rollers

- possible options

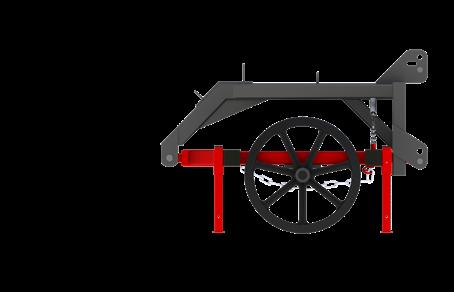

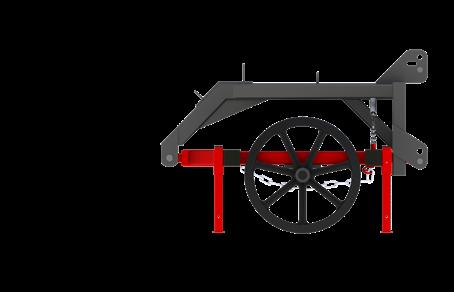

Road wheels

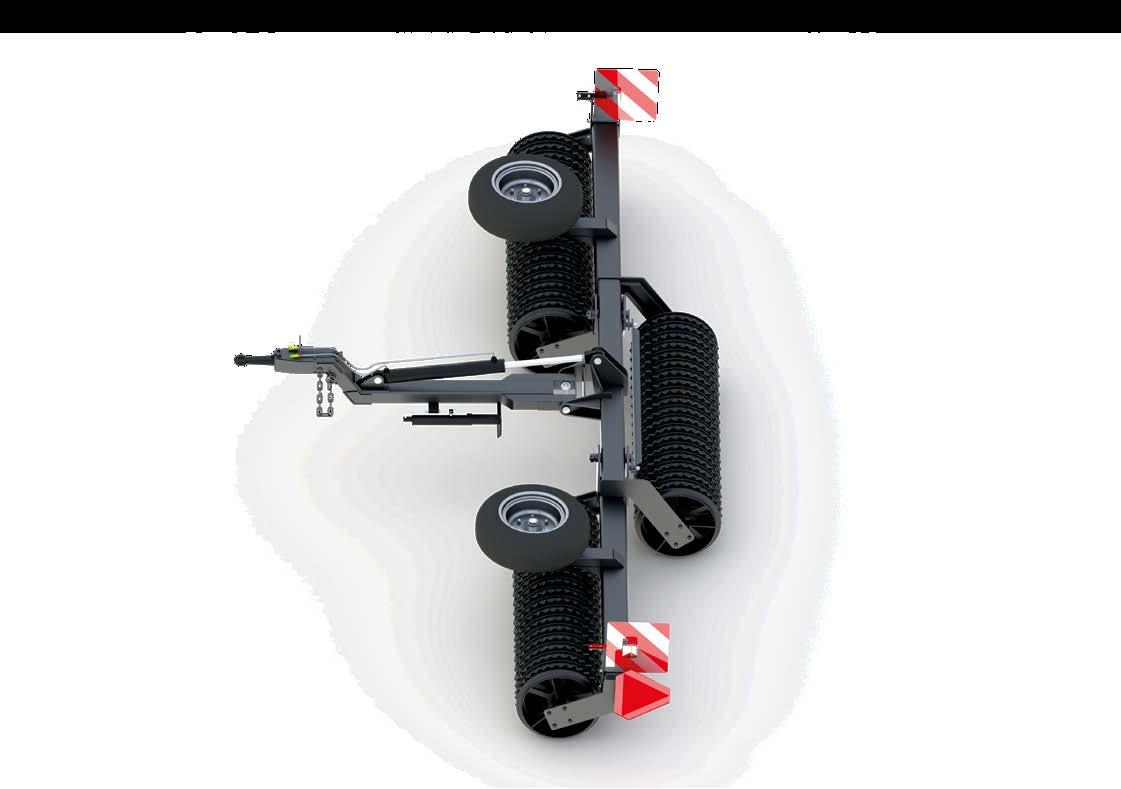

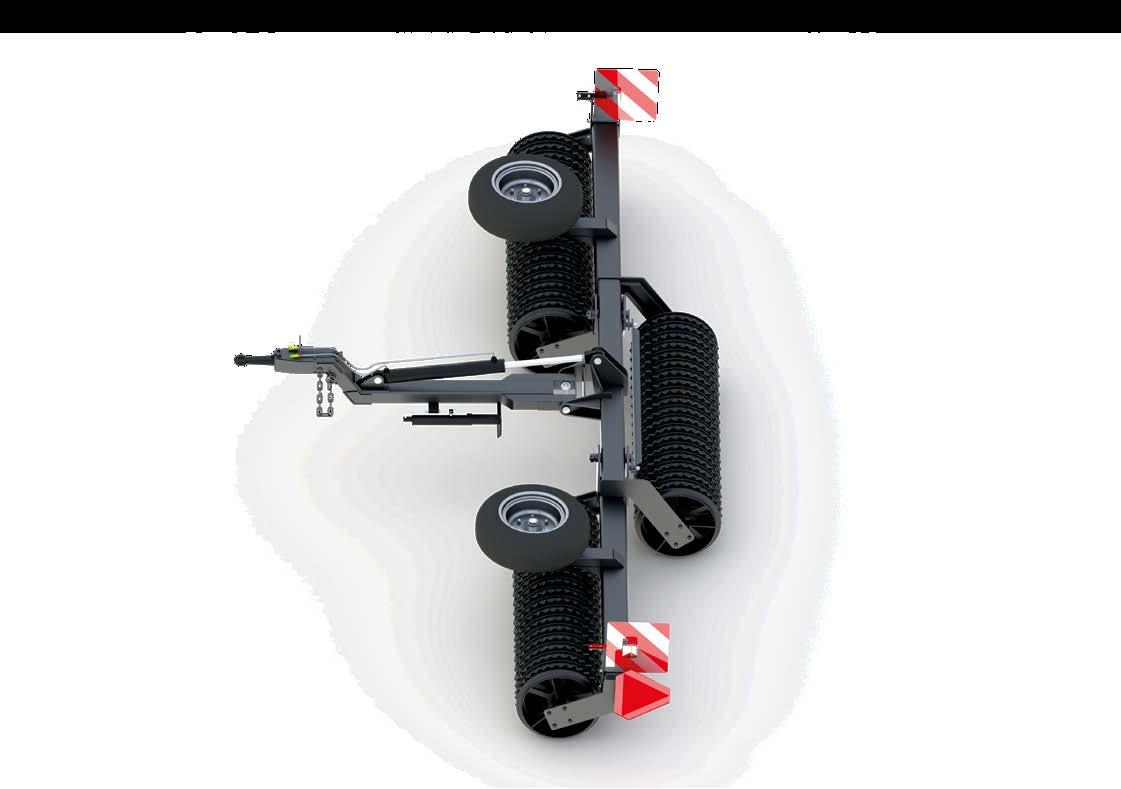

4 - 6,2 m - 10.0/75-15.3

7,5 - 9 m - 11.5/80-15.3

Additional options

Good to know

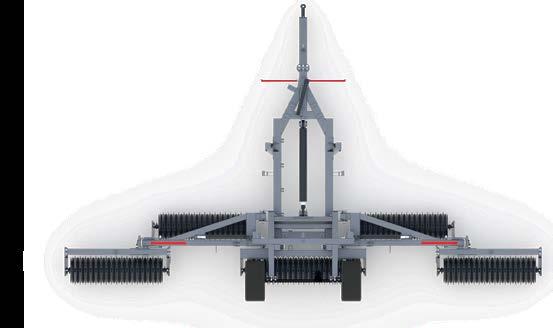

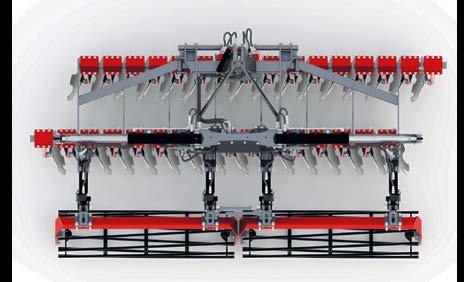

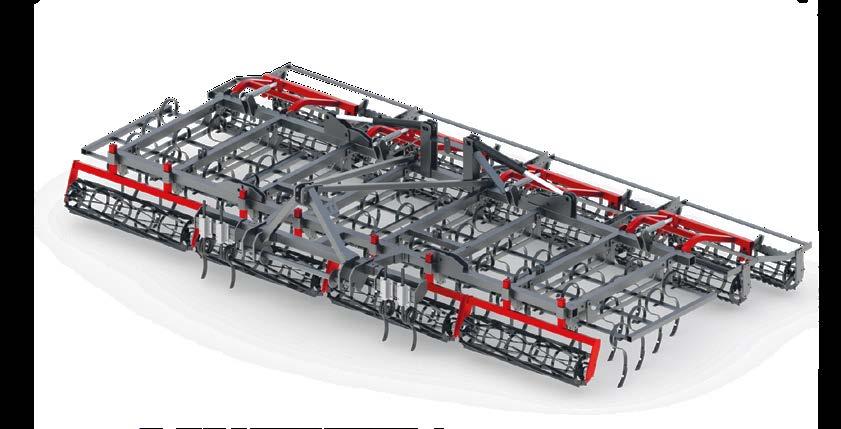

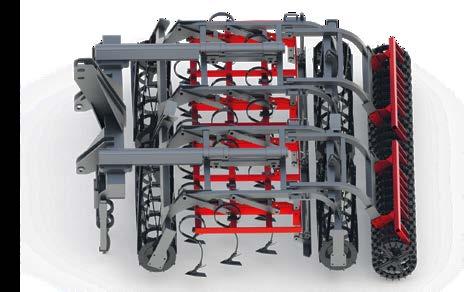

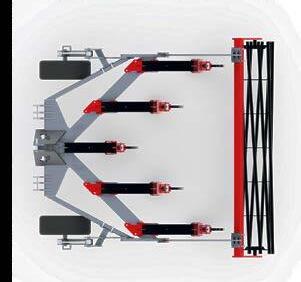

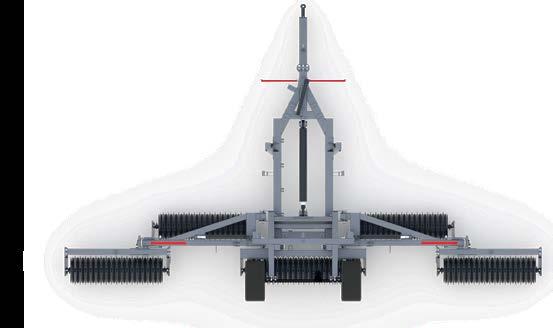

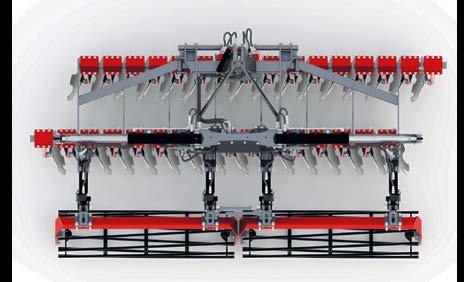

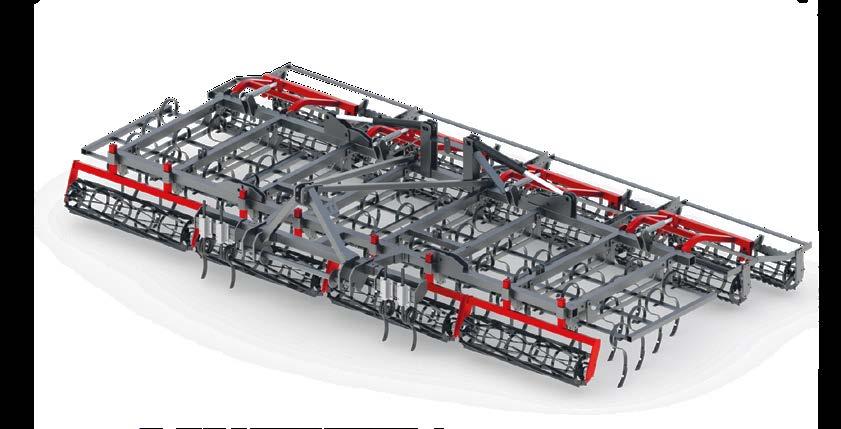

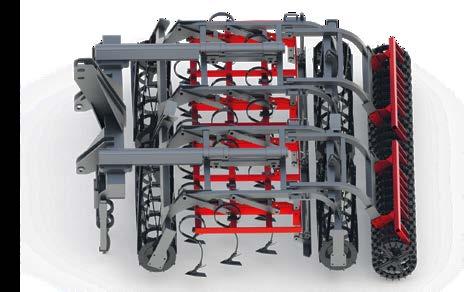

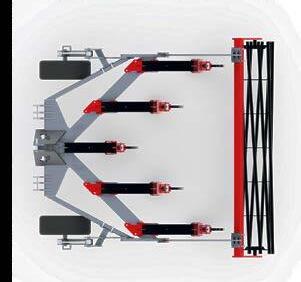

