Edition 5 / October 2022 // PROJECT DRIVESAFE Keeping our drivers safe, no matter the terrain. // WORKWEAR FIT FOR WOMEN Gender shouldn’t be a trade-off for comfort on the job site. // CONNECT WITH A BLACKWOODS TECHNICAL SAFETY SPECIALIST

TAKING SAFETY TO NEW HEIGHTS

Falls are one of the most common causes of serious injuries and deaths in the workplace. Therefore, it is essential that employers have effective safety measures in place to reduce the risk for their employees.

WOMEN’S FOOTWEAR THAT’S ON POINT

Anatomically, there are several differences between men and women’s feet. Adopting a “one size fits all” model and providing smaller sizes of men’s work boots for female employees, is not appropriate safety footwear solution.

MORE THAN MEETS THE EYE

Eye injuries in the workplace are common, but they’re also easily avoidable in the majority of cases. Therefore, ensuring employees are wearing the approved eyewear for a specific workplace is crucial.

THE CHANGING FACE OF RESPIRATORS

Respiratory protection is a necessary part of many jobs, throughout many different types of industries, with several options available for consideration, depending on the environmental contaminants.

2 Edition 5 / October 2022Safety Spotlight

04 1412 28

// KEEPING SAFE WHEN THE HEAT TURNS UP

Australia can be a harsh country. With its diverse climates and terrains, working conditions can present as some of the most challenging in the world. Not to mention, dangerous.

Heat stress can be a major health hazard for workers who are exposed to the elements or work in high temperatures. In view of this, employers have a duty of care to ensure their staff are safe from dehydration and sunburn.

Our bodies are comprised of 60% water, and dehydration occurs when you lose 1% or more of your body mass in fluid through sweating and other bodily functions. This can adversely impact mood, memory, vision and motor performance.

What this translates to is an increased risk of injury and accidents in the workplace and lowered productivity. A 2% loss of fluids can result in a 50% decrease in work performance. More severe dehydration can be fatal.

In addition to water, we need electrolytes to stay hydrated. The body functions by sending electrical impulses from and to the brain. Electrolytes are chemicals that help conduct these signals. Through sweating, we lose electrolytes, and this can interrupt the impulse transmission and homeostasis in our bodies, leading to fainting, seizures, and inadequate hydration.

A good solution is to provide your team with electrolytes on the go. Sqwincher offers a range of low-cost, low-sodium electrolytes that come in concentrates, powders, and ready-to-drink forms so workers can easily stay hydrated throughout the day.

“Workers wouldn’t think twice about the use of Personal Protective Equipment (PPE) when entering a worksite. So, it’s important an effective hydration plan is part of your PPE. It can mean the difference between life or death,” says Brad Houlihan of Pryme Australia.

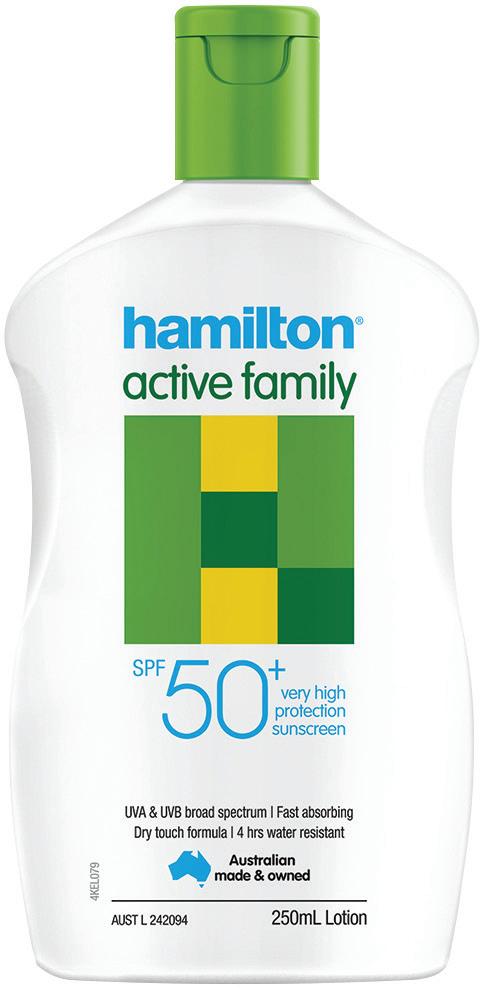

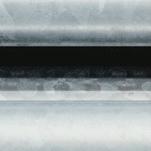

Sun protection is also essential for outdoor workers. Australia has the highest rate of skin cancer in the world, so providing PPE like hats, long-sleeved shirts and sunglasses is necessary, but even then, sun reflection and its ultraviolet light (UV) can do irreversible damage, even on a cold day. That’s why sunscreen should be an essential part of PPE. Hamilton has been making sun protection products specifically for Australia’s harsh climate for 90 years. Products within the Active Family or Sensitive SPF 50+ ranges such as the Hamilton Active Family 110g Tube gives strong protection but is still lightweight, dry-touch and fast absorbing.

Sunscreen cannot be effective if workers won’t comply because it’s sticky or hard to apply. So, we’ve taken particular care in supporting individual and business preferences, such as ‘workers own smaller tube’ or ‘business large pump packs’.

If your workers are consistently exposed to high heat, make sure you’re taking measures to keep them safe so they can keep a cool head on the job.

Always read the label and follow the directions for use. Reapply sunscreen frequently and wear protective clothing, hats and eye wear when exposed to the sun.

FOR MORE INFO.

Or contact your Technical Safety Specialist

3ASSESS | INFORM | EQUIP

CLICK

TAKING SAFETY TO NEW HEIGHTS

IT’S TIME TO UP THE ANTE ON FALL PREVENTION.

When working on a temporary platform, it’s easy to take shortcuts; not bothering to connect a safety harness because it’s ‘not that high’… ‘no one’s looking’… and even forgetting to tether a tool. But these simple behaviours can have terrible, and often fatal, consequences.

Working at height is a major safety hazard. Safe Work Australia’s 2021 Safety Report noted that in 2020, falls from height were responsible for 11% and being hit by a falling object for 9% of workplace fatalities. That’s 39 lives lost to preventable accidents in one year alone and 122 lives over the last five years.

While the Hierarchy of Controls and appropriate equipment, processes and training are there to be used when working at heights, they’re only effective to a point. In order to save lives, we need to look at the ‘culture of safety’ in the workplace.

Instilling a habit of safety from the top down and making this company ethos and policy, is essential to ingraining a safetyoriented company culture. But simply dictating down won’t get workers onsite to comply with procedures. They need to be included in the conversation about safety policy from the start and contribute from firsthand experience. This will make them more likely to follow these procedures and encourage others to do so, on the job.

Ricky Gleis, National Fall Protection Specialist from Honeywell, understands the importance of business-wide cultural change. “Changing the culture around working safely at heights cannot happen in a simple training session. It takes clear business processes, to firstly acknowledging existing behaviours around complacency, then subsequently use ‘influencers’ in the business to continually encourage, promote, and sustain a change in safety culture. It’s also about involving those who have skin in the game, such as workers themselves. This will support company-wide behavioural change.”

Once the core value of safety is established in a company’s culture, safety equipment and Personal Protective Equipment (PPE), are more likely to be used at all times and in the correct way.

From an Engineering Controls standpoint, there are many safety measures that can be taken to minimise fall risks. Examples are fall prevention devices like scaffolds, perimeter guard rails and safety mesh, as well as fall arrest systems like catch platforms and safety nets.

From a Personal Protective Equipment standpoint, there’s Fall Protection, such as harnesses and fall arrestors to keep the worker tethered to an anchor point, and tool lanyards to keep tools and equipment tethered to the person.

If a worker misses a step, slips on a wet surface, or in the case of being lowered into confined spaces, loses consciousness due to lack of oxygen or noxious gas inhalation, the Fall Protection equipment is the piece of PPE standing between them and loss of life or serious injury. And in a confined space situation, this is also a main piece of the rescue procedure.

“Choosing the correct harness for the task is essential, but equally important is the selection of supporting equipment, anchorage points and a rescue procedure. For tasks involving confined spaces the pre-work assessment process takes on even more critical importance. Reference should always be made to ensure compliance with Standards and Regulations, as well as the relevant Codes of Practice, to assist in performing the work at the highest level of safety,” says Nick Stinziani from MSA.

4 Edition 5 / October 2022Safety Spotlight

On the other hand, lanyards for tools protect the other workers on site. A tool falling from a height can have dire, if not fatal, consequences on the unlucky person below. The use of these type of PPE is not only about keeping the wearer safe but their teammates safe as well.

“In support of fall protection systems, a Drops Free Zone must be created. It’s not just about the cleared space below the work area, it’s how your tools are managed whilst in operation. As indicated by Safe Work Australia, any at height operations above two metres, requires proper tools tethering. Approved systems are invaluable and do save lives,” says Brad Houlihan, Sales Director from Pryme.

Pilots, when they experience an emergency in the air, have an Emergency and Abnormal Checklist. The co-pilot will pull out the book and go step-by-step through each action the pilot must take to handle the crisis. This may seem a clunky way to do it, but what it does is eliminate human error brought on by panic, fear, exhaustion, and bad decision-making.

