STUFF BLOWN UP

Baird Center page 14

COOL STUFF

Made & Designed in Wisconsin pages 6-9

CHOOSING A TECH SCHOOL

page 23

could I make a career out of this?

who makes it?

what is it?

DESIGNED, MADE AND BUILT IN SOUTHEASTERN WISCONSIN SEE PROFILES OF COMPANIES HIRING NOW ON PAGES 37-75

A GUIDE TO A SUPPLEMENT OF

FALL 2023

LEARN MORE

OPPORTUNITIES

ABOUT EXCITING CAREER

MATC is an Affirmative Action/Equal Opportunity Institution and complies with all requirements of the Americans With Disabilities Act. MATC is accredited by the Higher Learning Commission, Commission on Institutions of Higher Education, the national standard in accrediting colleges and schools for distinction in academics and student services. DOWNTOWN MILWAUKEE 700 West State Street MEQUON 5555 West Highland Road OAK CREEK 6665 South Howell Avenue WEST ALLIS 1200 South 71st Street MATC.EDU 414-297-MATC Wisconsin Relay System 711

CHECK OUT THE COOL CAREERS IN STUFF

DEAR READERS,

Welcome to the latest edition of STUFF Designed, Made and Built in Southeastern Wisconsin, from BizTimes Media. This print and digital magazine is an opportunity for students, educators, parents and job seekers to get a closer look at the available careers in manufacturing, construction and the trades. It also offers insights from those working in these industries on how they got their start, advice for nailing a job interview and data on the fastest growing jobs.

We publish STUFF because more than 80% of the expected annual job openings in Wisconsin through 2030 require less than a four-year degree. You can get a sense of some of those careers in “Hot Jobs” on page 27. It features positions that pay more than $40,000 per year on average, require less than a four-year degree and are in-demand. Go deeper on select careers with “Jobs in Detail” on page 28.

You can also explore some of the unique products made in our region and see the jobs that go into making those products with our “Cool Stuff” feature starting on page 6. Our “Stuff Blown Up” feature (page 14) highlights the jobs and companies involved in the expansion of Milwaukee’s convention center, and “Supply Chain” (page 26) maps out how complex getting products to market can be.

If you want to learn even more about careers available in manufacturing, construction and the trades, check out the company profiles starting on page 37. Twenty of our region’s best employers have shared insights on the careers they offer.

Whatever career path you choose, we hope STUFF helps you explore the wide range of options available right here in southeastern Wisconsin. To help you see how an interest in a job can turn into a career, we talked with area employees about how they got their start. Read their advice in “Career Spotlight” on starting on page 16.

Check out stuff.biztimes.com to find the digital edition and to learn more about these companies as well as other news, trends and career opportunities throughout the year.

A WORD FROM OUR SPONSOR

GPS Education Partners has been a proud supporter of STUFF magazine since its beginning and leverages many of BizTimes Media’s publications and events to stay in touch with our communities about the many benefits of high quality work-based learning. For us, STUFF magazine is the written and digital version of the actual work we do to bring students and businesses together to prepare the next-generation workforce. We want to thank our school partners who use this magazine as a vital part of their students’ career exploration experience.

Finally, we are especially grateful to our longtime partner, GPS Education Partners, who have supported this initiative from the very beginning in 2017.

We are confident that STUFF will help guide you on your career planning journey. If you have any comments or suggestions on additional ways STUFF and BizTimes Media can help, we want to hear from you. Send me an email at dan.meyer@biztimes.com.

Dan Meyer Founder and publisher BizTimes Media

For over two decades, GPS Ed’s Education Center & Youth Apprenticeship Program has been helping students develop essential employability skills and build a strong, positive work ethic. It also provides them with an important network of peers and employers that help connect the dots between learning and the real world of work.

We have partnered with hundreds of employers who get the opportunity to shape the next generation of skilled workers from an early stage and engage directly with the academic learning process in a meaningful way. These experiences can also help build a positive culture in the workplace as current workers see their employers commitment to training and giving back to their community.

GPS Ed supports local communities by keeping Wisconsin talent in Wisconsin businesses. If you’d like more information on any of our work-based learning programs visit GPSEd.org or email us at info@GPSEd.org.

