Impact Report 2024

Our journey to a world without sh*tty food tools.

Our journey to a world without sh*tty food tools.

At BOSKA, we believe that businesses have the power and the responsibility to drive positive change. Sustainability is not a side project for us; it is embedded in our core values. From designing products that last a lifetime to rethinking packaging, reducing emissions, and collaborating with impactdriven partners, we are on a mission to challenge industry standards.

This impact report is our way of sharing where we stand today, what we have accomplished over the past year, and where we are heading next. It is not just about numbers. It is about our journey with our challenges, our progress, and our ambitions for the future. We invite you to dive in, get inspired, and maybe even join us in rethinking what business can be.

“We are committed to moving forward step by step instead of taking easy shortcuts. We learn every day to become the best in our niche instead of becoming the biggest.”

Maurijn Legein CEO

Maurijn Legein, CEO BOSKA Food Tools for Life

Looking back at 2024, I am proud that BOSKA has improved on all aspects where we treat our business as a force for good. Our commitment to sustainability by delivering unmatched quality has remained steadfast. One of our most significant achievements this year was the introduction of our first completely plastic-free packaging range, which is not only environmentally friendly but also ultra giftable. Additionally, our partnership with XD Connects is a match made in heaven because it changes ‘the way we give’ by focusing on durable, high-quality gifts for life. At the same time, we see that politicians are challenging or completely abandoning global goals around inclusivity and sustainability set by recognized institutions. It’s like they forgot that we’re all in this together!

Despite all geopolitical and economical challenges, our dedication to making a positive difference has never wavered, and we will continue to lead by example in our industry. At BOSKA,

niche instead of becoming slicer that matters, but how it is designed and brings a smile on your

Our Impact Journey read

Vision and Mission read

Our sustainability strategy read

B Corp Certification read

Understanding our CO₂ footprint read

Justdiggit: greening the future read

Sustainability in action read

The BOSKA courant: our year in six stories read Looking ahead: keep moving, keep improving read

Our commitment to charities read Get in touch. read

Meet the BOSKAnians: our team, our strength & Employee satisfaction read

Some of life’s best moments happen around the table. A bubbling pot of fondue on a winter evening, a beautifully arranged cheese platter at a festive gathering, or a freshly baked pizza straight from the oven. Whether at home or in a professional kitchen, food has the power to connect people, create memories, and turn ordinary moments into something special.

Our journey began in 1896 near Gouda in the Netherlands, when blacksmith Willem Bos crafted his first cheese tools for local farmers. What started as a necessity quickly evolved into a legacy of craftsmanship and innovation. Over generations, BOSKA has remained dedicated to designing smart, high-quality tools that enhance the experience of preparing and sharing food.

For over a century, we have been on a mission to elevate food moments. From home cooks to professional chefs and artisans, our products are designed to celebrate craftsmanship and bring people together. Whether you are slicing, serving, or sharing, BOSKA ensures that every bite is an experience worth savoring, for life.

We are committed to designing food tools that last a lifetime, moving away from disposability. By focusing on culture and embracing craftsmanship that reduces environmental impact through lifetime guarantee, timeless design and plastic free packaging, we aim to set a new standard for the food industry, one where quality is sustainability.

Our vision is simple: a world without sh*tty food tools. A world where people invest in tools that they love, that perform flawlessly, and that do not need to be replaced every few years. With every product we create, we move closer to this goal.

BELIEF

Quality = Sustainability

VISION

A world without sh*tty Food Tools

MISSION

To create great Food Tools & make them cool

WHAT

We make Food Tools with:

- Timeless Design

- Lifetime Guarantee

- Fun

- Affordable for the many GOALS

- To change the industry standard to Lifetime Guarantee

- A BOSKA Food Tool in every home by 2030

- A BOSKA PRO Tool on every Fresh Deli Counter by 2030

THE REASON YOU BUY A BOSKA TOOL

- A BOSKA Food Tool is The Perfect Gift

- A BOSKA PRO Tool Makes Food Cool, brings more sales & less waste

Our core values:

At BOSKA, we believe that high-quality food tools should be built to last, reducing waste by eliminating the need for constant replacements. That is why we are committed to offering products with a lifetime guarantee and timeless design, ensuring they are not just for today, but for generations to come. A wellcrafted tool should be something you pass on, not throw away.

