BVS

An intelligent partner to help keep your animals healthy and comfortable

The BVS is a fully automatic robot that cleans livestock buildings by vacuuming up slurry. It helps to:

Keep animals cleaner

Keep cubicles cleaner

Decrease the working time needed for cleaning the passages between cubicles

Make animals more comfortable

Reduce the amount of liquid around the animals’ hooves and legs

Reduce the ammonia fumes released due to frequent passes

Outstanding cleaning performance

How the BVS works:

The two arms move the slurry towards the centre.

The build up of slurry around the tank’s suction mouth prevents any air from getting in.

As the tank is depressed (vacuum pump), the slurry is vacuumed up and stored in the tank.

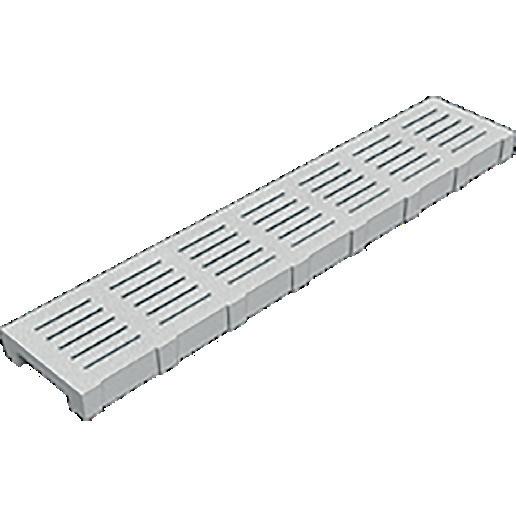

When the BVS passes over areas with slotted floors, the tank empties because there is no slurry to block the suction mouth.

When it arrives at its charging point, the BVS empties and the vacuum pump reverses to push the slurry out of the tank.

A machine for the long term...

The BVS is made entirely from painted stainless steel which protects it from corrosion and ensures an optimal service life.

Its rounded design allows it to turn 360°, reducing the need for manoeuvres when it reaches the edges of the building.

FEATURES

Minimum height under the barrier

mm

Electrical consumption 250 W/hour

Slurry tank volume 350 l

Water tank volume

l

Forward-moving speed 10 m/min

Autonomy with LITHIUM battery 14.5 hours/day

Permissible slope 8% (4% + 4%)

Empty weight

Filled weight

NOISE EMISSION (AT 1 M)

NOISE EMISSION (AT 10 M)

kg

dB

dB

Capacity / Robot* until 150 Milking cow

* depending on the battery, route and emptying point

Plug and play installation

WIFI coverage throughout the building will be required before installation to ensure optimal remote access.

No parts need to be installed in the ground to guide the robot. Thanks to its laser guidance system, the BVS moves around autonomously.

The first time that the robot is used, the operator (a qualified person approved by BouMatic) must create a virtual map by moving the robot throughout all areas of the building. Once the robot has learned its map, it will be able to move around freely in its area and the user will be able to adjust the frequency of the scrapings as they want.

The learning and the adjustment of any settings can be done from a PC or a smartphone. A remote control is provided for all movements in manual mode.

Any alerts are send by email and/or SMS and can be resolved remotely.

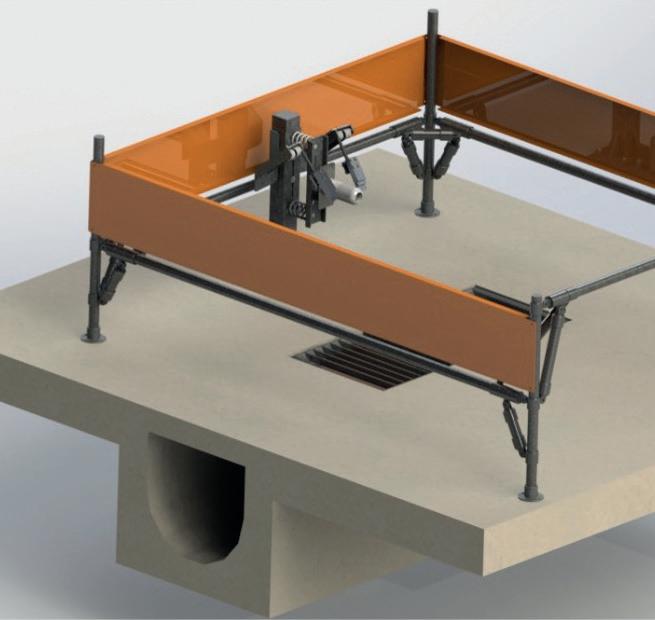

Emptying point

Several configuration options are available: On a reception pit On a channel On slotted flooring at the edge or in the middle of the building On a storage pit

Router

Satellites