3 stuff.biztimes.com | STUFF SE

PUBLISHER’S MESSAGE

DESIGNED, MADE AND BUILT IN SOUTHEASTERN WISCONSIN

A SUPPLEMENT OF

A GUIDE TO STUFF DESIGNED, MADE AND BUILT IN SOUTHEASTERN WISCONSIN - 2023

126 N. Jefferson St., Suite 403, Milwaukee, WI 53202-6120

PHONE: 414-277-8181 FAX: 414-277-8191

WEBSITE: stuff.biztimes.com

ADVERTISING EMAIL: advertise@biztimes.com

EDITORIAL EMAIL: andrew.weiland@biztimes.com

REPRINTS: reprints@biztimes.com

ADDITIONAL COPIES: sue.herzog@biztimes.com

Additional copies $15 each

PUBLISHER / OWNER

Dan Meyer dan.meyer@biztimes.com

DIRECTOR OF OPERATIONS

Mary Ernst mary.ernst@biztimes.com

COMMUNITY ENGAGEMENT / OWNER

Kate Meyer kate.meyer@biztimes.com

EDITORIAL

EDITOR

Andrew Weiland andrew.weiland@biztimes.com

STUFF - PROJECT EDITOR

Arthur Thomas arthur.thomas@biztimes.com

STUFF - ASSOCIATE EDITOR

Maredithe Meyer maredithe.meyer@biztimes.com

REPORTERS

Ashley Smart ashley.smart@biztimes.com

Cara Spoto cara.spoto@biztimes.com

Hunter Turpin hunter.turpin@biztimes.com

EDITORIAL INTERN

Ellie Batten ellie.batten@biztimes.com

ADMINISTRATION

ADMINISTRATIVE COORDINATOR

Sue Herzog sue.herzog@biztimes.com

AUDIENCE DEVELOPMENT ASSOCIATE/CIRCULATION

Derik Sneide derik.sneide@biztimes.com

SALES & MARKETING

DIRECTOR OF SALES

Linda Crawford linda.crawford@biztimes.com

SENIOR ACCOUNT EXECUTIVE

Christie Ubl christie.ubl@biztimes.com

ACCOUNT EXECUTIVES

Dylan Dobson dylan.dobson@biztimes.com

Paddy Kieckhefer paddy.kieckhefer@biztimes.com

Christy Peterson christy.peterson@biztimes.com

SALES ADMIN

Kristin Anderson kristin.anderson@biztimes.com

PRODUCTION & DESIGN

SENIOR GRAPHIC DESIGNER

Alex Schneider alex.schneider@biztimes.com

FREELANCE ART DIRECTOR

Meredith Jensen meredith.m.jensen@gmail.com

PUBLISHER’S LETTER

A note from Dan Meyer, publisher

COOL STUFF

P. 3

P. 6

Discover products designed and made by southeastern Wisconsin companies and learn about jobs they are hiring for.

WISCONSIN EXPORTS

P. 10

See where the top Wisconsin products end up around the world and how the state compares to the rest of the country.

STUFF BLOWN UP

P. 14

Get a closer look at the companies and jobs expanding the Baird Center, Milwaukee’s downtown convention center.

CAREER SPOTLIGHT

P. 16

Learn about the journey area employees have taken to their current roles.

CHOOSING A TECH SCHOOL PROGRAM

P. 23

Advice for navigating the process of adding new skills.

SUPPLY CHAIN ......................

P. 26

A breakdown of how raw materials become finished products.

HOT JOBS

P. 27

See the jobs projected to grow in construction, production, maintenance and transportation.

JOBS IN DETAIL

P. 28

A closer look at some of the fastest-growing jobs.

APPRENTICESHIPS BY THE NUMBERS

P. 30 Get a breakdown of a popular way to launch a career.

THE COST OF LIVING

Tackle the ins and outs of building a budget.

NAILING THE INTERVIEW

Tips and advice for landing the job you want.

LOCAL COMPANIES AND EMPLOYEE PROFILES

P. 32

P. 36

P. 37

Area businesses share a look inside their day-to-day and current positions in demand.

RESOURCES

P. 78

Career information sources and tools for students, employers, educators and job seekers.

