Inside AdP

Agile. driven. Positive.

Greetings from the new Technical Plant Manager, Markus Hildenbrand(AdP/PT)

Dear AdP colleagues,

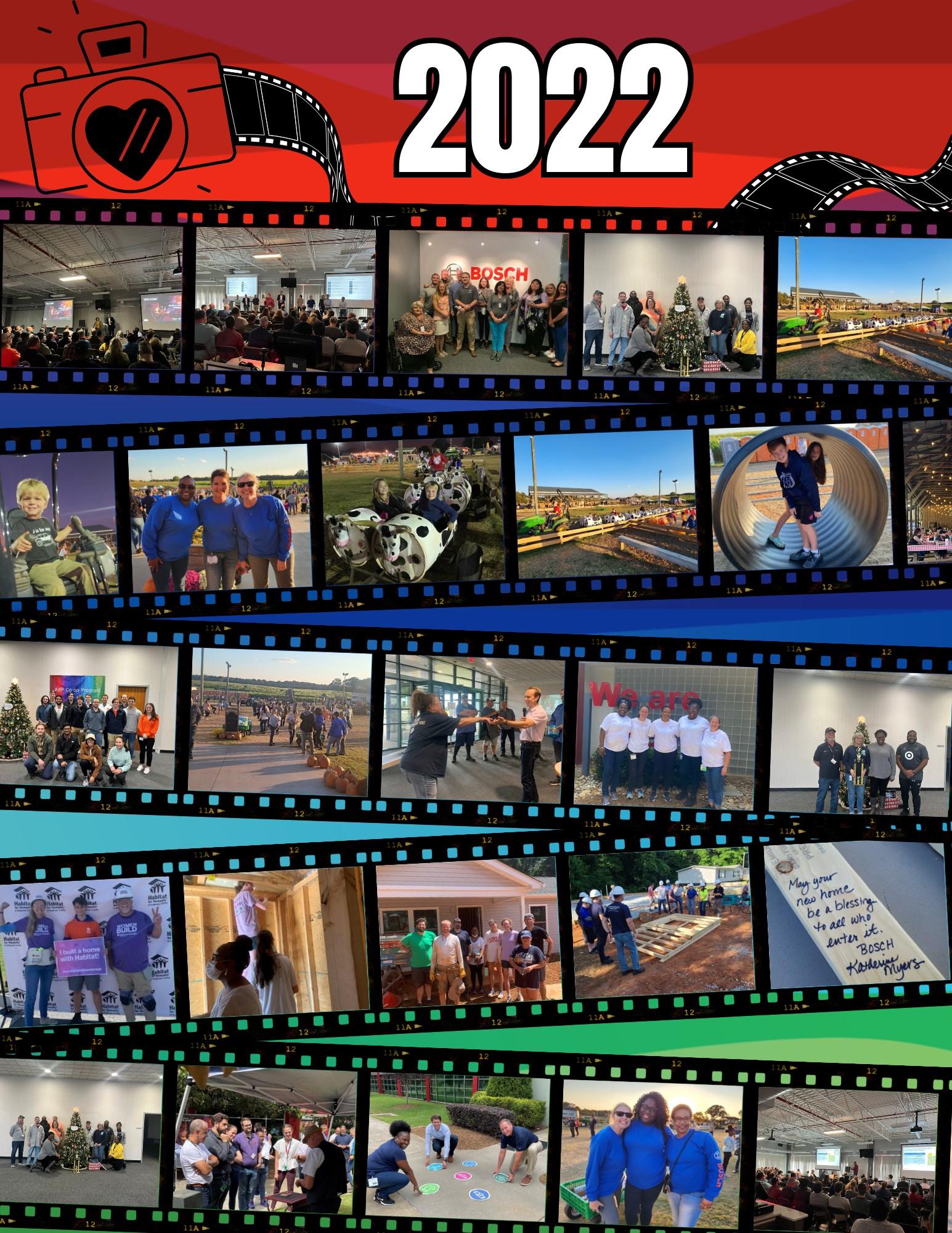

The 3rd month after my arrival is almost over already! I would like to thank all of you for the very warm welcome that I strongly received, and I appreciate all the topics we have already initiated together. I enjoyed meeting and connecting with many of you during the bright and sunny Family Fun Day. The event was extremely well organized and so many of you joined with your partners and kids.

I would also like to thank you for all of the tremendous efforts you have made in all areas of the plant and for continuing the very positive trends and strong achievements. These days we are able to experience more and more of a relief from the heavy burden that was the COVID crisis, as well as the Semiconductor crisis. Through this, we have realized that we are able to take back into our hands the steering wheel for our processes, step by step. These crises had a very strong impact on the AdP plant. When I went through each area of the plant, I learned that so many of you found ingenious solutions for tricky problems, giving us the ability to overcome the challenges that we have faced in the recent years. I am very happy to be a part of this extremely experienced, positive, and overall great team! This is a team that creates stability to our customers’ insecure supply chains. A team that fights for the quality and delivery with all means necessary.

Right from the beginning of my time here, I have encountered a team that not only works together unconditionally, but also sticks together in an overwhelming way. As a team, we reached our monthly targets in IDC in many areas and the targets in vendor backlog reduction. We also received very positive feedback from visitors during their business travels to AdP in the recent months. On behalf of the entire plant leadership team, let me thank you most sincerely for this unrelenting hard work. Let us continue to strive for excellence in the 2nd half of 2023 in the way we collaborate and synergize our manufacturing processes, standards and routines.

As a plant producing products with cutting edge technologies in volumes, we have given ourselves a Vision and Strategy with the aim to Make Magic Happen for the automotive industry. But not just that. With our Agile.driven.Positive attitude, we want to spark enthusiasm in our customers and in our related Business Units, which are connected to us in their assembly lines, plants, cars and trucks. I personally am in favor of our strategy because I believe that it will help us substantially shape our future. Therefore, I am curious and happy to work with all of you to bring AdP to an even better tomorrow!

Best wishes to all of us,

Markus Hildenbrand

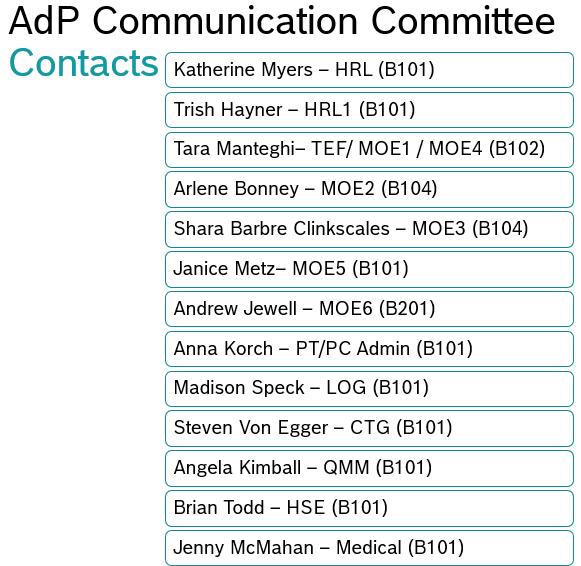

AdP I Ӏssue 19 Ӏ July 2023 New faces at AdP 2 Update from MOE1 3 MOE2 Highlights 4 MOE3 Topics 5 Update from MOE4 6 High-Five MOE5 7 Welcome to MOE6! 8 Coming Soon: MOE7! 9 2022-2023 10-11 Security Building Grand Opening 12 QMM-Quality is No Accident 13 CTG Update 14 AdP LOG 15 Vision Update / Community Involvement 16 Clubs / Team F.A.M. 17 HRL Recruitment Partnerships 18 HSE / Wellness 19 Wellness / Communications 20 Inside this issue:

The Newsletter is Back!

The newsletter was put to a jarring halt with our last edition being distributed in early 2020 when COVID spread throughout the United States. This is the first publication of the AdP newsletter since wearing masks and working from home became a common occurrence! That means there is a lot to catch up on! Within these pages, you will find Team F.A.M. information, an update on our AdP clubs, an update from each of the MOE’s and more!

