• Undergraduate work compilation

Done by Pablo zuluaga

CONTENT

• academic Projects

• non-academic projects

• fabrication projects

02 01

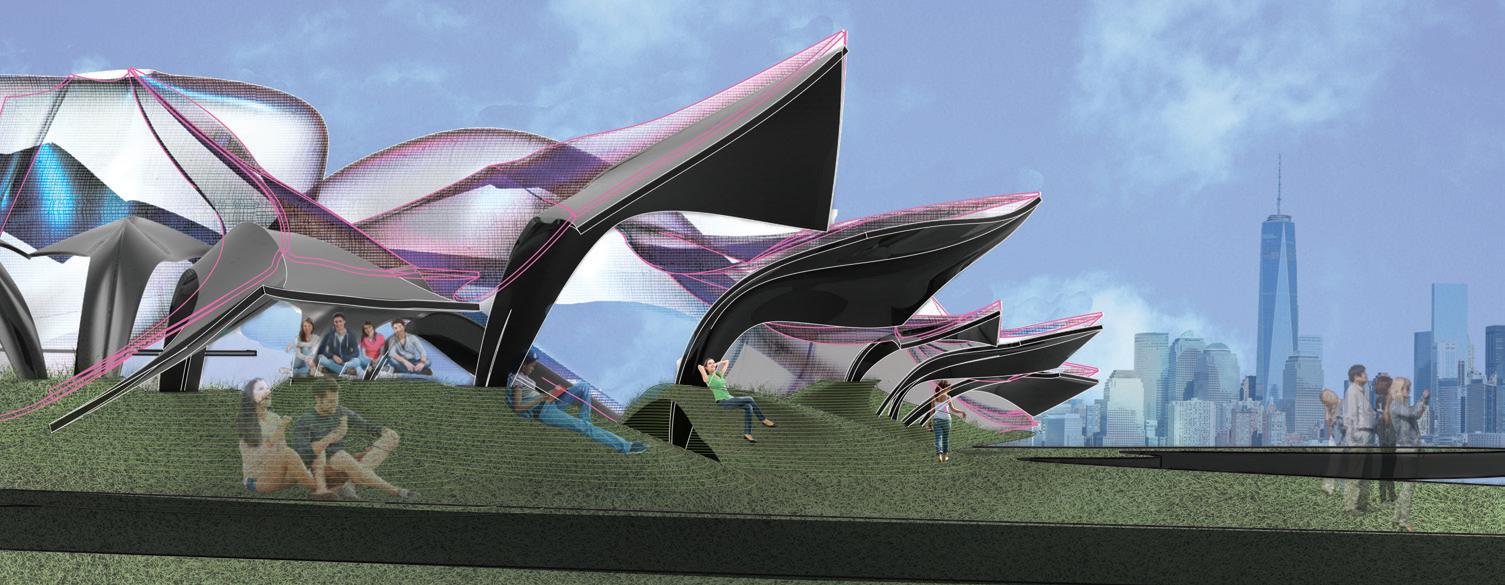

Project: Industry city ( re - thinking the PIER )

Studio: 7

Year: Fall 2014

06 03 05 04

Project: silver screen flirtations ( summer performance pavilion )

Year: Summer 2014

Project: glaucus performance pavilion

Fabrication: 3

Year: Fall 2014

Project: Coral Studio: 8 Year: Fall 2013

Project: Solar Screen (Standard Hotel)