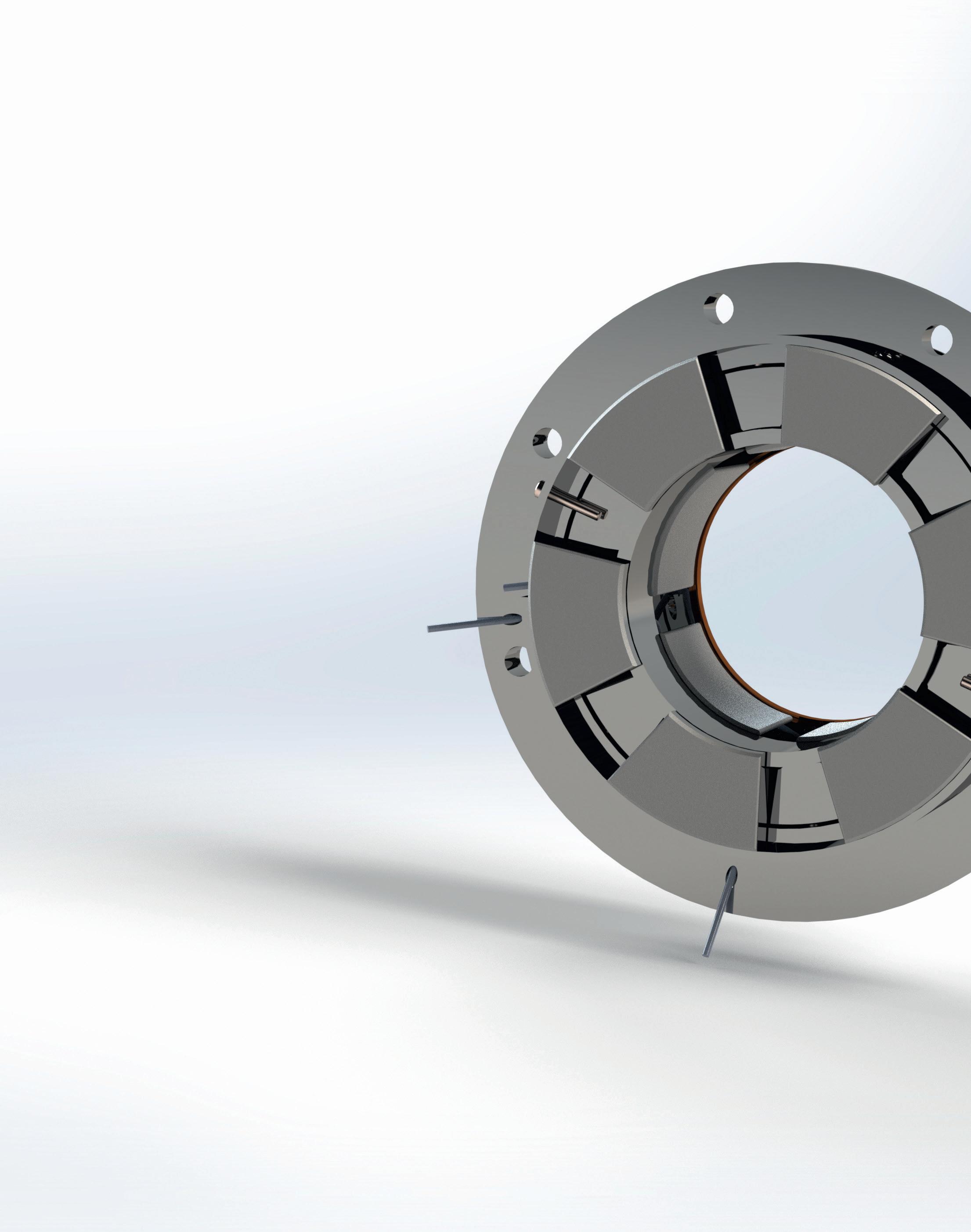

COOL STUFF PAGES 6-9

Designed, made and built in Wisconsin

STUFF BLOWN UP PAGE 14

Companies and jobs expanding Milwaukee’s convention center

SUPPLY CHAIN PAGE 26

How raw materials become a finished product

CHECK OUT

JOB PROFILES

PAGES 37-75

4 STUFF SE | Fall 2023 A SUPPLEMENT OF BIZTIMES MILWAUKEE

& LOCALLY OWNED • Founded 1995 •

CONTENTS INDEPENDENT

A GUIDE TO

FALL 2023

We change kids’ lives. Working here will change yours.

Health care is constantly evolving — but with change comes opportunity. At Children’s Wisconsin, you have the opportunity to develop a career that leverages innovation and technology to advance the health and well-being of children. With your skills and abilities, you have the opportunity to make the world a better place for children and families.

