Natural stone is inherent with beautiful markings and variation, so we advise that samples should be used as a guide only. Common types of variation include colour, fissures, quartz, veining, and ore patches. Examples of the variation can be provided if requested, in order to manage expectations. It is incredibly important to make your tiler/fitter aware of the variation in the product so they can incorporate it into the application.

Variation in the production and geological makeup means that sizing for natural stone is nominal and may vary. The internationally accepted tolerance, in accordance to British Standard BS5385, is 1 to 5mm for dimensions and measurements. This is particularly relevant to natural stone tiles with a tumbled edges and textured surfaces which undergo processes to give them the desired look, as a result the thickness of the tile can vary. This means that a tile stated as 15mm could be between 10-20mm. Calibrated tiles are cut to a relatively even depth with lesser variables, usually around 22mm +/-, making it easier to lay The +/indicates a minor tolerance on the dimensions in accordance with British Standards. Note that products with riven textures may vary in thickness throughout the tile due to it's layered surface.

Tile manufacturers, produce their tiles in ‘ runs ’ or ‘batches’. As time goes by, the colour of these batches can change slightly, due to supplier changes with the substances used in the process. This is called ‘batch variation,’ and is incredibly common in the tiling industry. Sometimes, the difference in colour is very subtle, and you can get away with completing your project with the two different batches used side by side. If the batch variation is more drastic and you can’t use the tiles side by side, perhaps consider using the different shades in different sections of the room. To ensure all of your tiles are from the same batch, it’s best to place a full order from the same company, at the same time. This helps to ensure they are from the same pallet, and were delivered from the manufacturer at the same time (i.e. belong to the same batch).

The tolerance to European standards on most porcelain tiles is up to 3mm They don’t normally vary this much but these are the tolerances that are deemed acceptable from batch to batch. Porcelain tiles can also come with a ‘rectified’ edge, where the tiles are taken from the mould and are processed through machines that trim the edges of the tiles leaving a sharp, square rectified edge. The tolerance on the machines cutting these edges is very small, a minimal 0 5mm, making each tile practically the exact

As a manufactured product, you can expect porcelain tiles to always be the same thickness, however, overall dimensions may differ from published sizes and from batch to batch as detailed above. Also, in the construction and engineering industries, the term nominal size has been adopted to describe a manufactured products approximate size For example, in the tiling trade, you’ll read or hear sizes of 600mm × 600mm, when in fact the size could be 595mm x 595mm due to variation in manufacturers machinery, processes, and materials used.

If your order is reliant on exact sizing, please speak to Boniti to see if we are able to confirm the nominal sizing for the batch you are due to receive. Please note that this is not always possible, however we will endeavour to do our best.

When ordering your tiles, please be sure of your measurements and to confirm them with your tiler or fitter. We can provide estimates based on floor plans, but we will not take responsibility for any miscalculations. We recommend ordering 10% extra to allow for cutting, minor imperfections, breakages, and variation. If you are short of tiles due to not ordering wastage, charges will occur.

Once your tiles have been delivered, you will need to store them safely until they can be laid. You are able to store your tiles externally, however you will need to ensure that the tiles are sufficiently protected from the weather. Boniti recommends covering the pallet(s) with a tarp to keep out excessive moisture. Please note that wet tiles will need to be dried out completely prior to laying. This can be done by bringing the tiles into the property a few days before fitting and providing sufficient heating and airflow in the property. If there is no heating yet in the property, allow a few extra days for the drying process

Natural Stone tiles are porous by nature and must be sufficiently sealed prior to use. This should be done once the tiles are laid and prior to the grouting. Sealing works by filling up all of the open pores of the tile, ensuring that nothing can penetrate the stone and will therefore protect against stains and marks Most types of stone will require sealing twice, but more porous stones should be sealed even more to prevent any damage. If you are unsure about the application or the type of sealant to use, please contact Boniti for product specifications.

