Inverter Technology and Bosch Air Source Heat Pumps (ASHP)

Executive Summary

Due to increasing concern for energy savings and improved comfort, consumers are demanding an air source heat pump (ASHP) with a compressor satisfying high efficiency, low noise, low vibration, and improved comfort conditioning. Additionally, a compressor with the ability to operate within wide outdoor temperature ranges is desired. To answer these needs, the advent of inverter technology in recent years has revolutionized ASHPs beyond traditional models by enabling them to operate more efficiently and provide heating even in extremely cold temperatures.

To that end, Bosch Home Comfort offers several solutions equipped with next generation inverter technology, including applied to modern Bosch Inverter Ducted Split (IDS) systems, Bosch Inverter Ducted Package (IDP), and Bosch Climate 5000 Ductless Mini-split (MS) ASHPs are now available. Inverter technology variable speed compressors operate continuously with a controlling frequency while self-adjusting heating or cooling output to match the demand of the conditioned space. Additionally, they operate very quietly at lower speeds than traditional ASHPs, while consuming less energy which results in significant energy savings and lower carbon emissions. They can also operate with better heating Coefficient of Performance (COP) than traditional ASHPs by offering on/off control.

To achieve higher levels of efficiency and comfort, proper selection of these state-of-the-art Bosch inverter driven (referred to as “inverter”) ASHPs are dependent upon proper sizing for each application utilizing an industry-accepted load

must consider the adjustable capacity of the Bosch inverter ASHP versus the calculated structure loads.

Topics

Traditional ASHPs and Climate Differences

Traditional ASHPs have been common in the warmest parts of the United States for many years. In warmer climates, these ASHPs are typically sized for cooling and offer a portion of the heating capacity needed on colder days, often assisted by back up heat if needed. These warmer climate ASHPs have typically been equipped with single speed, single stage compressors. For colder climates, these ASHPs were often sized to meet heating needs, while being oversized for cooling, resulting in moisture issues and inefficient operation. With the introduction of single-speed, two-stage modulating compressors, two stage ASHPs found increased use in colder climates, as they could operate at full load during winter and part load during summer. Most ASHPs are split systems with one coil and fan inside the structure (indoor unit - IDU) and another coil, compressor, and fan outside (outdoor unit - ODU), or systems with all coils, compressor, and fans outdoors in a single unit (package heat pump). Bosch ASHPs are available as ducted or ductless, depending on the model, providing air distribution options for consumers.

Inverter Technology

Applied to Bosch ASHPs –The Solution for Different Climates

Bosch inverter ASHPs are now being utilized in colder climates as they run longer while meeting the structure heating needs while providing better comfort than traditional single, and two stage modulating, ASHPs. They also easily meet the lower cooling needs in colder climates as well. The opposite occurs in mild and warmer climates with the unit running longer to meet cooling needs, and less to meet heating needs. Bosch inverter ASHPs include all the typical components found in traditional ASHPs with the addition of several more components which enhance operational ability, efficiency, and comfort. These are the Inverter, the Inverter Variable Speed Compressor, the Electronic Expansion Valve (EXV), the Pressure Transducer, and the accumulator to store the extra refrigerant when not running at maximum speed.