The machine unfolds the side sections after unlocking the blocking beam when reversing, then lowers using the hydraulics another middle section. Frame with one hydraulic cylinder

11

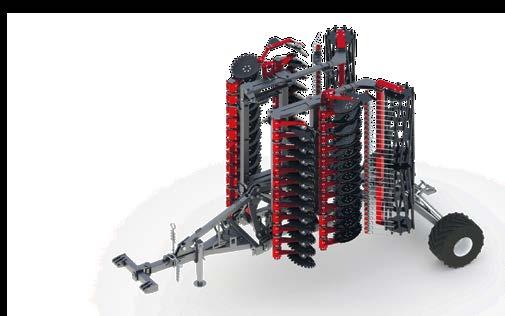

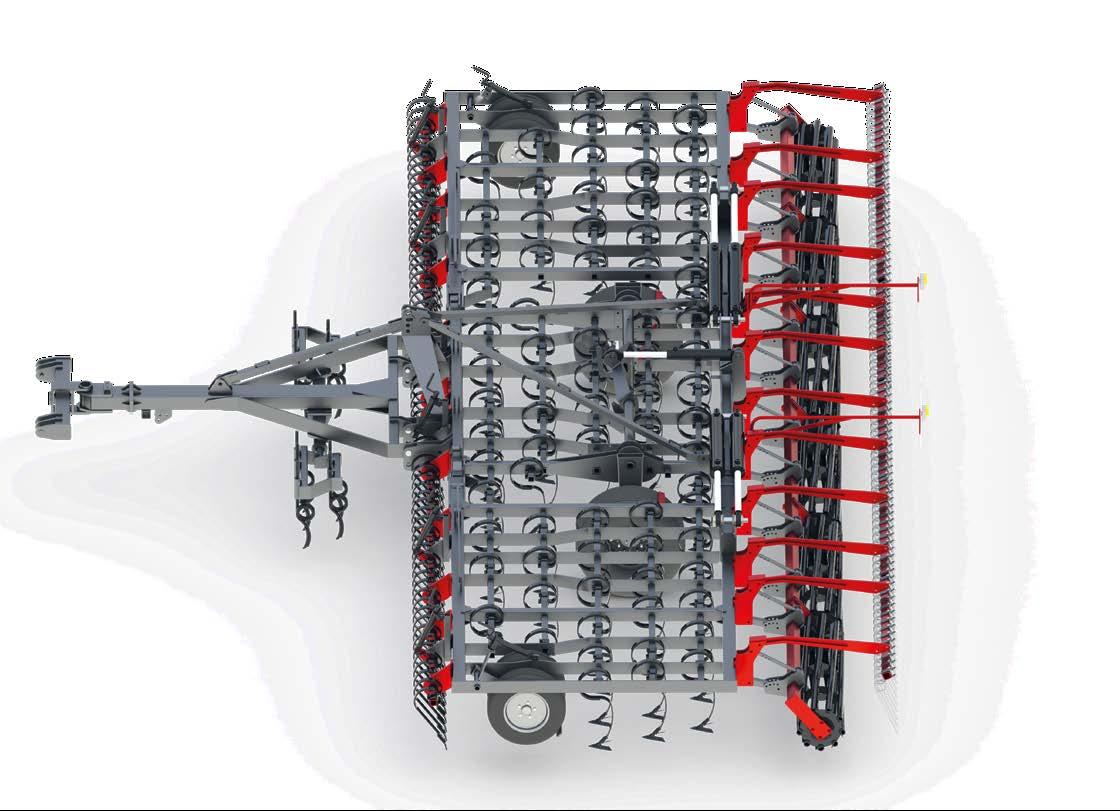

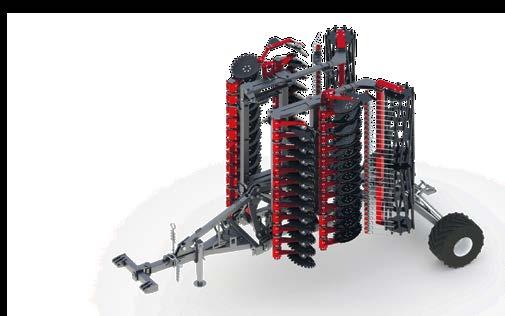

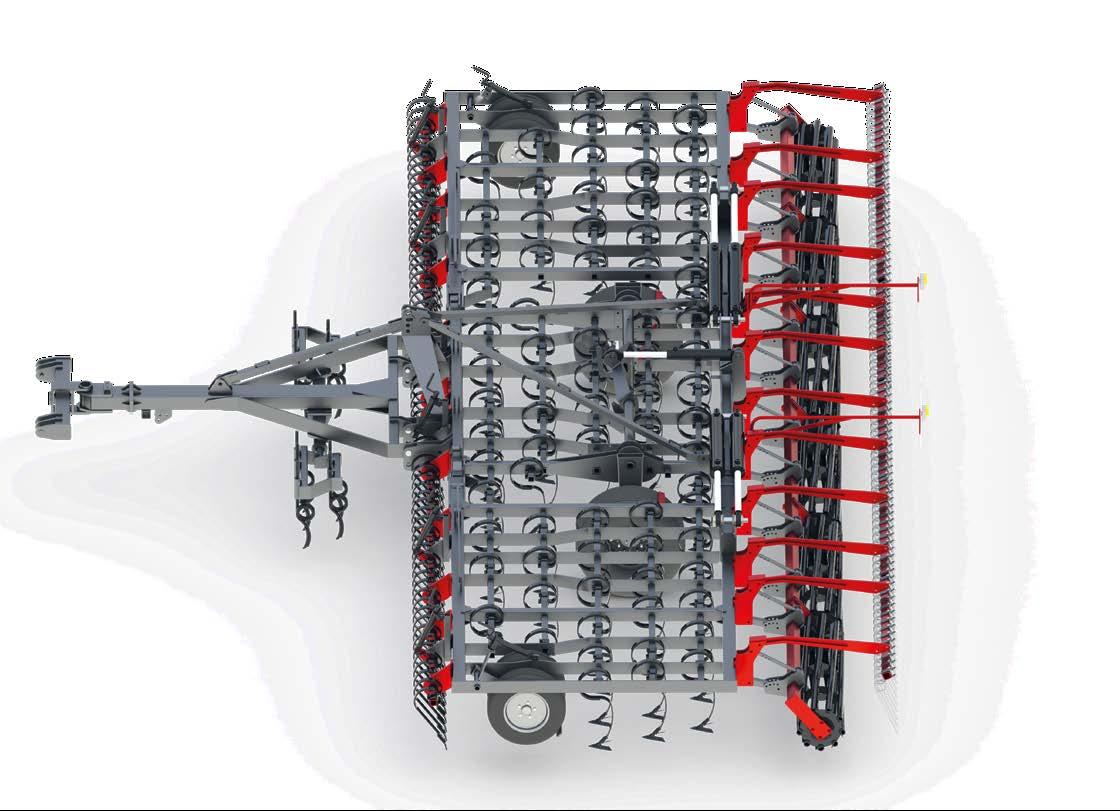

trailed, hydraulically collapsible - 4 | 5 | 6,2 | 7,5 | 8 | 9 m

A strip blocking the frame sections

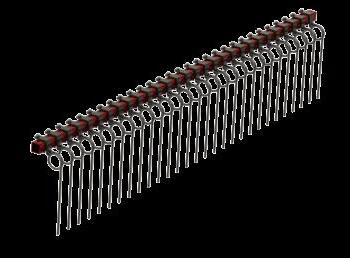

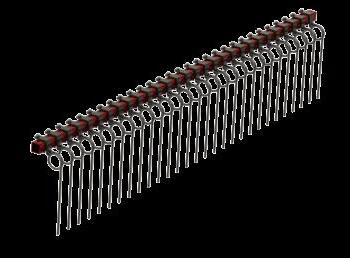

Cambrige roller Φ530 mm

Single point hitch upper or lower

Support foot

LED ligthing

80 86 99 112 81 101 123 149 4 5 6,2 7,5 2200 2570 2960 3420 Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM) 125 140 157 177 8 9 3580 4150 LED lighting zig-zag roller Φ530 mm cambridge