So too, in industry, there should be fail-safes against human error, and these are visible safety procedures, Safe Work Method Statements (SWMS), and ongoing training on how to use them until a pattern of safety behaviour becomes established, second nature and muscle memory.

“With all specialised operations, competent training must be conducted on the correct use of a safety harness,” says Johnn Panlilio from 3M. “No two are the same as there are specific harnesses for working at heights and confined space applications.”

Ricky went on to say… “Good product training can only support positive cultural change in any business.”

Earning a living to support yourself and your family should not come at the cost of your life. Business owners, managers, safety officers and workers themselves all have a duty of care to ensure everyone clocks off safely at the end of the day. Where human error fails, safety procedures, training, equipment, and PPE need to have your back.

CLICK FOR MORE INFO. Or contact your Technical Safety Specialist 5ASSESS | INFORM | EQUIP

SAFETY MADE GOOD, EVEN UNDER PRESSURE

The humble aerosol can is a reminder that, when it comes to safety, we should not take anything for granted. Did you know the aerosol can is deemed a Class 2 Dangerous Good?

Aerosol cans may contain hazardous substances such as adhesives, paints, and varnishes that can all be harmful if their vapours and/or gases are inhaled. If aerosol cans are placed under pressure, the results can be disastrous, as the cans can explode or even become projectiles. Accidents can happen all too easily. For example, you are taking a risk if you leave an aerosol can too close to a heat source such as a barbeque, or in a vehicle on a hot day.

This all poses important questions:

HOW SHOULD AEROSOL CANS BE STORED?

It’s important to store aerosol cans inside dedicated cages with perforated walls to deliver natural ventilation and away from direct sunlight, ignition sources, and machinery. It’s also important storage cages are manufactured to meet the requirements of AS/NZS3833:2007, which applies to the storage and handling of mixed classes of dangerous goods, in packages and intermediate bulk containers.

Spill Crew aerosol cages provide projectile protection in the event of a workplace fire. “Our high-quality range are used across many industries from small workshops and mechanical garages… to mine sites and large manufacturing facilities,” says Michael Carrigg, General Manager, Spill Crew Australia. “They’re robust, lightweight and easy to move… as well as lockable, enabling an extra layer of security and inventory control.”

WHY YOU SHOULDN’T STORE AEROSOL CANS IN A ‘DANGEROUS GOODS’ CABINET

Flammable liquids storage cabinets are specifically designed to safely store flammable liquids and prevent the entry of flames into the cabinet, preventing the spread and escalation of a workplace fire. So, it’s particularly important to never use flammable liquid cabinets to store aerosol cans, as dangerous vapours can be trapped inside by air-tight doors. “We understand only too well the dangers surrounding the handling and storage management of aerosols. That’s why our cabinets are specifically designed and built to comply with Australian Standards requirements,” says Michael. “We manufacture locally at our Melbourne manufacturing plant to suit varying Australian conditions. We’re also able to modify our products to meet our customer’s needs and site requirements.”

6 Edition 5 / October 2022Safety Spotlight

Other features include: • Heavy duty, powder coated steel • Solid steel roof and floors with bolt down plates • Appropriate warnings and safety signs

Cans can

also

explode and rupture if they are pierced or dropped, affecting the can’s structural integrity.

CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

// KEEPING A FINGER ON THE PULSE OF SAFETY DEVELOPMENTS

When the Sydney Harbour Bridge was built back in 1932, 16 lives were lost to accidents during construction. Thankfully, workplace health and safety has come a long way since. Particularly in the last twenty years, technological developments have spurred and enabled increasingly smart and effective safety gear to be designed to keep pace with the modern workplace.

One PPE item that has seen major improvements is gloves. In 2016, glove standards were reviewed to improve their protective function, as well as allow greater dexterity and comfort. Ansell has a firm grip on these changes. They use knitting technology that employs a mix of engineered, synthetic and natural fibres to design gloves that offer high cut resistance, touchscreen capability and protect the skin.

“As technology and workplace conditions have evolved, so too have the materials and designs of Ansell’s wide range of safety products,” says Theo Oostveen, Product Portfolio Manager of Ansell Ltd. “High-end comfort and safety performance remains a priority across a number of key areas.” These include…

CUT RESISTANCE

The new EN 388 mechanical protection standard provides a more accurate cut resistance rating than its predecessor. Where gloves were previously measured for abrasion, tear, puncture and cut resistance, they now go through two cut resistance tests. This is because the circular blade of the original test could become blunted on the glove material and affect measurements. The new cut resistance rating ranges from A (minimal) to F (extreme).

TOUCHSCREEN CAPABILITY

As technology advances, more touchscreens are being incorporated into devices, equipment, and machinery, making touchscreen capable gloves essential for worker safety. There are two categories of touchscreens –resistive and capacitive. The former can be operated with most flexible gloves. When it comes to capacitive, however, gloves need a conductive coating or to be made from fabric with a conductive thread. It’s important to note that ESD and anti-static gloves aren’t suitable for either category of touchscreens.

SKIN HEALTH

Finally, gloves need to be breathable and hypoallergenic, so they don’t cause harm to the user in terms of allergies or skin health issues.

Theo went on to say… “As always, worker safety remains our priority, thus our product selection service is there to ensure safety requirements are met, no matter what new challenges arise.”

If it’s time to update your glove compartment, take a look at Ansell’s range of ultra-light, comfortable and strong protective gloves.

7ASSESS | INFORM | EQUIP CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

WORKWEAR FIT FOR WOMEN GENDER SHOULDN’T BE A TRADE-OFF FOR COMFORT ON THE JOB SITE.

You can’t perform at your best when you don’t feel comfortable with what you’re wearing. Wearing ill-fitting clothes and not having the correct work uniform can make you feel uncomfortable and out of place; and this is just as prevalent on the job site.

In trade professions, physical tasks demand that you be mobile, agile, and not restricted by your apparel. Plus, having the same workwear as your colleagues allows you to feel a part of the team and gives you a sense of belonging. Yet women’s workwear in the trade industry has often fallen short.

With the recent pandemic and a dire skills shortage across the board, an increasing focus is being placed on recruiting and supporting women as they transition into trade roles. Not only does greater female representation across the trade industry across job sites and offices help reduce a staffing gap, but concrete evidence suggests that having more women on the team increases an organisation’s productivity, profitability and improves workplace culture.

A study by Workplace Gender Equality Agency (WGEA) and Bankwest Curtin Economics Centre (BCEC) looked at 4,841 reports submitted by Australian businesses capturing the data of roughly 4.3 million employees. The results showed that an increased share of 10 percentage points of top-tier female managers led to an increase of 6.6% in the market value of ASX-listed companies – which equated to around AUD$104.7 million.

Another study conducted by McKinsey & Company showed that companies that had greater workplace gender diversity were up to 21% more profitable. Yet, in the male-dominated trade industry in Australia, women make up only 2% of the workforce.

To help reduce the diversity gap and encourage women to consider a career in trade, state governments across Australia are implementing plans to support access to training and encourage women to stay in the industry long term. In 2020, the NSW Government announced it was launching a Trade Pathways for Women program to offer supported and accessible pathways to trade careers for women and improve their access to training with fee-free options.

The Victorian Government, with the help of the Building Industry Consultative Council (BICC), has launched the Building Gender Equality: Victoria’s Women in Construction Strategy 2019-2022. This will mandate that state construction projects have female representation in at least 3% of trade roles, 7% of non-trade roles and 35% of management, supervisory or specialist roles. High-level changes like these are a great step in the right direction, but how do we help promote gender equality in the workplace on a more individual or company level?

Dr Phillippa Carnemolla is a Senior Research Fellow at the University of Technology Sydney, who studied female high school students’ perceptions of the construction industry. She points to the need for female role models in leadership positions, better career guidance in schools that show trades as a viable option for women, and for leading companies to reform their company culture to be more inclusive.