Sustainability is an opportunity to continuously innovate and lead by example. While circular business models remain on our radar, we focus on longevity, plastic-free solutions and timeless design as powerful ways to minimize waste. Our Food Tool is not just functional; it is designed to stay relevant, to fit effortlessly into kitchens of today and tomorrow while being affordable.

By prioritizing long lasting materials and thoughtful aesthetics, we aim to inspire both our partners and the industry to move towards a more responsible and lasting approach to product development.

“Sustainability

is an opportunity to continuously innovate and lead by example.

Quality = Sustainability”

In November 2022, we became a Certified B Corporation, joining a global movement of companies committed to balancing profit with purpose.

Throughout 2023 and 2024, we actively worked on our B Corp improvement actions, enhancing our impact across all aspects of our business.

To better manage the social and environmental aspects of our business, we initiated a new materiality assessment, ensuring that we focus on what truly matters. We also refined our approach to goal-setting and tracking, implementing clearer and more measurable environmental or social objectives for all employees.

Employee ownership at BOSKA grew in 2024, with the CEO and CFO joining the founder as owners. We also continued investing in personal development, offering both internal and external training programs designed to benefit our team, not just at work, but in their broader lives as well.

We reassessed and shifted key supplier relationships, ensuring that our partnerships align with our ambitions. We also took concrete steps to measure and reduce our environmental footprint, collecting data from suppliers on CO₂ emissions, waste, and water usage.

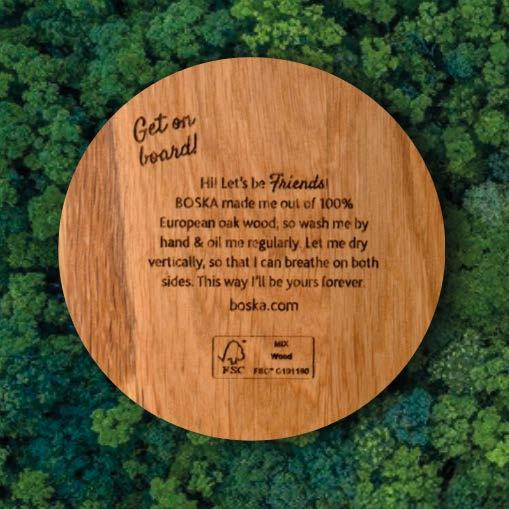

Sustainability is built into our product philosophy. In 2024, we continued refining materials, optimizing designs, and prioritizing reuse and recyclability. A major milestone was achieving global FSC certification, allowing us to sell FSC-certified products not only from our headquarters in the Netherlands but also from our offices in the USA.

Customer satisfaction remains a top priority, and in 2024 we took significant steps to optimize our service and personalization process.

• In 2024, we started closely tracking response times, ensuring that customers receive an answer within 2-3 working days. During the busiest period, our average response time was just 5 hours after receiving an email, showing that we now have better control and efficiency.

• Our personalization process has also been fully optimized. Previously, personalization orders required manual input, but in 2024, we transitioned to an automated system.

Customers can now easily customize BOSKA products online and easily discover for which tools they can add a unique touch to their favorite BOSKA tools.

B Corp is not about being perfect; it is about being accountable and show continuous improvement. It challenges us to keep improving, keep questioning, and keep pushing for a better way of doing business. And that is exactly what we intend to do.

Next summer, in 2025, we will roll up our sleeves and tackle the deep-dive recertification process to prove that we are still raising the bar.

“B Corp is not about being perfect; it is about being accountable and show continuous improvement. It challenges us to keep improving, keep questioning, and keep pushing for a better way of doing business. And that is exactly what we intend to do.”

Maurijn Legein CEO

Creating long-lasting products is one part of the equation, but every step in the process matters. From sourcing materials to how our products reach customers, emissions are generated along the way. That is why reducing our carbon footprint requires looking at the bigger picture.

In 2024, we took further steps to reduce emissions across the board. The next section outlines the progress we have made and where we are headed next.

Reducing emissions starts with understanding where they come from. Scope 1 covers the direct emissions from gas use in offices and fuel from lease cars. Scope 2 emissions are the indirect emissions resulting from the energy consumed in our operations, such as lighting, heating, cooling, and powering our offices.