Fabrication: 3

Year: SPRING 2013

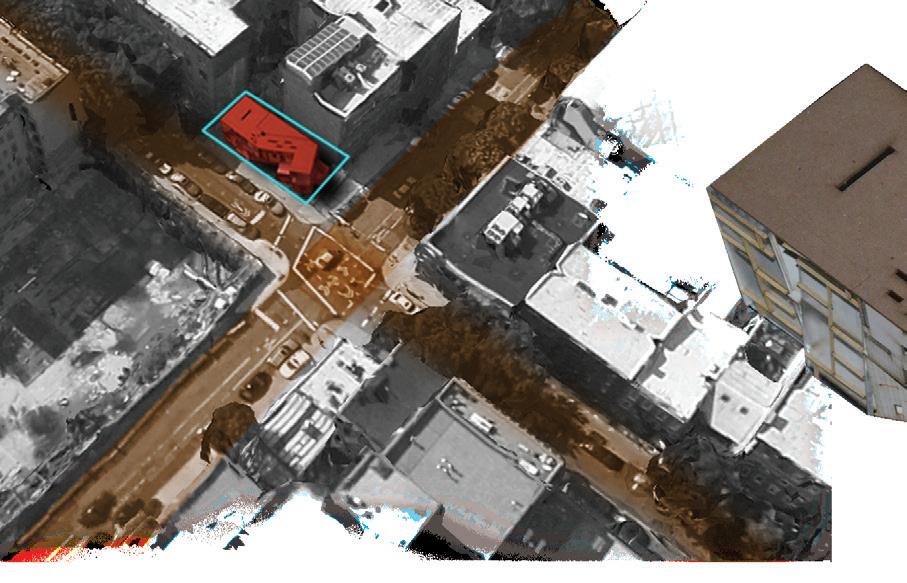

Project: The Container House

Studio: 5

Year: Spring 2013

Project: The burguer plant

studio: 5

Year: Spring 2013

Project: The Brooklyn Pavilion

Studio: 4

Year: Fall 2012

08

07

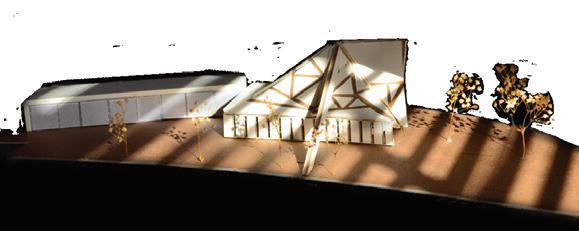

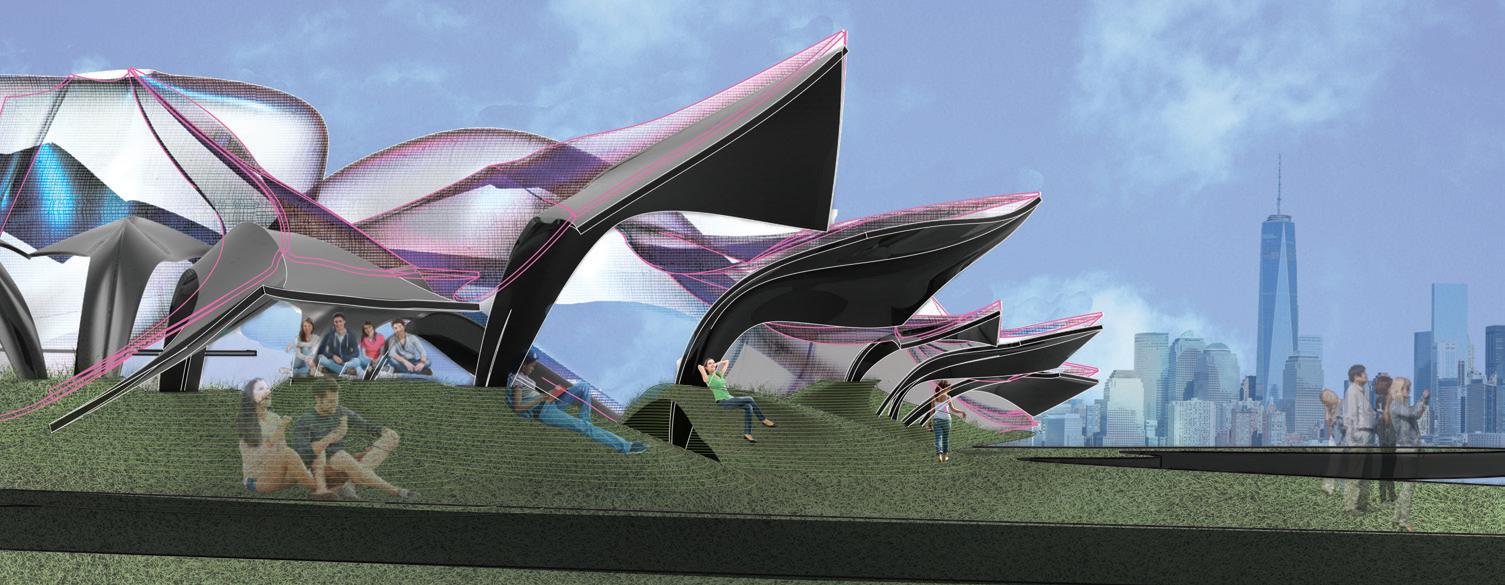

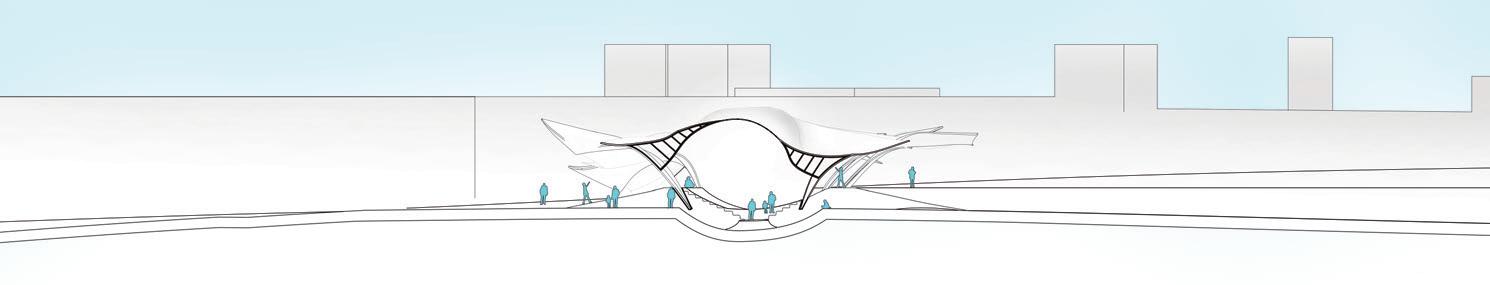

SILVER SCREEN FLIRTATIONS

(summer studio 2014: performance pavilion)

Location

Perrysburg, Buffalo

The screen silver flirtatious is born after local farmers were interested in develop a space to gather and have musical performances. As a team, we went about understanding and learning from the different patterns and conditions of the surrounding environment. The result of the investigation, was a conceived structure that could negotiate not only the flirtatious relationships between the man-made and natural states but also, one that performed as both as a shelter and structure.

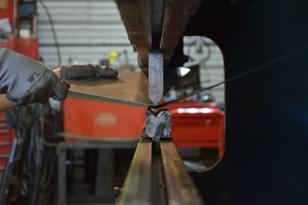

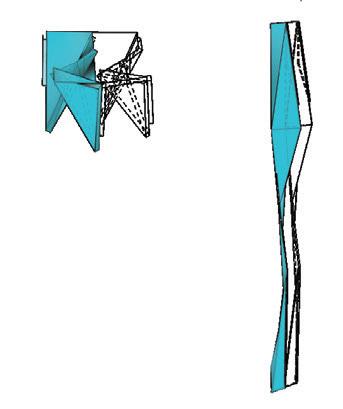

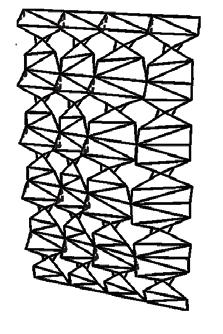

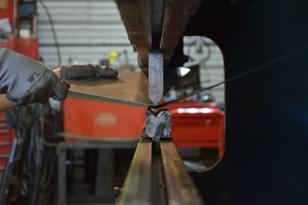

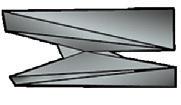

Digital and physical models were made to study the spatial and structural qualities of the design concept. A surface and terrain team formed, the surface (stainless steel), and terrain (wood planks). While being in the panel design team, I would always thought of the design of the panels as a single element that will later bring complexity to the over all image of the structure by repetition, the fact that I was able to manage a shape modular enough was what made the design and construction process successful, plus the computer assitance aid. As a result, the stainless steel surface was panelized into four (4) repetitive panel types that create one module. Later, we prepared for fabrication by producing printed work (cut + fold) templates from a rhino model.