Φ500 mm

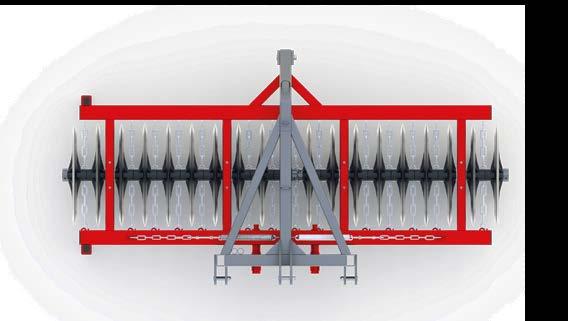

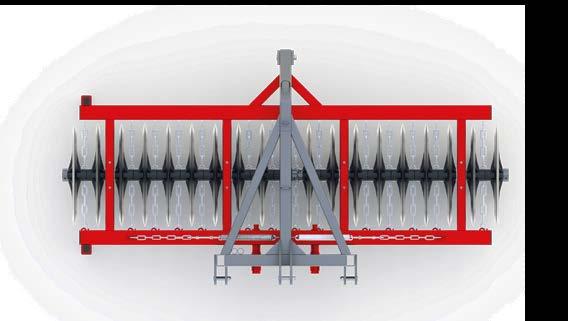

roller

- possible options

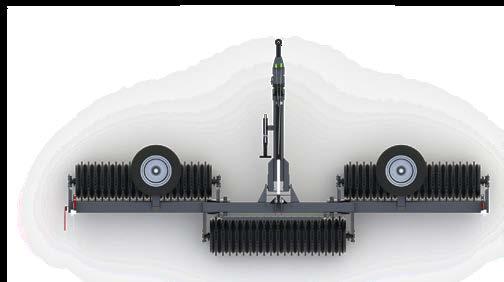

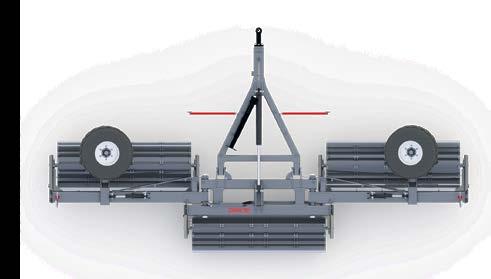

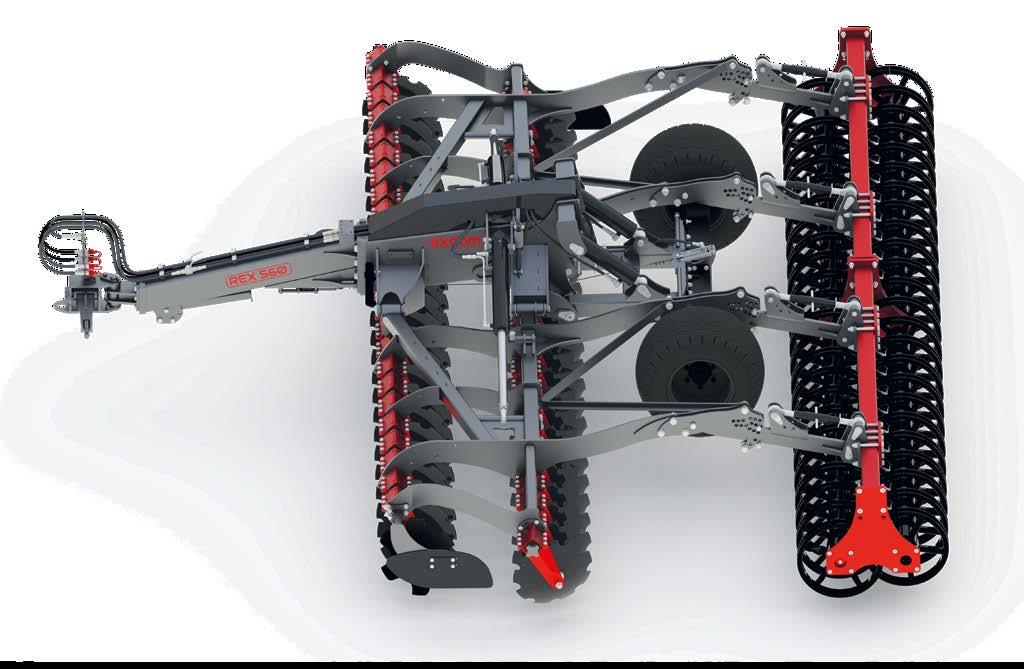

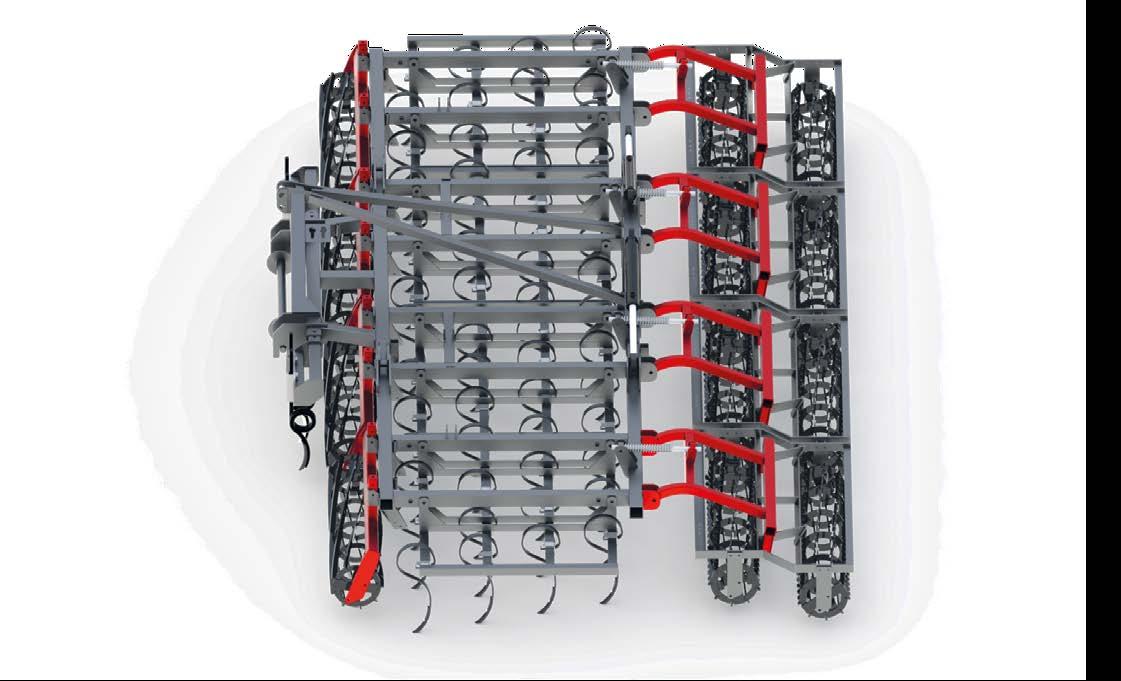

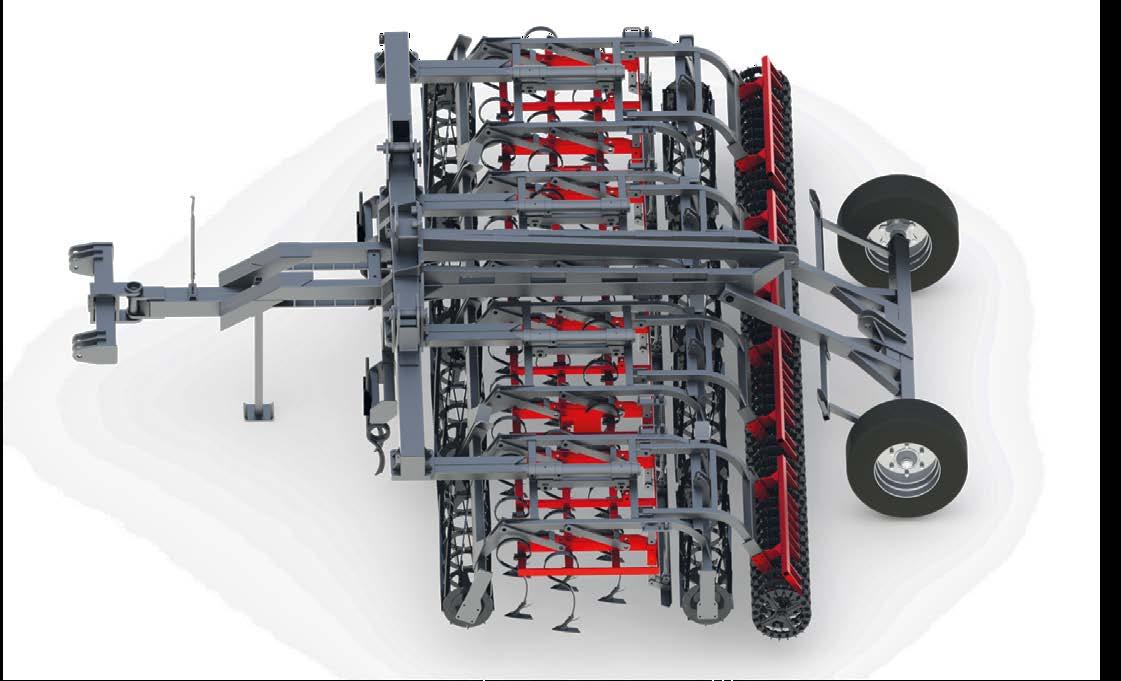

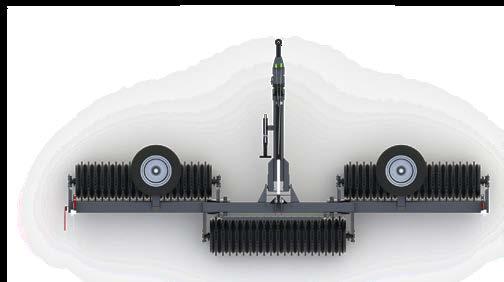

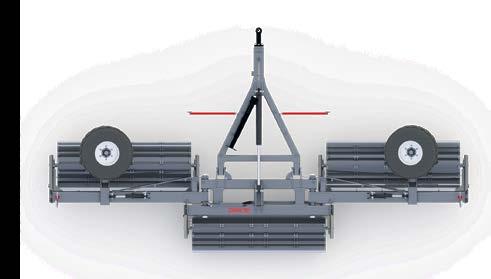

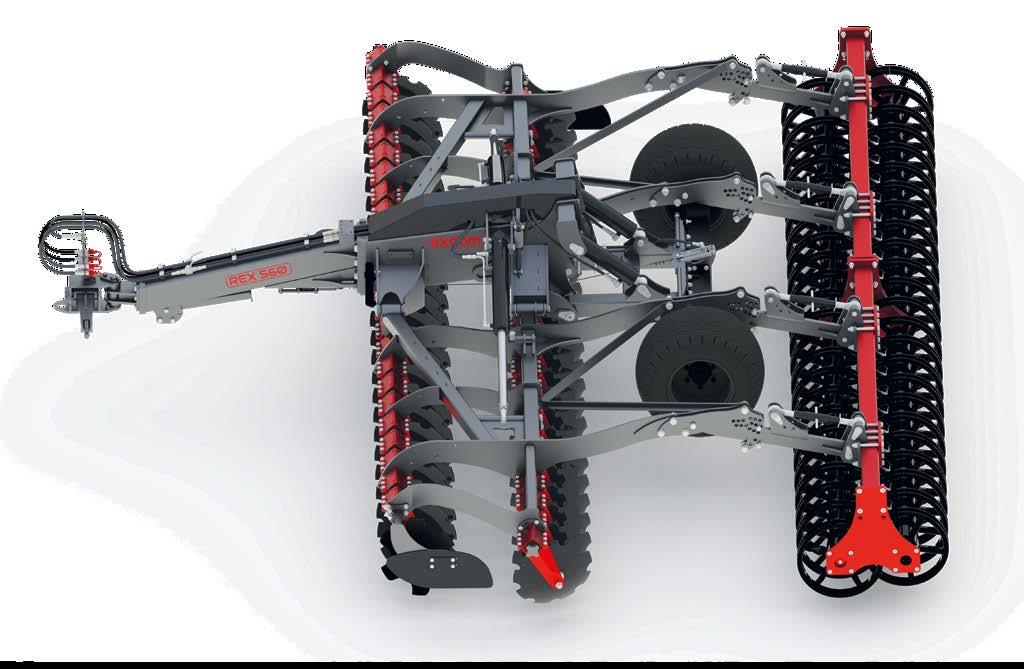

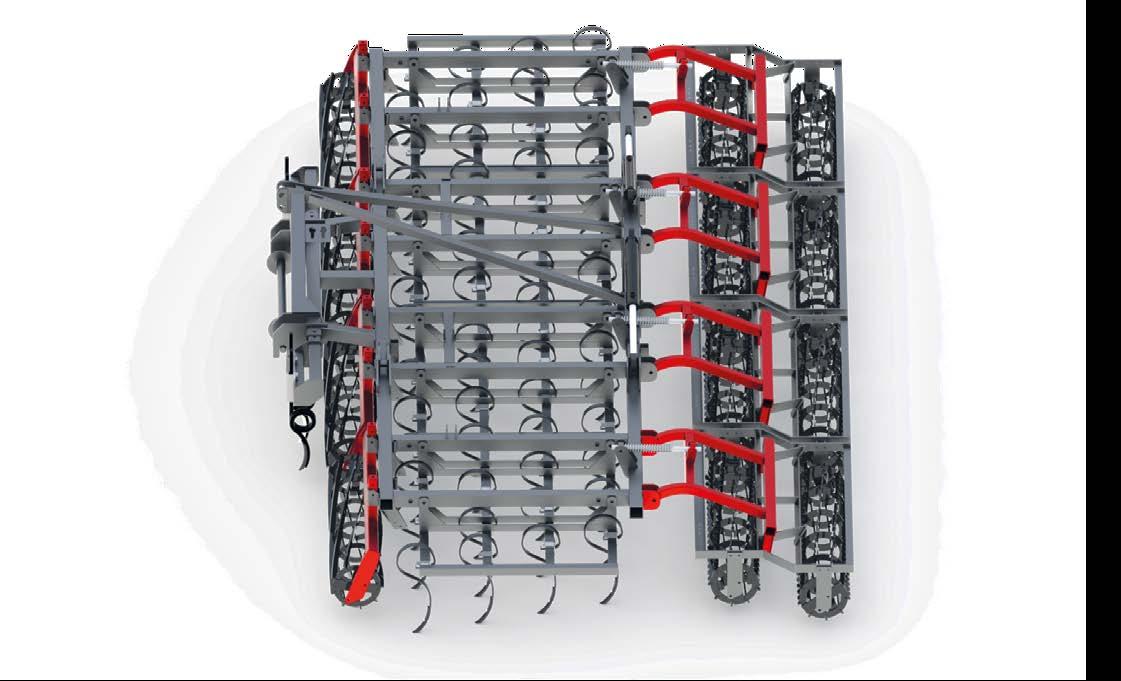