In 2024, both saw a significant drop. Scope 1 emissions fell by 14%, while scope 2 emissions plunged by 56%. A big part of this reduction comes from solar

panels installed end of 2023 at our office in the Netherlands, helping to power our operations with cleaner energy. The closure of facilities in 2023 also played a role, streamlining operations and reducing overall energy consumption in 2024.

Progress? Absolutely. Room for more? Always. The mission to trim down our operational footprint does not stop here. In 2025, we will take it a step further by defining our long-term sustainability goals for 2030, setting the course for an even greater impact.

“Progress? Absolutely. Room for more? Always. The mission to trim down our operational footprint does not stop here. In 2025, we will take it a step further by defining our long-term sustainability goals for 2030, setting the course for an even greater impact.”

If you are looking for the biggest chunk of our emissions, this is it. More than 98% of our total footprint comes from scope 3, covering everything from raw materials to logistics and business travel.

Raw materials like stainless steel, wood, and stone form the foundation of our food tools. While these materials are durable, they have an impact. That is why we are pushing for more responsible sourcing, FSC-certified wood, and efficient production methods from our suppliers.

Packaging is another key focus. Every gram of material counts. We have significantly reduced plastic, shifted to FSC-certified materials, and are minimizing packaging size wherever possible.

Logistics and distribution also play a role. Moving products across the world has an unavoidable footprint, but optimizing transportation, consolidating shipments, and reducing unnecessary freight help lower emissions.

In 2024, we saw an increase of 3.3% in scope 3 emissions compared to last year, and we are not here to sugarcoat it. Business is growing, which meant 71% more air travel for meetings, supplier visits, and audits. At the same time, we saw a 23% drop in staff commuting by car, explained by less employees working at BOSKA.

Our CO₂ emissions from productrelated activities increased by 4%. You might be thinking: “wait, what?” But let’s zoom out for a second. We sold 11% more food tools, which means more people are choosing high-quality, longlasting products instead of cheap throwaway alternatives. To really see if we are improving, we do not just look at total emissions. Instead, we measure CO₂ per euro of revenue = how much CO₂ is emitted for every euro we earn. And here is the good news: that number went down by 4% compared to last year. This shows that we are growing in a smarter way, making better product choices, and helping reduce waste in the long run.

“Every gram of material counts. We have significantly reduced plastic, shifted to FSCcertified materials, and are minimizing packaging size wherever possible.”

We know there is work to do, and we are on it. Here is what is already in motion:

• Smarter ways to get to work. A mobility plan is in the works to encourage employees to swap cars for public transport or bikes. Less traffic, less emissions, more fresh air.

• Bringing production closer to home. We are exploring options to relocate some of our production to Europe. Less shipping, lower emissions, and better oversight. It is still under discussion, and we are weighing all the pros and cons before making a move.

• Rethinking materials and sourcing. We are always looking for ways to reduce waste, refine materials, and make smarter sourcing choices. Because the best way to cut emissions is to never create them in the first place.

So, we are not there yet, and we know it. Tracking emissions, reporting transparently, and making reductions where we can? That is the baseline. The real challenge is pushing harder, making smarter choices, and refusing to settle for “good enough”.

There is always a way to do better, and that is what we are working on. As for scope 1 and 2, we are sharpening our reduction targets, making smarter decisions, and questioning what needs to change to keep pushing forward. The climate clock is ticking, and we are not sitting back and waiting.

“So,

we are not there yet, and we know it. Tracking emissions, reporting transparently, and making reductions where we can? That is the baseline. The real challenge is pushing harder, making smarter choices, and refusing to settle for “good enough”.”

3.2.1 Looking beyond reduction: A smarter way to tackle scope 3

Every year, we actively search for innovative ways to reduce our scope 3 emissions, knowing that these indirect emissions are the hardest to tackle. But let’s be honest: no matter how much we optimize, scope 3 emissions remain a reality of doing business. Instead of simply buying carbon credits, we wanted to support a solution that aligns with our values and creates long-term impact. That is where Justdiggit resonated with us.

3.2.2 A commitment that keeps growing

Since 2022, we have been working with Justdiggit to help regreen dry and degraded landscapes in Tanzania. This partnership is not just about planting trees; it is about restoring ecosystems, improving water and food security, and making a real dent in climate change.

We committed to investing €194,000 over 4 years to support Justdiggit’s nature-based solutions, which bring back vegetation and retain CO₂ where it matters most.

