenants beginning in 2027. We decided to exhibit at Breakbulk Americas this year to showcase the port’s availability, its capabilities and engage with potential tenants to foster new relationships and potential partnerships.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

The breakbulk industry is navigating complex challenges. Supply chain disruptions and port congestion generate the need for modernized infrastructure that can handle a variety of vessels and cargo. As demand for efficiency and resilience grows, the availability of well-equipped ports and upgraded facilities has become critical, particularly in high-volume and space-constrained markets such as New York.

Breakbulk provides an opportunity to strengthen partnerships across the supply chain. For us at SBMT, Breakbulk provides a platform to showcase our capabilities and capacity, while also contributing to the collective effort to ensure the industry is ready to meet future demands.

Motion Plus

Tim Hobbs Director of Sales (right)

Rick Burks Managing AgentAce Drayage (left)

Pennsylvania, USA Road Transport www.motionpluslogistics.com Stand K10

What is the most important thing about your company that you’d like the breakbulk community to know about?

Our company has a large drayage asset presence in Baltimore, Philadelphia and Harrisburg/Chambersburg. We have 40 total trucks that service those ports and rails, but we also have a brokerage that services the drayage, oversized/over dimensional and over-the-road markets as well. We service all industries and have moved most types of freight in our ownership’s 50 years of combined trucking experience. Every shipment is important to us because every shipment is important to our customers.

What made you decide to exhibit at Breakbulk Americas this year?

Our ownership has attended the Breakbulk Americas in Houston in 2023 and 2024 and decided to become a larger and more impactful part of the exhibit this year. We’re excited to have a booth that will be worked by our employees and owners while we’ll also be walking the floor to see what other companies are attending that we can potentially partner with as customers and vendors. We’re happy to introduce ourselves as well as network other contacts with each other and help everyone grow and thrive together.

What are the biggest challenges facing industry professionals and how can coming together in Houston benefit you and your colleagues?

Every day, millions of trucks move across the highways, carrying the food we eat, the medicine that saves lives, and the goods that keep our stores and industries alive. Without them, shelves go bare, hospitals run short, and factories grind to a halt. Truck drivers are the hidden arteries of the nation, pumping life into every corner of the country.

This is the paradox we live in: We depend on truckers more than ever, but discourage the next generation from joining their ranks. More simply, everyone knows how important truck drivers are to our country, but very few parents ever encourage their children to aspire to seek truck driving as a career. The United States and Canada are in constant need of dependable and experienced truck drivers, and there are plenty of opportunities for the next generation to begin their careers and begin providing for their families and their communities.

NEW EXHIBITORS AND SPONSORS AT BREAKBULK AMERICAS 2025

The Project Power Awards recognize excellence in the execution of complex energy-related projects across the Americas.

These awards serve as a platform to share innovations and practical expertise with the broader Breakbulk community, helping others learn from real-world challenges and successful strategies.

Join the awards ceremony at Breakbulk Americas on Thursday, Oct. 2 at noon on the Main Stage and stay for the celebratory reception! YOU’RE INVITED!

PROJECT POWER AWARDS SHORTLIST

2025 Power Project of the YearA People’s Choice Award

Conceptum Logistics Group

Empowering Clean Energy Through Precision Logistics: Conceptum Logistics’ Partnership with Enerkem Canada

Energy project type: Waste-to-Energy

Meet us at Breakbulk Americas, Stand L21

Port of Brownsville

Rio Grande LNG: A Transformational Energy Project at the Port of Brownsville USA

Energy project type: Carbon, Capture & Storage, Oil & Gas

Meet us at Breakbulk Americas, Stand K30

TRT International, LTD.

Moving Massive Transformers for the National Grid

USA

Energy project type: Battery Storage / Energy Storage Meet us at Breakbulk Americas, Stand G20

Wiz Logtec Solutions Inc.