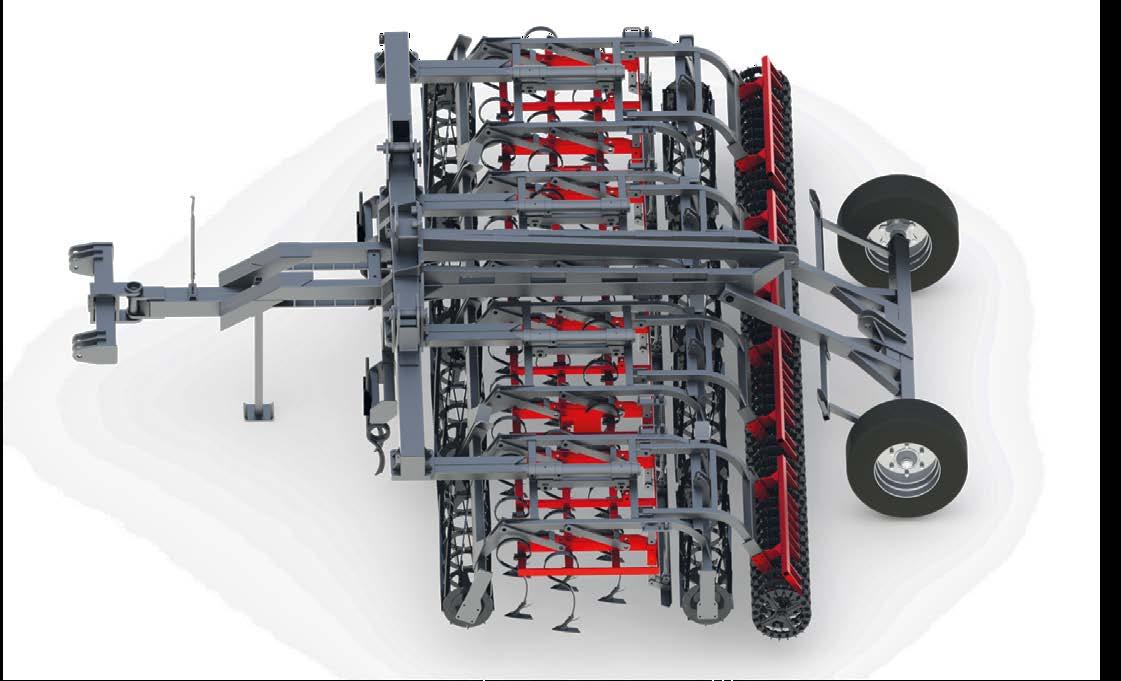

The machine unfolds the side sections after unlocking the blocking beam when reversing, then lowers using the hydraulics another middle section. Frame with one hydraulic cylinder

13

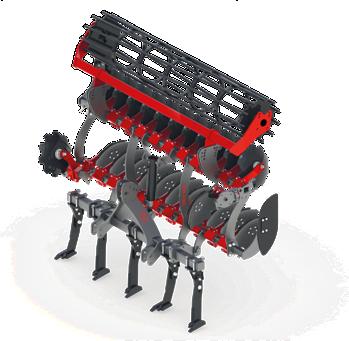

trailed, hydraulically collapsible - 6,2 | 7,5 | 8 | 9 m

wheels 400/60-15.5 Cambridge

Φ600

foot LED lighting 99 112 123 149 6,2 7,5 2960 3420 Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM) 125 140 157 177 8 9 3580 4150