02

Non-academic Project: Nick Bozza, Lida

Omar Ferwati, Yi He, Christin Hu, Lorraine Kung, Julia Lu, Chitra Mamidela, Pablo

,

Chrysanthou,

Zuluaga Morelo

Loyra

Yates,

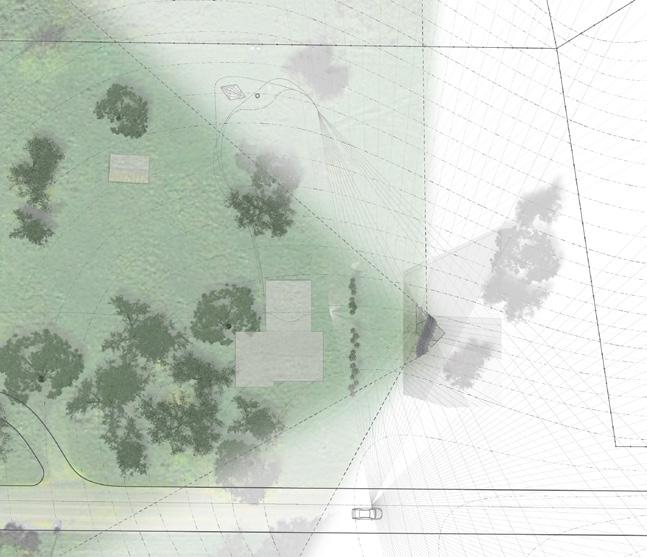

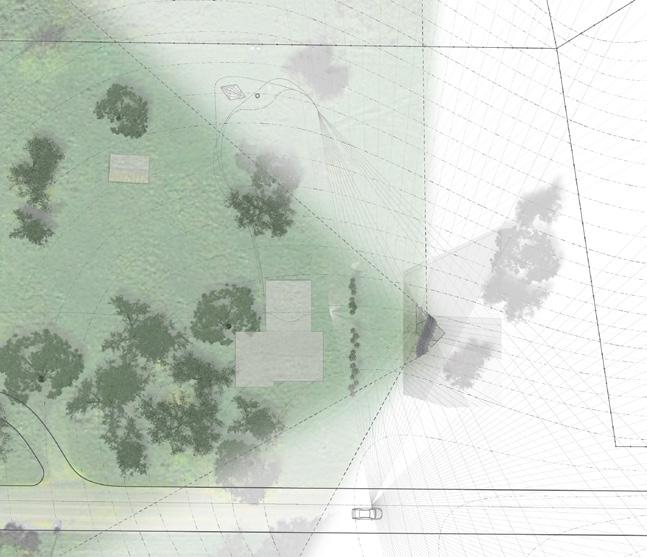

FINAL STAGE + lines of views SITE PLAN

Nunez, Solomon Oh, Brittany Lynne Piscopo, Jonathan

Lavender Tessmer, Joseph

Vidich,

Tim Brewster, William Haskas, Jeremy Luce, Jason

Schindler.v

Site Boundary

Area Boundary Lines of Views

Area Site boundary

points

area Final site Performance Pavilion Performance

Overlapping

Overlapping

Vantage

Overlapping

AXIAL TERMINATION_study

Fold out Fold in Panel A Top panel Third row Base

262.07˚ 260.89˚ 260.46˚ 261.48˚ 259.56˚ 253.82˚ 254.47˚ 256.15˚ 259.58˚ 257.02˚

surface Stepped wooden Planks

A

Panel

(18)

PanelC (9)

Lean forward Lean back

PanelB

Cantilever (9)

PanelD (9)

PanelE (5)

∑= 53 259.27˚

PanelF (3)