After a few years of living with your stone floor, you should consider resealing your tiles to keep them looking fresh and maintain the protection. This is dependent on how much wear the floor has received and how it has been maintained so can only be judged by you; typically you will notice the floor has a smeary appearance or is more prone to staining which are good indicators that the floor requires some work. Boniti offers a restoration service which will clean your natural stone tiles (including grout lines) and get them looking good as new. This service can also include minor repairs, so please get in touch for more information.

Porcelain tiles are known for their stain resistance and durability, and unlike natural stone which is routinely sealed, porcelain often doesn’t require any protection – but this isn’t the case for all types of tile. You can carry out a simple test on a spare tile/off cut by marking it with black marker pen. If the pen mark can be wiped off with a small amount of white spirit, then the tile is sealed and no further action is required If not, then we suggest sealing the tile prior to grouting to ensure there is no ‘framing ‘from the grout residues. Trapped residues will compromise the look of the tile, make it more difficult to maintain and could build-up and create a slip hazard. Please contact Boniti for further advice if you believe your porcelain tiles require treatment.

Standard deliveries are made on a large curtain/panel rigid lorry with tail lift (approx 17 ton and 13m in length) between 8am and 6pm. Please ensure that Boniti are informed of any access issues i.e. restricted access, gradients, gravel driveways, overhanging trees etc. Should a delivery fail due to incomplete or incorrect information being given in advance, additional charges may be incurred. Neither party wish this to be the case, so your assistance is greatly appreciated. If you are unsure of access, please give us a call so we can advise. Deliveries are made to the nearest accessible

point, which may be the kerbside or even some distance from the house. Labour must be available on site to inspect, accept, and move the goods onto the property. The driver is not permitted to bring products into your property and is unable to take away packaging or any empty pallets Boniti often uses the Palletline Network and as such we have no control of which delivery company will be delivering your goods from Palletline central warehouses. As such we cannot take responsibility for the drivers actions or attitudes.

Once unloaded the goods are your responsibility. We cannot guarantee delivery dates & times as these may be effected by circumstances outside our control. For this reason, we are unable to accept responsibility for lost working time and therefore recommend goods are ordered well in advance of any project start dates. On occasion, smaller orders will be delivered via courier however Boniti will advise you of this.

Please be advised that we will not be able to provide an ETA on standard deliveries. Should you require a more accurate timescale, then morning/afternoon or timed deliveries may be arranged for a small extra charge at point of confirmation. Please note that this service is not offered.

Your order should be inspected for any obvious damage or missing items and signed for as such, or reported within 3 working days of receipt. Avoid signing as “unchecked” as this may invalidate any future claims, and notify us of any issues as soon as possible and within your relevant timescale (see Terms and Conditions). We politely ask for photographs of any damages and details of the quantity affected. On the majority of orders, we will supply additional materials to replace any damages, however superficial damages such as small chips will not affect the application or overall look of the product and in these instances will not be replaced

If you would like us to estimate for the ancillaries we anticipate you may need to complete your project, then we are more than happy to do this for you. We base our estimates off of the square meterage you have provided and will ask a few questions about your subfloor so that we can suggest suitable products. Please note that we can only base our estimates on the manufacturers recommendations and therefore cannot allow for variable site conditions. Unless specified otherwise, all materials are estimated on the basis that the walls and floors are fully prepared by others and ready for fitting. We strongly recommend that your fitter confirms the required ancillaries on site prior to the date of fitting. Additional orders will incur further charges.

For projects over 30m2 and within range of our showroom, we are able to offer a site visit in order to specify the ancillaries required. This is a much more accurate way of quoting for materials and allows us to review all site conditions prior to estimating. We will also use this opportunity to speak with you and/or your installer to find out more about your project in order to make sure we have all of the correct information to work from. During this time, please feel free to ask any questions you may

have about the products or how they're best applied Once the site visit is complete, we will be able to submit our estimate to you for your approval.