By 2024, we have contributed €128,142, meaning we are well on track to reaching our goal by 2026. This funding helps restore millions of trees, capture billions of liters of water, and ensure longterm impact in the Singida region.

3.2.3 More than trees: strengthening communities

The progress is not only visible in the landscape but also in the communities. Justdiggit’s work goes beyond regreening as it empowers local farmers, village leaders, and policymakers to keep the movement growing. By

providing knowledge, training, and tools, they ensure that this transformation lasts far beyond our direct involvement.

3.2.4 Every year, every tree, every drop of water matters

If we can warm up the planet, we can also cool it down. By investing in nature-based solutions rather than just offsetting emissions, we want to contribute to real climate action. Every year, every tree, and every liter of water brings us closer to that goal. We are not done yet, and that is the best part. The work continues, and so does the impact.

Click to visit our BOSKA Impact page

Instead of simply buying carbon credits, we wanted to support a solution that aligns with our values and creates long-term impact.

In 2024, we took another step toward more sustainable packaging. Our new all-paper packaging reduces CO₂ emissions from packaging by 31% and is fully recyclable. The updated design allows the tool to be beautifully visible and touchable through a cleverly designed window, eliminating the need to open the packaging to see the product properly. A smarter, more sustainable solution that enhances both the experience and the impact.

Curious about the journey from idea to fully plastic-free packaging?

BOSKA started the first research on plastic-free packaging for its tools and realized that further development was necessary. Several people worked on the project, but without success.

The project was taken up, proposals were developed, samples were made in-house and these proposals were presented internally.

In cooperation with our factories, the first samples were made so that both tools and packaging could be produced in the same country.

Many samples went back and forth and consultations were held with retailers for feedback. It was decided to develop three packaging thicknesses so that each tool would fit into the most compact box possible.

A specification template for the packaging was created and could be applied to all tools. The first production orders followed.

The first Amigo collection arrived in our warehouse with the new plastic-free packaging; more packaging will follow soon.

“BOSKA takes a new step in sustainability: introducing all-paper packaging with 31% lower CO₂ emissions and fully recyclable materials. This is how we continue to innovate, for both our products and the environment.”

As of November 2024, BOSKA is globally FSC certified, meaning we can now sell FSC-certified products worldwide, not just in the Netherlands. This step brings us closer to ensuring responsible sourcing across all markets while also streamlining our operations.

With this certification, we are delivering on our sustainability commitments in a tangible way. It allows us to expand our FSC-certified assortment to the US market, making sustainable choices more accessible to even more customers. At the same time, it eliminates the need for double stock management, meaning all wooden products will be aligned under the same responsible sourcing standards.

32.5

Now that we are globally FSC certified, we will extend the FSC-Tree to the USA, ensuring the same transparency and commitment to responsible sourcing in all our markets. %

In the Netherlands, we introduced the FSC-Tree, a way to track our progress in making more of our wooden products FSC certified. Currently, 14 out of 40 products already carry the certification, bringing us to 32.5% and counting. Some items will take longer to transition, but we are steadily moving forward.

“This

step brings us closer to ensuring responsible sourcing across all markets while also streamlining our operations.”

Jens Luiten CATEGORY MANAGER CONSUMER GOODS

Black Friday is usually all about buying more, more, more. We decided to do things differently. Instead of throwing out discounts, we teamed up with Sumthing and Plastic Fischer to turn every purchase into something bigger: A cleaner planet.

3.3.3 Green Friday with Sumthing

For every order over €15, Plastic Fischer removed one kilo of plastic from the Ganges River in India. The result? 500 kilos of plastic gone in 2024, thanks to our customers who chose to buy our food tools that weekend.

This is not the first time we have committed to a cleaner world. In 2023, thanks to the involvement and support of our customers, we were able to make a significant difference, removing 640 kg of plastic from the Ganges. Together, this brings the total to an incredible 1140 kg less plastic in the River!

Remember 2023?

“500 kilos of plastic gone in 2024, thanks to our customers who chose to buy our food tools that weekend.”

Professional kitchens rely on tools that perform, day in and day out. When something breaks, the last thing anyone needs is a long, complicated repair process. That is why in 2024, we decided to stop outsourcing repairs and bring them in-house. Not because we needed more to do, but because it made sense.