options LED lighting zig-zag roller Φ530 mm

to know

rollers

A strip blocking the frame sections

Road

roller

mm Single point hitch upper or lower Support

Additional

Good

roller Φ500 mm

cambridge

Single point hitch upper or lower

rollers

Support foot

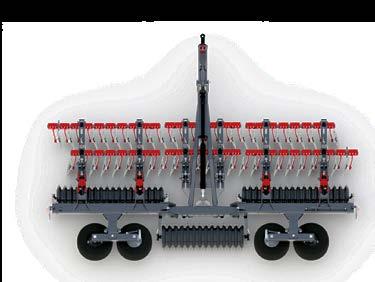

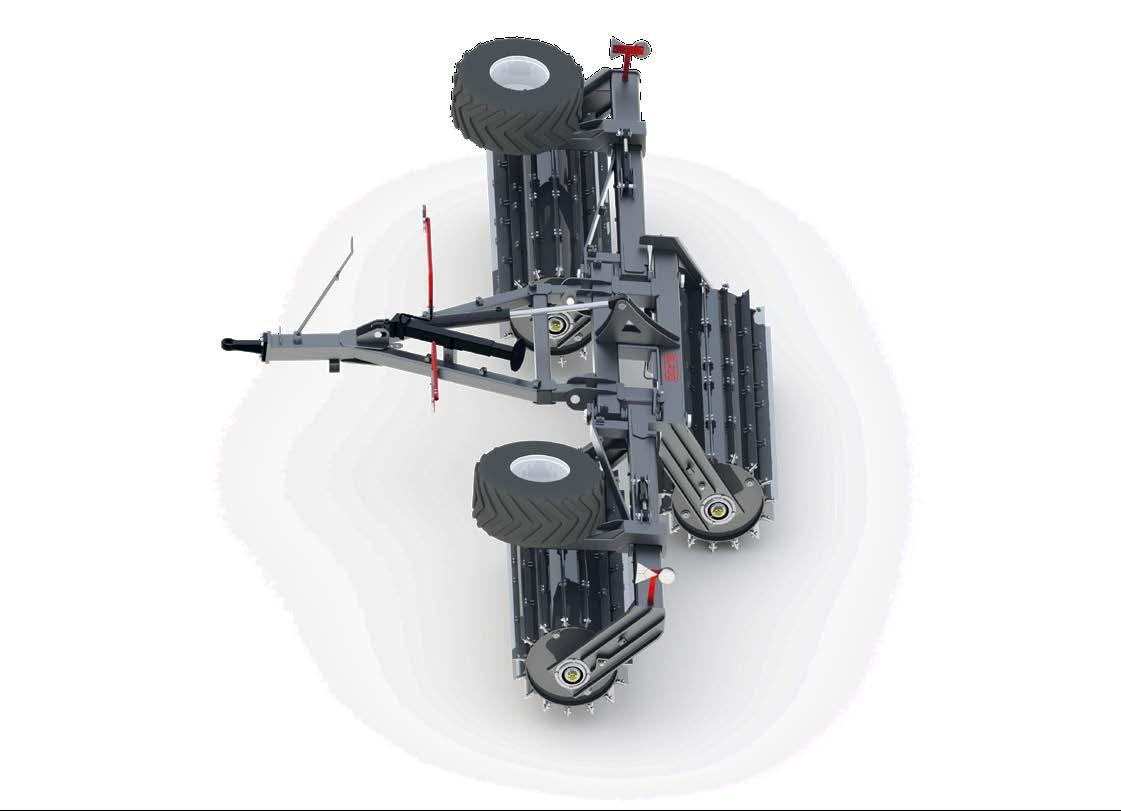

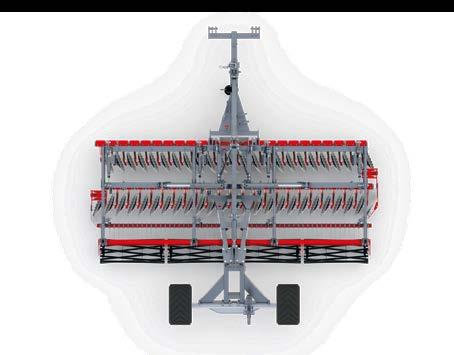

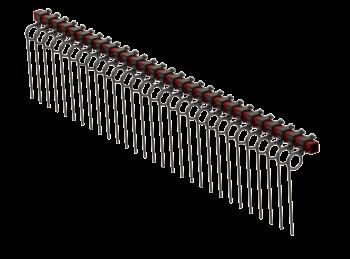

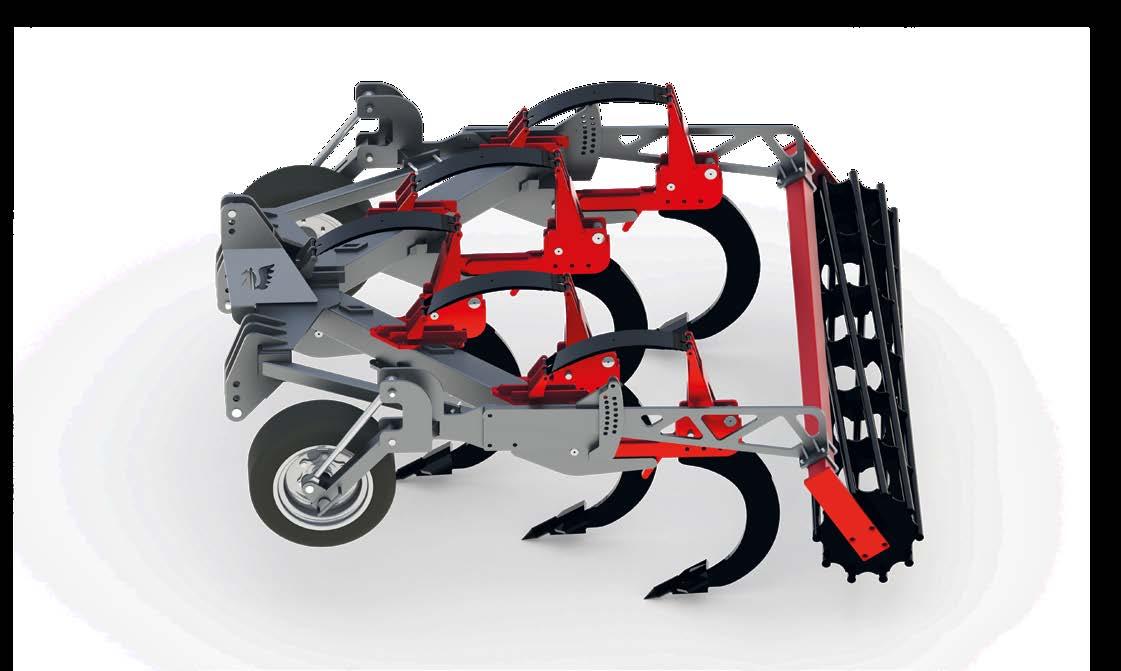

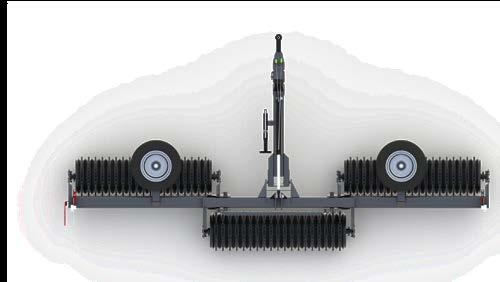

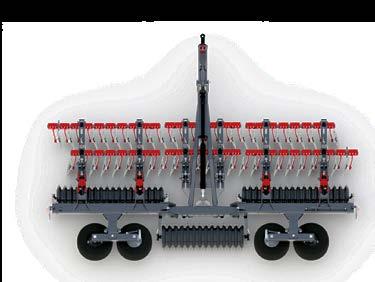

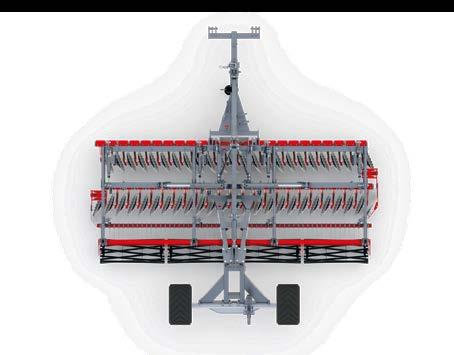

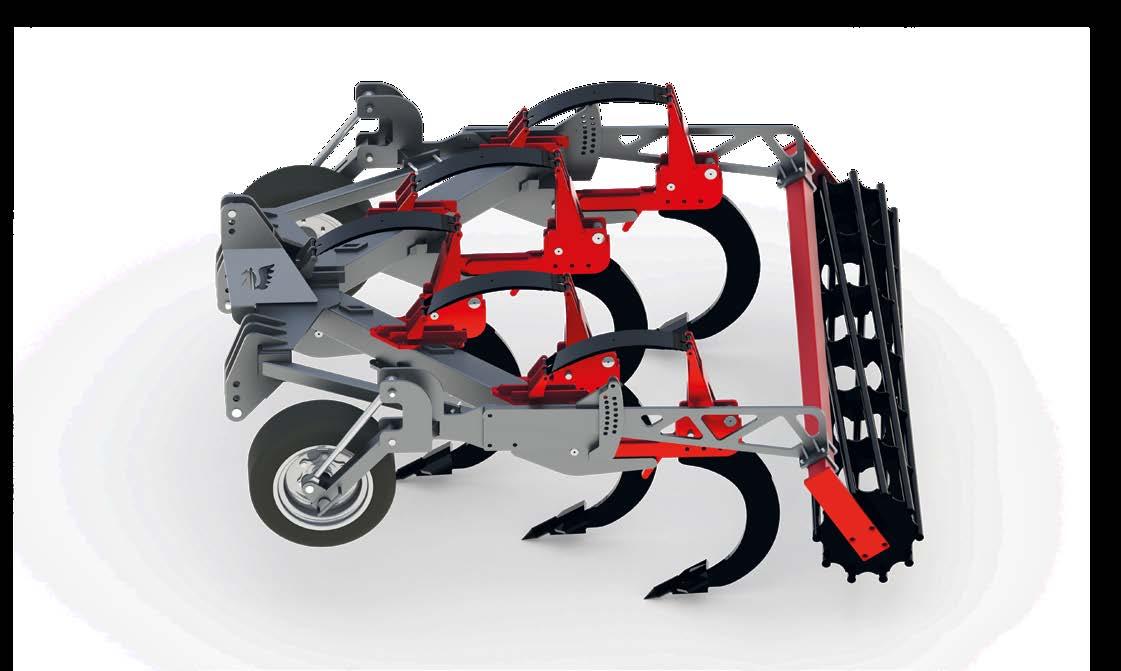

Spring tine harrow controlled hydraulically

- possible

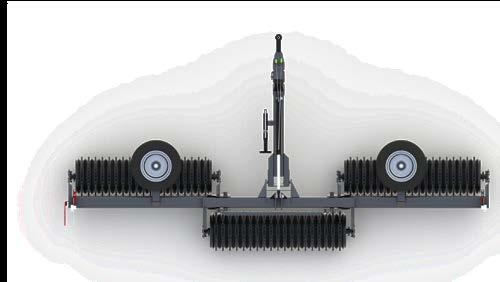