Bosch Inverter ASHP Components & Operation

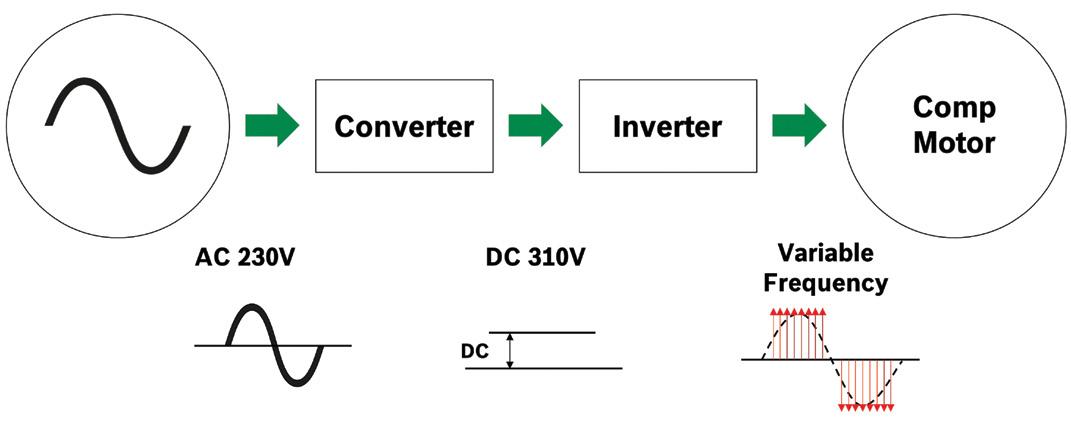

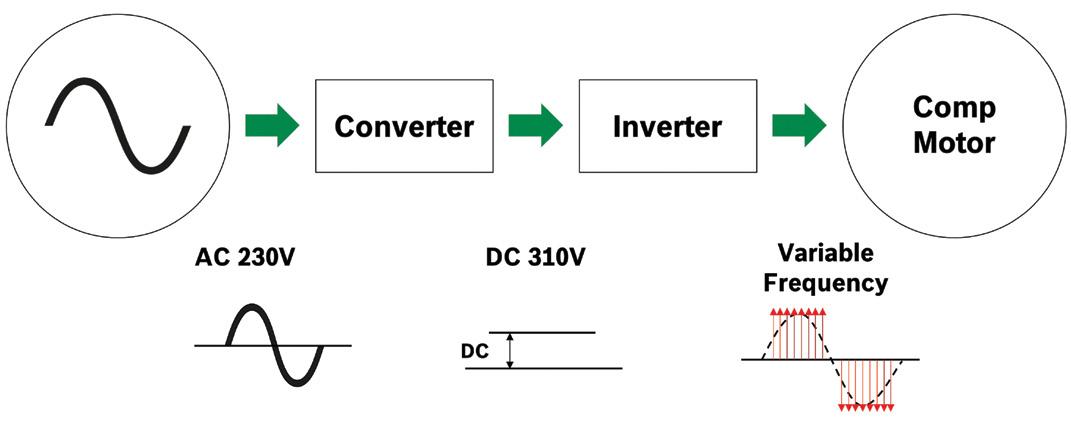

Inverter

An inverter is an electronic component that can turn Direct Current (DC) to Alternating Current (AC). Our system first converts the 240V AC to a ~300 V DC (with a rectifier), then converts back to a 3 phase AC (inverter) at different frequencies to control speed. Many applications exist for inverter technology. These include portable lights, televisions, kitchen appliances, and power tools. Renewable energy such as solar generation systems also use inverter technology, as well as battery powered mobile and marine vehicles, and electric cars. Stationary appliances such as window unit air conditioners, refrigerators, freezers, washing machines, dryers, and dishwashers also utilize inverter technology for improved operation. For heating and cooling applications, inverter ASHPs utilize this energy saving technology to eliminate wasted operation by efficiently controlling motor speed and providing continual and maximum compressor efficiency.

Inverter Variable Speed Compressor

Inverter ASHPs are equipped with variable speed compressors which are controlled digitally with DC voltage and operate almost continuously with less off and on than non-inverter (fixed speed and modulating 2-stage) compressors. An inverter ASHP with inverter technology can self-analyze structure load conditions while running and can self-adjust. Typically, inverter ASHPs turn on at slow speed to maintain temperature and speed up if the temperature changes due to load. The variable speed compressor can ramp up and down to provide load matching and set point matching. Minimal power is used compared to noninverter, traditional ASHPs, and improved comfort levels can be achieved. Additionally, inverter ASHPs allow system pressure changes in the refrigerant circuit, and compressor, and provide more precise control of the operating evaporator.

Two types of compressors are typically utilized for current inverter ASHPs in the heating, ventilating, and air-conditioning (HVAC) industry, rotary and scroll. Rotary compressors are utilized in lower capacity units in lieu of scroll compressors. These compressors use rotating impellers and are very compact with the working mechanism being simpler compared to scroll compressors. Scroll compressors are used in larger capacity units. They have two interleaving spiral-

shaped scrolls to compress refrigerant progressively, operating smoothly, quietly, and efficiently, with less moving parts than prior reciprocating compressors. The scroll design minimizes wear for long compressor life. Scroll compressors tend to be very energy efficient and have typically low load leading to alleviated noise and vibration issues. Both rotary and scroll compressors with inverter technology provide supremely efficient comfort by adjusting compressor capacity rather than a simple on/off control like traditional units, thereby reducing operating costs.