3.3.4 Fixing instead of replacing: why we took repairs into our own hands

Now that we handle repairs ourselves, we get direct insight into what goes wrong. If a tool stops working due to misuse, we can update instructions or share better usage tips. If the issue is in the design, we take that feedback straight to product development to prevent it from happening again. No more information getting lost along the way, just clear insights and real improvements.

Since April 2024, we have already repaired 42 devices, with 26 of them out of warranty. That means 26 machines saved from the scrap heap and back in action. The breakdown?

25x V35

10x Unika

7x Raspmolen

For professionals who cannot afford downtime, we also provided loaner devices 18 times, making sure kitchens kept running smoothly while repairs were handled.

It is not only about fixing what is broken. Every repair teaches us something. It helps us make BOSKA PRO Tools stronger, smarter, and built to last. If we see recurring issues, we tweak materials, adjust designs, or rethink the details that matter. The result is better products, fewer breakdowns, and tools that stay in use longer.

This shift also makes a real difference for sustainability. With repairs now more accessible, fewer tools end up being replaced unnecessarily, even after the warranty period. Some fixes come at a cost, but it is still a more responsible and cost-effective choice than buying a completely new product. For those who cannot afford downtime, we even offer loaner devices to keep things running.

What is next? Ideally, fewer repairs and tools that last even longer. The better we make them, the fewer breakdowns we will see. If we do this right, our professional food tools will stay in action for years because a tool that lasts is a tool that works. That’s the goal.

“It is not only about fixing what is broken. Every repair teaches us something. It helps us make BOSKA PRO Tools stronger, smarter, and built to last.”

Shipping stuff around the world creates emissions. We know it, you know it. So in 2024, we took a good, hard look at our packaging and logistics. We figured out some smarter, simpler ways to save space, cut waste, and cut emissions. Turns out, a few tweaks can make a big difference.

3.3.5 Optimizing space, smarter boxes and less CO₂

First up, we cut our storage needs from 1,977 pallets in 2023 to 1,483 in 2024. How? By rethinking how we pack our products. Some examples:

Our pizza peel now fits in a box half the size. Customers just snap it together at home.

Our large serving board shrunk by 1 cm, which means we can now stack 180 on a pallet instead of just 66.

Fewer pallets also mean less transport needed, leading to an estimated 3,120 kg of CO₂ reduction in 2024 compared to 2023. On top of that, by packing smarter, we sent 1,713 fewer packages, avoiding unnecessary waste and excess shipping materials.

Did we save money too? Absolutely. Efficiency comes with cost benefits, and we are happy with that too. These changes help us work smarter, reduce waste, and lower our impact on the planet, all in one go.

We will continue refining packaging, reducing unnecessary transport movements, and exploring direct shipping from suppliers to the UK instead of routing everything through Rotterdam first.

“A

few tweaks can make a big difference.”

2024 was another year of progress, with both success stories and challenges. Sustainability is not a checklist. It is a mindset. We are not just reporting numbers. We are questioning how to do better every single day.

From sourcing FSC-certified materials to cutting plastic, optimizing transport, and bringing repairs in-house, we are proving that small tweaks add up to big impact.

No greenwashing. No empty promises. Just a commitment to smarter growth, better products, and a planet that does not have to pay the price. The work is never done, and that is exactly how we like it.

“Sustainability is not a checklist. It is a mindset.”

This year has been filled with moments that brought us together, challenged us, and made an impact. From personal growth to giving back to our communities, here are six stories that capture what 2024 was all about:

4.1.1 Learning & growing: A personal development journey Growth does not happen overnight. Sometimes, it takes a moment of reflection, the right guidance, or a challenge that pushes you further than expected.

That is exactly what the Inzicht training is designed for. This program helps participants develop self-awareness, emotional intelligence, and better communication skills, both professionally and personally.

Denise experienced firsthand how the Inzicht training changed her approach to work and life:

“Through this program, I learned that even the smallest insights can make a huge difference. By becoming more aware of my behavior and reactions, I can now better recognize when I am reacting from my first emotion—and why. I see this in myself, but also more and more in others. The next step? Starting the conversation, because behind every emotion, there is always a deeper need. Addressing that need is what really matters, not just reacting to the emotion.”

A powerful realization, and one that does not just improve work, but the way we connect with others every day.