Data sheets are available for all of our ancillaries. We do not send these out as standard, so should you require further technical information, please contact Boniti and we can send over the relevant data sheets for you.

Most of our ancillary deliveries will be delivered via courier, and therefore we cannot always guarantee the delivery date. Please allow for this in your fitting schedule.

Large ancillary orders will need to be palletised, so please ensure that a suitable place is available for delivery For further information, please see our 'Important Info: Tile Edition' page.

Preparation:

Boniti to arrange start date of works with main contractor or client.

Boniti to arrange for all materials to be delivered to the site before the start date, main contractor or client to check for breakages or missing items upon delivery. Any breakages must be reported to Boniti with images.

Preparation of area to be carried out by main contractor by ensuring optimal conditions to fit tiles Will be assumed that all screed flooring is flat and fully dried and cleared, that subfloor is cleaned of dust and debris, conditions are dry, there is minimal foot traffic and suitable lighting and electricity.

Deviation from this must be made clear to Boniti as this may impact costs and fitting schedule

Fitter to ensure tiles are suitable for laying.

Apply primer coat to screed floor as supplied.

Fit ditra-matting, if applicable.

Identify and agree direction of tiles and layout with client.

Fit tiles to ditra mat with adhesive supplied, if applicable.

Clean off tiles.

Grout floor

Seal the floor at least twice (applicable to stone installations only) All debris to be left in skip provided.

Snagging works to be carried out by main site contractor or client

All debris to be left in skip provided.

Snagging works to be carried out by main site contractor or client.

Floor to be protected with breathable card if other works are continuing.

The process outlined above may vary depending on individual site conditions and the level of work required.

Consideration must be given for potential exposure to asbestos in buildings constructed before 2000

On construction sites, the main contractor/client is responsible for providing safe access and egress to the site Other works and operatives on site must not interfere with the fitters during installation

An area must be designated to dispose of waste and packaging This service is not provided as standard by Boniti unless requested.

If heating or electricity is not available at the property during the time of installation, then this must be made clear to Boniti so relevant arrangements can be made

Car parking must be provided, or a surcharge must be paid to allow fitters to park at a reasonable distance to the property.

W

Welfare arrangements are supplied by the client. All sites are to have a minimum amount of welfare facilities available for workers which include the following:

Toilets

Washing facilities

Drinking water

First aid box

For everyday cleaning of your internal stone, we recommend lightly sweeping, vacuuming or microfiber mopping to remove loose dirt and dust. Specially formulated stone cleaners should be used to wash your floor with. To maintain your external stone, we would recommend regular sweeping with a stiff brush to remove debris and using a more intensive stone cleaner to remove any stains Please contact Boniti so we can specify the correct cleaner for your natural stone tiles. Don’t use vinegar, lemon juice, or other cleaners containing acids on marble, limestone, travertine, or onyx surfaces. Cleaners that contain acid include bathroom cleaners, grout cleaners, or tub & tile cleaners. Avoid using vacuum cleaners that are worn as the metal or plastic attachments or the wheels may scratch the stone’s surface

After living with your stone floor for a few years, you may want to consider a deep clean and a reseal. Please contact the Boniti team so we can tell you more about this service.

For daily maintenance or your porcelain tiles, the first step is to sweep away dust, crumbs, and other debris that have accumulated since your last cleaning Next, wash with clean water and an appropriate porcelain tile cleaner. If you choose to use a mop for your flooring, be sure you have swept up debris beforehand and use a flat mop rather than a sponge mop to keep from pushing dirty water into the grout lines. After, dry thoroughly either by air-drying or using a microfiber cloth (a dry flat mop is great as well). Don’t use acidic cleaners, including vinegar. Don’t use oil- or wax-based cleaners as they leave a residue that may attract dirt, and avoid using steel wool or other abrasive scrubbers.

Ensure that all furniture is removed (where possible) from the area, and dogs and cats are kept away from the cleaning process, as we use strong cleaning solutions and sealants that have a strong smell initially. The costs outlined in the sales order are based on an area being free of furniture/objects ready for work to begin at 8.30am. If the area is not clear this will impact on the time quoted and will incur extra cost.