Drawings by Pablo Zuluaga

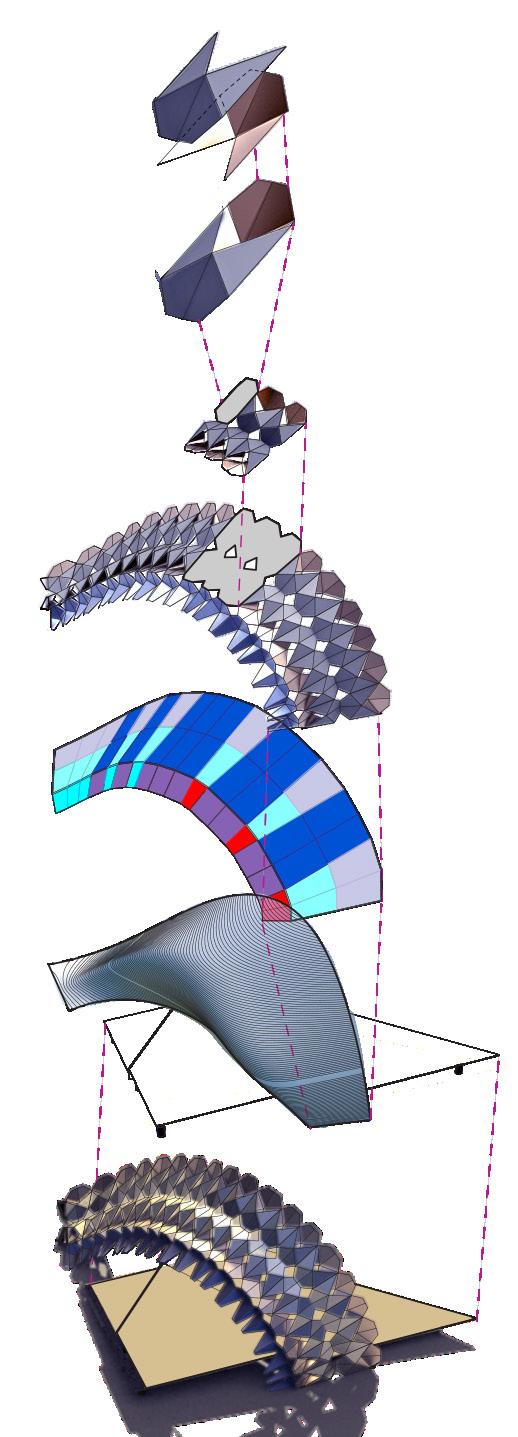

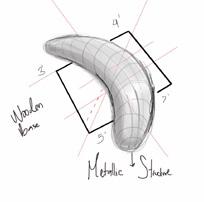

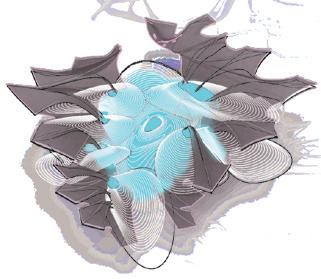

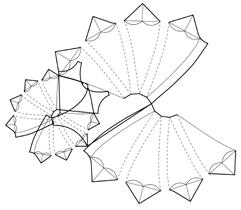

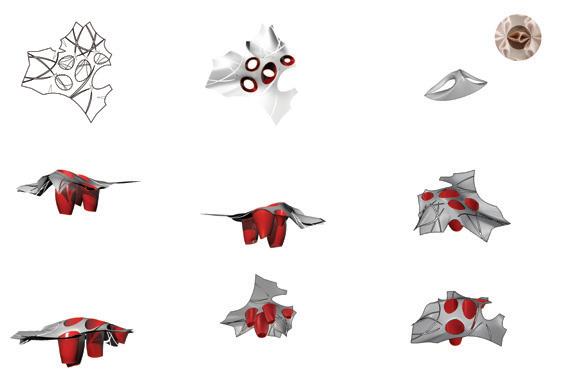

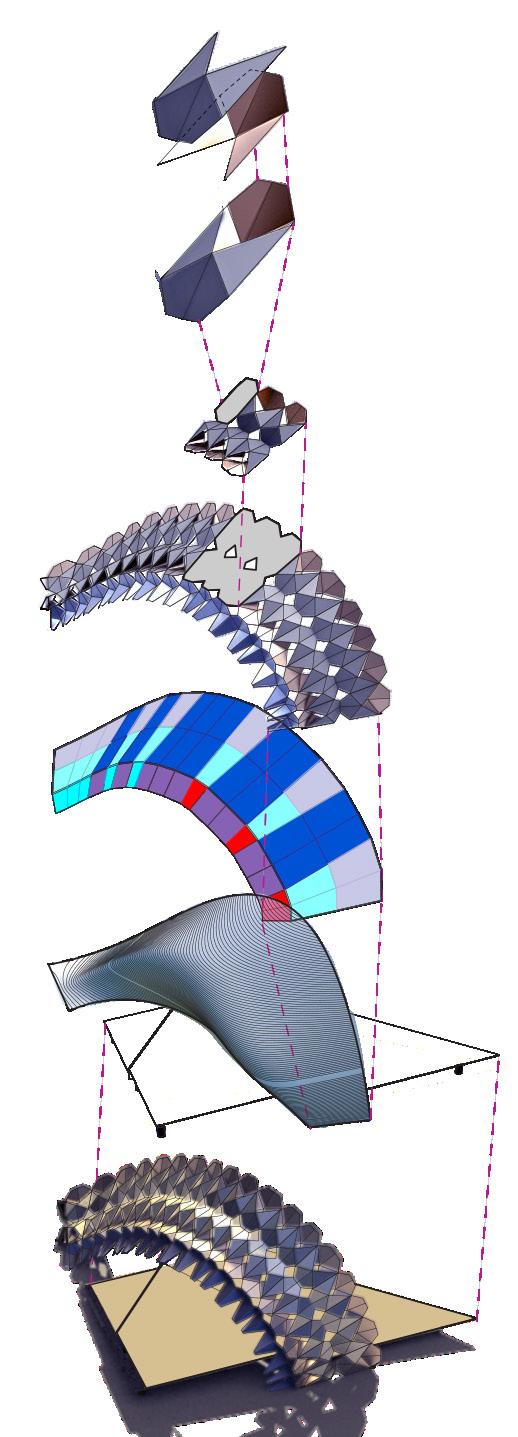

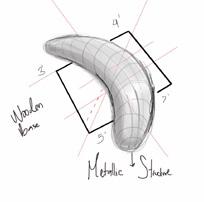

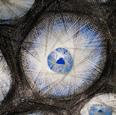

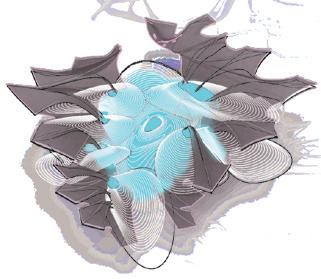

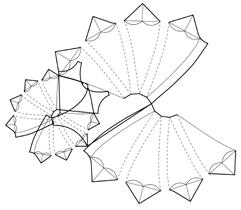

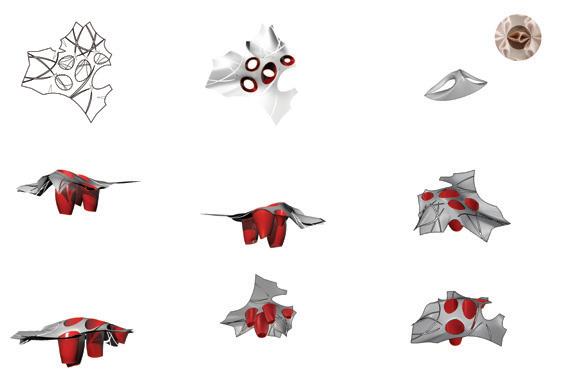

GLAUCUS PERFORMANCE

(research pavilion)

Glaucus performance is a structure that was created after re-interpretating patterning and sewing techniques used in the fashion industry. The center or core of the structure is where the pinching technique gets more visible and adds to the structure a natural strong lifting to room activities in its interior. As well, on the roof of the structure the pinching technique is used again , this time however, by combining the pinching and gathering methods the people comes a lifted structure arises.