Supporting What Could Become America’s Largest Solar Panel Manufacturing Plant USA

Energy project type: Solar

2025 Power Move: Barge Transport

De Mase Trucking

Equipment Barged to Ontario for Honda EV Battery Production Canada

Energy project type: Hydrogen

Meet us at Breakbulk Americas, Stand M06

Mallory Alexander International Logistics From India to West Virginia With Planning and Precision USA

Energy project type: Oil & Gas

Meet us at Breakbulk Americas, Stand Q30

UNIMAR AGENCIAMENTOS MARITIMOS LTDA

Navigating the Amazon During a Historic Drought Brazil

Energy project type: Oil & Gas

Ulog Argentina S.A.

Cross-Border Barge Transport of 10 Complete Wind Turbines from China to Bolivia via Argentina

Bolivia

Energy project type: Wind

2025 Power Move: Best Logistics Strategy for an Energy Project

COLI Shipping

The Crossing of a Giant: The Journey of a 280-Ton Transformer from Brazil to Chile Chile

Energy project type: Wind

Erhardt Projects USA LLC

Erhards Projects Handles Global Shipment to Meet Power Demand in New York

USA

Energy project type: Hydroelectric

Meet us at Breakbulk Americas, Stand K12

Luminary Logistics Solutions

Transformer Transport from Brazil to Oregon: A Model for Complex Energy Logistics

USA

Energy project type: Battery Storage / Energy Storage, Solar

Meet us at Breakbulk Americas, Stand E40

RAMPS Logistics

Ramps Logistics Uses MAWI to Automate Customs Info for Valaris

Trinidad & Tobago

Energy project type: Oil & Gas

TRT International

Battery Storage Delivery Strategy for Sungrow USA

Energy project type: Battery Storage / Energy Storage

Meet us at Breakbulk Americas, Stand G20

2025 Power Move: Best Use of Equipment

Atlas Heavy

Transcontinental Transport of the Largest U.S.-Built Storage Tanks USA

Energy project type: Battery Storage / Energy Storage, Oil & Gas

Meet us at Breakbulk Americas, Stand N41

Bragg Companies Gonzaga Ridge Wind Farm USA

Energy project type: Wind

Meet us at Breakbulk Americas, Stand M36

Roll Group

LiMA Project in Bay City, Texas USA

Energy project type: Oil & Gas

Meet us at Breakbulk Americas, Stand F20

2025 Power Move: Ocean Transport

AAL Shipping

AAL’S Engineering Team Achieves Market Firsts With Super B-Class in 2024/2025

Mexico and Chile

Energy project type: Wind

UTC Overseas

Complex Maritime Transport Excellence

USA

Energy project type: Oil & Gas

Meet us at Breakbulk Americas, Stand D21

2025 Power Move: Road & Rail

Anderson Heavy Haul and Rigging

Large-Scale Transportation and Installation: Delivering 700,000-pound Transformer

Canada

Energy project type: Hydroelectric

Meet us at Breakbulk Americas, Stand H31

Bragg Companies

Cross-Country Journey for Refinery Boilers

USA

Energy project type: Oil & Gas

Meet us at Breakbulk Americas, Stand M36

Mallory Alexander International Logistics

Railcars From Switzerland to Maryland for Track Renewal USA

Energy project type: Oil & Gas

Meet us at Breakbulk Americas, Stand Q30

TRT International LTD

Battery Storage Delivery Strategy for Sungrow USA

Energy project type: Battery Storage / Energy Storage

Meet us at Breakbulk Americas, Stand G20

Tradelossa

Powering the North: 282-Ton Transformer Journey from Altamira to Apodaca Mexico

Energy project type: Battery Storage / Energy Storage, Hydroelectric, Solar

PROJECT POWER AWARDS JUDGES

Thank you to our judges for contributing their time and expertise to the Project Power Awards, a first for Breakbulk Americas. Many of our judges will be on hand at the ceremony in Houston on Thursday, Oct. 2 at noon. Join us at the reception to talk about the awards and the energy infrastructure scene. Let’s celebrate together!