Inverter Compressor Background

A Bosch inverter ASHP compressor is variable speed while energized, always closely matching the heating or cooling structure load at all outdoor ambient temperatures during normal operation in either cooling or heating. The inverter system does not have a compressor contactor but instead converts 230V AC voltage to ~310V DC using a diode bridge rectifier. The DC voltage then passes through a filter, smoothing the voltage and sending it to an inverter. It is then “inverted”, or reformed, back into a 3-phase sine wave that is sent in small increments called “hertz” (one cycle per second = one revolution per second) of compressor crankshaft speed to the compressor at variable frequency. The compressor motor speed is then controlled by the AC hertz delivered to it by high-speed bipolar transistors, depending upon the heating or cooling load conditions, and can ramp up or down as needed.

The system first detects reference temperatures with sensors (return air temperature and set point, outdoor air temperature). The system calculates the corresponding capacity and controls the compressor. It then detects the operating pressure at the suction line every 20 seconds and calculates the deflection from the target pressure. Adjustment of compressor frequency (hertz) is then ramped up or down as necessary to match load requirements.

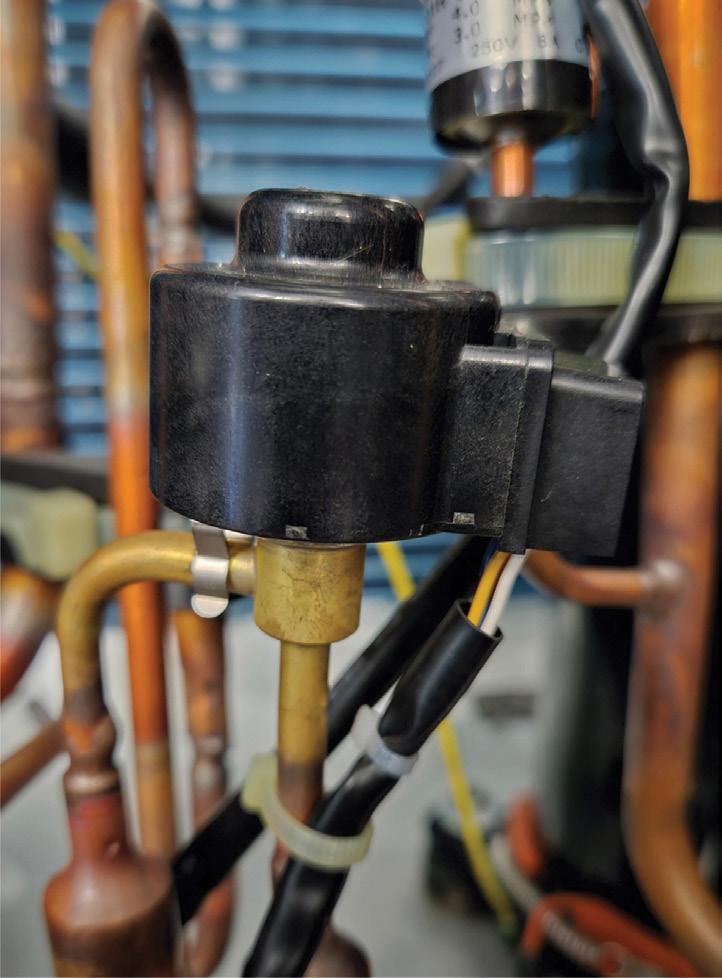

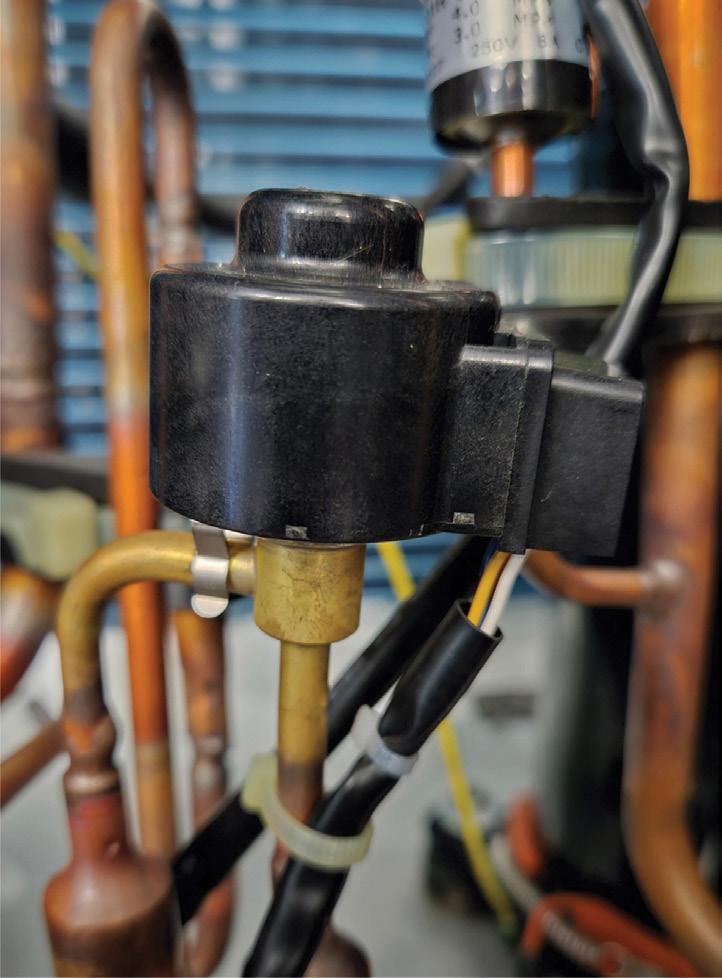

Electronic Expansion Valve (EEV or EXV)

All Bosch inverter ASHPs will have an “Electronic Expansion Valve” (EXV) metering device designed to regulate and ensure proper refrigerant flow during all conditions, with the primary function relating to the heating mode. This helps optimize the unit’s operation to the highest efficiency possible (1) . The EXV has a “Pressure Transducer” (PT) (currently IDS/IDP only) and temperature sensor (IDS/IDP/MS) at the evaporator outlet that constantly measure the refrigerant. The controller reads these signals and uses refrigerant data stored in the controller to convert the pressure into the refrigerant’s saturation temperature. The controller compares the actual temperature to the converted temperature to calculate the operating superheat. The controller then sends a signal to the EXV’s stepper motor to energize the coils and adjusts the valve’s position as necessary. This allows the compressor to have a much greater range of operation than with a traditional Thermostatic Expansion Valve (TXV), allowing