Section a-a”_esc1/8 1'-0'' 03 Academic ProjectProfessor: Hart Marlow

Location

Williamburg Brooklyn, New York

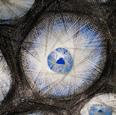

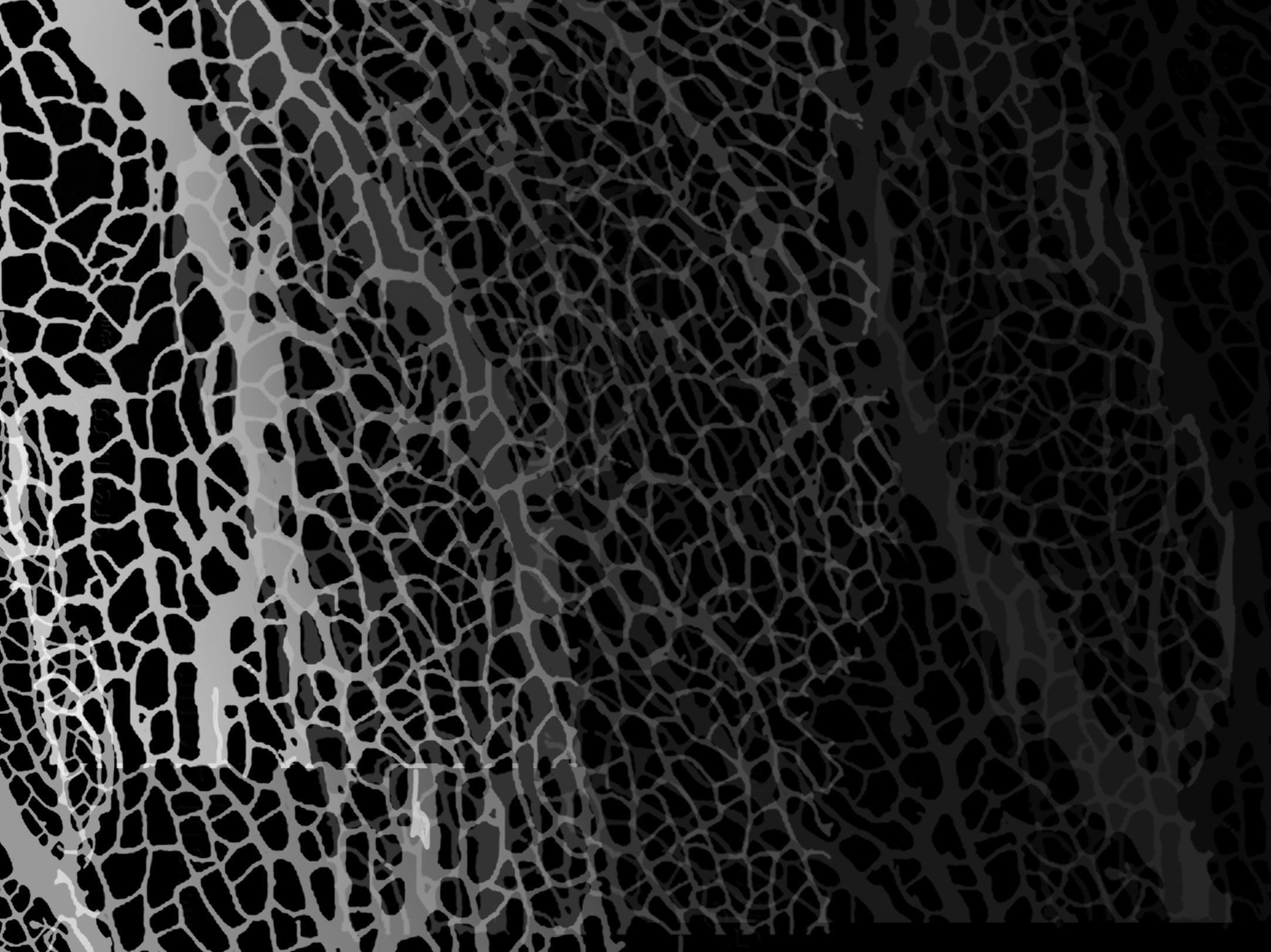

RESEARCH COMPONENT FOR FABRICATION

MATERIAL INTENT

Connecting surface Core

Lifted Surface

Secondary structural support-Arch

Primary structural support-Columns

Fiber cloth or Carbon fiber + acrycliic 3/32 or acrylic

PLA or 1/16 in acrylic

Black concrete

Mold in resin

-Milling surface - resin application

- fiber cloth application

-Paper patter inside the molding surface

RESULTS

-Exploring internal structure material scale and strenght

-Exploring material Color and pattern flexibility

-Exploring material trans-

-Heat shaped acrylic on mold - two layers - black and whyte

-Heat shaped acrylic on the mold - White

FINISH POSSIBLE MATERIALS

Casting piece- A MDF 16''x 16'' x 6-1/2'' Casting piece- B MDF 16''x 16'' x 6-1/2'' Casting piece- A + B MDF 16''x 16'' x 6-1/2''

Circulation

ACTIVITIES

- Communal gatherings

- Public performances

- Seating

- Relaxing

Plan esc1/8 1'-0''

EXPLODED AXON

Elevation South

esc1/64 = 1'-0''

Elevation East

esc1/64 = 1'-0''

Elevation North-

esc1/64 = 1'-0''

Elevation West

esc1/64 = 1'-0''

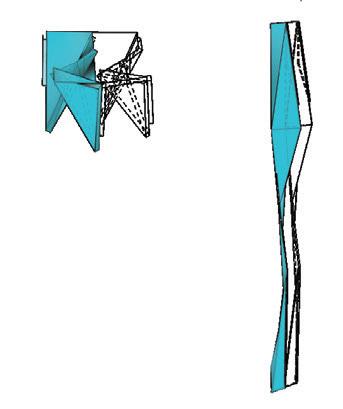

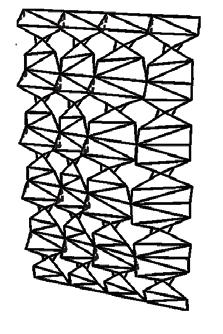

DESIGN PROCESS 2D-3D

SHARP & SNAPPY C Original piece step 1 step 2 step 3 step 4 add + scaled up cut + rotate segment Rotate Darting Cutting Seaming Folding Step 1 add + scale up Step 2 add + scale up Rotate STAGE 2 Rotate Step 4 Rotation FINAL STAGE Repetition + Controlled Scaling STAGE 1 Mirror INITIAL PIECE