John Amos President Amos Logistics

Steve Hill

Director, Global Logistics McDermott International

Amanda Duhon

President & Regional Director, North and Central America Energy Industries Council (EIC)

Peter Jessup Owner

Proactive Change Supply Chain Management Consultancy

John Hark

Chartering Director, North America

Bertling Logistics; Adjunct Professor Texas A&M University

Margaret Kidd Executive Director

Houston Maritime Center and Museum

Dennis Mottola

Owner and Lead Project Logistics Consultant

Mottola Global Logistics LLC

Geanean Ordonez

Project Logistics Manager - Procurement Technip Energies

Tania Smith Global Logistics Manager Freeport McMoRan

John Vogt President WWBC

John Rowe Vice President, Business Development SEA.O.G.

Thomas Skellingsted Managing Director LPX Partners

Grant Wattman President Jade Management Group

Andrew Young Corporate Manager of Logistics / Manager of BGL Bechtel Corporation

LIFTING THE INDUSTRY: MYCRANE’S US$50M EXPANSION

As new Breakbulk exhibitor MYCRANE expands with a Trading business, we look at the capabilities of the different crane types, and highlight a breakthrough lifting innovation from Mammoet, the world’s largest engineered heavy-lifting company.

MYCRANE is best known for developing the world’s first online crane rental platform, putting an end to constant phone calls, inefficient communication and hard-to-compare quotes. Since its launch in 2021, the platform has allowed users to enter their lifting requirements online and receive quotes from a range of crane owners, with registration free for both users and equipment owners.

Now the Dubai-based company is building on that success with the launch in August of MYCRANE Trading, a new division that will handle the sale, leasing and maintenance of cranes and lifting equipment. Based in Dubai’s Jebel Ali Free Zone, the business has already secured US$50 million in investment from a DIFC-based holding company and will operate in partnership with the existing rental platform.

“We’ve seen rising global demand for both new and used cranes, and growing appetite from asset owners to monetize surplus equipment,” says MYCRANE founder and CEO Andrei Geikalo.

“With MYCRANE Trading as a key partner, we can now respond directly to this demand by instantly connecting sellers with the rental platform’s thousands of fleet-owning users, many of whom have urgent purchase needs.”

The new arm combines a physical stock of cranes with the digital reach and transparency of the rental platform, giving customers worldwide access to equipment at competitive prices. The initial focus will be on the Middle East, Africa, CIS and Asia, where MYCRANE already has a strong footprint. All terrain, crawler, rough terrain and tower cranes will be offered, each supplied with certified inspections and safety reports.

MYCRANE has recruited an experienced management team for the new division. Sudheesh Mohan has been appointed head of

sales and marketing, while Mina Asham heads the tower crane business, both based in the UAE.

Geikalo emphasizes that the same principles behind the rental platform will apply at MYCRANE Trading: transparency, verified equipment, and simplified procurement. “Every crane is carefully sourced, with full documentation and inspection available, giving customers trusted access to verified equipment at competitive prices,” he says.

The launch of MYCRANE Trading is the latest in a series of milestones for the company, which has expanded internationally, added new features to its digital platform and collected three industry awards in 2025.

“Our mission has always been to simplify crane procurement,” Geikalo adds. “This new collaboration allows us to do that — not just for rentals, now for ownership too.”

Andrei Geikalo, MYCRANE

The MYCRANE Trading team. Credit: MYCRANE

KNOW YOUR CRANES

From high-rise towers to heavy industrial plants, cranes are the backbone of construction projects. Each type brings distinct advantages and emerging technology is reshaping how they’re deployed. Here’s what you need to know about the machines that keep global projects moving.

Mobile Cranes

The workhorses of construction sites everywhere. These all-terrain and rough-terrain machines excel at quick deployment, with lifting capacities spanning 25 to 1,200+ tons. The trade-off is straightforward: outriggers extended means maximum capacity, while operating “on rubber” cuts lifting power significantly. Today’s models integrate Load Moment Indicators (LMIs) — sensors and computing systems that monitor load weight, boom angle and radius in real time, warning operators or taking action before safe limits are exceeded.