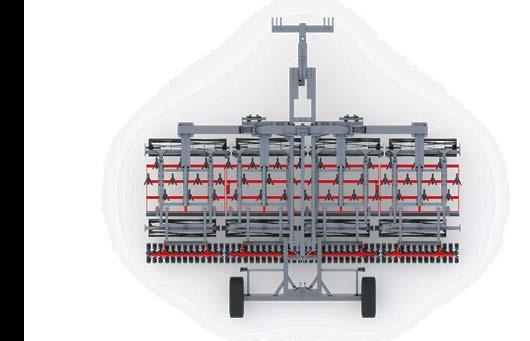

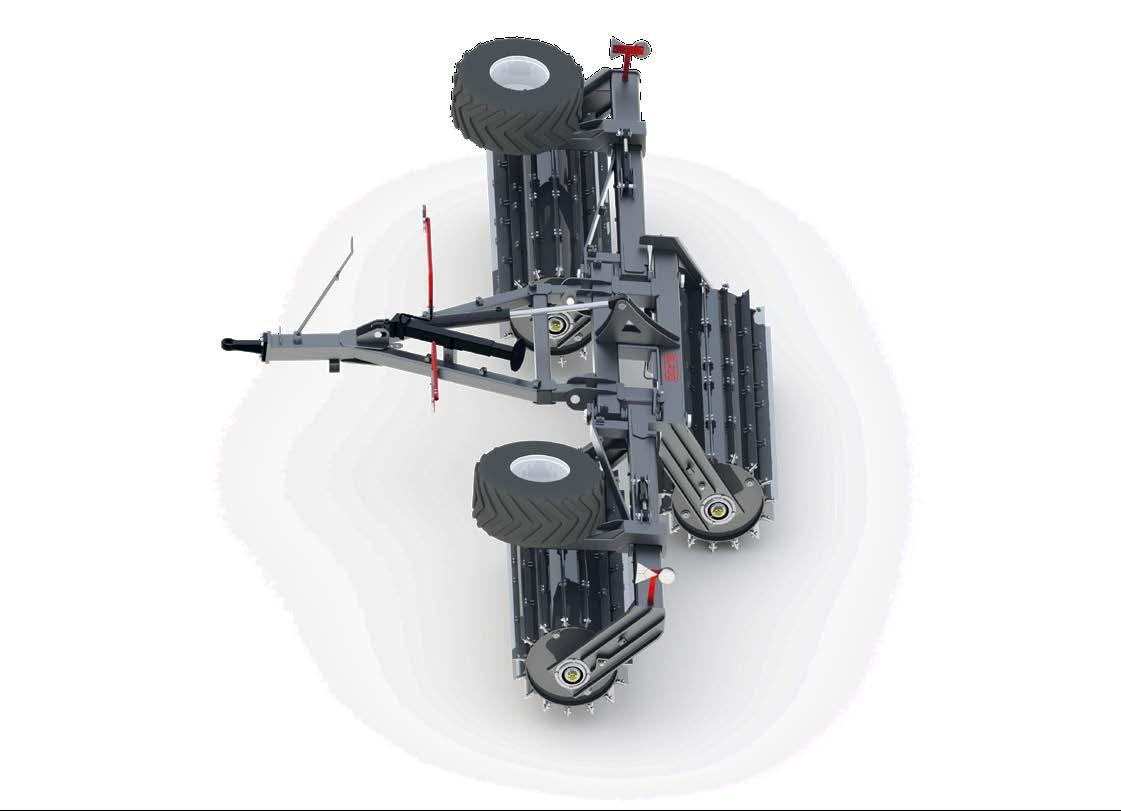

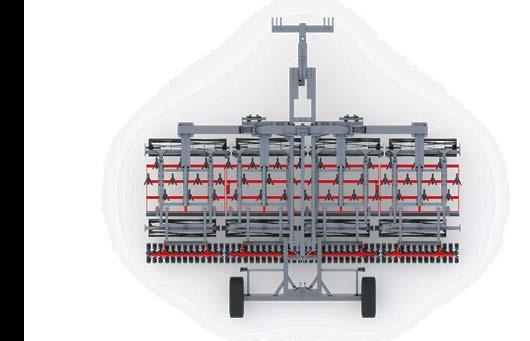

A strip blocking the frame sections

Additional options

Cambridge roller

mm Φ530 mm Φ600 mm

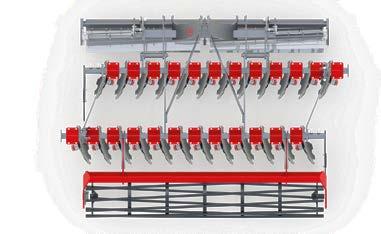

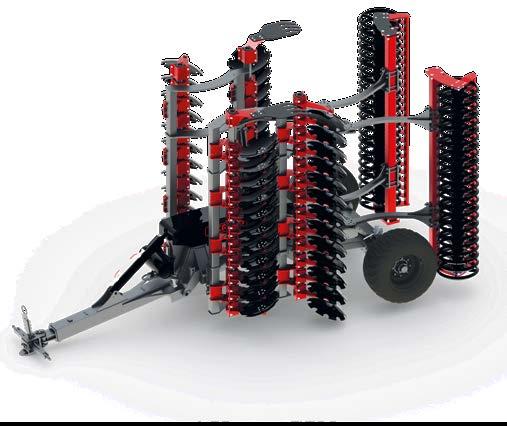

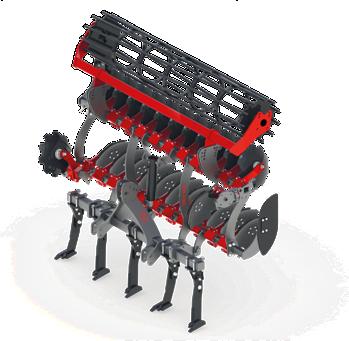

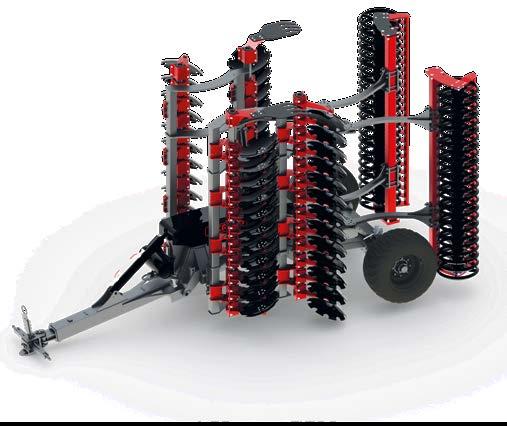

options trailed, hydraulically collapsible - 4,2 | 6,2 m

After unlocking the blocking beam, the machine folds out the side ones sections when reversing, then with hydraulics leaves the next center section.

15

Road wheels 400/60-15.5

Φ500

LED lighting

80 100 83 123 4,2 6,2 2570 3460 Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM)