ARCH

Presented by: Pablo Zuluaga Morelo

3690 Presented to: Prof. Marllow + Sitkas

STAGE 1 STAGE 2 FINAL STAGE repetition + controlled scaling STAGE 13d interpretation of gatehering STAGE 23d interpretation of pinching STAGE 23d interpretation of pinching

STANDARD HOTEL (solar

screen)

THE CHALLENGE...

As it happens in the majority of buildings, the hotel has a great energy consumption when trying to cool down the inside. The fact that it has a glass enclosure, increases the sun exposure in the rooms. Overcharging the capacity of the cooler system.

THE SOLUTION...

It was developed a sun screen to shade the sunlight and also an element that was permeable enough to allow the appreciation of view from the rooms.

Location 848

Washington St, New York,

Little W12th St Washington St

High Radiance Low Radiance +Section Section Section 05 Academic ProjectProfessor: Bryan Ringley + Zack Downey

INDEX OF PANELS APERTURE

Population final result axis X Y X ( 1 ) Y (20 )

Initial

Irradiation Summer

population

3rd Stage

2nd Stage

1st Stage

With the aid of high end software such as Rhinoceros and plug-ins (Grasshopper and DIVA). We were able to adapt the screen in such a way that the light could still enter during the winter time and shade from the intense summer sun.