As you can appreciate the floor space will be wet during certain times and we kindly ask that you keep clear of the floor area whilst we are working During the sealing process it is important that the floor is not walked on when the sealants have been applied and are drying. You will be able to walk over the floor later in the day once it is fully dried.

Any furniture/equipment can be moved back once the sealant has dried and cured. Do not wash the floor with any cleaning solutions for at least 5 days, as the sealant needs to ‘ cure ’ . We will instruct you on the long-term care and cleaning.

Arrive at 8.30-9.00am or the pre-agreed time. Floor Technicians to work over and hand brush/detail the surface of the floor. Using a

wet diamond cutting process, or similar, work on the surface of the stone, wetvac remove all residues and dry off the surface. Manually clean the entire surface. Rinse with clean water, wet vac off and allow to dry. We do a test seal area and then apply start to apply the wax. In between each coat we mechanically buff the sealant into the surface to a finish in keeping with the floor. We detail the edges vacuum and clean off the surface.

The Floor Restoration team will use their knowledge and experience of floor restoration and endeavour to restore, clean and seal floors to a satisfactory condition. In some cases, deep marking will be reduced, but not totally removed.

We are not responsible for marks, stains, and spillages once we have left the site. We are not responsible for water ingress and damp issues with floors which do not have a damp proof membrane (DPM) or damp course.

We are not responsible for the complete removal of any preexisting conditions with the floor such as mechanical markings, pitting, breaking up, shaleing, scuffs and scratches. We will endeavour to improve the appearance of these. But please be aware these issues could reoccur even after our restoration.

Sealants are dressings and should not be regarded as impenetrable, everlasting barriers. As the seal wears the surface becomes less resistant and more susceptible to staining. The method in which a floor is maintained will determine how long a sealant is effective.

Please appreciate that your floor has an existing history that we have not been involved in. Using our specialist knowledge and experience we aim to achieve the best possible result with the surface that we are working with. Repairs to cracks, holes and pitting are pre-existing conditions and we cannot guarantee that

they will not reappear. We can treat again but it would be regarded as a new job.

Now you have spent the money to have your floor restored, let us help you maintain the finish using our specialist products. We can outline which products are best suited to maintain your particular floor and keep them looking good as new. Give us a call once your floor has been restored so we can outline your simple maintenance routine.

Timber flooring is derived from natural products and is inherit with variation and markings. It's important to note that different woods contain varying amounts of tannins, which affect the final appearance. Common variable traits are knots, sapwood, and medullary rays. Samples should be used as a guide only, and examples of the variation to expect can be provided.

Some timber products are fumed and/or distressed. Due to the process of fuming, the initial colour of the planks will appear slightly darker and will soften and settle after installation and exposure to daylight. Any timber floor, fumed or not, will change in colour over its lifetime due to the same oxidisation which changes the colour of a fumed floor. When a product is distressed, expect to see marks, dents, and scratches across the surface and on the edges of the boards, as would occur on a floor naturally over time. This is a random process and as such we cannot control where on the surface or edges will be affected. This process creates an old reclaimed looking floor with lots of character – it does not affect the quality or structural integrity of the product. This process can also damage some tongues and grooves, however this does not impede installation. Simply use a sharp knife to either open up the grooves or remove the chipped section of tongue.

When ordering your timber, please be sure of your measurements and confirm them with your fitter. We can provide estimates based on floor plans, but we will not take responsibility for miscalculations. We recommend ordering an additional 10% for planks and 15% for herringbone or other parquetry. This allows for cutting, minor imperfections, damages, and natural variation. If you are short of planks due to under ordering, charges will occur. Please ensure that confirmation of measurements/ancillaries is sought from your builder/fitter, as returns and additional costs incurred through incorrect information will be charged.