more precise control at lower capacities and greater refrigerant flow when higher capacities are needed. For example, if the cooling load increases, the refrigerant in the operating evaporator boils off faster, which increases the suction pressure and temperature. The EXV senses this and opens to allow more refrigerant into the operating evaporator. Conversely, if the cooling load decreases, the EXV closes, limiting refrigerant into the operating evaporator. These EXVs are fully open when the compressor is on (normal operation) during cooling mode and adjusted during heating mode. They are controlled in heating mode via compressor discharge superheat (2) . In the heating mode the superheat is calculated from the low-pressure equivalent saturation temperature converted from the pressure detected by a low-pressure sensor in the ODU and the temperature detected by a suction line thermistor. The EXV valve opening is regulated so the superheat becomes close to the targeted superheat value.

Bosch IDS/IDP ASHPs also have a traditional TXV positioned in the indoor air handler (like all traditional split system ASHPs) to control superheat during the cooling mode. The TXV at the cooling coil auto adjusts the amount of restriction against refrigerant flow to ensure that the refrigerant is completely gas after leaving the cooling coil to protect the compressor from slugging, and controls operating superheat. Bosch MSs will not have a TXV. Single zone MSs will have ODU EXVs and temperature sensors. Multizone MSs will have ODU EXVs, temperature sensors, and a capillary tube metering device.

Pressure Transducer (PT)

Bosch inverter IDS/IDP ASHP compressor speed is controlled based on coil pressures monitored by the unit’s PT located on the suction line in the ODU and compared to a desired value or set point. The PT then converts that pressure into a proportional electrical output signal, typically in the form of frequency. The PT provides compressor frequency control, EXV control (in heating mode only), high pressure protection (in heating mode), and low-pressure protection (in cooling mode) (3) . The Low GWP IDP, and IDS will have the same control logic. To ensure stable and adequate capacity, the compressor speed will modulate relative to evaporator pressure (indoor coil) during cooling operation and relative to condensing pressure (indoor coil) during heating operation. The target pressure can automatically adjust based on compressor operation so optimal capacity can be achieved.