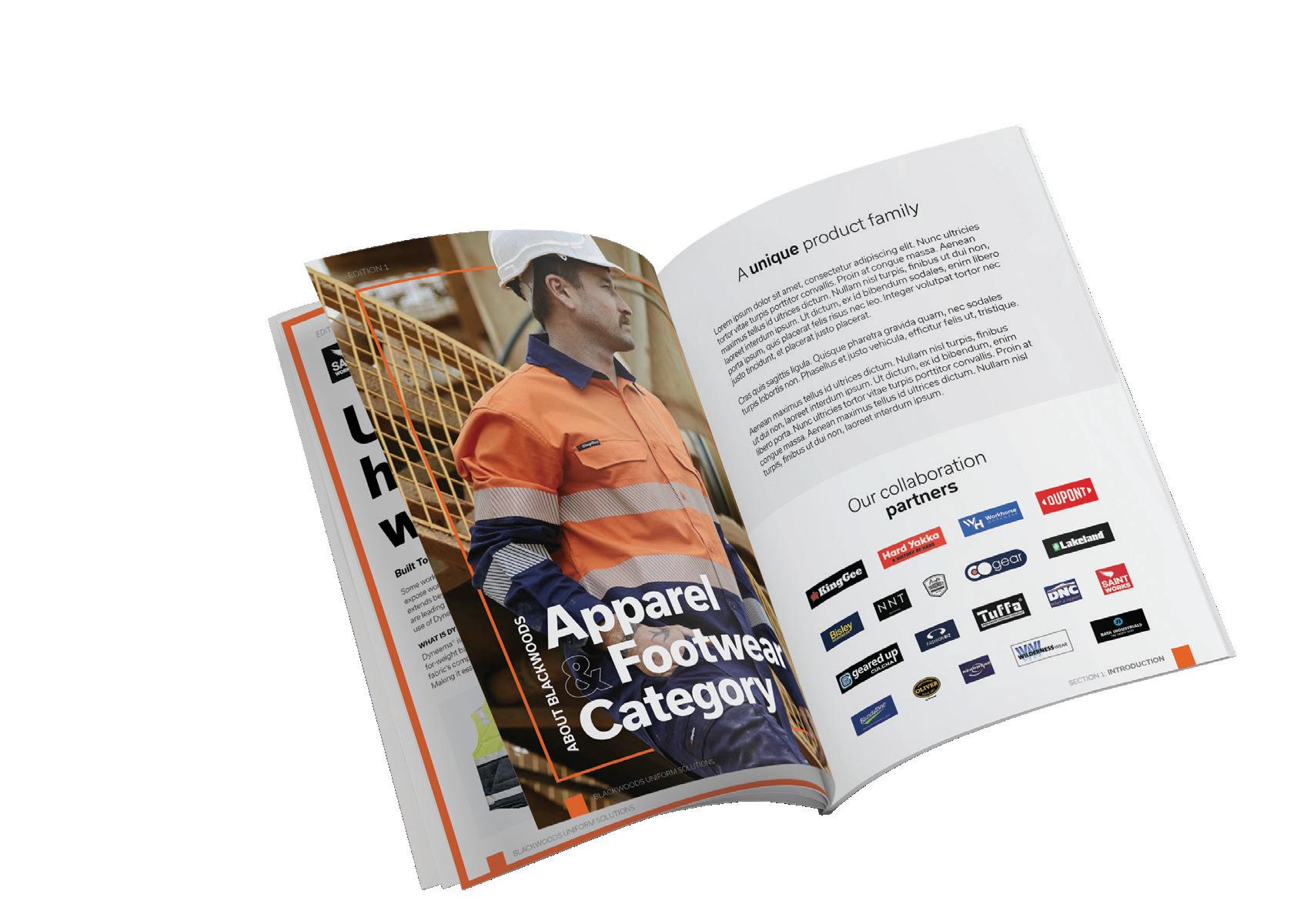

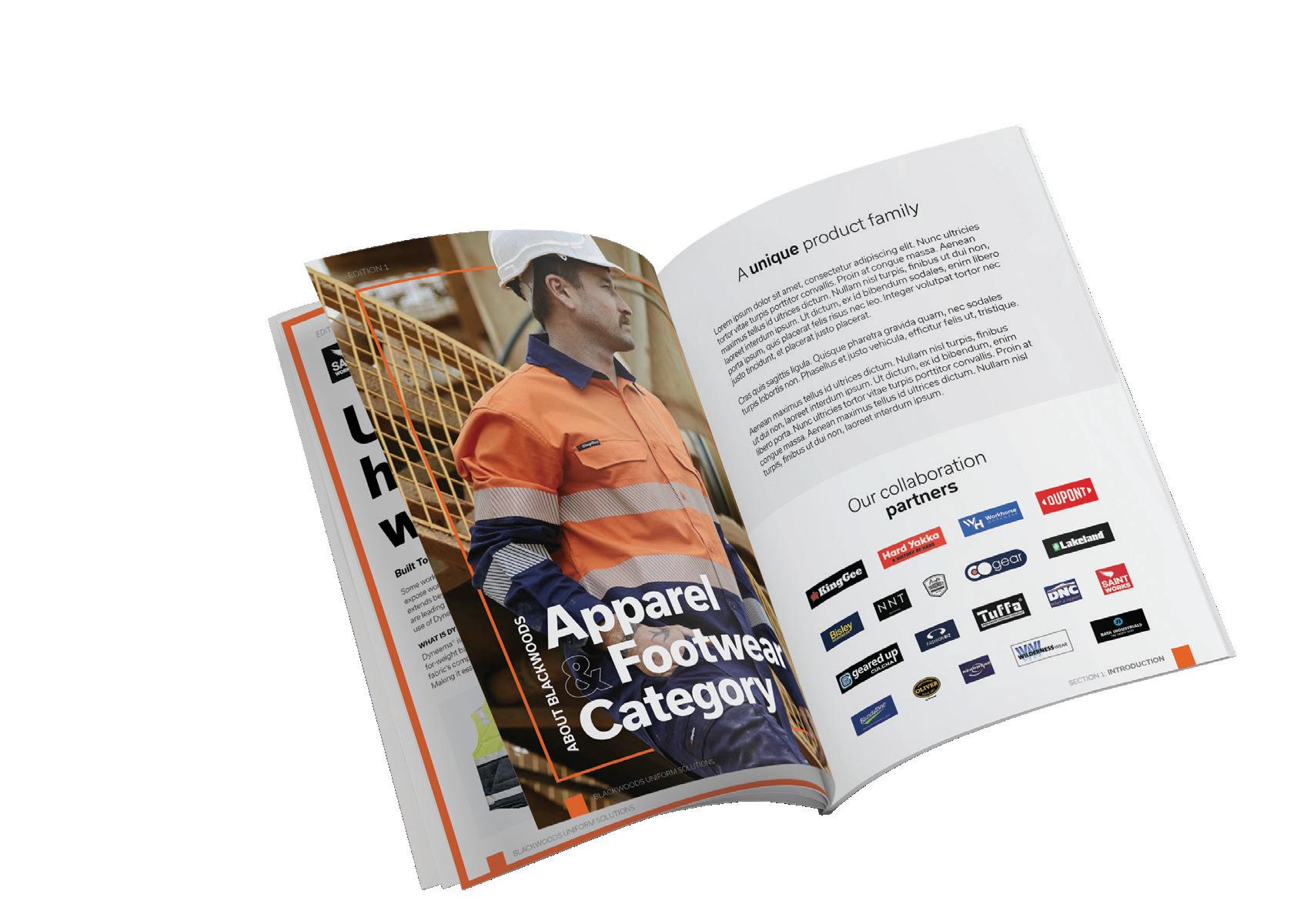

A simple way that women can feel more included and comfortable on the worksite is to have fit-for-purpose apparel. A company leading the way in developing specific workwear tailored to women is Workwear Group, across both their KingGee and Hard Yakka brands.

Safety Spotlight

8 Edition 5 / October 2022

“We recognise women are becoming an integral part of the industrial workplace, as such makes complete sense to have the right apparel and footwear to suit individual needs, irrespective of gender,” says Peter Allery, National Sales Manager (Safety), Workwear Group.

“Each brand has reviewed their range of workwear and high visibility clothing, to design them for women’s figures and take into consideration comfort, fit and covering modesty areas effectively. This means female tradies can get stuck in and feel confident and at ease on the job site,” says Peter.

KingGee has committed to ensuring there is a female equivalent of every male garment in their range. New features include:

• New pants in two cuts to suit different body types (straight and curved)

• A women’s style in the fleece and puffer jacket range

• A new stretch denim style to accommodate fit and boot height

“At Blackwoods, we’re conscious of the ever-changing face of the construction, infrastructure, and mining industries. It’s terrific to see gender parity in apparel and footwear, is now a reality. It not only means greater comfort and inclusion for women, it’s also about greater productivity on the job site,” says Leigh Eam, NCSM - Apparel & Footwear, Blackwoods. Whether you’re on the job site, in the office or on the road, every team member should feel safe, included and part of the team. While there is a long way to go to get to gender parity in the trade industries, getting women the right workwear is a first step towards a more equal and balanced workplace.

CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

9ASSESS | INFORM | EQUIP

HI-VIS

IMPROVING HAND PLACEMENT AND AWARENESS

It’s time to put your hands up and say: ‘I want to be seen by others, and I also want to see myself.’ If that applies to you in the workplace, the new PROSAFE Kashi General Purpose Work Gloves can help.

The need for workers to be visible in hazardous workplaces is fundamental to worker safety. That is why we see more and more workers wearing Hi-Vis clothing, which is often PPE, in all sorts of situations. Wearing suitable gloves is part of the safety solution, whether it be in mining, construction, firefighting, emergency rescue, traffic direction, dirty or low light environments, or many types of work in general.

One of the biggest benefits of Hi-Vis gloves is ‘hand placement.’ The glove wearers know exactly where their hands are, as do their colleagues who are working with them. To be seen, is to be safe. This is relevant in many workplace situations, including when using machinery or high-impact tools such as hammers. “It’s the very reasons why we’ve developed the Kashi Hi-Visibility Work Glove. It’s critical in the prevention of accidents and injuries in the workplace. They also allow HSE (Health, Safety & Environment) team members to easily see that workers are wearing hand protection,” says Nic Williams, Own Brand & Product Development Manager.

The PROSAFE Kashi General Purpose Work Gloves include:

• 15 gauge seamless Hi-Vis yellow knit liner

• Hi-Vis yellow foam nitrile pam coating that enables grip durability and abrasion resistance while also allowing touchscreen compatibility, reducing the need to take gloves off to use devices. Nic went on to say… “Whatever colour they are, all work gloves should be fit-for-purpose, providing the user with the right balance of protection and dexterity to properly complete the task or application without needing them to be removed.”