LED lighting

roller Φ530 mm

Φ500|530|600 mm

zig-zag

cambridge roller

Single point hitch adjustagble

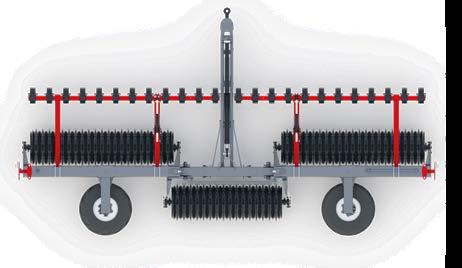

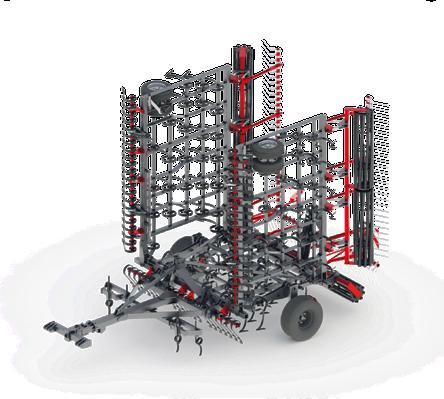

- possible options

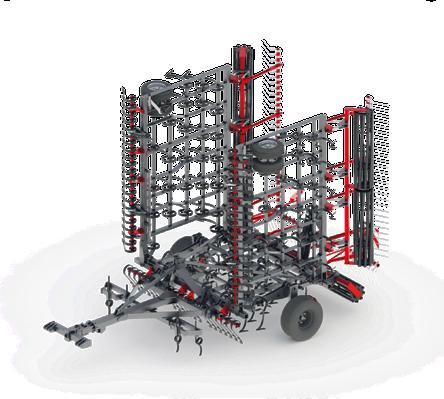

Road wheels 340/55-16

Additional options

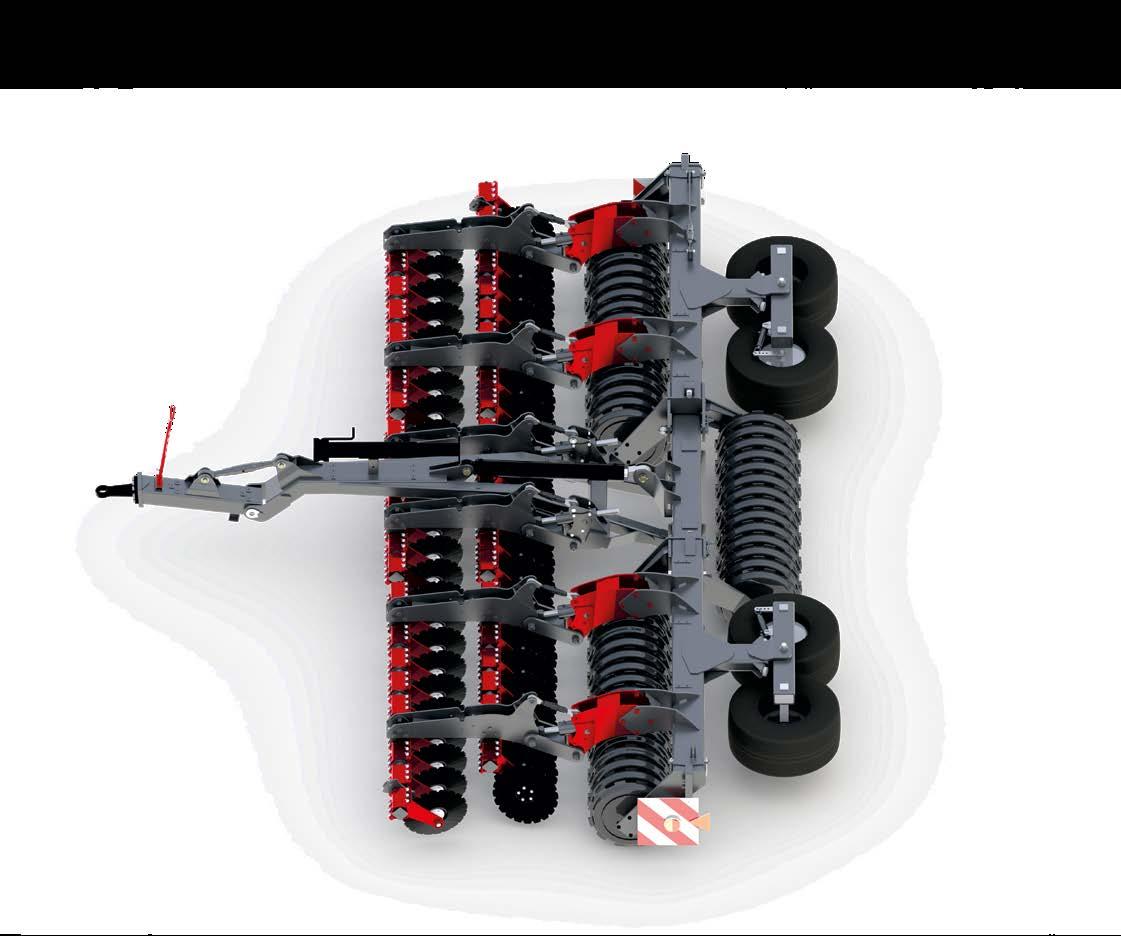

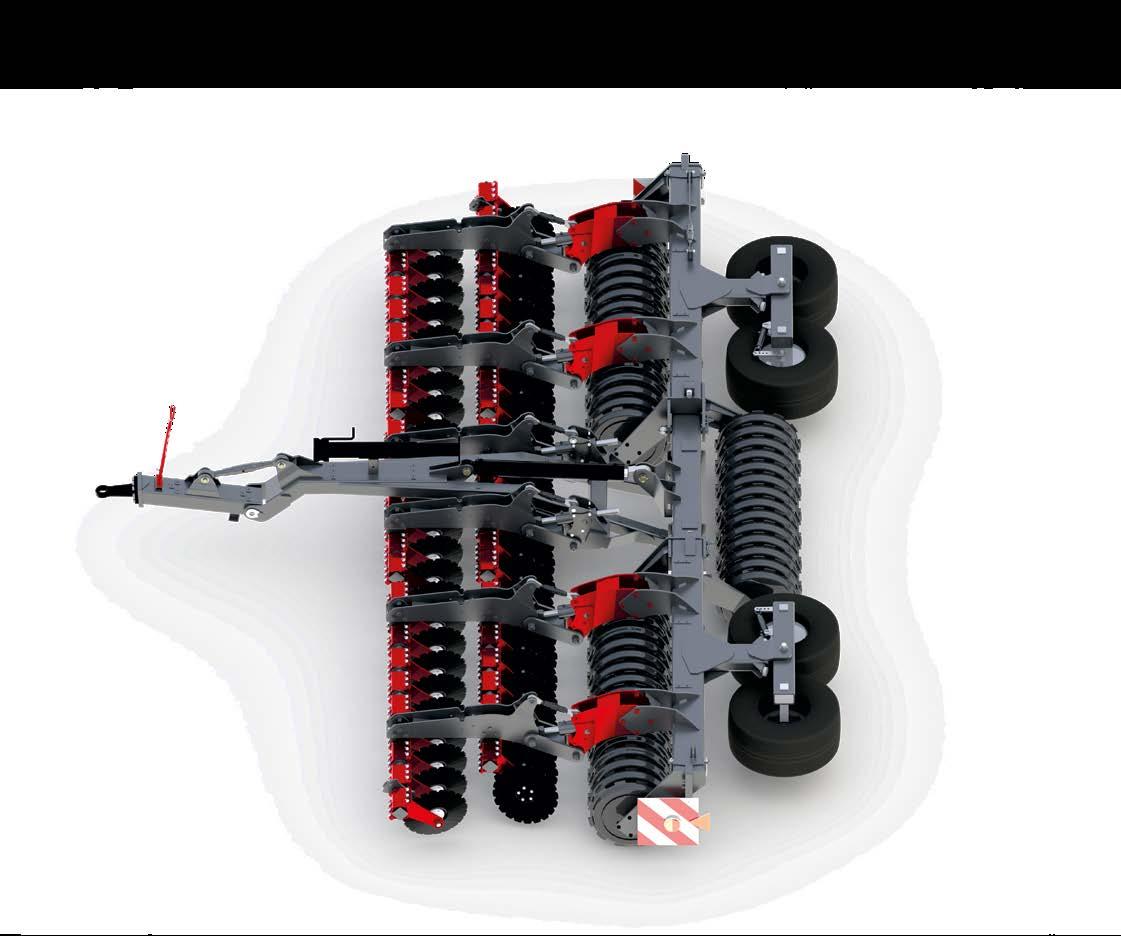

cambridge roller Weight (kg) Number of discs (pcs.) Working width (m) Power demand (KM) Number of sharps (szt.) 7 7

mm

Break axle pneumatic or hydraullic LED lighting

Steel pack roller Φ600 mm Disc section disc Φ460 mm maintenance-free bearing

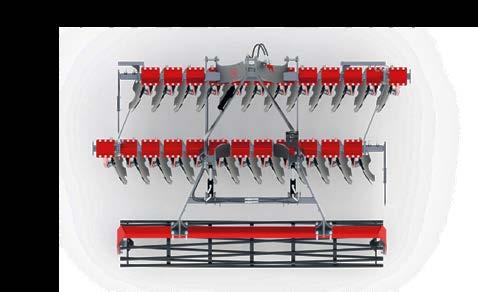

trailed, hydraulically collapsible - 4,2 | 6,2 m

Good to know

zig-zag Φ530

mm

front knife shaft 7 pieces of replaceable shafts hardox, hyd. adjustable

17

Support foot

Rubber protection each disc

can be equipped with a spring tine harrow hydr. adjustable sharp roller and a roller adapted to the needs Φ500/530/600

Transport position 120 180 34 50 4,2 6,2 4980 6810

- possible options

19

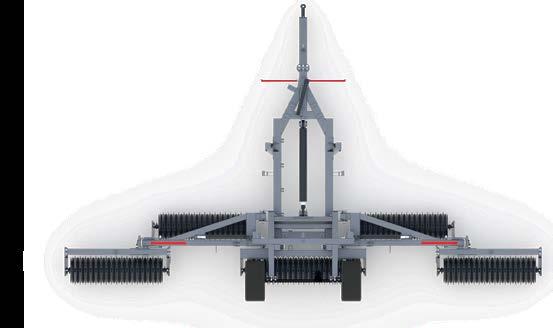

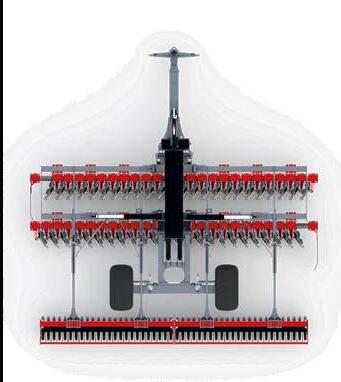

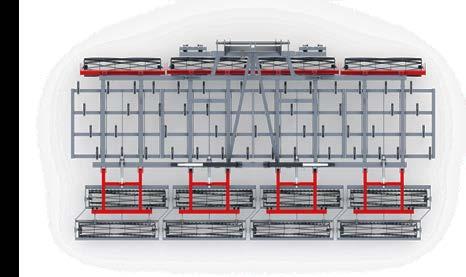

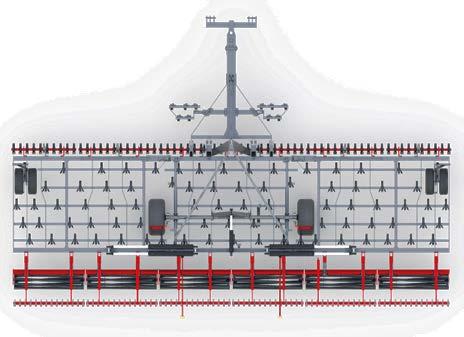

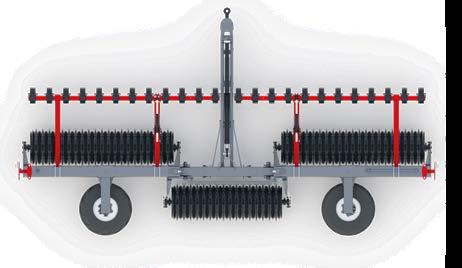

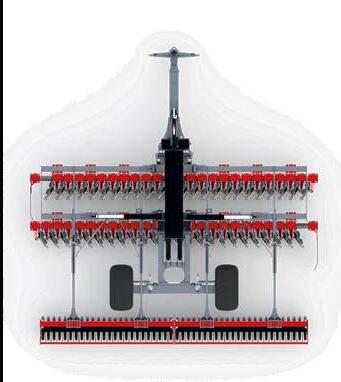

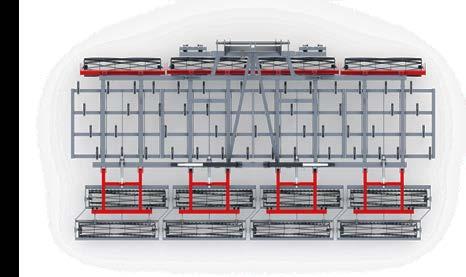

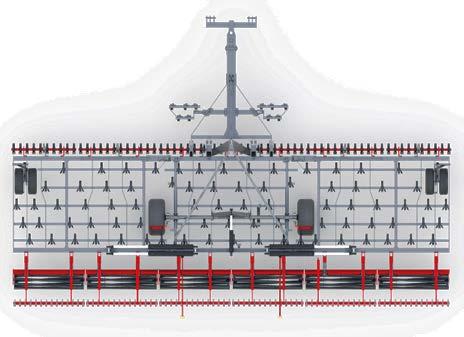

trailed, hydraulically collapsible - 9 | 12 | 15 m

400/60-15.5

Φ530

brake

Cabling

Support foot

lower drawbeam 140 160 191 247 9 12 5570 6860 Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM) Additional options (EU approval)

to know LED

zig-zag roller Φ530 mm Transport

Frame

hydraulic cylinders 180 15 8150 303 cambridge roller Φ500 mm

Road wheels

Wheel wedges Cambridge roller

mm Pneumatic

axle option hydraulic Overall ligthing

organizer

Single point hitch

Good

Hydraulic accumulator with pressure gauge

position

with four

Good

CONTROL SYSTEM for equal pressure on the ground of all roller sections, the machine is equipped with two

21

trailed,

- 9 | 12 | 15 m

Flotation

- possible options

hydraulically collapsible

Road wheels 520/50-17 SG

Overall

lower drawbeam Cabling

Support foot 190 220 183 239 9 12 7100 8300 Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM) Additional options (EU approval) LED lighting PRESS

hydraulic

a pressure gauge

Wheel wedges Cambridge roller Φ600 mm Pneumatic brake axle option hydraulic

lighting Single point hitch

organizer

accumulators with

250 15 9000 295

Proprietary folded system

to know

Cabling

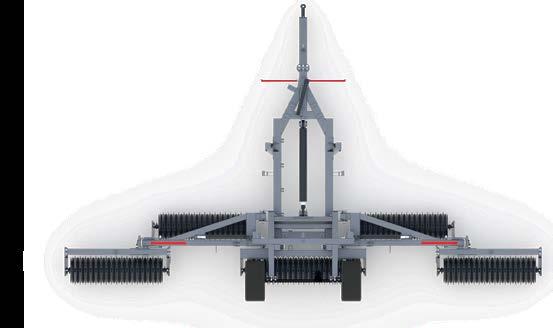

rollers

- possible options

Working width (m) Power demand (KM)

Weight (kg) Roller type

120 Φ840 6,3 2850

Support foot

LED lighting

Road wheels 400/60-15.5

Good to know

Working elements locker during transport

Drain plugs 2 each side

Transport position

Drain plugs

trailed, hydraulically collapsible - 6,3 m

The working element of the shaft is a D = 610 pipe with 15 special knives mounted on it hardox steel. The knives are arranged along the steel tube every 24 degrees, i.e. the entire shaft has diameter 840 mm. Each section of the shaft has flood plugs that we use to flood the water with the target regulating the weight of the machine. Recommended working speed 17-23 km / h. In addition, each working element has a protection for transport, where a pin inserted between the frame and the shaft hole locks each section.