Are you passionate about helping kids? Are you excited by working in an innovative environment with cutting-edge technology? Do you want a career with a purpose? Join the Children’s Wisconsin team. We are currently hiring for both clinical and non-clinical roles.

Apply today at childrenswi.org/careers

COOL STUFF designed,madeandbuiltinWisconsin

The next time you’re driving down the highway or pass a business park full of what might seem like boring, rectangular buildings, take a few minutes to wonder what might be going on inside. Wisconsin is home to thousands of manufacturers that make a wide range of products, from lemonade to flagpoles to generators. For every one of those companies, there are also dozens or even hundreds of smaller suppliers that help make the final product.

These companies all need employees and offer a chance to build a great career. Take a look at the descriptions below to get a better idea of some local products and a glimpse at some recent job openings at these companies.

FLAGS AND FLAGPOLES

EDER FLAG | Oak Creek-based Eder Flag Manufacturing Company makes flag poles and flags, including American flags. The company was founded in 1887 by seven brothers. It initially focused on making pillows, felt pennants, rag dolls and hunting jackets. Its flagmaking business began in 1903. It began to handcraft American flags during the Great Depression. Today the company sells more than 20,000 different products and produces more than 5 million American flags per year. Eder Flag has been employee-owned since 2016.

JOBS AT EDER FLAG

PRODUCTION LEAD: Communicates and coaches improvement in production methods, equipment and operating procedures; disperses job orders daily to production staff; monitors inventory levels of raw materials; monitors production process; completes and processes daily orders assigned by the sewing manager; assists with production planning; prioritizes work orders; trouble shoots and performs maintenance on industrial sewing and slitter machines.

FABRICATION UTILITY: Does basic welding; operates plasma cutter; operates drills, saws, and machines in fabrication; drills, taps, cuts and deburrs products; assembles retainer rings and flag arrangements; produces cable assemblies; polishes flagpoles with lathe.

6 STUFF SE | Fall 2023 A SUPPLEMENT OF BIZTIMES MILWAUKEE COOL STUFF

LEMONADE

The King Juice Company | Milwaukee -based King Juice Company makes Calypso branded lemonade, limeade and tea in a variety of flavors. The original Calypso lemonade recipe was created in 1985 in Milwaukee by the owner of King Juice Company, who wanted to create a lemonade drink with real lemons and real sugar. The company’s original lemonade was given the name Calypso in 2000 and grew into four lemonade blends. By 2018 it had more than a dozen lemonade, limeade and zero sugar drink combinations available.

JOBS AT KING JUICE COMPANY

CESS OPERATOR: Monitors and records the product and tests the quality of the product. General duties include hooking up tanks, monitoring temperature changes in the facility, making flavor changes, adding the codes to the bottle and putting boxes on the line.

MAINTENANCE MECHANIC: Troubleshoots, repairs, and completes maintenance on the mechanical equipment. Also installs, dismantles, and moves heavy equipment according to blueprints or drawings.