A lot of our timber products are made to order, and therefore we cannot refund deposits for these bespoke items should you change your mind.

Your timber boards will arrive with industry standard 10% moisture content after being kiln dried. Prior to installation, you must allow a minimum of 48 hours (ideally we would recommend 7 days) for the boards to acclimatise in their packs. Ensure all wet trades have finished, that the screed is suitably dry, and check that house conditions are RH40-65%. You can then place the timber in the room that it's to be fitted in - please do not unpack the timber as this can affect the acclimatisation process. Any substantial damage will be apparent from the packaging and must be reported within 48 hours of delivery. If your order is for more than one room, then it should be broken down into the individual room quantities and stored in the respective rooms.

Standard deliveries are made on a 17 ton delivery vehicle (approx. 13m in length) between 8am and 6pm. Please ensure that Boniti are informed of any access issues i.e. restricted access, gradients, gravel driveways etc. Should a delivery fail due to incomplete or incorrect information being given in advance, additional charges may be incurred. Neither party wish this to be the case, so your assistance is greatly appreciated. If you are unsure of access, please give us a call so we can advise. Deliveries are made to the nearest accessible point, which may be the kerbside or even some distance from the house. Labour must be available on site to inspect, accept, and move the goods immediately into the property. The driver is not permitted to unpack products into your property and is unable to take away packaging or any empty pallets Once unloaded the goods are the responsibility of the site team. We will endeavour to deliver at the agreed time however, we cannot guarantee delivery dates & times as these may be effected by circumstances outside our control. For this reason we are unable to accept responsibility for lost working time and therefore recommend goods are ordered well in advance of any project start dates. On occasion, smaller will be delivered via courier however Boniti will advise you of this.

Your order should be inspected for any obvious damage and signed for as such. Avoid signing as “unchecked” as this may invalidate any future claims, and notify us of any issues as soon as possible and within your relevant timescale (see Terms and Conditions). We politely ask for photographs of any damages and details of the quantity affected. On the majority of orders, we will supply additional materials to replace any damages. Often, superficial damages will not affect the application or overall look of the product and in these instances will not be replaced.

If you would like us to estimate for the ancillaries we anticipate you may need to complete your project, then we are more than happy to do this for you. We base our estimates off of the square meterage you have provided and will ask a few questions about your subfloor so that we can suggest suitable products. Please note that we can only base our estimates on the manufacturers recommendations and therefore cannot allow for variable site conditions. Unless specified otherwise, all materials are estimated on the basis that the walls and floors are fully prepared by others and ready for fitting. We strongly recommend that your fitter confirms the required ancillaries on site prior to the date of fitting. Additional orders will incur further charges.

We offer a full range of finishing profiles to complete your floor including t-bars, scotias and bullnosed pieces. Please contact Boniti so we can understand your requirements and make the best recommendation for you. These can be matched to your chosen floor or are sold unfinished. Please note that profiles are typically made to order so may incur a small lead time.

Preparation: Installation of timber flooring:

Boniti to arrange start date of works with main contractor or client.

Boniti to arrange for all materials to be delivered to the site before the start date, allowing time for acclimatisation Main contractor or client to check for breakages or missing items upon delivery. Any breakages must be reported to Boniti with images.

Preparation of area to be carried out by main contractor by ensuring optimal conditions to fit timber Will be assumed that all screed flooring is flat and fully dried and cleared, that subfloor is cleaned of dust and debris, conditions are dry, there is minimal foot traffic and suitable lighting and electricity.

Deviation from this must be made clear to Boniti as this may impact costs and fitting schedule.

Fitter to ensure timber is suitable for laying

Apply primer coat to screed floor as supplied, if applicable.

Identify and agree direction of timber and layout with client. Fit timber flooring with adhesive supplied, if applicable. Clean off timber.

Handover:

All debris to be left in skip provided.

Snagging works to be carried out by main site contractor or client.

Floor to be protected with breathable card if other works are continuing

The process outlined above may vary depending on individual site conditions and the level of work required.