“The new PROSAFE Kashi gloves are perfect for light-duty material handling, assembly, maintenance applications or any tasks that require extra grip and agility whilst helping keep hands clean and visible.”

FOR

contact your

Safety Specialist

NEW KASHI

GLOVES,

Edition 5 / October 2022Safety Spotlight

CLICK

MORE INFO. Or

Technical

MAKING SOUND DECISIONS THE RIGHT HEARING PROTECTION

Noise-induced hearing loss (NIHL) affects 4,700 Australians a year and is a major yet preventable workplace hazard, resulting in 11% of occupational disease claims.

It’s essential to control potential hearing damage due to noise in the workplace. An obvious step would be to eliminate or substitute the source of noise, but this isn’t always possible. Another option is to separate the source of noise from workers. When noise can’t be avoided, choosing the right PPE and personalising it for each worker is key.

The first step is to determine the hearing protection class needed (rated from 1 to 5). The next step is to assess the job type, length of exposure and consider what other PPE the worker wears. The third step is to choose what is comfortable and convenient based on personal characteristics like earrings or long hair to determine whether earplugs or earmuffs are the right fit.

CLICK FOR OUR EASY GUIDE. Focus on Hearing Protection

WARNING

Employers must provide suitable hearing protection equipment where noise exceeds 82 dB(A)

DEAN ANDERSON

TECHNICAL SAFETY SPECIALIST - QLD

Having spent seven years in Mackay before transferring to Brisbane to be closer to family, Dean has now clocked up over a decade of experience in safety equipment, particularly in lifting and rigging and height safety.

“I think safety is a critical part of any business, no matter how big or small. I enjoy sharing my knowledge with the customer and the end user to help eliminate injuries.”

Dean’s appreciated by customers for his honesty and integrity. “I won’t give a solution for just a sale. I suggest the right product that will eliminate the safety risk. I won’t put anyone at risk, so I take it upon myself to ensure they have the right solution.”

He also sits on the safety committees of several large companies so is privy to the inner workings of customer operations. “This allows me to offer appropriate or bespoke safety solutions to clients. New technologies and innovation are key to the meet new challenges on a customer site.”

Short exposure causes moderate to severe loss. Wear hearing protectors.

Brief exposure can cause permanent loss.

When Dean’s not offering expert advice on respiratory, height safety and gas detection PPE, you can find him at the rugby field supporting the Brisbane Broncos, catching a movie at the local cinema, or spending time with his wife and 18-month-old boy.

GO TO PAGE 30 TO CONTACT DEAN.

11ASSESS | INFORM | EQUIP

30 40 50 60 70 90 100 110 120 130 140

Pain threshold

Threshold of hearing

Soft Whisper Conversation

Lawn Mowing

Construction

Jet Takeoff

82 dB 13YRS

WOMEN’S FOOTWEAR THAT’S ON POINT SAFETY AND COMFORT FROM THE GROUND UP

12 Edition 5 / October 2022Safety Spotlight

Were you ever forced to wear an older sibling’s hand-medown shoes as a child that never quite fit properly? Maybe they were that bit too snug, so your toes breathed a sigh of relief when you took them off, or a little on the loose side so your heel was rubbed raw every time you took a step.

You would know that it’s impossible to feel comfortable and confident when you’re trying to walk in someone else’s shoes. And it’s not safe either. You’re more likely to trip over your own feet or lose your footing and fall. Now imagine you were wearing those shoes in the workplace.

With more and more women entering the industrial and trade space, many things have started changing on the jobsite.

Having both men’s and women’s bathrooms is one such change that’s increased everyone’s comfort. Having a range of women’s apparel to suit a female form is another change that is essential for maximum productivity and safety.

Another key area is footwear. Did you know that in the past, much of women’s footwear used on the jobsite was just a smaller version of the male design? Many brands took work boots made to fit men’s feet and simply reduced the size and called them a ‘women’s range’.

Yet, according to a study on the differences between men’s and women’s feet, there are four foot-shape, five ankle and two calf differences between the sexes.

Women’s feet are generally shorter and narrower but have a higher arch than men’s feet. They have a larger ball to heel ratio meaning, unlike men’s feet, the heel is noticeably smaller than the circumference of the ball of the foot. A woman’s ankles are more flexible, meaning they are more prone to sprains and twists. The big toe is shallower, and the outer foot is shorter than a man’s.

Women also have a larger Q-angle – the angle from hip to knee – due to having wider hips than men. This puts pressure on the foot in a different way. Women’s feet tend to flatten out more with each step, leading to bunions, heal pain, calluses and tendonitis.

Things like pregnancy, the contraceptive pill and menopause also affect the risk of injury or pain in women’s feet and ankles. With all of this in mind, it’s very clear that one shoe does not fit all.

When you’re on the job site, you need to be comfortable, safe and free to move. And a big part of being agile and avoiding injury is the footwear you choose. Ill-fitting, cumbersome boots put pressure not only on your feet and ankles but on the rest of your body that has to compensate to stay upright and balanced in any situation.

That’s why it’s essential to have a safety boot that fits specifically to a women’s foot. One well-known brand is revolutionising women’s safety footwear. Oliver has created a range of safety boots designed based on the science and anatomical studies of women’s feet and how they move.

Their 49 range are moulded to women’s feet and provide boots that are tough, long-lasting, comfortable, and fit for purpose.

“At Oliver, we understand the that comfort and safety in the workplace is of the utmost importance. Ill-fitting footwear only adds to things such as fatigue, productivity, and risks to one’s own safety. That’s why we have developed a comprehensive range of women’s Safety Boots, for both light and heavy industries,” says Brett Huggins, Product Development Manager, Honeywell.

Safety starts from the ground up and wearing the right boots that are made for your feet and give you support on the jobsite is essential. Let’s leave those hand-me-downs in the past where they belong and make safety and comfort in footwear a priority for the whole crew.

your

13ASSESS | INFORM | EQUIP

CLICK FOR MORE INFO. Or contact

Technical Safety Specialist

CO-BRANDED EYE PROTECTION. MORE THAN MEETS THE EYE.

Ok, you are reading this article right now. That’s important, because, among other things, it is demonstrating how valuable your eyesight is to you. Just take a moment to think about the impacts that a serious eye injury (let’s hope it never happens!) could have on your life. In the literal blinking of an eye, your life could be impacted forever.

In the workplace a person is most likely to suffer an eye injury if they are not wearing compliant protective eyewear. So, the solution is common sense: make sure you wear approved protective eyewear that is most suited to your workplace.

Bollé Safety is a leader in providing compliant & certified protective eyewear in the workplace. As part of its services, it offers co-branding. This means customers can order Bollé Safety glasses that can incorporate the customer’s own company colours and logo on the lens.

“With a co-branded product, the company ensures the approved eyewear for a specific workplace is being used. Moreover, having great-looking, comfortable safety glasses that employees are not embarrassed to wear will increase the chance of them being worn, improving compliance, and reducing safety risks,” says Rimma Shabanova of Bollé Safety.

These glasses are available in four models:

In addition to the most important benefit of providing eye protection, these glasses enhance the appearance of workers and bring a consistency of company branding and presentation across the whole workplace.

“It’s a great way for a business to extend their brand identity beyond their own product or service and to encourage comradery among employees,” says Rimma.

14 Edition 5 / October 2022

RUSH+

RUSH+ SMALL SILEX+ SILEX+ SMALL

// STAY AHEAD OF THE GAME WITH CUSTOMISABLE HARD HATS

Of all the protective gear out there, the hard hat is one of the most important. Workers in industry, mining and construction can’t set foot on the worksite without one and for very good reason.

A SafeWork Australia report showed that from 2019-2020, there were 4,539 claims for head injuries. This highlights the importance of using high-quality head protection at all times. But a hard hat can do more than just protect. It can also serve to solidify brand identity and image and clarify roles on a jobsite. With the right customisation, hard hats can be both an advertising mechanism and organisational tool as well as an essential component of Personal Protective Equipment (PPE).

3M has been developing high-quality safety gear since 1972. Their hard hats are purpose designed with a shell and 6-point harness suspension system to offer optimal shock absorption and impact protection. “They’re Australian made and most are compatible with a number of add-on safety devices such as face shields, brow shields, and hearing protectors,” says Kevin McComb, Technical Manager Product Specialist Head, Eye and Face Protection portfolio at 3M.

If you want your team to look professional and uniform when facing customers or out in the public eye, as well as feel a sense of belonging when they get to the job, a branded hard hat speaks for itself.

3M’s hard hats can be branded with your company’s logo and/or labelled with specific job titles to make it easier to identify workers on the jobsite. “In emergencies, this serves as a useful communication aid to expedite response procedures,” says Kevin.

Their hard hats can also be fitted with reflective tape that is fully compatible with ABS (Acrylonitrile Butadiene Styrene) and polycarbonate materials. This increases the visibility and, therefore, safety of workers on shift at night or in dark areas like tunnels or mines.

Hard hats are an essential and unavoidable business expense, so it just makes good sense to get the most use out of them possible. Customisation and the addition of reflective tape turns the humble hard hat into a multipurpose and recognisable piece of worker attire.

15

ASSESS | INFORM | EQUIP CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

BIOMOTION IS NO LONGER A NICHE TERM.

IT’S NOW IN PLAIN SIGHT.