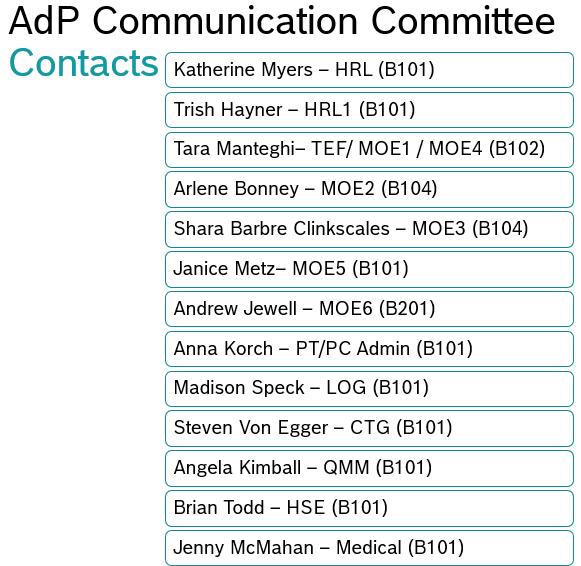

Moving forward, the newsletter will be published twice annually. If you have a suggestion for the newsletter, let us know! Send your ideas to any of our Communication Committee members (names and titles located on the back page of the newsletter).

Markus is joining the Anderson team from Stuttgart, Germany. He has been with Bosch for more than 24 years and has worked at several Bosch sites around the globe. Markus is married with 2 daughters. He received a doctoral degree in engineering with a focus in Process Technology from RWTH Aachen University, followed with an MBA Post-graduation in Business Administration with the focus in Operations Management from State University of New York. Markus is known for his “can do” attitude. In his free time, he enjoys activities with his family, running and skiing.

Steven was born and raised in the United States near the Washington, DC, metro area. He is married and has 3 dogs. A few of his hobbies include running marathons, barbecuing with friends, building motorcycles, and traveling. Steven studied Financial Management and Accounting at Clemson University and is now the Director of Controlling at AdP. He started his career at AdP with HTI and has worked at several other Bosch sites in the U.S. and abroad. He is excited to be a part of the great team here in Anderson again!

On June 1st, AdP welcomed the new QMM Director, Ana Chequer! Ana comes to us with 30 years of automotive experience. In her history, she has worked for Schaeffler, Dana, ZF and Bosch where she has gained experience in Quality, Engineering, Project Management and HSE. Ana moved to Anderson with her husband and son. She also has two step-sons residing in Canada. Ana is coming to us from SrbP (Sorocaba, Brazil).

Rainer is joining the Anderson team from Stuttgart, Germany, where he has been with Bosch for more than 10 years. Additionally, he and his wife Karin have already fallen for the captivating area that is downtown Greenville, as their house is just a short walk from Main Street. They always have something new to do on the weekends, either finding new areas to explore or going to new locally orchestrated events. Rainer is very proud to have joined such an amazing logistics team!

2 I Inside AdP Ӏ July 2023 2 I Inside AdP Ӏ July 2023 July 2023

Markus Hildenbrand AdP/PT

Steven Von Egger AdP/CTG

Rainer Ott AdP/LOG

AnaAdP/QMMChequer

LFS cycle time reduction saves $110K annually

-Teamwork makes the dream work!

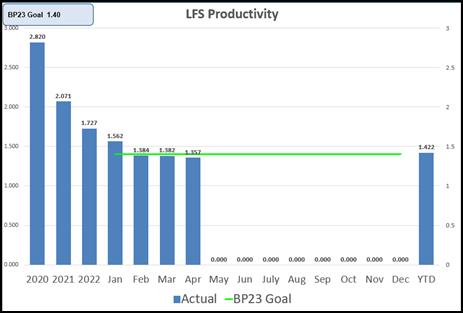

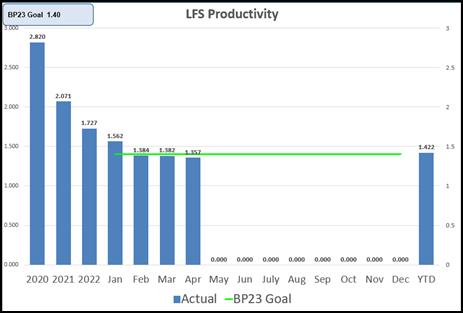

MOE1 reduced the LFS (Linear Force Solenoid) cycle time on two fully automated production lines by 5% each. This increased output for a total annual savings of $110k.

The initiative started with MFE1 taking a close look into the EOL waiting time standards that were set with the first LFS lines in NuP over ten years ago. By making a simple program change at no cost, the re-programming saved 5% of the total testing time! But they didn’t stop there – now it was on to the next bottleneck! Given the fast-paced automation, size, and complexity of the LFS lines, achieving an overall cycle time reduction was a challenge. The team regularly analyzed all processes, identified various weaknesses and made many quick improvements at no additional costs. These optimization efforts have now reduced the overall cycle time from 4.0 to 3.93 seconds, which is a 5% reduction on both lines! The cycle time improvements are also being seen in the performance metrics of the LFS lines, especially with productivity. This metric has been trending favorably and has now reached target level for three consecutive months!

Not everything went smoothly, nor perfectly, but in the spirit of ‘Teamwork makes the dream work,’ the team mastered the project and implemented it. A great team spirit, high level of commitment, mutual support, fun and a great interest in new topics were the key factors for success. The team is currently partnering with the IPN to leverage these solutions to the other LFS production lines in BljP, NuP, SlpP & WxXi.

Time to say Goodbye - Ramazan Dede

I am very proud to have supported LFS during its very successful rampup. Living internationally, I was able to gain a lot of new and valuable experiences for the future, which will enrich me both professionally and personally. This process isn't always easy, but it has increased my "think outside the box" spirit. The takeaways are very real, and that's very motivating.

In July, I will be returning home to Nuremberg (NuP1), where an exciting task awaits me. As I reflect on my past four years in AdP, while celebrating 25 years with Bosch, some thoughts come to mind: trusting, being open, and consistent, always working towards one goal. The international move was certainly associated with many challenges including the COVID restrictions, but these were outweighed by the overall positive experiences. My time in the USA was an unforgettable experience for me and my family. The weekends often provided the opportunity to explore different parts of the country. We visited Key West, Niagra Falls, New York, and we also went international to Toronto/Canada Many thanks to the entire MOE1 team for your friendliness and good cooperation, especially Kraig Miller and Ross Aylor, during my invaluable time in AdP!

Welcome Grace Bowser to the MOE1 Team!

Grace joined the MO1 team as their new BPS Coordinator. She started her Bosch career in 2015 as a QMM co-op at AdP in the MOE1 area. She was hired by Bosch in Atlanta after graduation and worked there until 2019 when she returned to AdP in QMM9. She is excited to be back in MOE1 and getting back to her Industrial Engineering roots. She’s looking forward to new challenges ahead and thanks the team for the warm welcome back!

3 I Inside AdP Ӏ July 2023 3 I Inside AdP Ӏ July 2023 July 2023

Grace Bowser, AdP/MOE1

“Ring the Bell”

Daniel Lott (AdP/MFO2)

If you walk through the aisleways of B104 during shift change you might hear more than just the rumors of MOE2’s recent successes. You might hear the clanging of a large brass bell known as the MOE2 Victory Bell. Victory is rarely an achievement of an individual but through the combined effort and perseverance of a team. This is true for what has happened in MOE2. There is no single individual or group responsible for the success we are having, and it took around three years to systematically clear the path and build up the current momentum.

We are rebuilding a culture of accountability, trust, discipline, and appreciation in how we handle ourselves and the barriers we face. There were many factors and tough decisions to reach this point, but it has absolutely been a team effort and for that we could not be prouder.