“We can’t say learning is a core value without investing in our people in an educative way. It is great to see how people collaborate in their work and give each other feedback because they see it makes them grow.”

4.1.2 Giving back, getting together and celebrating in style Nothing brings people together like good food, good company, and doing something meaningful. This year, we teamed up for two initiatives that made an impact. One in the community and one right in our own office.

First, we put on our aprons and headed to a local care home to bake pancakes. The smell of fresh batter, the sound of laughter, and

a table full of happy faces. It may seem like a small gesture, but for the residents, it was a moment of joy. And for us, a reminder that sometimes the simplest things have the biggest impact.

A few months later, we also braved the wettest day of September to help out at the local children’s farm and playground. Overgrown fields were cleared, barns got a deep clean, and yes, we got muddy. But seeing the

transformation and knowing that some of our colleagues visit the playground regularly and still see the results made it all worth it.

After a day of volunteering at the children’s farm, we headed back to an office that had been completely transformed into a 1920s dream. Vintage decorations, jazz-age dishes, live music during dinner, and a DJ to keep the party going long into the night.

“Nothing

brings people together like good food, good company, and doing something meaningful.”

4.1.3 Lunch and learn, feeding our minds, one bite at a time What is better than learning something new? Learning something new while stuffing your face with good food. That is exactly what Lunch & Learn is all about. Every month, a different team steps up, not just to share knowledge, but to treat everyone to a delicious lunch while they are at it.

In 2024, we covered everything from how our logistics costs are built up to how to spot and stop a phishing scam before it stops you. We also practiced an evacuation, because knowing where to run when things get smoky seems like a good life skill. Each session is prepared and presented by a different team, giving us a chance to learn directly from each other’s expertise and experiences.

And let’s be real, the food is always a highlight. We lunch together everyday, but on these days, it is extra special. One team always goes the extra mile to make sure we were not just fed, but properly spoiled. Wether it’s a delicious choice of risotto or a vegan stew with chips, it stops us from getting hangry. Learning, eating, laughing, this is a tradition that is here to stay.

“Every month, a different team steps up, not just to share knowledge, but to treat everyone to a delicious lunch while they are at it. We lunch together everyday, but on these days, it is extra special.”

4.1.4 One product, one step closer to local production

For one of our products, the Cheese Commander Pro+, we saw an opportunity to bring production closer to home and rethink how it is made. Together with Timmerije B.V., we started exploring how to redesign and optimize it for Dutch production.

The first results? Less material, same strength. We are also looking into which parts can be made recyclable and how to create a closed-loop system, ensuring that when the product reaches the end of its life, it does not go to waste.

If this works, we will have the first of its kind produced entirely in the Netherlands. A small step, but one that could open doors for more local production in the future.

“If this works, we will have the first of its kind produced entirely in the Netherlands. A small step, but one that could open doors for more local production in the future.”

4.1.5 A new partnership: XD Connects

We are thrilled to have kicked off an exciting new European partnership with XD Connects, bringing BOSKA food tools into the corporate gifting space. Corporate gifts often end up as clutter, forgotten in a drawer or thrown away after a few uses. We want to change that.

Through this collaboration, we are offering our BOSKA food tools as gifts that people will actually use, and keep. Instead of disposable items with a short lifespan, companies now have the opportunity to give something that lasts, brings people together, and reduces waste.

Since this partnership started at the end of 2024, we are only just getting started. In 2025, we will dive deeper into its impact and explore how we can expand this initiative further. The potential is big, and we are excited to see where this journey takes us.

“Corporate

gifts often end up as clutter, forgotten in a drawer or thrown away after a few uses. We want to change that.”

4.1.6 A customer story that says it all

Sometimes, the best way to understand the impact of our work is through the people who use our products every day. Take this review from our customer GuitarJos:

“BOSKA Monaco, the Rolls Royce of cheese slicers!”

My daughter (32) asked for a BOSKA Monaco cheese slicer under the Christmas tree. She already knew the quality of the brand because we have had a BOSKA slicer in our home for about 35 years. A perfect slicer that still works incredibly well.

The slices come off the cheese perfectly, whether it is aged, crumbly cheese or young cheese, all result in beautiful slices.

Need to remove a rind?

The BOSKA slicer does it.

Thousands of rounds in the dishwasher?