Indoor Coil Target Temperatures

In a Bosch inverter ASHP system, the “Electronic Control Unit” (ECU), or control board, adjusts the compressor speed/input according to ambient environment (temperature) based on system pressure and temperature readings (occurring constantly during run), designed to consistently maintain a target indoor coil temperature in cooling or heating. Target coil setpoint varies based on model.

The Bosch inverter IDS/IDP ASHP target cooling mode evaporator temperature is currently 46ºF (or reduced by 4°F in cooling to 42°F if selected for Accelerated Cooling on the unit’s control board), that is constantly being sensed and maintained below dew point. This process assures that dehumidification will continually be occurring during cooling without having to change blower speed or air flow volume Cubic Feet per Minute (CFM). There will be no need to adjust indoor air flow to maintain the indoor conditions at the desired “Sensible Heat Ratio” (SHR). The Bosch inverter IDS/IDP ASHP target heating mode coil temperature is currently 108°F (or increased by 4°F in heating to 112°F if selected for provide Accelerated Heating, by increasing unit capacity on the ECU). Bosch IDS/IDP ASHPs have enhanced humidity control features and can be more efficient that traditional ASHPs and features an “adaptive capacity” function. This feature is “self-learning” which allows a range of target coil temperatures to adapt for better unit operation and reduced short cycling (4)

Electrical Limitations (In-rush Current)

Traditional ASHPs have a high start-up current when energized in either heating or cooling which can result in voltage fluctuations. This frequent on and off for traditional units creates an in-rush current surge which uses more energy and causes unneeded wear and tear on the system (5) .

The inverter system smoothly ramps up operation, avoiding spikes in energy use and protecting the system’s life cycle (6) . Bosch inverter ASHP compressors will provide true soft start with no in-rush current as compared to traditional ASHPs.

Through the flexible start-up control technology of the compressor, the inverter compressor can achieve low-frequency step-by-step start-up. Taking the AHRI210/240 A2 condition as an example, the instantaneous start-up current of a 5-ton inverter compressor is about 1A, while the start-up current of the same fixed-speed compressor will reach more than 20A. On the one hand, this process can reduce the load on the compressor and other electronic components during start-up, improve the reliability of the heat pump equipment itself, and on the other hand, the smaller start-up current can also reduce the impact on the power grid (7)

ASHP Coil Freezing & Defrost

In mild or warm climates, when humid air passes over a traditional or inverter ASHP outdoor coil in the heating mode, it can cause the temperature to drop significantly and reach freezing. This can lead to condensation freezing on the coil, which can prevent the system from extracting heat efficiently. ASHP coils can also freeze for other reasons, including poor airflow, low refrigerant levels, improper installation, or inadequate defrost controls. Temporary frosting or icing of outdoor coils is normal during winter, but if it freezes for more than four hours or does not defrost properly, it could damage an ASHP and cause it to malfunction. The onboard solution to this issue in Bosch inverter ASHPs is the included next generation demand-defrost control and extended run time. During the defrost cycle, the Bosch inverter ASHP shifts the system from heating to cooling mode, forcing hot gas from the compressor discharge into the frozen outdoor coil. Bosch inverter ASHPs will develop less coil icing than traditional ASHPs due to their extended run time during heating to match the structure load, while running at lower variable speed.

For IDS/IDP, supplemental electric heating is available, but will operate very infrequently based on the structure heating load and outdoor conditions. Supplemental heat is not an option for MS models. Properly sized Bosch inverter ASHPs will typically be able to provide the heating capacity to meet the home’s heating needs under most conditions, and even at extremely low outdoor temperatures in many cases, due to inverter technology and variable speed compressor ability.

Various industry-recognized load calculation methods exist for performing heat loss/gain structure loads. The most recommended version to determine residential heating and cooling loads is Manual J Residential Calculation, Manual J 8th Edition, a load calculation method developed by the Air Conditioning Contractors of America (ACCA). Manual J 8th Edition is the national ANSI-recognized standard for producing HVAC equipment sizing loads for single-family detached homes, small multi-unit structures, condominiums, townhouses, and manufactured homes. A proper load calculation, performed in accordance with the Manual J 8th Edition procedure, is required by national building codes and most state and local authorities (9) , and will allow design and sizing of the appropriate Bosch inverter ASHP to meet structure load calculations.