Crawler Cranes

Built for the long haul on challenging terrain. These tracked giants handle capacities from 50 tons up to 4,000 tons or more, making them

MAMMOET MEGA-CRANE RAISES THE BAR

Mammoet’s latest innovation, the SK6000 crane, is already making waves across the heavy-lift sector. Described as the world’s most powerful land-based crane, it can lift up to 6,000 tonnes and raise components weighing as much as 3,000 tonnes.

A proprietary mega-crane developed in-house, Mammoet designed, assembled and tested the SK6000 at its Westdorpe facility in the Netherlands, with hundreds of its team members directly involved.

Its capability opens the door for larger modular pieces to be built offsite, reducing time and cost pressures on complex infrastructure projects and the crane’s impact has not gone unnoticed. This year, the SK6000 won the Innovation prize at the 2025 ESTA Awards of Excellence, with judges praising its potential to reshape construction practices in industries such as offshore wind and nuclear.

indispensable for major infrastructure and industrial projects. Their secret weapon? Exceptional stability when lifting at extended radii where other cranes would tip. The downside: they require complete disassembly for transport between sites, making them less nimble than their mobile counterparts.

Tower Cranes

The defining silhouettes of urban skylines. These vertical specialists dominate high-rise construction with capacities ranging from compact two-ton units to massive 100+ ton industrial models, though most fall in the 4-20 ton range for typical building work. Their jibs can stretch 80 meters or more, delivering consistent lifting performance across their entire radius while consuming minimal ground space. It’s this combination of reach and compact footprint that makes them irreplaceable in dense urban construction.

Just as significant as its size is its sustainability profile. The SK6000 is designed to operate using grid power or battery packs, allowing it to run with zero onsite emissions. Mammoet said this feature reflects growing desire among contractors to decarbonize project execution without sacrificing lifting power.

Using a modular design that can be containerized for transport, Mammoet expects to make the SK6000 available worldwide as demand grows for bigger, cleaner lifts.

Credit: Mammoet

THE VOICES BEHIND BREAKBULK

Breakbulk Magazine’s Editorial Board brings together industry leaders whose expertise shapes the stories you read. By sharing their perspectives, insights and bringing in new expert resources, these executives help deliver the knowledge that matters most.

John Amos

President, Amos Logistics

26 years at Bechtel Corporation, including as global head of traffic and logistics. Co-founded Breakbulk in 1989, responsible for high-level speakers. Established Amos Logistics and now serves on the board of U.S. Exporters Competitive Maritime Council (ECMC).

Tina Benjamin-Lea

Project Logistics Executive

Brings 30+ years in project logistics, shipping and heavy-lift. Known for expertise in post-conflict regions with roles at SNC-Lavalin, Air Products, Kerry Project Logistics and Northvolt.

Fayçal Boumerkhoufa

20+ years in air charter and project logistics. Former Panalpina and Volga Dnepr executive, specializing in energy, oil and gas CAPEX projects, and defense programs.

Dea Chincuanco

President – Americas, dship Carriers

Over 20 years in maritime, managing LNG, nuclear, FPSO and renewable project cargo. Global MBA from the Fletcher School of Law and Diplomacy, dedicated to advancing diversity in shipping.

Elisabeth Cosmatos

Managing Director, Cosmatos Group

Managing director of Cosmatos Group in Greece and first female president of The Heavy Lift Group. Brings more than 25 years of shipping, forwarding and logistics experience.

Dennis Devlin

Managing Director, DT Project America

Veteran of Panalpina, BDP, Maersk, and Schenker, Devlin now leads DIMOTRANS Group’s U.S. project arm. Long-time Breakbulk speaker with decades of project logistics expertise worldwide.

Payne Fischer

Head of Capital Projects, North America, Kuehne+Nagel

Over 15 years in project logistics with leadership roles at Agility, deugro, and GEODIS. Now leads capital projects at Kuehne+Nagel from Houston.

Dharmendra Gangrade

Head of Logistics Management Center, Larsen & Toubro

Over 25 years in global logistics across EPC, oil and gas, chemicals and automotive. Leads L&T’s logistics operations worldwide from Mumbai headquarters.

Itoro Ibanga

Project Logistics Specialist, Air Liquide

Experience at Port Houston, MSC and Fracht; Master’s in Maritime Transportation. Active with YoungShip Texas and Air Liquide’s African American Network.