Working at night presents its own dangers. For example, think of road maintenance workers on a busy highway. But let’s not limit these dangers to darkness. In reality, such workers are also at-risk during daylight hours, particularly when visibility can be affected by such factors as rain or generally overcast conditions. No matter what time of the day, deaths and injuries happen. In a bid to further understand how workers can be better seen, an Optometry research team at the Queensland University of Technology (QUT) conducted a study relating to night-time road workers. They concluded that retro-reflective markers that are positioned in ‘biomotion’ configurations on clothing can significantly enhance the night-time visibility of road-workers. This, of course, can keep the workers safer, particularly in relation to being seen by drivers in passing vehicles and onsite work machinery.

Biomotion refers to retro-reflective markers, usually tape, being placed on a person’s clothing in a way that enables the movement of the person to be easily identified. Markers are usually placed in hoops in the following positions on the clothing:

• Slightly above elbows

• Slightly above wrists

• Either side of the knee joints

• Around the chest or waist areas

“Having reflective markers positioned in this way over standard vest configurations, amplifies visual movement significantly. In fact, by having them positioned both at the top and bottom of a workers’ uniform, makes clear the outline of the human body and the direction the worker is actually moving. This is particularly important on busy roads or fast laneways, where drivers are required to ascertain objects and make decisions quickly,” says Cahal Callanan, Blackwoods Own Brand, Product Development Manager, Workwear.

The Aust.NZ standards “Committee SF-004-03” has introduced the biomotion configuration into its standards concerning high visibility garments: AS/NZS 4602.1 2011. ‘Biomotion’ is no longer a niche or specialised term. “For Workhorse we consider Biomotion to be now part of everyday work and safety vernacular and practice, and we aim to continue to grow every workplace’s awareness of it,” says Cahal.

Biomotion will be implemented across the entire Workhorse range, including in New Zealand. Furthermore, it will be available in stretch material which ‘moves’ with the person, as opposed to gathering stiffly and segmenting on clothing. The use of such workwear is not restricted to night-use. As mentioned earlier, visibility of day-time workers can be hampered in various situations, and there are also many indoor and underground work environments where this is also the case.

16 Edition 5 / October 2022Safety Spotlight

As time moves on, we hope Biomotion will become the norm in many workplaces. Biomotion saves lives.

CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

‘KNOW SAFETY, WORK SAFELY’ OCTOBER IS NATIONAL SAFE WORK MONTH AND REMINDS US ABOUT THE IMPORTANCE OF HEALTH AND SAFETY IN THE WORKPLACE.

At Blackwoods, we’re proud to continue our support of Safe Work Month, as it aligns with our core business values and objectives, both externally with our safety product and service offerings, and internally with our four pillars of safety:

Partnerships, Presence Problems and Preventions - the 4P’s.

PROBLEMS

Our problem-solving activities have been centred around our introduction of the SAM (Stop Access Move) program. SAM encourages staff to think about ways to negotiate situations to avoid injury, no matter where our people are working – in the warehouse, the office or at a customer site.

PREVENTION

In terms of prevention, a major focus has been supporting our team members wellbeing and psychological fitness. We empowered all of our leaders across Australia with a wellbeing toolkit. “This toolkit included activities to support team members during COVID-19 lockdowns and provided multiple pathways for staff and leaders to seek support if required.”

PARTNERSHIP

Improving engagement in our Monthly Safety Leadership forums, has been one of our key focus’s. “Meetings are now structured to ensure every participant is contributing to the key agenda items of personal safety ‘shares’, incident learnings and celebrating success Whilst we have the safety lead team supporting the structure of these meetings, they are no longer a stand-alone voice.”

PRESENCE

The COVID-19 pandemic resulted in the HSW’s team presence being of the utmost importance, whether it be communicating Government Health directions, issuing training on prevention protocols, or creating robust tools to assist with something we have never seen before. “A great safety team in any business, is created through the eyes and ears of how our people are feeling. They will often be trusted advisors,” says Amanda.

CLICK FOR MORE INFO. And to download a campaign kit for your workplace

18 Edition 5 / October 2022Safety Spotlight

Every one every day goes home safe

//

PROJECT DRIVESAFE KEEPING OUR DRIVERS SAFE, NO MATTER THE TERRAIN

It’s a good feeling, to be just you and the open road without another soul for miles. In Australia, we have ample rural roads that stretch as far as the eye can see, but they can be treacherous. According to one study, between 2016 and 2019, rural roads in Australia saw 3,739 fatal accidents, which equates to 14 fatal accidents per week. These numbers are concerning, especially when you operate a business that consistently has workers driving long distances through regional areas.

At Blackwoods, we service industries all across Australia, which means many of our professional service people spend time travelling long distances in adverse weather and at times travel on unsealed roads. And if we’re going to preach safety, we have to practice it. That’s why we launched our DriveSAFE project to keep Blackwoods and sister company Bullivants drivers, safer on the road.

One aspect of the project was to upskill our drivers. We enlisted the services of Performance Driving Australia to conduct training over two days in Queensland and two days in Western Australia. “We are a preferred training provider for many large organisations across Australia - government, private business and the mining, oil and gas industries. Our mission is to safeguard road users by increasing the knowledge and skills of drivers, through superior driver training programs,” says Mark Butcher, Managing Director at Performance Driving Australia.

A total of 50 drivers were taught the necessary skills for driving in remote areas. The training covered aspects like advanced driving techniques, understanding the driving dynamics of 4WDs on and off road, towing trailers, driving on unsealed roads, tyre changing, the physics of emergency braking and more.

“It was important to me and the Executive Leadership Team to invest in external training and resourcing and give our team traveling in adverse conditions the skills and practical knowledge to stay safe on the roads,” says Amanda Haddad, Head of Health, Safety and Wellbeing at Blackwoods.

The next step was to understand the data our Telematics system fitted to all company owned vehicles was telling us. This data has given us insights into how we can further improve individual driver behaviours in three key areas:

• Speeding “hot spots” and trends through accurate GPS pinpoints

• Journey management planning through travel times and distance

• Driver reaction through harsh breaking and heavy acceleration

Telematics insights are utilised to host leader led feedback conversations with individuals about their driving behaviours and gives the team member the opportunity to correct their own approach to driving.

19

ASSESS | INFORM | EQUIP

OUR VISION FOR A BRIGHTER FUTURE SAFETY EYEWEAR SALES

HELPING OTHERS SEE

At Blackwoods, we’re committed to engaging with our local First Nations communities and organisations across the country, to make a meaningful difference in their lives and build a better Australia for all Australians.

Blackwoods and our team continue to do our part in supporting the goals of the Wesfarmers’ Reconciliation Action Plan (RAP - Elevate level) and contribute to helping build a more reconciled Australia. We do this by increasing

employment and career opportunities for Aboriginal and Torres Straits Islander people and partnering with Indigenous Australian owned and led suppliers and contractors, or those with a reconciliation and community engagement focus. But before there was even a RAP, we were (and still are) supporting The Fred Hollows Foundation.

Fred Hollows was an ophthalmologist and humanitarian who was appalled at the conditions in which Aboriginal and Torres Strait Islander Australians were living in back in the ‘60s.

“We cannot go on as a modern country living with this scandalous situation of Aboriginal living conditions in Central Australia.” Fred Hollows

Fred dedicated himself to the task of reducing the number of people that were going needlessly blind.

In Australia, there is an obvious gap between the eye health of Indigenous and non-Indigenous Australians, where Indigenous Australians are three times more likely to be blind. Yet 94% of vision loss for Aboriginal and Torres Straits Islander people is preventable.

For over 10 years, we’ve been donating to The Fred Hollows Foundation’s Indigenous Australia Program through the sale of PROSAFE eye protection, accessories, and Armadillo products. In fact, several of our team also personally contribute via our workplace giving program. We’re proud that our contribution can go towards helping local communities access their right to good health, and to continue to help end avoidable blindness.

“We chose to partner with The Foundation because it’s goals, aspirations and philosophies align with our own culture and vision for our business, and the engagement of communities in which we operate. The Fred Hollows Foundation Indigenous Australia Program has a national footprint and aligns with our national eye safety product and support offering, so that we and our customers can contribute financially alongside our employment, development, and community engagement,” says Barry Hoare, Leader - Indigenous Talent & Development, Blackwoods.

So far, Blackwoods has donated over $2.7 million and with your help, we can keep working to close the gap. In 2021 alone, our partnership with The Foundation contributed to:

• 9,148 people screened

• 1,075 eye operations and treatments

• 1,715 pairs of glasses distributed

• 13 clinical staff trained

• 728 children and community members educated

“We’re extremely thankful for the contributions both our customers and employees have made in supporting this important partnership. We have seen first-hand the great work The Fred Hollows Foundation are doing in remote communities through attending “The Fred Hollows See Australia” program, which is something we’re very proud to have experienced,” says Andrew Bray, CEO Blackwoods.

The Foundation is now celebrating 30 years of working to provide culturally sensitive eye care, education, and screening in our local communities.

Every PROSAFE eye protection, accessories, and Armadillo products sold in Australia contributes to helping First Nations Australians retain their vision for a brighter future. So, if you want to help too, simply choose PROSAFE.