Bosch Inverter ASHP Operating Ranges

Contractors will be concerned about the operating ranges of each specific Bosch ASHP when discussing options with customers. They will need to know each range available for the Bosch IDS, Bosch IDP, and the Bosch MS ASHPs based on size. Bosch inverter ASHPs with inverter driven variable speed compressors can adjust to speeds ranging from 26% to 130% (based on model) to perfectly cool and heat (a) home using minimal energy for maximum comfort (8)

Bosch Inverter ASHP Load Calculations, Sizing, and Selection

All ASHPs work accurately only if sized properly, installed per manufacturer’s recommendations, and used as intended, and are typically sized for cooling. To accurately determine the necessary size of a residential cooling and/or heating system, the first step is to perform a load calculation. This process determines the cooling load on one of the hottest afternoons of the year and the home’s heating load on one of the coldest nights of the year. These conditions are referred to as the standard cooling and heating design conditions. Subsequently, these calculated BTU loads determine the size of the required cooling equipment needed for comfort conditioning at design conditions, and the associated heating capacity needed of the system during winter, all based on appropriate variables. Traditional ASHPs often do not have the heating capacity below approximately 30⁰F outdoor ambient temperature and require supplemental electric or fossil fuel heating to help maintain comfortable indoor temperatures.

Bosch inverter IDS ASHPs, with 2-to-5-ton capacities, depending on model, capacity, and matching ODU/IDU, or ODU/Cased Coil for Bosch BGH96 Series furnace/ASHP combination, can operates in heating mode from 5⁰F to 86⁰ (IDS Light, IDS Plus), and from -4⁰F to 86⁰F (IDS Premium, IDS Premium Connected). Bosch inverter IDP ASHPs, with 3 and 5-ton capacities, depending on model and capacity, can operate in heating mode from 5⁰F to 86⁰F (IDP Plus), and from -4⁰F to 86⁰F (IDP Premium). Bosch MS ASHPs, with .75 to 4-ton capacities, depending on model, zones, and matching ODU/IDU combinations, can operate in heating mode from -13⁰F to 86⁰F (Regular), from -22⁰F to 86⁰F (Max Performance), and from 5⁰F to 86⁰F (Light Commercial).

The inverter compressor can adjust the compressor motor speed to a set point that allows the desired temperature to be met, and sizing issues are not as critical. Variable speed operation continually meets the load at any temperature within an acceptable outdoor ambient range for the locale. The system is unlikely to be either over or undersized in most instances. This assumes the total cooling capacity of the system matches the design cooling load of the structure. With inverter variable speed compressors, oversizing should not be a problem since it should adjust its speed to the meet the need. It is often advantageous to focus on a balanced cooling and heating approach. Proper sizing of a Bosch inverter ASHP typically requires the minimum compressor heating capacity be approximately 20% smaller than the structure heating load at design conditions (i.e., a heating load of 45,000 Btu/H would require a Bosch inverter ASHP with a minimum compressor heating capacity of approximately 36,000 Btu/H).

With the wide frequency range available with inverter technology, load calculation results used to select the appropriate inverter ASHP will be simpler with greater range in heat vs cool loads (10) . On fixed-speed units where the selection of compressor and other components is usually based on the rated capacity, the ambient temperature fluctuation cause frequent start and stop of the compressor due to the unit’s excessive capacity output. However, inverter compressors allow for a wider range of adjustable frequencies, which means that the unit can respond to a wider range of building load demands under different ambient temperatures and avoid frequent start and stop. Studies have shown that frequent start and stop of the units can cause more than 20% of energy waste, and the frequent start and stop of components can also negatively affect the service life of the equipment. Variable speed compressors can improve this situation, significantly reducing the interval of frequent start and stop, making the equipment more energy-efficient and more dependable. Additionally, Bosch inverter ASHPs with variable speed compressors smoothly adjust operating speeds and run much more quietly than traditional ASHPs, easily avoiding the noisy on-off cycling of typical on/off models.