Consideration must be given for potential exposure to asbestos in buildings constructed before 2000

On construction sites, the main contractor/client is responsible for providing safe access and egress to the site Other works and operatives on site must not interfere with the fitters during installation

An area must be designated to dispose of waste and packaging This service is not provided as standard by Boniti unless requested.

If heating or electricity is not available at the property during the time of installation, then this must be made clear to Boniti so relevant arrangements can be made.

Car parking must be provided, or a surcharge must be paid to allow fitters to park at a reasonable distance to the property.

Welfare arrangements are supplied by the client. All sites are to have a minimum amount of welfare facilities available for workers which include the following:

Toilets

Washing facilities

Drinking water

First aid box

A

House conditions need to be RH 40-65% and the maximum surface temperature of oak must never exceed 27°C. When using under floor heating, introduce the heat gradually as to not damage the floor. Do this by increasing the temperature by a couple degrees over a few days. Be aware, using rugs over underfloor heating will increase the temperature of the wood. If boards cup, crown or split they have gotten too dry/hot/wet. If this is the case, there are issues in the property that will need addressing promptly. If other works are continuing once the floor has been installed, ensure it is covered with breathable card in order to avoid dust collecting in the grain and spoiling the appearance. Do not use plastic to cover the floor.

For everyday cleaning, we recommend light hovering, brushing or dry microfiber mopping to pick up loose dirt and dust. For marks, try a gentle mop on the floor by wringing the mop out completely and using only water. Be aware that if you have used products containing ammonia with your mop before, there is a possibility that it may transfer to your floor and affect the finish. For this reason, we suggest using or purchasing a separate mop for your floor.

For stronger cleaning, more specific cleaners are available and Boniti can help find the right one for you.

UV Coating - This helps to prevent the Decor layer from fading and keeps your flooring looking amazing even in the sunniest of environments.

Wear Layer - This adds a natural texture to your flooring which helps achieve that great non-slip surface whilst keeping your flooring 100% waterproof.

Decor Film - Where the magic happens, the decor film is the look of your flooring, completing your room with that perfect wood effect, without the worry of humidity or water damage.

Core Board - A mineral based core made up of magnesium oxide (MGO core) reinforced with tough fibreglass for stability and durability. This means it is fireproof, dent proof. shift proof and mould proof, whilst being environmentally sustainable.

IXPE Underlayer - You don’t need any additional underlay with Impervia Flooring as built into every board is an IXPE underlay, creating a acoustically dampening surface which is suitable for use with underfloor heating.

C O N S T R U C T I O NPreparation:

Boniti to arrange start date of works with main contractor or client.

Boniti to arrange for all materials to be delivered to the site before the start date.

Main contractor or client to check for breakages or missing items upon delivery. Any breakages must be reported to Boniti with images.

Preparation of area to be carried out by main contractor by ensuring optimal conditions to fit. Will be assumed that all screed flooring is perfectly flat, fully dried and cleared of dust and debris, conditions are dry, there is minimal foot traffic and suitable lighting and electricity. The optimum room temperature range shall be 18 °C- 21 °C for 24 hrs. before, during and after installation, and a humidity range of 40-60% is recommended. CAUTION: Impervia FLOORING cannot be installed over carpet or any type of underlay This product is not suitable for any outside use, sunrooms, solariums or saunas. We also highly recommend you do not install in rooms that are not temperature controlled. Fitter to ensure product is suitable for laying.

Installation of impervia flooring:

Identify and agree direction of flooring and layout with client. Fit impervia via floating or with adhesive, if supplied, Clean off flooring.

Handover:

All debris to be left in skip provided.

Snagging works to be carried out by main site contractor or client.

Floor to be protected with breathable card if other works are continuing.

Consideration must be given for potential exposure to asbestos in buildings constructed before 2000

On construction sites, the main contractor/client is responsible for providing safe access and egress to the site

Other works and operatives on site must not interfere with the fitters during installation

An area must be designated to dispose of waste and packaging. This service is not provided as standard by Boniti unless requested.