So what’s the deal with the MOE2 Victory Bell, you may ask? At the end of 2022, shop floor teams began breaking output records; shifts started competing and records started being broken regularly from one end of the department to the other. Chip Ryan, our Final Assembly MFE manager, developed the idea. The Bell may only be touched during a bell ringing celebration by the operators and technicians who have just broken an output record during their shift. It has been rewarding for us to see the smiling faces of our associates as they celebrate with each other at the Bell. So, if you’re walking through B104 one day and hear the clanging of the MOE2 Victory Bell and the supportive cheering, you’ll know the fighting spirit of AdP carries on, leading the way for a strong future for Bosch North America.

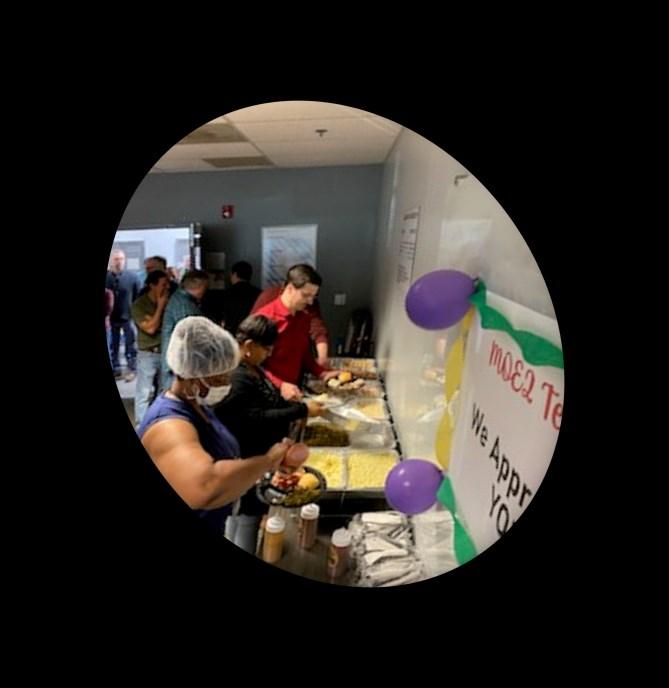

With Success Comes Celebration

We held our first of many appreciation lunches in March across all shifts so that everyone could spend time together eating, playing games, and socializing with their colleagues, support groups and leaders celebrating the amazing hard work and success.

Here’s what one associate had to say: “The MOE2 appreciation dinner was a hit! I absolutely loved being able to break bread with people from pre-assembly. It’s not often that Pre-Assembly and Final Assembly get to spend extended time together for lunch/ dinner. It really made us feel appreciated and our hard work hasn’t gone unnoticed. It was just an overall good feeling and it really made everyone feel appreciated. I definitely look forward to breaking more records and having more appreciation dinners in the future”.

-Robyn Wallace 2nd shift associate

Everyone associated with MOE2 has come together to put us on our path toward our true goal and vision ‘To be the preferred AE manufacturing partner globally.’ Winning is a habit and we must keep pushing that mindset within our entire value stream. I see people enjoying work and being motivated by their success and each other which is the most gratifying part of my job. Thank you to everyone on this journey, hold your head high and enjoy the victories that you have earned. Let that pride drive you to realize we have only started to achieve the potential within MOE2 and keep breaking records to show the Bosch world that we deserve new products. -

Mark Ratcliffe Director MOE2

Mark Ratcliffe Director MOE2

Thanks for being highly engaged with our MOE2 Team. We welcome you, Craig Lockhart!

(MOE2 HR Business Partner)

4 I Inside AdP Ӏ July 2023 4 I Inside AdP Ӏ July 2023 July 2023

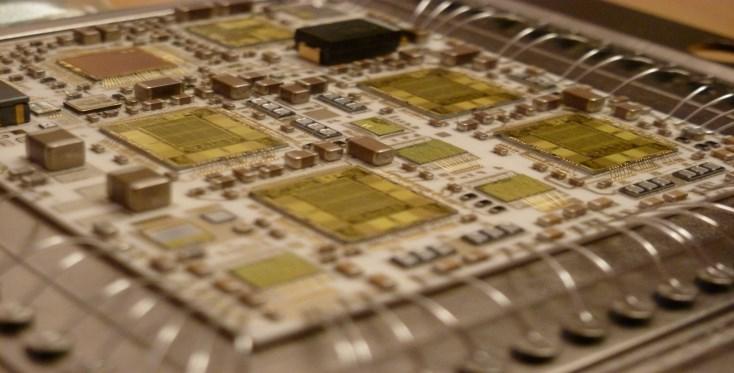

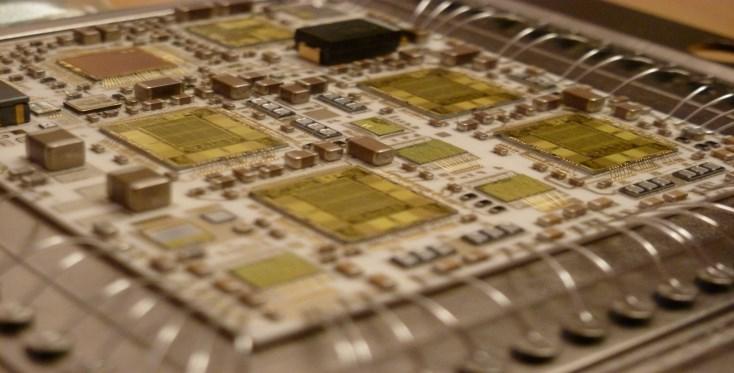

LTCC Consolidation Project:

Shara Barbre Clinkscales (AdP/ MFW3-4) Anderson is soon to become the lead plant for LTCC!

What this means: AdP will be the sole supplier of Bosch LTCC (Low Temperature Co-fired Ceramic) worldwide! To meet these demands, we have secured a number of additional MAE from Reutlingen Germany (RtP2). A second Brush and Pumice line has been installed in the Sinter Room and currently running production. We are also getting a Hotpress, Via-Fill Printer, RTL, Puncher, DSP Printer, Breaking Station and another SPEA. This new MAE will be supplemental to the equipment we currently have. To support all of the incoming equipment, there are plans to make several changes to the layout of all three rooms in MOE3 (LTCC CR, Sinter Room, and DSP CR).

AdP will also take on the production of the NOX sensor LTCC product which was previously made exclusively in Reutlingen. This is very exciting news for the department. RtP2 has been the lead plant for LTCC production since 1996. SOP (start of production) began here at the Bosch Anderson facility on Jan 1, 1998. Therefore, both plants have long-term experience in the LTCC production. RtP2 and AdP also have an identical process flow and process specifications for each LTCC technology. The estimated completion date for this project is October 2023. We are looking forward to the challenges that lie ahead and leading production of LTCC going forward!

Did you Know?

It takes 2 weeks to produce a single LTCC part from start to finish!

The main objective of the MFW3 advisory team is to get operator-level associate input while addressing issues and assisting in identifying and implementing improvements as needed throughout the value stream. The team consists of operators from all shifts (there are twelve total different shift models in MOE3). Each associate from every shift has the opportunity to nominate someone to represent his or her shift. The MFW3 advisory team was established in January 2023 and team members rotate out every six months. Being on the advisory team gives the operators an opportunity to make decisions and show ownership of the issues that directly affect them.