23

Sharp roller Φ840 mm

Single point hitch option drawbeam

organizer

of roller

Cushioned bearing ball bearing with rubber damper all around

- possible options

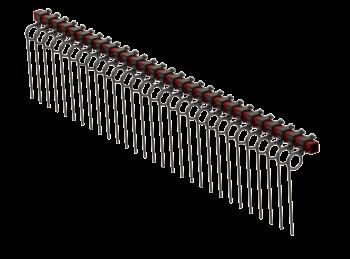

LED Campbell 30° 31 kg 60 70 19 22 3 3,4 940 1020

three-point linkage tractor with stabilizers

Additional options

80 26 4 1170 60 70 19 22 3 3,4 1100 1240 80 26 4 1430

lighting Weight (kg) Number of shaft rings (pcs.) Working width (m) Power demand (KM)

Stabilization springs

Good

Support feet

Chains that clean the rings

25

rigid frame, mounted on the front - 3 | 3,4 | 4 m

Campbell

roller Φ700 mm

Hitch on the front Campbell 45° 42 kg

to know blade angle 30° or 45° two or three-row cultivator attachment Spring tine harrow hydraulically adjustable

Chains that remove dirt from the rings effectively reduces clogging during work

DISC HARROWS

Disc Φ510 mm Disc Φ560 mm Disc Φ610 mm Standard tubular Φ540 mm | Φ600 mm V-RING Φ600 mm C-RING Tandem Φ580 mm 28 Cutting front (REX 510) Φ380 mm

disc harrows

Smooth regulation the aggressiveness of the discs

- possible options

Road wheels 400/60-15.5

Brake axle hydraulic

Cabling organizer

Additional options

support wheels manually adjustable

Drawbeam

Support foot

Disc Φ560 mm

Maintenance-free hub

Stable chassis transport

Tubular roller Φ540 mm

Spring scraper Φ12 mm

Side shield screens mounted, hydraulically folded - 4 m mounted, not folded - 3 | 3,5 | 4 m

hydraulically folded

LED

Φ600

m

29

6

trailed,

- 4 | 5 |

m

100 120 140 140 24 28 32 32 3 3,5 4 4 1800 2400 3000 4440 Weight (kg) Number of discs (pcs.) Working width (m) Power demand (KM)

lighting

3 | 3,5 | 4

Transport

Good to know 160 180 40 48 5 6 4800 5160

Hydraulic angle change the aggressiveness of the discs

position

V-Ring roller

mm

3-point hitch

disc harrows Disc Φ510 mm

- possible options

Working width (m) Power demand (KM)

Weight (kg) Number of discs (pcs.)

Side shield screens

Rubber protection each disc

Tubular roller Φ540 mm

Maintenance-free hub

70-130 70-130 24 24 3

Additional options (LED lighting)

1190 1240

shifted tip blade 20x590 mm cutting roller Φ380 mm

Good to know

V-Ring roller Φ600 mm

Version with front cutting roller

Machine equipped with a hydraulic cylinder allows for work of both the disc and the shifted tip blade themselves

31

mounted - 3 m

3

HYDRO LIFT

33

possible options mounted, not folded - 3 | 4 m Disc Φ560 mm

hub

each disc Tubular roller Φ540 mm

working

a roller 3-point hitch

-

Maintenance-free

Rubber protection

Smooth hydraulic adjustment

depth witha

70 90 24 32 3 4 1290 1620 Weight (kg) Number of discs (pcs.) Working width (m) Power demand (KM) Additional options Good to know LED lighting Providing a maximum ground clearance of 570 mm distance between the beams 800 mm Standard Tubular roller Φ540 mm 570 mm 800 mm V-Ring roller Φ600 mm

Side shield screens

35

mounted, hydraulically folded - 4 | 5 | 6 m

foot Disc

hub Rubber protection

disc

- possible options

Support

Φ560 mm Maintenance-free

each

Tubular roller Φ540

mm

Smooth hydraulic adjustment working depth with a roller

- III

130 150 32 40 4 5 2760 3120 Weight (kg) Number of discs (pcs.) Working width (m) Power demand(KM) Additional options

to know LED lighting Providing a maximum ground clearance of 570 mm, distance between the beams 800 mm 170 48 6 3490 570 mm 800 mm

3-point hitch cat. II

Hydraulic lock wings during transport Disc Φ560 mm deep dentition

Good

mm Standard

V-Ring roller Φ600

Tubular roller Φ540 mm

Hydraulic lock wings during transport

Side shield screens

37

trailed, hydraulically folded - 4 | 5 | 6 m Disc Φ560 mm

- possible options

Maintenance-free hub

Rubber protection each disc

C-RING Tandem Φ580 mm Road wheels 480/45x17

depth

Φ560

140 150 170 36 40 48 4 5 6 3930 4130 4500 Weight (kg) Number of discs (pcs.) Working width (m) Power demand (KM)

options

to know c-ring tandem roller Φ580 mm V-Ring roller Φ600 mm LED lighting

a maximum ground clearance of 570 mm, distance between beams 900 mm Standard Tubular roller Φ540 mm 570 mm 900 mm

Drawbeam kat. II - III Support foot Simplified setup working

Brake axle hydraulic Cabling organizer Disc

mm with deeper dentition

Additional

Good

Providing

- possible options

Weight (kg) Number of discs (pcs.) Working width (m) Power demand (KM)

- R 22,5 (radial) Ball hitch 4,5 5 6

drawbeam cat. III

Drawbar cylinder

Support foot

Rubber protection each disc

Disc Φ610x6 mm

Side shield screens

Road wheels 500/45 - 22,5 (diagonal) 150 170 200

5850 6350 6660

500/45 36 40 48

Additional options

LED lighting

Good to know

Maintenance-free hub labyrinth protection V-RING roller Φ600 mm

Providing maximum ground clearance 770 mm, the distance between the beams

770 mm 1070 mm Standard Tubular

1070

39

- 4,5 | 5 | 6 m

trailed, hydraulically folded

Brake axle pneumatic or hydraulic K-80

tine harrow Φ12 mm behind the roller support wheels

mm

roller Φ540 mm c-ring tandem roller Φ580 mm

FIELD CULTIVATORS

Narrow coulter tine

32x12 mm

+ option

reinforcement goose foot

Narrow coulter tine

45x12 mm

+ option

reinforcement goose foot

Narrow coulter tine

32x12 mm

42

field cultivators

- possible options

Front 9-string roller

diameter 315mm

Additional options

reinforcement, completed goose foot

levelling board

3-point hitch cat. II - III

Spiral rippers behind tractor wheels

4 rows of tines 32x12 mm with a straight double-sided share

Double string roller

Φ315 mm

Tine 32x12 with a share straight, double-sided

43

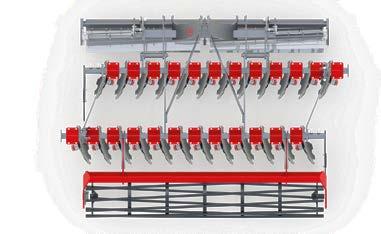

mounted, hydraulically folded - 3,6 | 4,2 | 4,9 | 5,6 m

88 102 130 150 36 42 49 56 3,6 4,2 4,9 5,6 1150 1300 1540 1630 Weight (kg) Number of tines (pcs.) Working width (m) Power demand (KM)

Good to know LED lighting

instead of the front rollers

Drawbeam cat. II - III

Spiral rippers behind tractor wheels

String roller Φ335 mm

- possible options

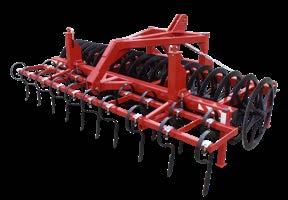

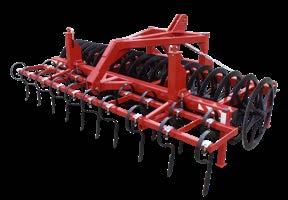

Three rows of tines 32 x 12 mm with reinforcement ended with a goose foot

rigid frame with a chassis - 4 m rigid frame - 3 | 4 m

field cultivators trailed - 5,3 | 5,7 m

Rear pin roller Φ370 mm

Leveling board

Rear string roller Φ335 mm

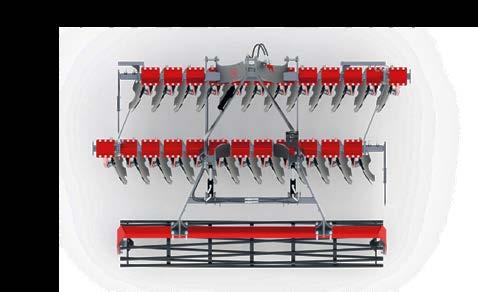

hydraulically folded, mounted - 4 | 4,5 m

170 39 5,7 3030

Additional options

straight tooth 32x12 mm JACKPOT

3-point hitch cat. II and III - pins

string

roller instead of pin roller Φ370 mm

45

4|5 m:10.0/75 - 15.3 5,3|5,7 m: 11.5/80 - 15.3 92 120 145 160 20 26 30 34 3 4 4,5 5,3 1540 1890 2130 2950 Weigt (kg) Number of tines (pcs.) Working width (m) Power demand (KM)

Road wheels

Good to know LED lighting

Side guards mounted at the height of the rear string roller

Mounted version

Side, support wheels 24 x 8,00-14.5

field cultivators

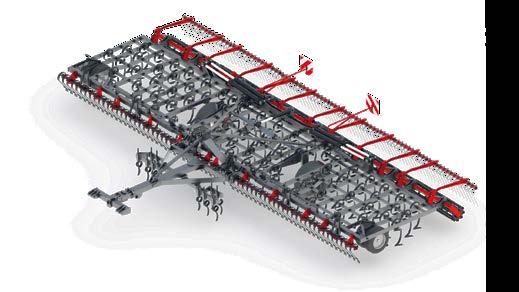

- possible options

Road wheels

340/55-16-(6-8 m) 400/60-15.5 - (10 m)

Additional options (LED lighting)

Smooth regulation working depth

Drawbeam cat. II i III

Spiral rippers behind tractor wheels

Spring tine harrow manually adjustable

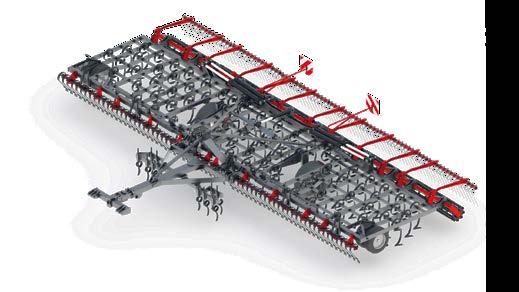

5 rows of spring tines 45x12 mm Tubular roller Φ400 mm

spring tine harrow or front leveling board reinforced tooth 45x12 with a goose foot tine harrow 12 mm

Warto wiedzieć

Machine as standard equipped with spring tines 45x12 mm (without goose feet)

Transport position

47

trailed, hydraulically folded - 6 | 7 | 8 | 10 m

120 160 190 250 57 67 77 98 6 7 8 10 3850 3950 4150 4450 Weight (kg) Number of tines (pcs.)

width (m) Power demand (KM)

Working

SUBSOILERS GRUBBER

Standard Tubular Φ540 mm | Φ600 mm V-RING Φ600 mm

50

Tine harrow Φ12 mm

3-point hitch cat. II

subsoilers

- possible options

Spring protection adjustable spacing of corps

Tubular roller crushing and kneading

Φ540 mm point depth adjustment

Additional options

Front support wheels

10.0/75 - 15.3

manually adjustable

Steel sheet tines thickness 30 mm reinforced with hardox

support wheels adjustable manual

roller Φ600 mm

51

rigid, mounted frame - 3 m

120 160 170 3 4 5 3 3 3 1530 1745 1865

i III

Weight (kg) Number of tines (pcs.) Working width (m) Power demand (KM)

V-Ring

Good to know LED lighting

Hardened replaceable tooth tip Component spring protection