Mechanical Testing Services

The assessment of material responses to applied forces is performed through mechanical testing services. The testing methods guarantee both product safety and reliability, and performance standards. Our company follows testing standards from ASTM, ISO, and EN.

Tensile Testing

The tensile test procedure evaluates both tensile strength and elongation values. A specimen experiences uniaxial tension until it breaks during this test method. The stress-strain curves reveal essential tensile properties for measurement. The use of steel alloys in bridge construction enables them to provide adequate bearing strength.

Tensile Strength

Maximum stress a material can withstand.

ASTM Standard: ASTM E8/E8M

Yield Strength

Stress at which material begins to deform permanently.

Elongation

Measure of how much a material stretches before breaking.

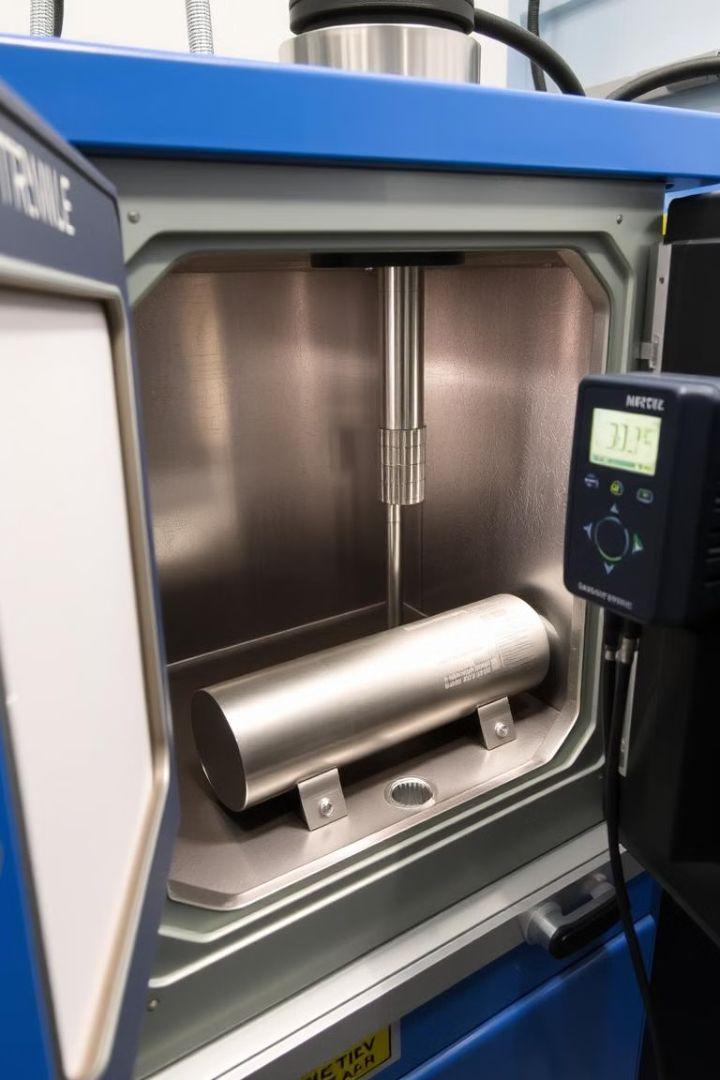

Hardness Testing

The evaluation of material resistance to plastic deformation is what hardness testing accomplishes. The Rockwell and Vickers, and Brinell testing methods are among the techniques used for hardness testing. The evaluation of heat treatment success and material choices occurs through this assessment. The evaluation method determines gear hardness to assess its wear resistance.

Rockwell Vickers Brinell

ASTM Standards: ASTM E18 (Rockwell), ASTM E92 (Vickers), ASTM E10 (Brinell)

Flexural Testing

Bending experiments analyze materials' strength against flexural forces as well as their strain behavior when subjected to such load conditions. Testing occurs through setups that use three-point or four-point bending methods. The testing method determines the strength capabilities of polymers and composites. Plastic component testing helps prevent product breakage when they are used.

Three-Point Bending

Simple setup for basic material testing.

Four-Point Bending

Provides a uniform stress region for accurate results.

ASTM Standard: ASTM D790

Impact Testing

The method of impact testing helps determine the ability of materials to withstand sudden impact forces. Two standard testing methods used for impact analysis are Charpy and Izod tests. High-impact environment suitability assessment is conducted through this test method. The testing method determines automotive bumper impact resistance.

Charpy Impact Test

Measures the energy absorbed during fracture.

Izod Impact Test

Determines the resistance to impact from a swinging pendulum.

ASTM Standard: ASTM E23 (Charpy), ASTM D256 (Izod)

Fatigue Testing

The evaluation of fatigue behavior through cyclic loading tests helps determine material fatigue life. Specimens undergo repeated stress cycles. The S-N curves enable researchers to establish fatigue strength values. The method predicts the operational lifetime of components, including aircraft wings.

Stress Cycles

S-N Curves

Standard: ASTM E466

Creep Testing

The evaluation of long-term deformation under constant load at high temperatures occurs through creep testing. Deformation is measured over time. The test evaluates materials to determine their capability for high-temperature use. Structural integrity tests are performed on turbine blade materials.

1 Constant Load Maintained throughout the test duration.

2 Elevated Temperature Simulates extreme operating conditions.

3 Deformation Measurement Tracks long-term material behavior.

Standard: ASTM E139

Non-Destructive Testing

Non-Destructive Testing (NDT) detects internal material flaws by avoiding any damage to the tested components. The testing methods for non-destructive evaluation consist of ultrasonic testing and radiographic testing, and dye penetrant testing. This ensures quality control. Welded joints can be checked for porosity through the use of ultrasonic testing methods. 4

Ultrasonic Testing

Radiographic Testing Magnetic Particle Testing

Relevant standard: ASTM E165

Dye Penetrant Testing

Benefits of Our Services

Product reliability and safety undergo enhancement through mechanical testing procedures. The testing method helps organizations meet their industry regulatory requirements. Improved material selection optimizes design. The implementation of these tests helps prevent equipment breakdowns before their warranty period ends. The optimized material usage leads to cost savings.

Partner with Us

https://bmptesting.com/page/mechanical-testing