20 Edition 5 / October 2022Safety Spotlight

21ASSESS | INFORM | EQUIP CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

Image supplied by The Fred Hollows Foundation

ROOTING OUT SOIL CONTAMINATION WITH WORKPLACE SAFETY TODAY A CRITICAL FACTOR TO BUSINESSES LARGE AND SMALL, SO TOO IS ENVIRONMENTAL SAFETY.

In certain operational settings, the use of industrial absorbents to mop up oil, fuel, paint, and chemical spills on hard surfaces, is a well-recognised workplace safety practice.

However, spills like these are only one part of the hazardous waste problems many modern industrial businesses face. There are other threats to safety and the environment, which are harder to detect than others.

According to Hazardous Waste Australia 2021, more than 35% of all spills in Australia happen on soils. As such, businesses in mining, oil and gas, construction, and manufacturing are all being held to account for their own ‘eco footprint’. This means they’re expected to address hazardous waste problems they cause, using safe and more sustainable environmental protection solutions.

Enretech is one company that is well-versed in providing sustainable cost-saving solutions for the modern industrial business. This includes soil remediation. “Our sustainable products such as Kleen Sweep have been keeping petrol station, supermarket, factory and workshop floors free from surface oil and other spills for many years,” says Managing Director Gordon Irons. “In addressing the growing global problem of soil contamination, we have been pioneering environmentally sound soil remediation technologies, which are both sustainable and effective.”

“Using a combination of microbial cultures and renewable cotton waste absorbents, Enretech’s latest version of Remediator

, is being internationally recognised as the most potent bioremediation solution to date for spills on soil,” says Gordon.

100% biodegradable, Remediator has been approved for environmental compliance by all EPA agencies in Australia as well as several state and local government agencies in NSW, Queensland, and Victoria. It has also been accredited for use by environmental agencies in Canada, USA, Vietnam, Philippines, Malaysia, and Indonesia.

Soil remediation, which includes bioremediation, is recognised globally as a proven sustainable approach to environmental remediation and helps organisations to achieve their ESG goals and objectives. As a result, leading APAC environmental consultants such as EnviroPacific and Socadis have also recognised the benefits of bioremediation to address soil contaminants and use Remediator to quickly and cost effectively achieve desired EPA targets for their clients.

CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

22 Edition 5 / October 2022Safety Spotlight

DID YOU KNOW. In Australia over $2 billion* a year is spent cleaning up contaminated land and water.

*Source

University of Newcastle

DON’T BE LEFT IN A TIGHT SPOT UNPROTECTED THE IMPORTANCE OF THE RIGHT GAS DETECTION EQUIPMENT

Fact. Confined spaces are leading contributors to workplace injuries. While there are many health and safety risks concerned with working in such spaces, the biggest are coming from atmospheric conditions, particularly deficient levels of oxygen.

It is imperative that atmospheric conditions are checked, via a ‘live Risk Assessment’ before workers enter any confined space. When doing so, there are commonly three potential hazards that must be considered:

• Levels of oxygen and the likelihood of oxygen depletion

• The presence of toxic gases and/or vapours

• The presence of combustible gases and/or vapours

“Given the immediate risks of inert or toxic gases, confined space entry can be more dangerous than other industry operation - an unknown quantity and often ‘shift-changing’, meaning it contains many complex issues.” (MSA The Safety Company).

When choosing a gas detector for your worksite/s, here are some basic questions you need answers to.

• Is it designed for the specific environment and hazards in which it will be used?

• Is the equipment durable? For example, is it ‘drop test’ rated? And does it have an IP (Ingress Protection) Rating for water and dust?

• Do the sensors respond (T90) in an adequate timeframe, for the hazards in which it was calibrated for?

• What alarm features does it have?

• What is the warranty? How long does it last and what does it cover?

After doing your research, you must be confident that your life-saving equipment is so reliable that you will have peace of mind whenever you or others work in a confined space.

“It’s also important a gas detection instrument is bump tested and calibrated for the specific risk. For example, shipping containers that have remained sealed for some months at sea, may present a wide range of contaminants, therefore it’s important the right gas detector is used, bump tested and calibrated for a suspected containment range.”

CLICK FOR MORE INFO.

Or contact your Technical Safety Specialist

“At MSA, we stress that gas detection is only one part to a successful confined space operation. That’s why we provide a full range of Personal Protective Equipment (PPE) that includes: fall protection, head protection, self-contained breathing apparatus (SCBA) and other relevant PPE, to safely navigate different types of confined spaces.”

23

ASSESS | INFORM | EQUIP //

GIVING WORKPLACE INJURIES THE BOOT.

USING BIOMECHANICS TO DESIGN SAFETY FOOTWEAR IS A GIANT LEAP IN THE RIGHT DIRECTION.

Putting your foot in it, taking a wrong step, getting cold feet, getting itchy feet, having two left feet. We use a lot of foot clichés to describe situations, yet when it comes to looking after our feet, they often take a beating or are neglected entirely. Especially in the workplace.

Feet are incredibly complex with 26 bones, 33 joints and 100 muscles, tendons, and ligaments. That’s a lot of moving parts to keep you going. The average person will walk 185,000 km in their lifetime, meaning you’ll likely walk the distance of circling the globe over four times in your life. Your feet also take a beating in terms of load with an average day seeing hundreds of tons of pressure being put on them – the equivalent of a truck loaded with cement. And yet, many people don’t give much thought to their footwear. When it comes to the worksite, however, this is an area that we can’t afford to overlook.

According to Safe Work Australia, falls, trips and slips are responsible for a massive 23% of workplace injuries across trade industries, with a high number of these being traumatic joint, ligament, muscle or tendon damage. Safety footwear is essential but it’s often hard to design a boot that’s both safe and comfortable. The heavy steel toe that you need to prevent compression injuries means your feet are working extra hard just to get from A to B. And when you’re on your feet all day, that’s not ideal.

Blundstone, a well-established Tasmanian-based safety footwear producer, has turned to science to solve the problem - namely biomechanics. They embarked on a vast, multi-layered research project to understand consumer’s purchasing decisions, and to design the ultimate safety boot, to combat the most common and debilitating worksite injuries.

The three-year-long study looked at every aspect of boot design, how the foot and ankle move, and it also included an in-depth consumer feedback survey to bring all the elements together. “The research has shown without doubt that wearers want better performing work boots,” says Adrian Blandford, Blundstone’s Global Work & Safety Range Manager. “They want them to be strong, lightweight, offer good grip and manoeuvrability, as well as high protection for the user.”

From this, a collaboration with the University of Tasmania’s School of Health Science’s Biomechanics experts ensued. What they came up with was the RotoFlex® range of boots, which uses composite toe caps that resist compression and meet safety standards, but don’t weigh heavy on the foot.