Shara Barbre Clinkscales (AdP/ MFW3-4)

Shara Barbre Clinkscales (AdP/ MFW3-4)

5 I Inside AdP Ӏ July 2023 5 I Inside AdP Ӏ July 2023 July 2023

New Automation Coming to MOE4

Henry Habig (AdP/MFE4)

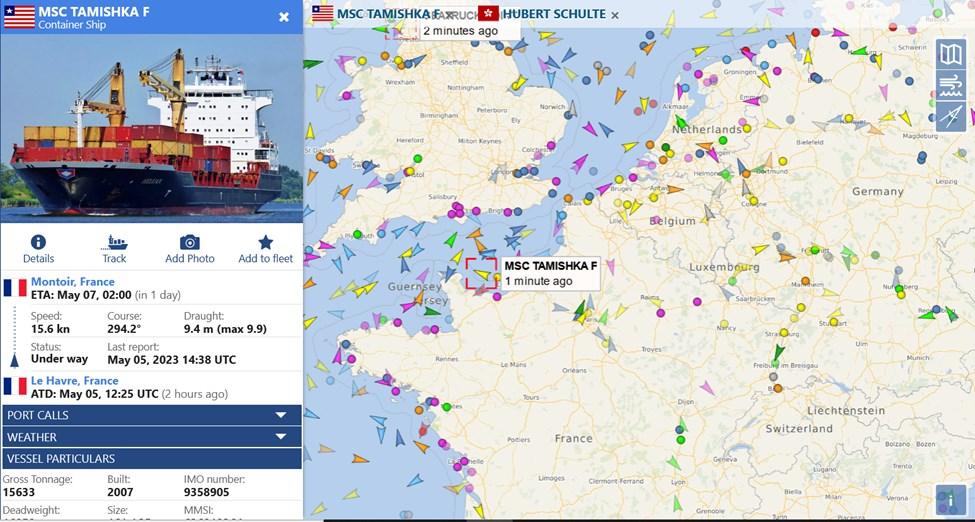

A new automation project is hitting the floor for Line 10 in June as they get ready to complete Final Acceptance on new automated pre-assembly stations! Preparations are nearly complete to prepare the new floor layout as this station will be added on to the current Line 10 design. The new stations will automatically place bushings on a sensing element using robots and vision systems similar to how the PM line currently assembles their short sensors. This new technology will drastically improve the productivity of Line 10 while also improving the line’s, output, cycle time, and IDC.

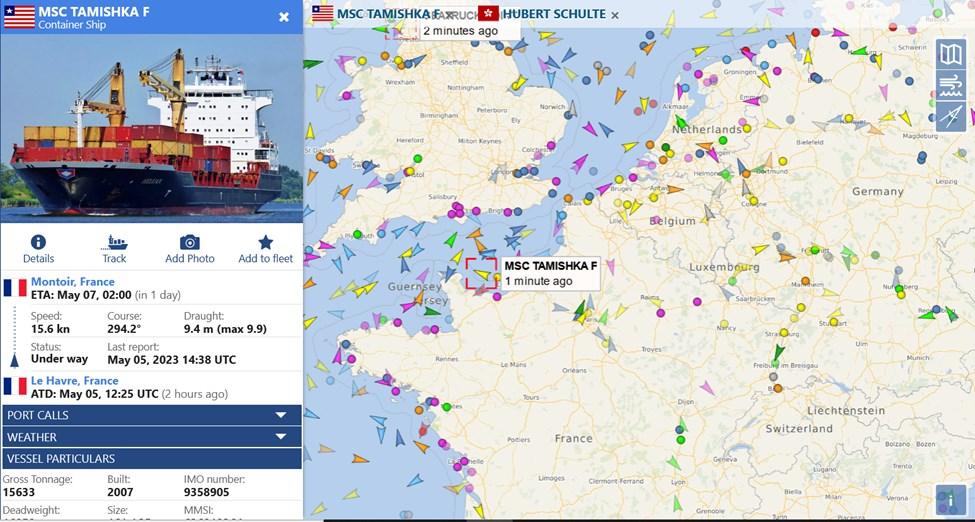

The new stations are copies of the current system deployed on Line 9 in Feuerbach, Germany, and were assembled in Bursa, Turkey. Colleagues from ATMO 1 in Feuerbach, ATMO 4 in Charleston, and ATMO 8 in Bursa will arrive at AdP to assist in the Final Acceptance process. The line is currently on its way across the Atlantic on a cargo ship called the MSC Tamishka F, which can be viewed on VesselFinder.com. Once the line arrives, Line 10 will be on a tight schedule to get the stations up and running to be ready for its new LSF6 production. Excelling in this setup process will help us better serve our customers. Thank you to the cross-functional team from Anderson and the IPN for their dedication!

The MOE4 Vision!

Seth Taylor (AdP/MOE4)

In 4Q2022, a MOE4 cross-functional team came together to discuss the 3-5 year vision for the value stream. This crossfunctional team consisted of operators, manufacturing engineers, quality engineers, line leaders, technicians, logistics specialists, group leaders, and program coordinators. The vision this team collectively decided on was the following:

This vision is made up of four key components:

People: Put people first by recognizing performance and empowering our associates, thereby retaining our workforce.

Longevity: Stabilize our value streams by improving work training standards, sharing good practices, and developing our current talent for future success.

Performance: Become the benchmark for operational excellence with transparent KPIs across all levels of the value stream.

Opportunity: Utilize our current capacities for future market share increases through automotive aftermarket.

This vision will serve as an input during our System CIP workshops. We decided in our 1Q2023 workshop that our first focus would be the people component. In March we held our first MOE4 townhall meeting since before COVID. Additionally, we will be having a MOE4 cookout to recognize our associates for their contributions.

The MOE4 Leadership Team would like to extend a big thank you to the cross-functional team that helped develop the MOE4 vision, and we look forward to making this vision a reality together over the next several years.

Rebuild Upstate: MOE4 Rebuild Project!

Through Rebuild Upstate, the team was able to build a new porch for Mr. V with a safe set of steps and safety railing around the porch all in one day with materials provided by an outside donor. Fabio Canha, Jacob Jordan, Michael Dockins, Jordan Sourbeck, Henry Habig, Chris Harrell, and Caleb Franz worked a long, but enjoyable day. Thanks to these gentlemen, Mr. V. can now access his home from the front and know that he and his family don’t have to worry about rotten decking and failing posts.

Chris Harpe is a site leader for Rebuild Upstate and helps coordinate projects and construction. If you have a group that may be interested in doing a project, please contact Chris @ 864

314

1297 or at wcharpe@gmail.com. We would like to make this an annual event for any number of groups in the Bosch family. If you’re interested, please let Chris know.

6 I Inside AdP Ӏ July 2023 6 I Inside AdP Ӏ July 2023 July 2023

Chris Harpe (AdP/MFE4-now retired)

-

-

HIGH 5 MOE5!

The number 5 is associated with positive change and new beginnings. That is certainly true in this case. On May 1st, MOE5 celebrated its first year as its own MOE under the leadership of Stefan Reichardt. Under this leadership, MOE5 has challenged the conventional methods of operation to branch out into positive and motivating ways of thinking. Together we succeed. MOE5 recognizes the importance of the support departments and the MOE’s working together to achieve our goals. “HIGH 5 MOE5” is our way to recognize and celebrate success!

Below is a highlight of some of the successes achieved in the past year.

• In Oct 2022, implementation of the OEE Championship Belt. Each month, the belt is awarded to the team who either has the highest OEE or is most improved. Record OEE’s have been seen at the Drill, HV80 and HV70.

• Internal defect cost (iDC) has also improved from 14% in July 2022 to 10% YTD in 2022. We are currently under 9% in 2023! There are even plans to deploy an iDC Championship Belt. Keep going with the fantastic work!

• Scrum meetings implemented to unleash the expertise and passion from MFE’s, Operators, Techs, Line Leaders, Group leaders, etc. to improve OEE quickly.

• Installed a practice of going to Gemba daily after DMM to remove barriers and to address production issues in the last 24 hrs.

MOE 5 Organizational Structure

Stefan Reichardt MOE5 Director

Janice Metz Administrative Assistant

Mark Jarriel BPS Manager

Craig McCarthy Engineering Manager

Tony Hallows Operations Manager

HV70 Celebrates highest ever OEE in April with the belt

• All associates have worked to improve the 5S standards in the department by completing two 5S blitzes. Eight hours of cleaning from the entire department. Don’t worry 3rd shift, your blitz is in the works.

• First RU2 elements shipped to Kefico after a successful visit in March.