If heating or electricity is not available at the property during the time of installation, then this must be made clear to Boniti

Car parking must be provided, or a surcharge must be paid to allow fitters to park at a reasonable distance to the property.

Welfare arrangements are supplied by the client. All sites are to have a minimum amount of welfare facilities available for workers which include the following:

Toilets

Washing facilities

Drinking water

First aid box

We hope you will love your new stone and tiles, however, we understand from time-to-time that there may be a reason to return a product or you may have a delivery issue. Please follow our guidelines below to make your returns as quick and seamless as possible:

If you notice any shortages or damages then please let us know via email (bath@boniti.com) within three working days of receipt. Please include photographic evidence. Delivery of incorrect products must be notified via email within three working days of receipt.

Any items must be returned in full boxes where applicable. Bespoke products, special-order products & Outlet/EOL products are exempt from cancellation or returns policies. All resalable returns on standard stock items are subject to a restocking charge and collection fee which will be deducted from the credit raised. Refunds will exclude collection/delivery charges. Returns for standard stock items will be accepted up to eight weeks following delivery/collection of goods.

Once the returned goods have been checked, we will refund your money within 5 working days.

Please note that we are unable to accept returns of timber and impervia products.

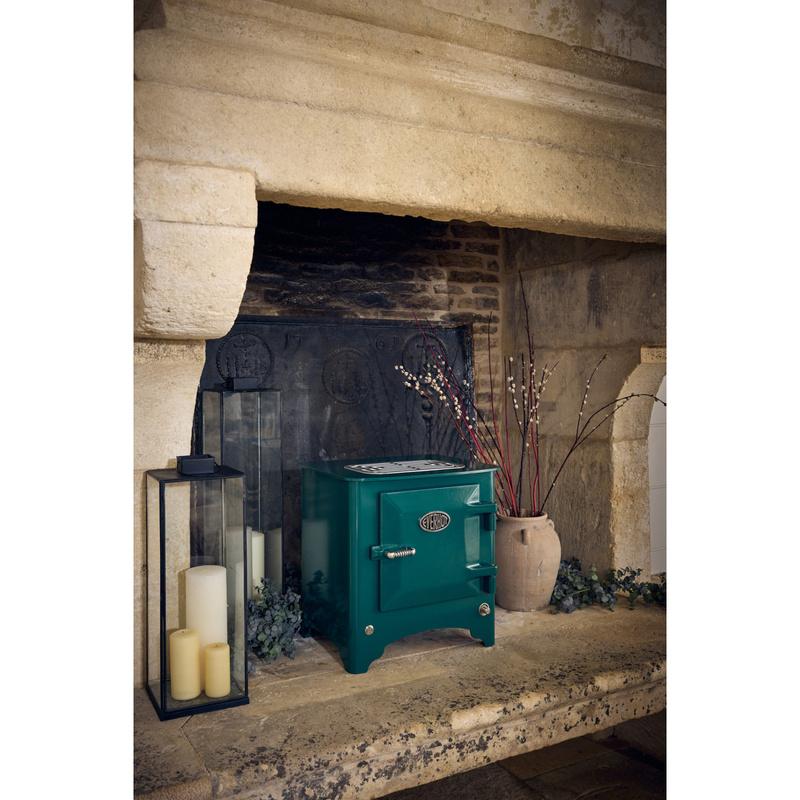

To place your Everhot order with Boniti, please fill in our Everhot Order Pack. This will ask for confirmation of your personal details, chosen model name, ideal delivery date, as well as details about access. Please return the order pack to us along with photos of access. If you need any help completing these forms, please give us a call. You do not need to confirm your Everhot colour at this stage. Approximately 6 weeks prior to delivery, we will be in touch to confirm your colour choice.