24 Edition 5 / October 2022Safety Spotlight CLICK FOR MORE INFO. Or contact your Technical Safety Specialist

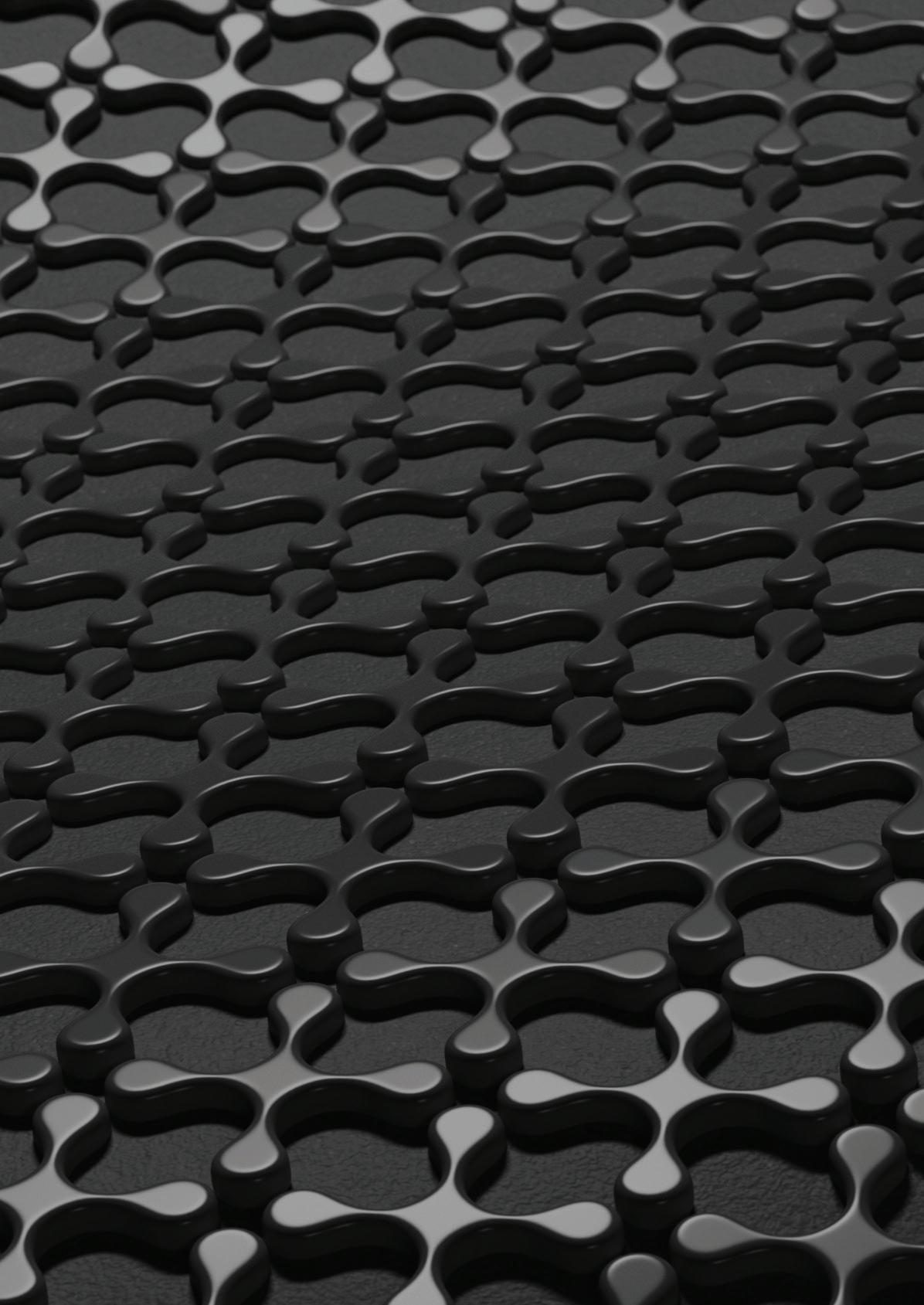

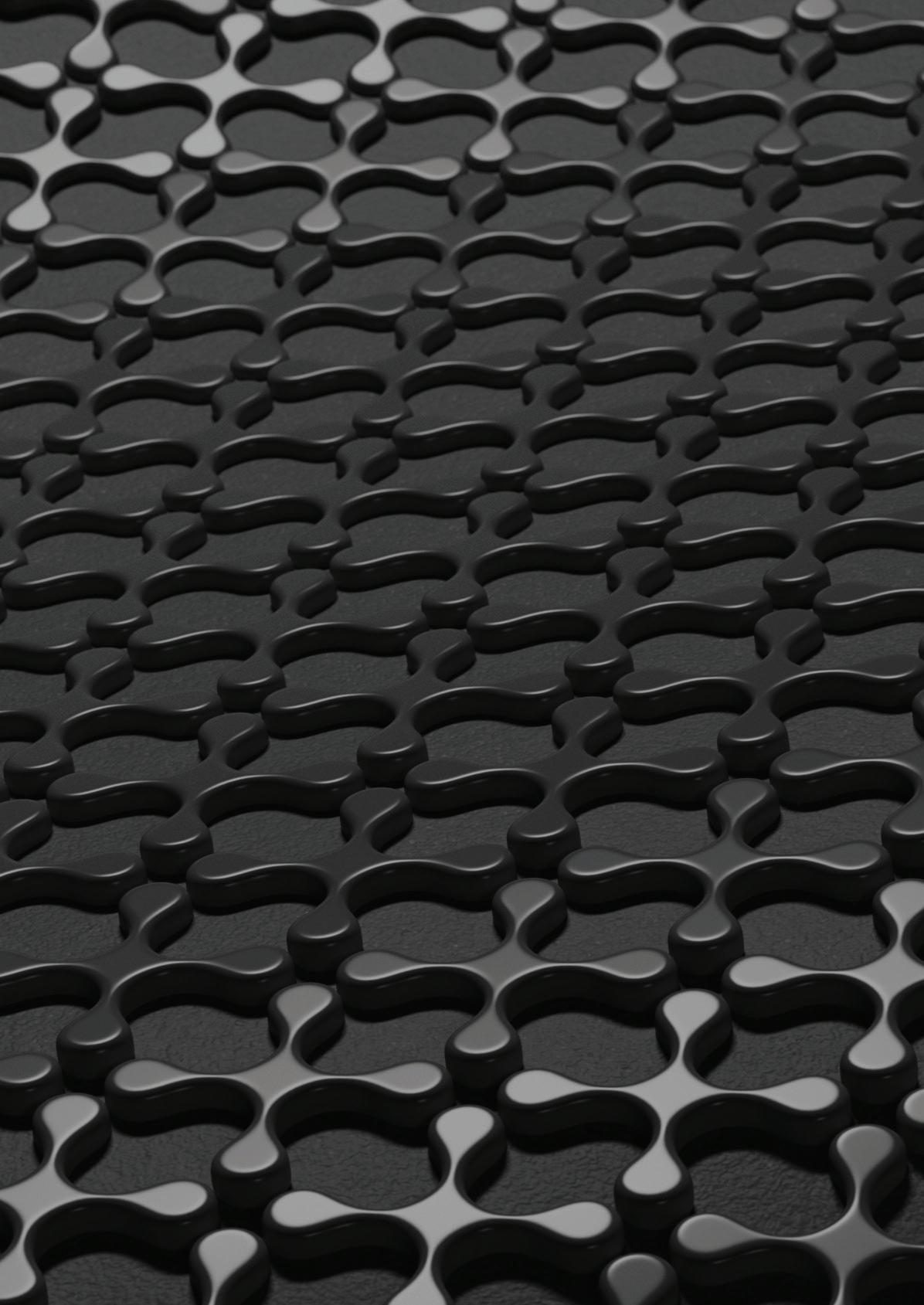

They incorporated the findings of their study into four key features of the boot: GripTek® HD

They started with the sole design using a unique polyurethane (PU) tread pattern that ensures stability on hard and graded surfaces. Along with that, the supercushioned midsole provides zoned support, meaning you’ll need to use less energy to move around. This reduces fatigue which, in turn, can help reduce workplace injuries.

Fortalite®

This composite toe cap means that you can have ultimate safety from impact or rolling compression without the heavy weight of the steel toe. They achieved this by using a compression-proof Polymer composite material that can withstand immense pressure.

AirCell

The footbed is designed to activate ventilation by allowing air to be pumped between the toes, to the arch of the foot and the heel. This results in better air circulation and moisture control, and since your feet’s 250,000 sweat glands produce up to half a pint of perspiration a day, this is a much-needed feature.

SoftCell

The unique fit system is biomechanical designed to cradle the foot and improve stability, balance, movability and comfort. The use of Infinergy E-TPU, a super elastic energy foam from BASF, means you’ll have a form-fitting boot that’s snug but still allows space to move and reduces the impact of your steps, so your feet won’t tire as easily.

The RotoFlex range is available in four unisex styles and two women’s styles, with wearer trials available through Blackwoods’ safety specialists.

Blandford went on to say… “RotoFlex will be the benchmark for boots in the safety footwear market.” Maybe it’s time to take

| | EQUIP

Uniform Solutions Guide

Ask Us About A Uniform Solution.

JON MARTIN TECHNICAL SAFETY SPECIALIST - WA

Long-term Perth resident, Jon is a Technical Safety Specialist with 25 years’ experience behind him. Starting out with Protector Safety Supply and Protector Alsafe before they were incorporated into Blackwoods, Jon is the go-to man for chemical handling PPE and he’s passionate about safety.

“I’m in a low-risk job however, I understand that our customers are performing in high-risk jobs, so I see it imperative to be at my best. It’s a motivator for me to get the right product or solution, so people go home safely.”

While Jon takes his job seriously, his English humour can’t help but come through despite 38 years living in Australia. Hailing from Bristol, he describes himself as “English by birth, Australian by choice”.

Besides safety, Jon’s other passions include soccer and AFL (he’s a West Coast supporter), German and Russian 20th Century history, post-WWII Australian politics. His taste in music is eclectic, ranging from Baroque to Classical to Pop to Glam and Punk & beyond. He’s been happily married for 37 years and values his small, but loving family.

You can always count on Jon for honest, straight up and expert safety advice with a smile and a cheeky yarn on the side. “My colleagues know I wear my heart on my sleeve.”

26 Edition 5 / October 2022Safety Spotlight 25YRS

GO TO PAGE 30 TO CONTACT JON. Launching November 2022

ORANGE IS THE NEW BLACK, WHEN IT COMES TO ‘HANDLING’ SAFETY

In so many walks of life, hands and eyes work together. Think of sport, playing the piano, a surgeon performing an operation… Hands and eyes are a team. And that partnership is apparent in many workplaces where hazards are commonly present, such as poor lighting, machinery, and environments in which there are chemicals, grease, mud, and various types of dust.

In such workplaces, a worker’s access to high-visibility equipment plays an essential role in the mitigation of hazards, and the prevention of injuries and accidents. Workers must be able to clearly see where their hands are. And that means, Hi-Vis gloves are a must for every worker.

The Glove Company (TGC) was the first manufacturer to introduce Hi-Vis Orange Nitrile Disposable Gloves to Australia. The benefits of these gloves include:

• Workers can safely see what they are doing even in low light/visibility environments.

• The bright orange reinforces hand placement, ensuring hands can be kept out of harm’s way.

• The bright orange enhances the chance of finding gloves should they be misplaced, have fallen off or are torn off. This can be critically important in some environments where errant gloves may cause contamination of the workplace. For example, in machines or food.

• Easy to tell if the glove has become compromised due to contact with chemicals.

• The orange colour can be used as part of an internal system to designate risk levels, so safety managers can readily see if workers are wearing their Hi-Vis PPE.

“The TGC Hi-Vis Orange Nitrile Disposable Gloves provide a glowing contrast to blue, green, and dark gloves. Everything for the dark-glove worker becomes increasingly difficult when they don’t have the same hand awareness in their workplace. It just makes sense to wear a bright colour,” says Ben Kessey International Sales & Operations Manager at The Glove Company.