• Installation of a MFQ department under Team leader Barry Kaldenbach.

• High 5 trophies recognizing those going above and beyond.

7 I Inside AdP Ӏ JulyJuly20232023

to MOE6!

Andrew Jewell (AdP/MFW6-1)

Andrew Jewell (AdP/MFW6-1)

Welcome to MOE6, home of Car Multimedia of North America. In 2020, Car Multimedia brought the North America HUB to Anderson, South Carolina, which brought the expansion of the old AFCO building and developed 100 new job for Bosch Anderson.

One always asks what is Car Multimedia? What is it that Car Multimedia does? Car Multimedia designs and develops software for navigation systems and media systems, as well as serves as the customer support system for customers such as Nissan, BMW, Volvo, and General Motors. Through the work of dedicated associates and engineers of our Malaysia plant project management and our Bosch Anderson management team, MOE6 secured the North America HUB in Anderson, South Carolina. MOE6 also secured new business with General Motors and their next generation media system that will take MOE6 and Bosch Anderson into the future.

With growth in the business, one must seek out new and experienced talent to ensure the business grows as part of securing the future. MOE6 has been doing just that by recruiting new and experienced talent to add to the team! We would like to welcome veteran engineer, , from MOE1, Mack op program, to the MOE6 team.

Billy brings 35 years of experience to MOE6. He started out his career at Bosch as a technician and worked his way up to Advanced Technician, before furthering his career in the engineering field with the assistance of Bosch. He has held various engineering roles throughout Bosch Anderson and is currently the Lead Senior Manufacturing Engineer over the new VCU General Motors line in MOE6. In Billy’s own words, Bosch has become a second home for me enabling me to grow as a person and develop long-lasting working relationships and friendships that will last a lifetime.

Mack Self comes to MOE6 as a recent Clemson University graduate with a degree in Engineering. Mack served as a coop for MOE6; and during his time with the group, he assisted with developing transparent processes, troubleshooting software developments, and assisting with obtaining the VCU business with General Motors. MOE6 knows with Billy Lewis’ knowledge and years of experience, along with Mack’s new innovative ideas, that MOE6 will be a true success. There is still room for more talent on the MOE6 team; there are two additional Engineering positions open for people that are experienced, innovative, and enjoy tackling challenging projects.

MOE6 would also like to acknowledge and wish bon voyage to two of its associates that are retiring this month to explore the next chapter in their lives. Sheri Goodin and Susan Bowers both have given Bosch Anderson 20 plus years of service, serving in a multitude of roles while at Bosch.

Sheri Goodin started her career at Bosch Anderson in 1989. She has been a line operator, forklift driver, Group Leader, Training Coordinator, PSO, and Inventory Control Associate. Sheri has also traveled to Germany as a trainer to bring in new production lines to Anderson. Sheri always greets you with a smile and is always willing to assist you with whatever issue you may have. MOE6 would like to thank Sheri for her 34 years of loyal service and know that she will always be missed by her MOE6 Team.

Susan Bowers started her career at Bosch Anderson in 2000. Susan has held multiple roles in her years of service, such as line operator, PSPL, Safety Committee Team member, and a Quality operator. She has played a vital role as part of the MOE6 Team, especially as Quality Operator ensuring daily quality standards are met and maintained and serving on the Safety Team for Building 201. Susan is always willing and able to assist her team in any way. MOE6 would like to thank Susan for her loyal years of service and that she too will be missed by her MOE6 Team. Thank you, Susan, and enjoy your retirement as you head off to your next adventure.

8 I Inside AdP Ӏ July 2023July 2023

MOE7 Introduction!

Patty Stamey (AdP/ PJ-MOE7) AdP/PJ-MOE7 is responsible for manufacturing planning and relocation project execution for the H2 Fuel Cell Stack. This innovative product, part of the Fuel Cell Electric Vehicle system, will SOP in AdP in 2028 and support the North American market. AdP will produce not only the fuel cell stack and final assembly module, but also the components Membrane Electrode Assembly (MEA) and BiPolar Plate (BPP) (seen on the right).

3 associates in AdP: Director David Crews, Project Manager Patty Stamey, Sr Engineer Chris Echter

2 associates on assignment in the leadplant in Bamberg, Germany (BaP): Robert Hughes, Mike Glass. Robert is focused on the assembly of the fuel cell stack and module, and Mike is focused on fuel cell stack testing methods.

In addition, the AdP/LOG team will shortly begin using a Nikola BEV (battery electric) truck for shuttle runs between the plant and our offsite warehouse! Keep an eye out for these cutting-edge trucks on the road!

To learn more, and to keep up with PJ-MOE7 team news and H2 Fuel Cell news, please see our Docupedia page: https://inside-docupedia.bosch.com/confluence/pages/viewpage.action? pageId=2320222614

9 I Inside AdP Ӏ July 2023 9 I Inside AdP Ӏ July 2023 July 2023

BiPolar Plate (BPP)

Above photo: (Left to right) David Crews, Robert Hughes, Mike Glass, Patty Stamey, Chris Echter

Left Photo: (Left to right) Patty Stamey, Robert Hughes, life-size Shawn cutout, Chris Echter