No problem! The BOSKA handles it with ease.

A BOSKA cheese slicer is an investment in a longlasting, durable partnership between people and their tools. And it makes a family a happy family. Go for it!!”

GuitarJos

“This is what we aim for. Food tools that last, moments that stick, and a community that keeps growing.”

This is what we aim for. Food tools that last, moments that stick, and a community that keeps growing.

For those who love a good story, we hope these moments brought BOSKA’s journey to life.

2 days of volunteering as a team, plus 7 colleagues who took individual action during working hours to give back.

And for those who prefer numbers, here are a few highlights of 2024:

5 out of 5 departments went out for a teambuilding activity and a great meal, all on BOSKA.

In 2024, we wrapped up 39 Mondays with a proper bootcamp session, just after work and just down the road, it became our unofficial Monday ritual. A shared sweaty moment, and yes— still sore on Tuesday.

Countless pancakes flipped during our volunteer day at the care home using 26 pancake mix boxes.

9 internal trainings, including mindfulness and AI

8 external trainings covering coaching and hard skills.

Merel, our biggest learner during her first Padel tournament

Every year, we commit 0.1% of our revenue to charity, and that has not changed. But in 2024, we decided to put most of our focus on one goal: helping Sunday Foundation getting a new jungle school built in Sierra Leona, now, not years from now.

A jungle school is exactly what it sounds like, a school built in the heart of nature, in places where no education facilities exist. These schools provide children in remote villages in Sierra Leone with access to learning, breaking the cycle of poverty and creating real opportunities for the future. But the impact goes beyond the classroom.

Waiting was not an option. We wanted to fast-track the process so that more children could start learning as soon as possible. In 2025, we will see the school taking shape, and we cannot wait to share the progress of this project that we are incredibly proud to support.

In addition, we continue to offer a corporate employee matching gift program, where BOSKA matches donations on a 1:1 basis, up to € 100 per year. In 2024, five employees participated, contributing a total of € 370.

“In 2024, we decided to put most of our focus on one goal: helping Sunday Foundation getting a new jungle school built in Sierra Leona, now, not years from now.”

Behind every great cheese slicer, fondue set, or cutting board, there is a team that makes it all happen. Meet the BOSKAnians, a group of people who bring creativity, dedication, and a lot of fun to the office every day.

We are a team that challenges each other, supports each other, and grows together.

Every one of these voices shapes BOSKA. Our strength? It is not just in what we do, but in how we do it together.

“I love that we are trained by Inzicht. It has helped me both in my personal life and at work.”

Ramon

“I really appreciate the openness in communication at BOSKA. Everyone is heard, and transparency is key.”

Nadine

“I am proud that, at just 25, I had the opportunity to visit our factories in China. BOSKA gives young professionals real chances to grow.”

Domino

“Proud that BOSKA is a place where you can truly be yourself. Your personal life matters here, because at the end of the day, you are one and the same person.”

Nadia

our BOSKAnians*!

“Q Rocks are now spread across the entire team instead of just management, which shows that employees are given more space and responsibility.”

Denise

the Netherlands.

“Every one of these voices shapes BOSKA. Our strength? It is not just in what we do, but in how we do it together.”

Behind every great cheese slicer, fondue set, or cutting board, there is a team that makes it all happen. Meet the BOSKAnians, a group of people who bring creativity, dedication, and a lot of fun to the office every day.

We are a team that challenges each other, supports each other, and grows together.

Every one of these voices shapes BOSKA. Our strength? It is not just in what we do, but in how we do it together.

“Last year, one of our raw material suppliers suddenly ran into trouble. A key machine broke down and production came to a halt. Instead of waiting and hoping for the best, we immediately got in touch and visited the factory the same day. Being there in person showed we were serious about finding a solution, not just placing pressure.

Back in the Netherlands, the team was kept in the loop in real time.

Together we looked at how to prioritize orders and temporarily source non-essential parts elsewhere. It was a great example of how strong teamwork across continents can really pay off.

We also like to keep improving the little things. During a product project, we noticed that the standard packaging could be better—less wasteful and easier to ship. So we came up with a more sustainable and compact design that ticked both boxes.

What makes our collaboration with the team in the Netherlands work so well is the openness. We share ideas, challenges, and wins regularly.

Their insights into the European market combined with our knowledge of local manufacturing is what keeps us moving forward together.”