Once we receive your completed order pack, we can advise whether a standard delivery or a build on site is required, and can then send back a Sales Order with a 20% deposit request. After the deposit has been paid, your order will be secured.

Some properties have much trickier access than others, and this might mean that you require your cooker to be built on site. The Everhot delivery team will deliver the shell of the cooker to you and will then send an Everhot engineer to install the inner workings to get it up and running. Please note that this service is at an additional cost to the standard delivery charge. This charge is calculated on a case-by-case basis and requires the completed Everhot Order Pack

as well as clear images of the access. As this is a specialised service, there is limited availability for these delivery slots and may incur a longer lead time.

Standard deliveries are made on a large Sprinter van with the Everhot delivery team of two. The delivery team will use protective ply boarding to create a pathway to the point where the Everhot is to be installed. Once in position, they will ensure that the cooker is level, plugged in and running correctly.

You will receive a delivery date offer by Everhot with a specific date and three-hour delivery window. If you are not ready to receive your delivery, then it can be delayed by weeks or months. Please note that once dates are pushed back, they are unable to be brought forward. In the Everhot Order Pack, you will be asked about your ideal delivery date - Everhot will endeavour to reach this date, however we cannot guarantee that this exact date will be offered. Everhot prefer it if the kitchen is ready with a space for the Everhot to be delivered into, however if this is not possible then you should ensure that the majority of your building work has been completed before delivery. For example plastering, tiling and any flooring need to be completed first.

When you receive your cooker you will also receive an Everhot tote bag filled with accessories. This bag is usually kept in the top oven during transport and has a big tag attached to make you aware. Ensure that this bag has been removed prior to turning on. Should you need to cancel your delivery, you must give us at least 48 hours notice. If you cancel your delivery with less than 48 hours notice, charges will be incurred. Although you can delay delivery to suit your project, if delivery has not been arranged within one year of placing the order, your order may be subject to price increases.

Everhot offer a parts and labour warranty for 24 months following purchase – although the heating elements are covered for 5 years (parts and labour).

Everhot allow two weeks after your deposit has been paid for cancellations. After this, charges will be incurred which are relative to your delivery date. Please contact Boniti for further details

To place an order for your Everhot Stove with Boniti, please confirm your personal details, colour choice and ideal delivery date. Once these have been received, we can then send back a Sales Order and will request payment in full. Your order will then be processed and the estimated lead time will be confirmed.

Approximately 1-2 weeks before your Stove is due to be delivered, Everhot will be in touch to confirm your delivery date. Standard deliveries are made on a large Sprinter van with the Everhot delivery team of two. The delivery team will bring the Stove into the property. Please note that they will not remove the packaging or set up the stove for you. Should you need to cancel your delivery, you must give us at least 48 hours notice. If you cancel your delivery with less than 48 hours notice, charges will be incurred.

Everhot Ltd. undertakes that if, within 24 months of the date of purchase, this appliance or any part thereof is proved to be defective by reason only of faulty workmanship or materials, we will repair the same free of any charge for labour or materials on condition that:

The appliance has been correctly installed and used only on the electricity supply stated on the rating plate, or in a renewable system with an appropriate energy controller. The appliance has been used for normal domestic purposes only, and in accordance with the manufacturer’s instructions. The appliance has not been serviced, maintained, repaired, taken apart or tampered with by any person not authorised by us.

All service work under this guarantee must be undertaken by an Everhot appointed body.

Any appliance or defective part replaced shall become the property of Everhot Cookers

This guarantee does not cover:

Damage or calls resulting from transportation, improper use or neglect, including water damage from spillages.

Damage caused to the base material or finish caused by misuse

Costs incurred for calls to put right an appliance, which is improperly installed or calls to an appliance outside the UK mainland.

Appliances found to be in use within a commercial environment.

Appliances found to have no fault

C A N C E L L A T I O N S

Everhot allow two weeks after your order has been place for cancellations. After this, charges will be incurred which are relative to your delivery date Please contact Boniti for further details.