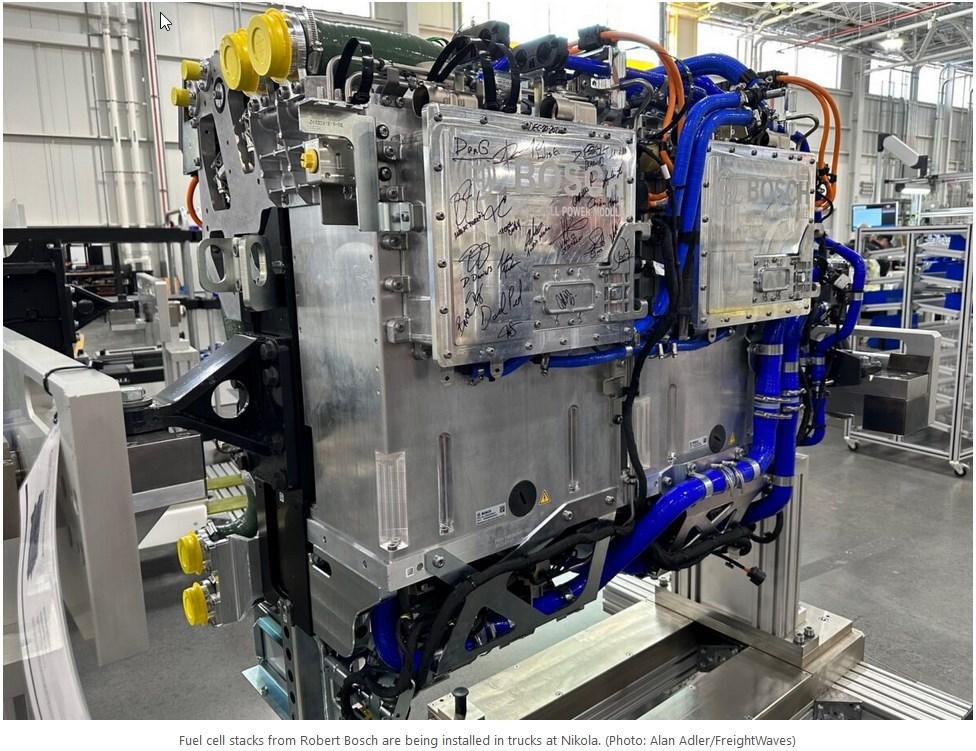

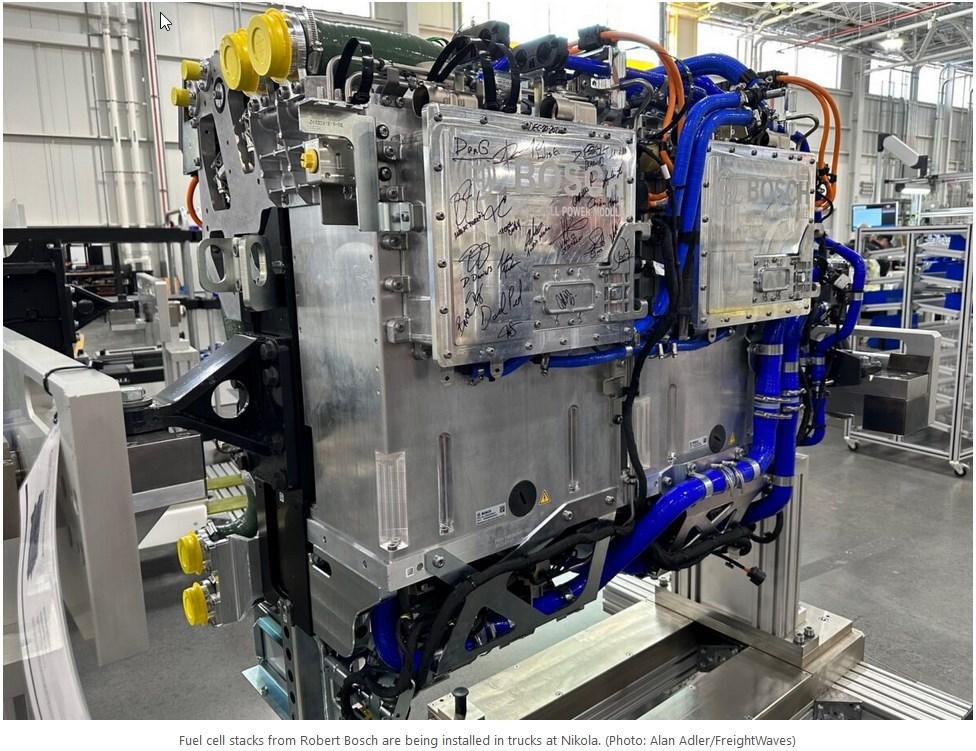

Fuel Cell stacks are currently in production in BaP (pictured above), where they are produced and shipped to the Bosch plant in Feuerbach, Germany, to be built into the Fuel Cell Power Module for Class 8 Trucks.

We are excited to have onsite, temporarily, an FCEV Class 8 truck from our North American customer Nikola (pictured below)

The PJ-MOE7 currently has 5 associates planning for the launch of the Fuel Cell Stack in AdP:

10 I Inside AdP Ӏ July 2023 10 I Inside AdP Ӏ July 2023 July 2023

11 I Inside AdP Ӏ July 2023 11 I Inside AdP Ӏ July 2023 July 2023

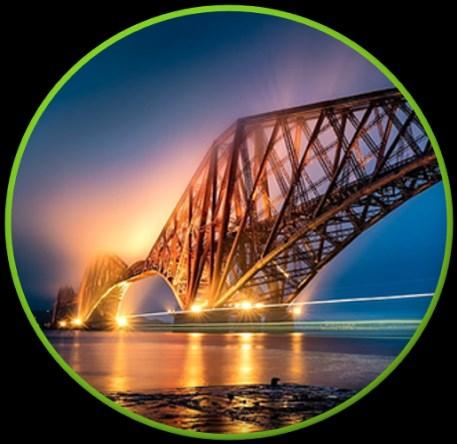

December 7, 2022 – Grand Opening

Security Building Grand Opening

Travis Wicker (FCM-Ad)

On December 7, 2022, AdP had the grand opening for the new security building. Christian Kolzem, Suzana Cizmic, and the Extended PLT welcomed Peter Tadros, Mike Mansuetti, Werner Quirant, and several members of the local and state government to join in the celebration. The ceremony kicked off with speeches from each of our guests, which highlighted the new security building as the first of many positive changes coming in the years ahead. These include the hydrogen fuel cell that will strengthen our product portfolio and ensure Bosch remains a pillar of the Anderson community for many years to come. The celebration continued with the group walking to the newly finished security building for a ribbon cutting ceremony and building tour for our guests.

What does this mean for you as Bosch Anderson associates?

The new security building makes this site more secure with one entry/exit point for customers, visitors, emergency personnel, and truck traffic for deliveries/shipments. A key part of this project was adding a short road between the asphalt area of B102/B104 to the asphalt area of B101. This allows vehicles to enter the new security gate and travel to any building inside the secured perimeter of this campus, which was not possible before. This saves precious time for emergency vehicles, reduces confusion for visitors on where to enter the site and park, and presents a modern first impression to everyone that

June 7, 2022 –Groundbreaking

To view a timelapse of the Security Building being built scan the QR Code

Quality is no Accident

Many Thanks to Len Sutton! Len took on the role of acting director in November, while continuing to be the Manager of QMM4. He later also took over managing QMM1. QMM is very fortunate to have a strong leader like Len to step in without hesitation to ensure the department did not falter while waiting on the new director to arrive.

eLPC Revamp

The eLPC system recently went through an optimization project based on user feedback. Jordan Pickerel met with each department to obtain their feedback. From this, the following improvements were made:

• Standard questions updated for all departments

• The TL frequency reduced in half

• PowerBI visualization for tracking progress in MOE5 from LL - Director

• Next phase is TEF, HSE and BPS.

Calibration Extension

Thank you to all who made the calibration extension project a success. Each month in 2022, the QE’s and MFE’s reviewed a list of gages with 5 years of history with no out of tolerance in the last 3 years. Extending the calibration on gages that would not add risk to the process, QMM8 was able to save $51,420 or $25,710 in year-overyear annual savings as long as the gage is in use.

Welcome aboard Ana!

To see more information about the new QMM Director, Ana Chequer, please see page 2!

13 I Inside AdP Ӏ JulyJuly20232023

Christian Munoz QMM2

Hector Zarco QMM2

Matthew Watson QMM2

Cameron Carli QMM4

Nic Lynch QMM1

Hugo Merlo QMM1

“Change is inevitable. Growth is optional.”

-

John Maxwell

Here are some of the new faces of

QMM:

Nick Arnold QMM2

Franz Lipkau QMM2

Laith Henke QMM2

What’s Happening in CTG ?!?

Steven Von Egger (AdP/CTG)

Wow, 2023 is flying by! The team's year started with a successful 2022 year-end close, financial reporting to stakeholders, and then we quickly turned our focus to 2023 results! We ramped up this year with many high-level visitors and have already delivered our second current forecast of the year. CTG has also been focused on new business prospects for Bosch Anderson. In May, a special focus team was established to support adding new products to the AdP product portfolio. The CTG group is directly supporting these activities with feasibility studies, cost calculations, and helping stakeholders understand how the site can tap into government funding and secure new profitable business!

Anderson’s ticket to new business is success today; therefore, from May until June the CTG team, together with each Value -Stream, will conduct our annual Long-term Plan Commercial. This is an extensive 7-year business plan that aligns to the latest Automotive Market Report. With Anderson’s commitment to continuous improvement, our goal is to deliver realistic projections that will enable us to steer and help secure our own future.

Thanks for everyone's strong contribution to our plant results so far this year!

Welcome!

Raymond Garrison will be the new Plant Support and Capital Controller for AdP. Raymond graduates from Anderson University this December with a Bachelor’s in Accounting and has been working for Bosch already for two years. He started his Bosch journey with Bosch Rexroth in Fountain Inn and loves Bosch’s influence in shaping the future of EVs. In his free time he enjoys working on his car, spending time with family, and is recently engaged so he is spending time with his Fiancé, and planning their wedding. He is excited to continue his career with Bosch and looks forward to getting to know everyone in AdP!

Good Luck!

Ross Davis will transfer from CTG1 to CTG2 and take over AE Product Controlling from Alex Wendler. Ross brings years of Bosch Operations and Overhead Controlling know-how to his new role! We wish Ross a great start.

Welcome!