Lai - Manager BOSKA China

*from China.

“Their insights into the European market combined with our knowledge of local manufacturing is what keeps us moving forward together.”

Behind every great cheese slicer, fondue set, or cutting board, there is a team that makes it all happen. Meet the BOSKAnians, a group of people who bring creativity, dedication, and a lot of fun to the office every day.

We are a team that challenges each other, supports each other, and grows together.

Every one of these voices shapes BOSKA. Our strength? It is not just in what we do, but in how we do it together.

“A typical day at BOSKA for me starts on the train. I take the subway down to Midtown where we have an office in the WeWork building by Bryant Park. Those are the first 2 ways we integrate sustainability here in the US. The subway is self explanatory I’m sure, and WeWork (which is co-working space) allows us to have an office space perfect for Lisette and I, without taking up as many resources as an office typically associated with corporate offices.

My day to day tasks have me managing the logistics for some of our key accounts and one thing I appreciate about BOSKA is the freedom we have in our roles with the expectation that we have the tools to figure out the best way to do our jobs. One example of this is how we were able to change the way some of our customers place orders with us. Many jobs would say “ if it ain’t broke, don’t fix it”, but in one move, we were able to consolidate the process for some customers. This resulted in fewer (but larger) orders which meant : less time processing orders, less time spent on labor and

our BOSKAnians*!

fewer packages on trucks. In the end, we were able to keep the revenue stream, reduce the overall workload and save some gasoline from being pumped into the atmosphere, for us and the customer! Where other jobs would look at you funny for deviating from the norm, BOSKA has a culture that embraces something new.”

“BOSKA

has a culture that embraces something new.”

Avinash - BOSKA

USA

the US.

Feeling heard, valued, and supported to grow: that is what makes a workplace thrive. In 2024, employee satisfaction and engagement hit 82%, right on target with the goal we set last year. But stopping here? Not a chance. We are aiming for 100% in 2025.

How did we get here? By investing in coaching, being even more transparent about business decisions, and continuously building an open culture based on trust. A place where people feel safe to speak up, share ideas, and challenge each other when needed.

So how do we push this even further? By making things clearer, from pension plans to career growth, and rolling out a solid plan for personal development. In 2025, we are also introducing a mobility plan to encourage more sustainable commuting options. The goal is simple: when people grow, BOSKA grows with them.

Opportunities for professional development

Opportunities for professional growth matter just as much as satisfaction. Our baseline score for professional development was 72% in 2024, and we are aiming for 100% in 2025. To get there, we are rolling out a new “learning & development” plan that makes it clear what opportunities are available, how employees can access them, and how we can all support each other’s growth, personally and professionally. Coaching each other, asking for feedback, and taking initiative in our own development is becoming second nature at BOSKA.

“A place

where people feel safe to speak up, share ideas, and challenge each other when needed.”

Opportunities for professional development

If there is one thing we know for sure, it is that impact is never ‘done.’ There is no final destination, no finish line where we say, “That is it, we have made it.” Because every time we reach a milestone, we see the next challenge waiting. And that is exactly what keeps us moving.

In 2025, we will push forward on all fronts. We are taking the final steps toward 100 percent plasticfree packaging. We continue rethinking materials and product design to make our tools last even longer. We are rolling out a mobility plan to help our team commute more sustainably. We are expanding our corporate gifting efforts so more people get gifts they will actually use and not toss in a drawer. And of course, we are gearing up for our B Corp recertification because measuring our impact keeps us accountable.

But beyond the numbers and checklists, what really matters is the mindset. The drive to do better, to challenge the status quo, to make choices that are smarter for the planet, for people, and for the long run. That is the BOSKA way. Not chasing perfection, but choosing progress every single day.

So, here is to another year of creating food tools that last, making business a force for good, and bringing people together. One bite, one choice, one step at a time.

“But beyond the numbers and checklists, what really matters is the mindset. The drive to do better, to challenge the status quo, to make choices that are smarter for the planet, for people, and for the long run.”

Be part of the next chapter.

Read something you loved? Or something you’d do differently? We are not perfect, and we do not pretend to be. So if you have an idea, a wild thought, or just something we should really hear: tell us. We are already cooking up our plans for 2025, and who knows… your input might just make it into next year’s report.

Join us in making a difference.