In Australia, orange has become one of the most popular and powerful colours used to help mitigate hazards. Is your business taking the right action to ensure your workers are safe? The Hi-Vis Nitrile Disposable Glove can help you and the overall wellbeing of your staff.

CLICK FOR MORE INFO.

Or contact your Technical Safety Specialist

27

ASSESS | INFORM | EQUIP

WORKPLACE SAFETY.

THE CHANGING FACE OF RESPIRATORS

While tackling the harmful effects of, silica dust, hazardous gases, and airborne viruses, other factors such as user comfort, fatigue and the work environment have contributed to an increasing trend towards the use of Powered Air Purifying Respirators (PAPR).

With Reusable Respirators (RR) still commonly used on worksites, perhaps looking at the differences in more detail, may provide better insight as to why ‘the PAPR’ is fast becoming the ‘go-to’ respiratory protection equipment (RPE) for many customers.

“THE RR”

Reusable Respirators, often referred to as ‘half-face’ and ‘full-face’, come with a variety of different cartridges and filters. The RR’s get their name from the fact that many of their components can be maintained, replaced, and re-used.

If they are well maintained, they can last for some time. Also, it is of critical importance that they must be fit-tested to each individual wearer. “Because of the negative pressure created on inhalation, it’s imperative to conduct regular fit checks of the assembled respirator, prior to entering any contaminated workplace,” says Graham Powe of Safety Equipment Australia.

As with the case with any respirator, it’s essential that the correct type of filter is chosen according to its suitability to protect from relevant contaminants and hazards. “It’s critical filters are replaced frequently, in line with a risk assessment conducted by a competent person, with a full knowledge of the respiratory hazards in the workplace,” says Timothy Khoo of 3M, Personal Safety Division.

Safety Spotlight CLICK FOR MORE INFO. Or contact your Technical Safety Specialist 28 Edition 5 / October 2022

“THE PAPR”

A Powered Air Purifying Respirator uses a battery powered fan-unit that pulls ambient air through the filters delivering clean air to the head coverings or facepieces. Unlike RR’s, the PAPR…

Does not require individual fit-testing if used with loose fitting head and face coverings, such as hoods or helmets.

Potentially increases the comfort of the wearer. This includes the option of reducing the weight of filters carried on the facepiece, particularly during long periods of use.

Potentially allows the wearer to integrate multiple types of PPE (Personal Protective Equipment).

There are many benefits of using PAPR’s. They can help keep the wearer cool and provide protection factors of up to 100+ for certain configurations. “A PAPR helps reduce the workload for the user, due to the positive airflow the fan unit delivers inside the mask,” says Graham.

“There’s also a wide range of hoods, head tops and accessories to suit a variety of applications. Some with hearing protection and microphone, and two-way communications”, says Sanya Kranenburg of 3M, Personal Safety Division. PAPR’s are ideal for use in a vast array of situations and industries, including:

• Asbestos removal

• Jobs in which silica dust is present

• Pharmaceutical manufacture

• Smelting

• Waste Control

• Land remediation

• Welding

• Agriculture

Because of their suitability to variety different situations, PAPR’s are becoming more widely used in the workplace, and the global COVID 19 pandemic saw the expanded use of PAPR in the health care sector as a means of protecting medical personnel.

Use with various SundstrÖm hoods, face shields, full face mask and SR900 half mask.

SR500 PAPR Gas & Particles

29ASSESS | INFORM | EQUIP

OUR TECHNICAL SAFETY SPECIALISTS

Our team of Technical Safety Specialists

experienced in a wide range of

and invest time with customers to understand the specific hazards they

share knowledge so that customers are equipped to ensure that every employee, contractor and visitor returns home healthy and injury free.

The Blackwoods technical safety team help customers get the right product, technical knowledge and training, at the right time.

we help more people build a better Australia.

DEAN ANDERSON

JON MARTIN

CRAIG POSTILL

DREW DAUNCEY

CHRIS BEATON

Dean.Anderson@blackwoods.com.au

SIMON FOSTER

SAFETY SPECIALIST

Simon.Foster@blackwoods.com.au

CAITLIN DE BIASIO

BRENDAN RYAN

-

Brendan.Ryan@blackwoods.com.au

JANELLE COCCIA

Janelle.Coccia@blackwoods.com.au

DARREN GALLAGHER

SHANE WOOD

PETER AGNOS

LEIGH EAM

30 Edition 5 / October 2022Safety Spotlight // MEET

are

industries

face. They

Together

HEAD OF TECHNICAL - NATIONAL +61 417 819 584 Peter.Agnos@blackwoods.com.au +61 407 728 860

TECHNICAL SAFETY SPECIALIST - QLD 13YRS

TECHNICAL

- QLD +61 418 259 239

14YRS +61 408 571 120 Caitlin.DeBiasio@blackwoods.com.au

TECHNICAL SAFETY SPECIALIST - QLD 13YRS +61 417 231 550

TECHNICAL SAFETY SPECIALIST

NTH NSW 35YRS +61 459 805 179

TECHNICAL SAFETY SPECIALIST - STH NSW 26YRS +61 437 998 112 Chris.Beaton@blackwoods.com.au

TECHNICAL SAFETY SPECIALIST - VIC 7YRS +61 408 624 653 Drew.Dauncey@blackwoods.com.au

TECHNICAL SAFETY SPECIALIST - VIC/TAS 24YRS +61 417 998 488 Craig.Postill@blackwoods.com.au

TECHNICAL SAFETY SPECIALIST - SA/NT 17YRS +61 438 439 155 Jon.Martin@blackwoods.com.au

TECHNICAL SAFETY SPECIALIST - WA 25YRS +61 439 021 868 Darren.Gallagher@blackwoods.com.au

NATIONAL CATEGORY & SOURCING MANAGER , WORKPLACE SAFETY, RESPIRATORY,FALL PROTECTION, AND LIFTING & RIGGING +61 418 417 779 Shane.Wood@blackwoods.com.au

NATIONAL CATEGORY AND SOURCING MANAGER EYE, FACE, HEAD, HEARING & HAND PROTECTION +61 457 859 360 Leigh.Eam@blackwoods.com.au

NATIONAL CATEGORY AND SOURCING MANAGER APPAREL AND FOOTWEAR

// OUR INTEGRATED APPROACH TO SAFETY

For over 140 years, we’ve been Australia’s leading industrial and safety equipment provider. You’ll find us across the country on construction sites, mine sites, and on desert roads, making sure workers are protected when it matters most.

We work with customers to understand the specific hazards they face. Drawing on the knowledge of our technical team, we share the expertise needed to review, test and manage safe work practices.

Where stock is critical and time is limited, we can provide streamlined solutions using smart technology to help you better manage inventory, reduce cost, free-up capital and improve productivity.

When managing safety on worksites, knowledge is the key to prevention. Our goal is to stay abreast of the latest safety standards, recommendations and technology so we can keep our customers informed.

Our Technical Safety Specialists are experienced in a wide range of industries, from mining to construction. They offer a wealth of hands-on practical knowledge and a passion for helping customers stay informed and protected.

Our global sourcing expertise and capability coupled with long-standing relationships with market leading manufacturers throughout the world ensures our customers are provided with any best-practice developments and innovations in the safety space.

With fit-for-purpose product selection guidance, sourcing, delivery and post purchase support in line with applicable standards, we have everything you need to get the job done safely, and if we don’t have it, we can get it.

But our approach goes far beyond simply supplying safety products. We invest time and expertise in our customers and share our broad depth of knowledge, so they are equipped to ensure that every employee, contractor and visitor returns home healthy and injury free.

It’s what we refer to as our assess, inform, equip model. At each stage of the process, we collaborate with clients to ensure they get the right product, technical knowledge, and training, at the right time. Our holistic approach to safety is what sets us apart and it’s something we’re incredibly proud of. Because when our customers can do their job safely and confidently, then we know we’ve done ours. Together we help more people build a better Australia.

ASSESS

We work with customers to understand the specific hazards they face. Drawing on the knowledge of our technical team, we share the expertise needed to review, test and manage safe work practices.

Where stock is critical and time is limited, we can provide streamlined solutions using smart technology to help you better manage inventory, reduce cost, free-up capital and improve productivity.

INFORM

When managing safety on worksites, knowledge is the key to prevention. Our goal is to stay abreast of the latest safety standards, recommendations and technology so we can keep our customers informed.

Our Technical Safety Specialists are experience in a wide range of industries, from mining to construction. They offer a wealth of hands-on practical knowledge and a passion for helping customers stay informed and protected.

EQUIP

Our global sourcing expertise and capability coupled with long-standing relationships with market leading manufacturers throughout the world ensures our customers are provided with any best-practice developments and innovations in the safety space. With fit-for-purpose product selection guidance, sourcing, delivery and post purchase support in line with applicable standards, we have everything you need to get the job done safely, and if we don’t have it, we can get it.

Our holistic approach to safety is what sets us apart from other suppliers and it’s something we’re incredibly proud of. Because when our customers can do their job safely and confidently, then we know we’ve done ours.

Together we’re helping build a better Australia.

32 Edition 5 / October 2022Safety Spotlight blackwoods.com.au13 73 23