We are excited to have Maddie Carpenter join the team as a Co-Op! She attends Anderson University, and is originally from Hickory, NC. She plays on the softball team at AU where she is double majoring in Accounting and Finance with a minor in Financial Planning. She has an eleven-month-old mini goldendoodle named Bentley and loves Clemson football (Go Tigers)! A fun fact about her is that she is an only child. She is excited to have joined the Bosch family this summer!

Good Luck!

Alex Wendler, from CTG2, was promoted on May 1st and will be the new regional business unit Controller for PS-SU in Farmington Hills! We want to say Thank You Alex for your dedication to AdP and we wish you success in your new role!

14 I Inside AdP Ӏ July 2023 14 I Inside AdP Ӏ July 2023 July 2023

The Storm Even Logistics Couldn’t Have Predicted: COVID

By Madison Speck (AdP/LOP4)

By Madison Speck (AdP/LOP4)

2020 in Logistics started off just like any other, with the usual escalations about missing materials, suppliers and customers alike coming back from holidays with problems. The normal! But just like that, as we were all settling in after the new year, things took a turn for the worst. COVID hit like a ton of bricks, bringing the worldwide supply chain to a screeching halt! Customers were shutting down, suppliers were scrambling to cancel shipments, and here in Anderson we were just trying our best to maintain composure in the face of an uncertain future.

A Team Bonded in the Fire

Looking back on this hectic time, Anderson Logistics has a lot for which we can be proud. During the beginning stages of lockdown, our warehousing and planning teams worked seamlessly together, canceling shipments where possible and juggling an abnormally high amount of product in our on-site and off-site warehouses.

However, do not think for a moment that Anderson Logistics was waiting around for the all clear before getting started with some improvement projects. No way! In the midst of a pandemic, AdP/LOG still managed to successfully move to a bigger, newer, off-site warehouse that we fondly refer to now as The Exchange Warehouse! We needed to make the switch for a while, and nothing, not even COVID, could stop us!

Emerging from the Flames Triumphant

All around, Logistics survived the worst supply chain disruptor in recent history and came out stronger on the other side. We also did so while still hitting our goals: PS & AE both reduced days of inventory on hand significantly to help with our cash flow topics, both business units have had great success in recovering our customer backlog to Bosch Aftermarket, and one of our biggest wins coming on the heels of this pandemic has been that we have FINALLY had a month where we received a 100% score in customer delivery performance for AE product T93. After three hard years of struggle, we finally have a great story! And the future just keeps looking brighter and brighter for the whole Anderson Logistics team!

15 I Inside AdP Ӏ JulyJuly20232023

InInside AdP Ӏ July 2023

“Cameras on!” was the motto during lockdown to stay connected to the team

Breaking ground at the new off-site warehouse location

Costume Contest (Oct. 2021)

The team reconnecting outside of work after lockdown

LOP4 team welcoming new planners with a team lunch

The AdP Vision and Strategy Making Magic Happen!

AdP Vision AdP Strategy

The AdP Vision - Agile. driven. Positive. This is our way forward. These are the characteristics we want to embody as associates and as a manufacturing facility. We want our customers, suppliers, and partners to see these traits clearly each time they interact with us.

The AdP Strategy - The AdP Strategy and its 6 elements were specifically chosen to provide the framework for achieving our vision. The first three (People, Leadership, Partnership) refer to the connection side of the business...connecting and growing with each other and with our partners. The last three (Value Stream, Process Transformation, Product Strategy) refer to the technical aspect of our business and how we strive for operational excellence while continuously improving our processes. This is vital to secure Anderson’s future through our current products and new business opportunities.

With this Vision and Strategy integrated into our everyday work, we will be successful...together! We are Anderson!

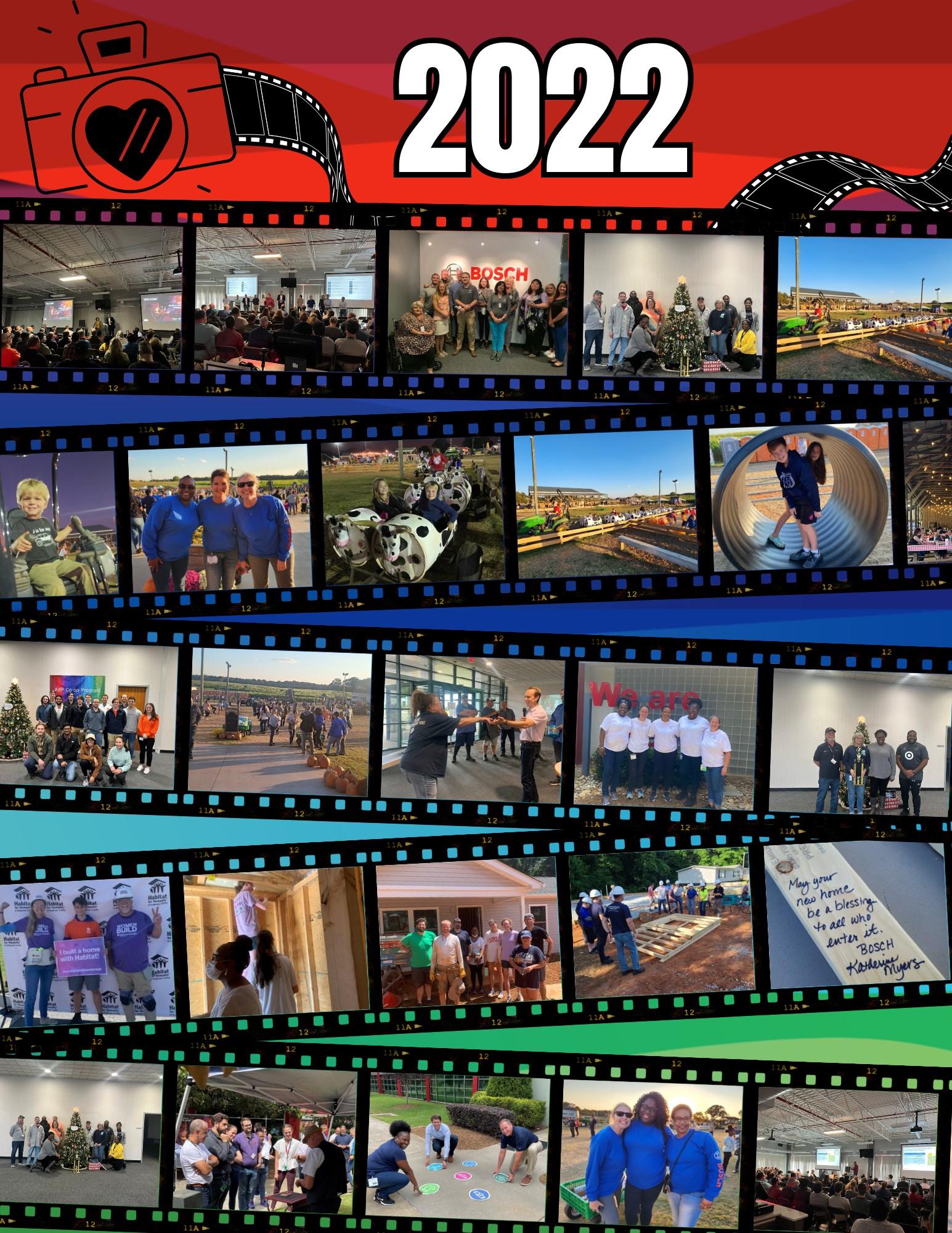

Get involved with Bosch!

Are you looking to get involved with the community?

There are plenty of opportunities that Bosch offers for you to get involved by doing community service! As a Bosch employee, you are allotted 8 hours of pay through the Beyond Bosch program. There is a form that you have to complete, along with an approval process - connect with your HRBP to find out more details. Below are some of the current organizations that we support, but don’t let that stop you! If there is an organization that you are interested in joining, let us know so we can add it to our list and recommend it to other people!

If any of this interests you, please reach out to Katherine Myers or your HRBP to get involved!

16 I Inside AdP Ӏ JulyJuly20232023

Bosch AdP Wellness & Clubs

Looking for fun things to do ?