John Hark

North America Chartering Director, Bertling Logistics

30+ years in Houston maritime industry and Texas A&M adjunct professor. Leads education initiatives linking logistics and academia to reduce talent gaps.

Margaret Kidd

Executive Director, Houston Maritime Center and Museum

At the helm of Houston’s Maritime Center and Museum, she teaches at the University of Houston and is a frequent media commentator on supply chains. Instrumental in Breakbulk Education Day around the world.

Jake Swanson

Regional Vice President, DHL Industrial Projects

Over 20 years in logistics across EPC, carrier and forwarding sectors. U.S. Merchant Marine Academy graduate with MBA from University of Houston.

Edward Talbot

Managing Director –Americas, Roll Group

Mechanical engineer with global experience delivering complex oil and gas, petrochemical, power and renewable projects. Former ALE Middle East GM.

Grant Wattman

President, Jade Management Group

50 years in logistics leadership. Former CEO of Agility Project Logistics, founder of Combi Lift Americas, now advising supply chains worldwide.

Andrew Young

Corporate Manager of Logistics / Manager of BGL, Bechtel Corporation

Responsible for coordinated logistics strategies across Bechtel’s EPC projects, guiding teams globally and standardizing best practices company-wide. Distinguished technical specialist with experience in LNG projects, chartering and global EPC logistics roles.

Thought Leader

TARIFF TENSIONS: THE HIDDEN COST TO ENERGY PROGRESS

By Margaret Kidd

Margaret Kidd

Tariffs imposed on key energy-related imports often aim to protect domestic industries or address trade imbalances. However, these measures can have unintended consequences that ripple through energy supply chains, impeding progress toward clean energy goals and exacerbating existing infrastructure challenges. One of the most significant yet overlooked effects is the worsening of interconnection backlogs—the delays in connecting new energy projects, especially renewables, to the electric grid. According to Berkeley Lab’s Energy Markets & Policy, these delays grew by 30% in 2023.

Solar panels, wind turbines, battery components and grid infrastructure rely on a globally integrated supply chain. When tariffs raise the cost or limit the availability of these components, project timelines are delayed, and developers face increased uncertainty. This not only slows the deployment of renewable energy but also exacerbates grid congestion and backlogs. For instance, developers often postpone or cancel projects due to unpredictable costs, which in turn clogs the queue of projects waiting for grid interconnection. These delays directly undermine national and regional efforts to meet decarbonization targets and modernize energy infrastructure.

Moreover, tariffs can create mismatches between domestic manufacturing capacity and the urgent demand for clean energy technologies. While encouraging local production is a worthy long-term goal, short-term overreliance on tariffs without a robust industrial base can backfire. Energy markets operate on tight timelines and thin margins—any disruption can cascade into long-term impacts on energy availability and prices.

To mitigate these issues, smarter trade policy is essential. Policymakers must balance the need for economic and national security with the realities of clean energy deployment. This includes establishing clear exemptions or streamlined

import processes for critical energy components, investing in domestic manufacturing through tax incentives in parallel, and improving coordination between trade and energy policy. Ultimately, aligning trade measures with climate and grid modernization goals will be vital to avoid undermining the very energy transition they are meant to support.

Although tariffs may serve geopolitical or economic interests, their unintended consequences, especially on energy supply chains and interconnection backlogs, are disrupting a longstanding system of trade liberalization governed by the World Trade Organization, highlighting the need for more integrated, forward-looking trade policies.

About the Author

Margaret Kidd, a member of the Breakbulk Editorial Board, is the president of the Houston Maritime Center & Museum and an adjunct lecturer on supply chain and logistics at the University of Houston.

Tariffs can have unintended consequences that ripple through energy supply chains.

Credit: Dominic Chasse, Unsplash

Gallup (2019, 2024)

WOMEN IN BREAKBULK

WOMEN STEERING AMERICA’S WATERWAYS

WIMOs is an official partner of Women in Breakbulk, Americas Edition

By Angelica Brooks