Bosch Inverter ASHP Energy Consumption

Contractors must understand the ability of the Bosch inverter ASHP to adapt to the changing requirements of unit output caused by indoor and outdoor temperature changes. Compared with fixed-speed units with constant compressor and fan speeds, the target evaporating/condensing temperature control technology equipped in Bosch inverter ASHPs can make the equipment more intelligent and adapt to the changing requirements of unit output caused by indoor and outdoor temperature changes. When the outdoor temperature is high, the output of the unit is high, and the compressor and fan run at full frequency; when the outdoor temperature is low, the unit will automatically adjust and reduce the output, while ensuring sufficient capacity and reducing the frequency of the compressor and fan, making the unit quieter and more energy efficient (11)

Bosch Inverter ASHP Performance Data

Contractors will need readily available performance data focused on the Bosch inverter ASHP cooling and heating capacity at different ambient conditions. These values can be used for sizing and selecting Bosch inverter ASHPs for all climates. The performance range for traditional ASHPs is typically down to approximately 5⁰F during heating, but their rated heating ability typically falls off below the structure balance point, often requiring additional back up heating. Bosch inverter ASHPs will have the ability to extend compressor operation well below the structure balance point in most situations. Consequently, most Bosch IDS/IDP ASHPs may not require supplemental heating except for occasional use and for emergency situations (refrigerant circuit failure). This is possible as the Bosch inverter ASHP variable speed compressor closely matches the heating load of the structure and is more able to extract heat from outdoor air that traditional ASHPs.

Conclusions

a. Bosch inverter ASHPs with inverter technology provide consumers with enhanced operation ability, energy savings year-round, and much quieter operation, than traditional ASHPs.

b. Compared to traditional ASHPs, Bosch inverter ASHPs offer greater flexibility of operation. This makes it easier for designers and contractor to appropriately structure load calculations and select the best equipment for the project.

c. Manual J 8th Edition, as the national ANSI-recognized standard, is recommended for Bosch inverter ASHPs.

d. During summer cooling the Bosch inverter ASHP is better at removing and limiting indoor humidity compared to traditional ASHPs, lessening moisture issues in the indoor air.

e. Bosch inverter ASHPs with inverter technology are an excellent heating system for colder climates that have outdoor conditions below freezing as they can extract more heat from outdoor air than single-speed systems during winter heating.

f. Bosch inverter ASHPs provide indoor temperatures remarkably close to desired with the advantage of less hot or cold spots throughout a home. Traditional ASHPs frequently cycle on and off, resulting in uncomfortable temperature fluctuations. Bosch inverter ASHPs with inverter driven technology self-adjust, providing consistent room temperature, even when the temperature outdoors dips below freezing.

Inverter ASHPs & Alternative Energy Sources

Contractors may be asked if the Bosch inverter ASHP can be energized from alternative sources. It is possible to run Bosch inverter ASHPs with alternative energy sources such as solar energy and generators but requires proper integration and compatibility checks. Bosch inverter ASHPs combined with solar would typically involve integrating the HVAC system with a solar power system that includes solar panels, inverters, and battery storage. Running the Bosch inverter ASHP with a generator would require ensuring that the power output and stability are sufficient to meet the Bosch requirements.

References

(1) https://issuu.com/boschthermotechnology/docs/bosch_ids_family?fr=sNzZmMTM0ODk1MzU

(2) https://www.bosch-homecomfort.com/us/media/country_pool/documents/ downloads-for-bosch-products/heat-pumps-manuals/ids-manuals/bosch_ids_bova20-bva20_service_manual_07.2021_external.pdf

(3) https://www.bosch-homecomfort.com/us/media/country_pool/documents/ downloads-for-bosch-products/heat-pumps-manuals/ids-manuals/bosch_ids_bova20-bva20_service_manual_07.2021_external.pdf

(4) https://www.bosch-homecomfort.com/us/media/country_pool/documents/downloads-for-bosch-products/heat-pumps-manuals/ ids-manuals/bosch_ids_bovb18_iom_11.2023.pdf

(5) https://issuu.com/boschthermotechnology/docs/bosch_ids_family?fr=sNzZmMTM0ODk1MzU

(6) https://issuu.com/boschthermotechnology/docs/bosch_ids_family?fr=sNzZmMTM0ODk1MzU

(7) (Bosch Product Management, 2024) Bosch PRM

(8) https://issuu.com/boschthermotechnology/docs/bosch_ids_family?fr=sYmYyNDIwODA0Mzg

(9) https://www.acca.org/standards/technical-manuals/manual-j

(10) (Bosch Product Management, 2024) Bosch PRM

(11) (Bosch Product Management, 2024) Bosch PRM