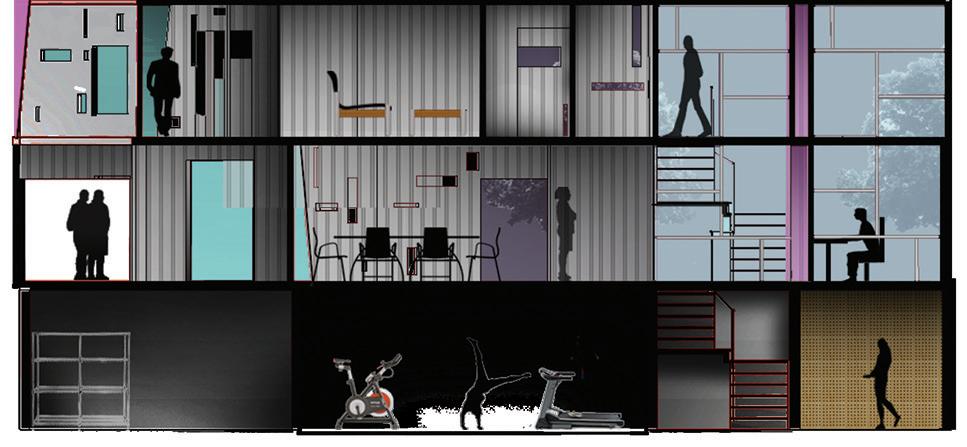

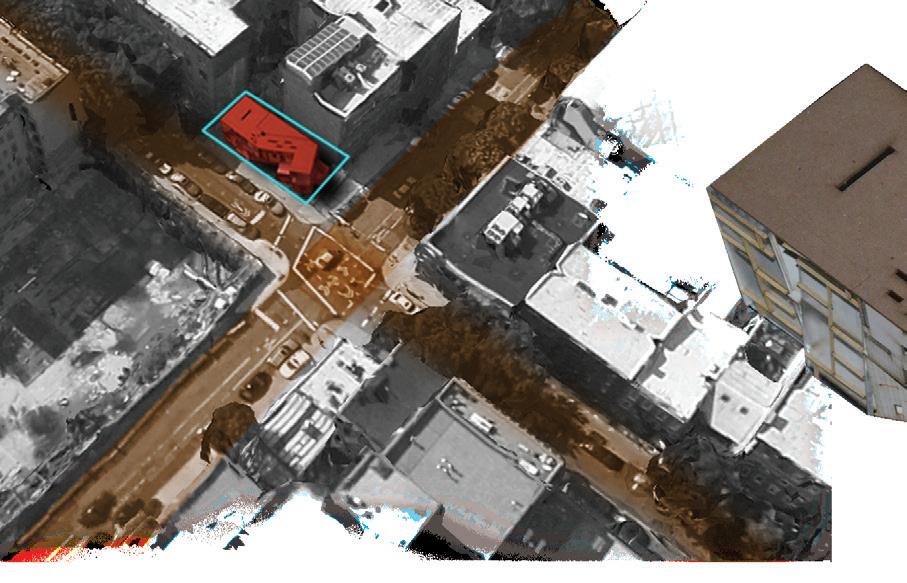

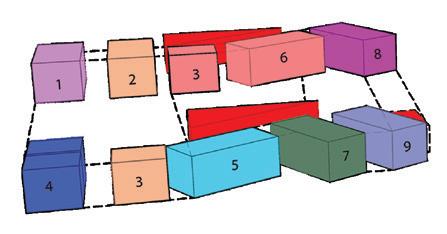

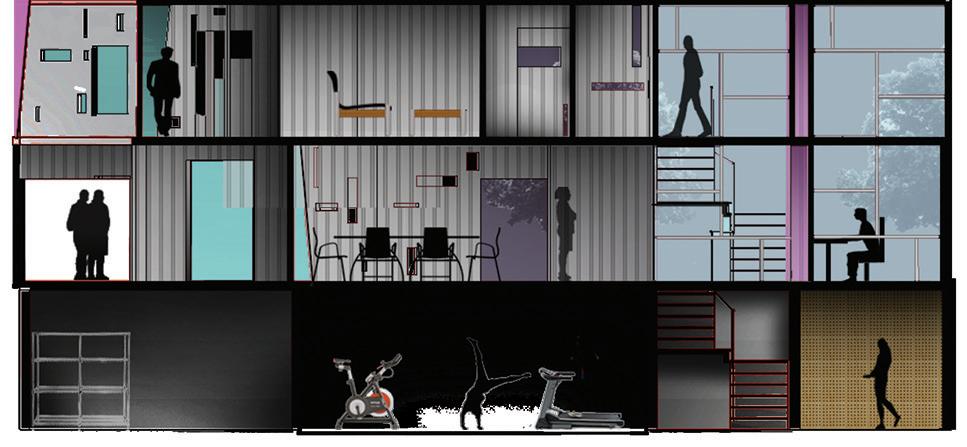

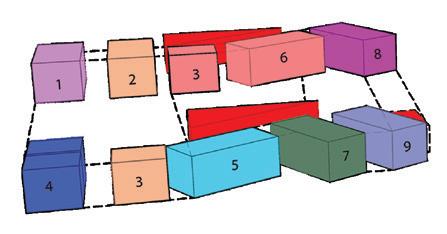

THE CONTAINER HOUSE

THE CHALLENGE...

First of all, NO more than 50% of the long side of the containers could be taken off. And second of all, very specific areas such as modeling room, sound proofing room and an open concept kitchen were needed on the program.

THE PROPOSAL...

This project needed to satisfy the housing requirements of a family of 5 beings (2 adults + 2 kids + 1 dog), and also, the reuse of 9 shipping containers was the primary requirement construction material THE SOLUTION...

The shipping containers were rearranged in a manner where the busiest part of the massing was on the back (1+2+3+4) fig.1 and the less congested on the front facing Boureum place street (6+7+8+9)fig.2. All, with the intention to reflect the activities of the parents. Where the father was a busy anchorman (back) and the mother was a copy editor (front.)

In order to stay within the requirements container 3 and 4 were divided into halves and then relocate to create other sections

Inside

Length: 20’

Width: 7’-8”

Height:8’-10”

Outside

Length:20’

Width: 8’-0”

Height: 9’-5” of the house without affecting the integrity of the container.

SHIPPING CONTAINER DIMENSIONS

fig. 2 fig. 1

fig. 2 fig. 1

Location 242

25’x 75’ Pacific

Boureum Pl

Pacific Street, Brooklyn

St

06 Academic ProjectProfessor: Jill Borotauglu

3.

Cellar 1.

Boiler

2. Storage

Gym

4.

Music Room 1st Floor 1. Backyard 2. Kitchen 3. Dinning/ reading area 4. Modeling room 2nd Floor 1. Masterbedroom

1 2 3 4 1 2 3 4 4 3 2 1 CELLAR 1st FLOOR 2nd FLOOR 1 6 8 9 10 7 2 5 3 4 Section 1. Storage 2. Gym 3. Music room 4. Modeling room 5. Dinning room 6. Kitchen 7. Backyard 8. Master bedroom 9. Living room 10.Daughter’s room West elevation Section a-a’ North elevation a a’

2. Balcony 3. Living room

4.

Daughter’s room

THE BURGUER PLANT

THE CHALLENGE...

The primary concern about this project were the dimensions of the site. It was a very awkward triangle shaped lot at 1 Boureum place in Brooklyn.

1 Boureum Place, Brooklyn

THE PROPOSAL...

A vegetarian hamburger local was proposed, with the advantage that it will have most of their vegetables harvested in the store, thanks to a hydro phonic wall. With the meaning of having a constant and fresh product type

Location

Fulton St

Lot size a b c a: 85’ b: 24’ c: 86’ 07 Academic ProjectProfessor: Jill Borotauglu

Boureum Pl

1.Boiler 2. Storage 3. Bathroom 4. Elevator 5. Kitchen 6. Employees only BASEMENT 1. Boiler 2. Storage 3. Bathroom 4. Elevator 5. Kitchen 6. Employees only 1 2 3 6 5 4 Cellar 1 Section 1. Seating area 2. Dumbwaiter elevator 3. Service area 4. Boiler room 5. Storage 1 1 1 2 3 5 4 6 7 1 1 8 6 6. Elevator 7. Kitchen 8. Employees