General Wellness Contact — Kinsley Rollins

Have you heard of Team F.A.M?

The team is AdP and F.A.M is Fun. Amazing. Memories. Many memories we have and many more to be made.

Team F.A.M is a group of associates that remembers and wants to inspire more great times together here at Bosch AdP. It was created to bring associates closer together and build a family atmosphere. Together we come up with ideas for bringing back that family feeling at Bosch.

You have probably participated in some of the fun events sponsored by the group in the past year - pumpkin hunts, elf hunts, spirit weeks, holiday tree decorating contest, and Veterans Day to name a few. We are always looking for new ideas that YOU think would be good for Team F.A.M. to sponsor that would bring joy to all of our Bosch family. Thanks for all the great memories so far, and we can’t wait to make many more!

Please contact a Team FAM member in your building if you are interested in being a part of the team or just submitting ideas.

Bldg 101- LeShekia Merriweather, Kim Duncan, Tracy Rice, Dorothy Trotter

Bldg 102– Trish Sauers, Tiffiany Ford

Bldg 104- Kelly Chappell, Krystal Crompton, Audrey Wilson, Thomas Handy

Bldg 201- Andrew Jewell, Summer Breazel

17 I Inside AdP Ӏ July 2023 17 I Inside AdP Ӏ July 2023

July 2023

CYCLING OFF - ROADING RUNNING Contact: Kevin Shealy Contact: Tyler Crumley Contact: Amy Wilson (If you would like to join one of these clubs please reach out to the person listed as Contact. Each club has new events each month. The times and dates are posted in the Plantwide, Facebook, and on the TVs.)

Our Bosch AdP associates have been busy investing in our community and building relationships over the last year by partnering with our local charities, high schools, universities, and career centers.

“Recruiting and hosting these events with our very own Alumni, along with the mindset we are meeting our future Bosch family, is what makes our job so rewarding.”

Partnerships Matter! #LikeABosch

18 I Inside AdP Ӏ July 2023 18 I Inside AdP Ӏ July 2023 July 2023

-Kim Nelms AdP/HRL3

Tri-County Technical College

Palmetto High School Senior Mock Interviews

Westside High School Career Fair

Anderson County Congress of Christian Education

University of Tennessee Career Fair

Upstate Fatherhood Coalition

Clemson University Career Fair Anderson Institute Technology Career Fair

University of South Carolina career Fair

HSE Update

(Brian Todd, AdP/HSE)

(Brian Todd, AdP/HSE)

AdP has had great participation in our Safety Campaigns. Many Associates have identified hazards in their work area of responsibility. Each week, winners have been rewarded with $50 gift cards. The campaigns have enhanced awareness, resulting in 2022 year end meeting all safety metric targets. Many safety improvements were implemented ranging from ergonomic solutions to machine remodifications.

-Complete hazard reports and idea cards

-Join a safety team

-Participate in Gemba walks

-Perform regular process confirmations

We are looking for new HazMat members. We especially need volunteers for off-shift. If you are interested, contact the HSE department.

We ended 2022 meeting our Safety Targets and ended Q1 of this year with no accidents or OSHA recordables. This is outstanding performance as a result of our proactive safety culture.

We have noticed associates looking down at their phone while walking, Bosch does not permit distracted walking. Remember AdP’s Mobile device policy of no walking and texting.

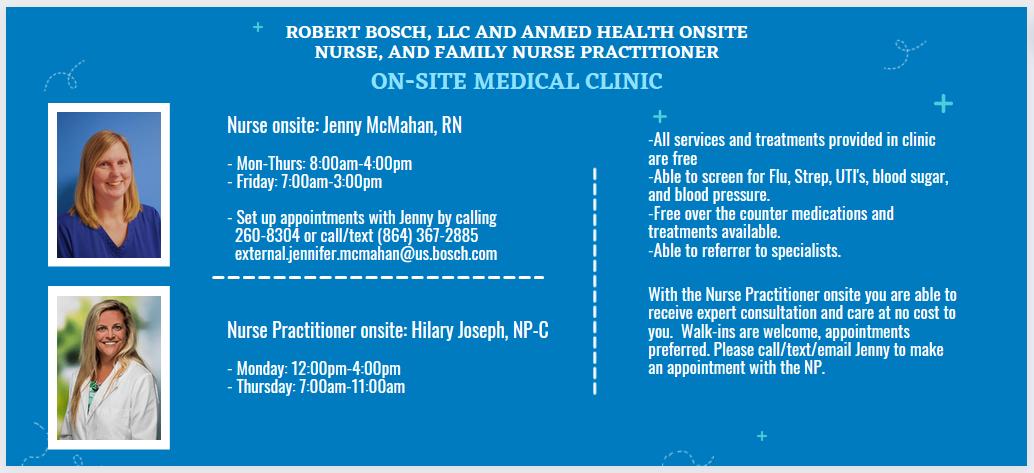

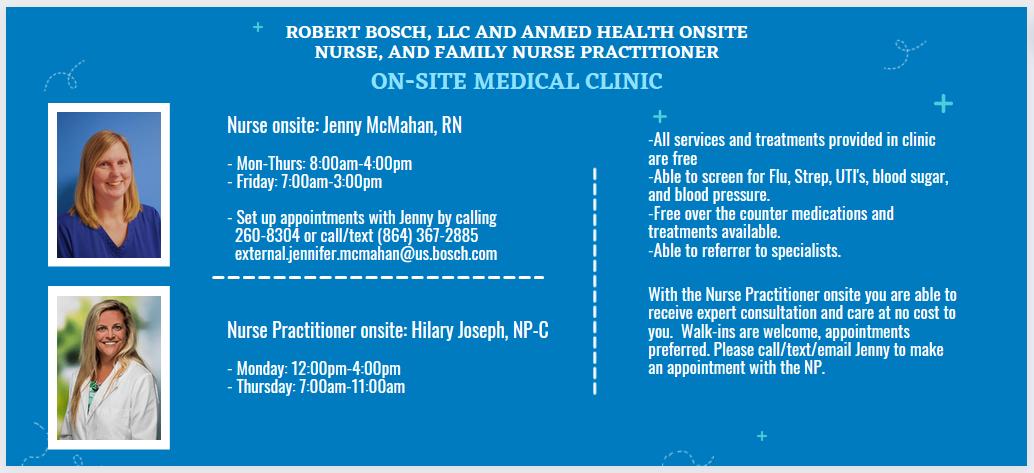

All medical team members are CPR/AED/First aid trained. Feel free to personally ask a medical team member for assistance, or call security at 864-260-8922. If calling security, please specify if it is an emergency or non-emergency in need of medical team.

We have a few openings for new medical team members. If you are interested in assisting your fellow associates, please contact the nurse at external.jennifer.mcmahan@us.bosch.com or at 864-367-2885 to discuss.

19 I Inside AdP Ӏ July 2023 19 I Inside AdP Ӏ July 2023 July 2023

us in owning our workplace!

Join

Know your Med-Team!

How can you contribute?

Search for “Bosch Anderson Plant” or scan the QR code to request membership.

We currently have over 600 members!

EXCITING NEWS: MyBoschApp Coming Soon!

• MyBoschApp for AdP is currently in the pilot phase; official rollout date ETA later this year!

• We are the 1st plant in North America to pilot the app!

• Can be accessed on personal phone!

• Stay tuned for more details!

AdP Communication Channel Overview

20 I Inside AdP Ӏ July 2023 20

July 2023

Mark Ratcliffe Director MOE2

Mark Ratcliffe Director MOE2

Shara Barbre Clinkscales (AdP/ MFW3-4)

Shara Barbre Clinkscales (AdP/ MFW3-4)

Andrew Jewell (AdP/MFW6-1)

Andrew Jewell (AdP/MFW6-1)

By Madison Speck (AdP/LOP4)

By Madison Speck (AdP/LOP4)

(Brian Todd, AdP/HSE)

(Brian Todd, AdP/HSE)