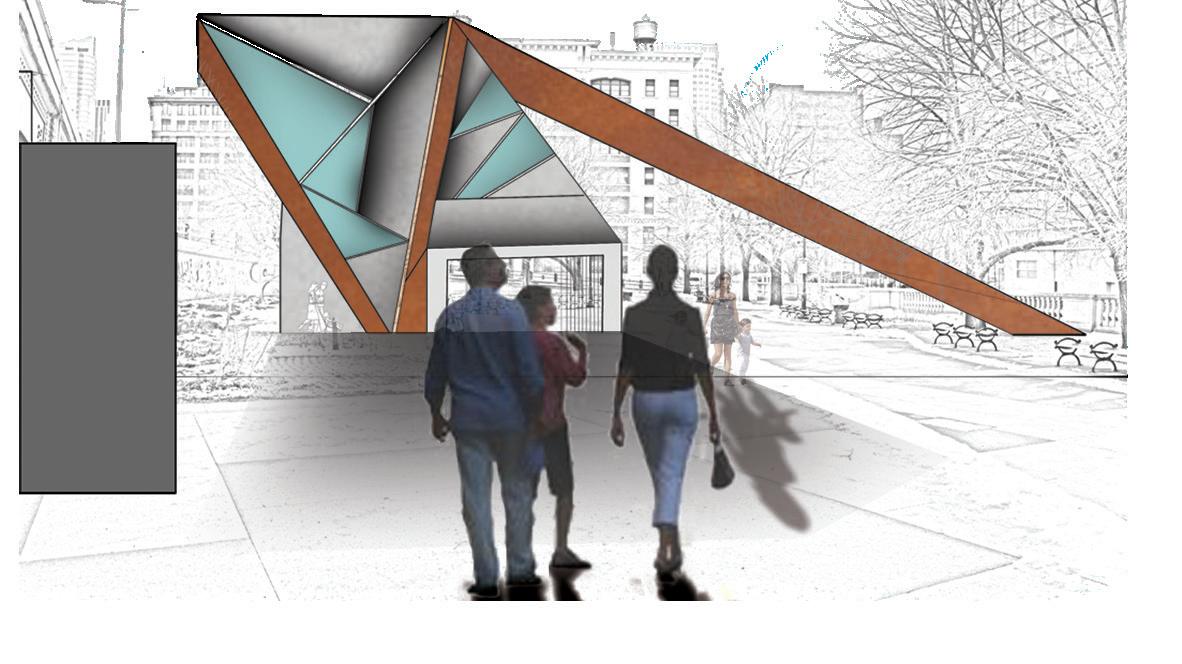

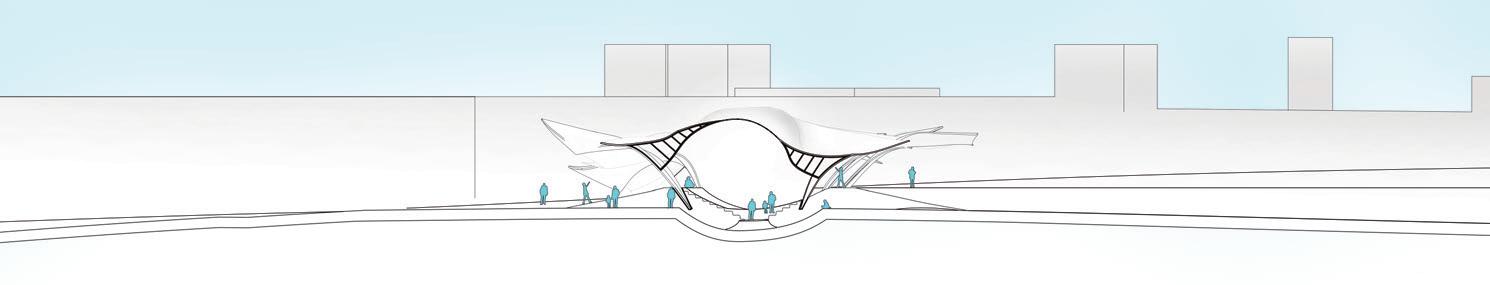

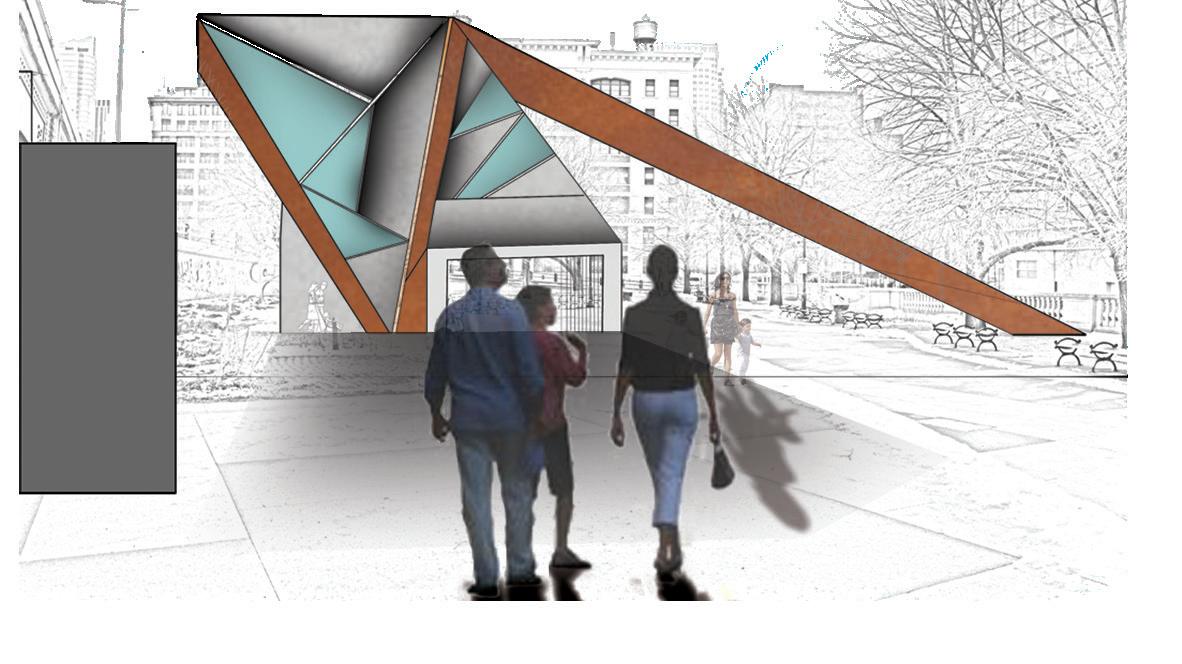

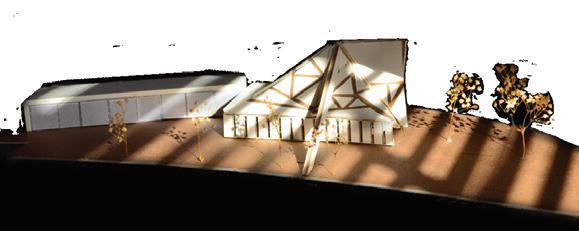

THE BROOKLYN PAVILION

THE PROGRAM...

What is happening in Brooklyn, where to go, what are the best places to visit and most importantly how can we get to each of these places are the questionsnewcomers have when they come to brokyloklyn. Therefore, an information pavilion was designed. The transportation was solved through a bike sharing program, and later a snack stand and bathrooms were a added.

THE CONCEPT...

Starting from the triangular shape of the huge white trusses that bring structural support to the bridge. The sense of grandeur given by this structural feature was what it was wanted for the pavilion’s over all image

Location 180 Jay

Street, Brooklyn Jay St

Section Perspective (a-a’)

08 Academic ProjectProfessor: Tim Maldonado

Manhattan Bridge

General Plan

2 1

1. Information booth 2. Snack stand 3. Bathrooms 4. Bike rack

fig. 2 fig. 1

fig. 2 fig. 1