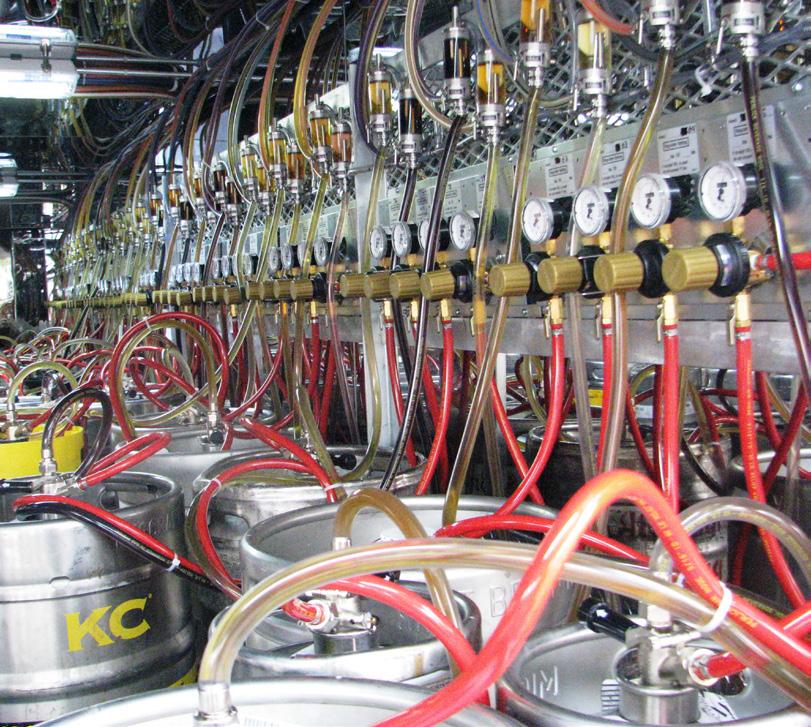

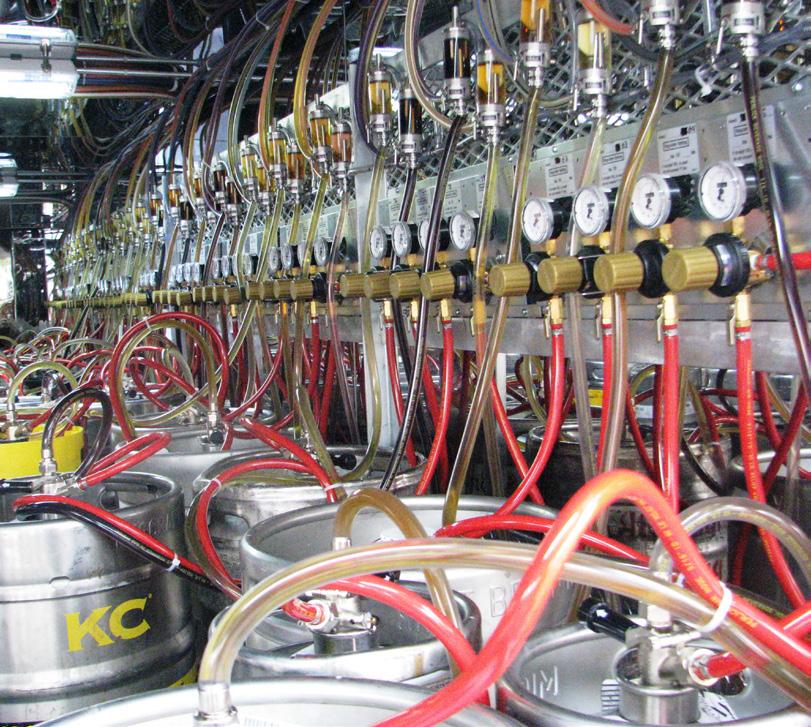

BAR EQUIPMENT

Perlick | Milwaukee -based Perlick makes commercial bar and beverage equipment, including taps and premium residential refrigerators. The company traces its roots to 1917, when Robert K. Perlick, a German immigrant, started R. Perlick Brass Works in Milwaukee. Perlick and his family grew the business into a thriving enterprise supporting the city’s booming beer industry. More than 100 years later the company is still family-owned. The company continues to evolve as a global manufacturing leader in commercial bar and beverage systems, premium residential refrigeration, and brewery fittings.

JOBS AT PERLICK

PRESS BRAKE OPERATOR: Operate press brakes to perform a variety of forming and bending operations of various materials. Requires a knowledge of press brake equipment and procedures as is usually obtained in two years of high school or vocational school education program.

JOURNEYMAN TOOL AND DIE MAKER: Construct temporary fixtures and jigs, grind specialpurpose tools; improvise measuring devices to check components and project assemblies. Grind, sharpen, recondition and repair cutting and forming tools and dies and replace worn or damaged sections when necessary; assist in repair of production machine tools.

MEN’S DRESS SHOES

Allen Edmonds | Founded in 1922, Allen Edmonds Shoe Corp. makes premium men’s footwear in Port Washington. The company uses premium leathers for its shoes that are handcrafted through a 212-step process.

JOBS AT ALLEN EDMONDS

SALES ASSOCIATE: Interacts directly with customers. Resolves customer concerns and ensures a positive customer experience. Completes product and operational training. Stocks products and produces visual displays. One year of experience with retail sales or customer service required.

PRODUCT DEVELOPMENT SPECIALIST: Works with designers to make sure development information and updates are communicated to overseas partners. Monitors the status of each style from prototype to sample stage. Supports internal and external teams and collaborates on brand and product direction for the season. One to two years of design or product development experience required. Starting salary is $54,288.

7 stuff.biztimes.com | STUFF SE

SOY SAUCE

Kikkoman | Japan-based Kikkoman Corp., the world’s leading manufacturer of soy sauce, has a production facility in Walworth The plant opened in 1973. The company selected the site in Wisconsin because of the state’s soybean farm production. Today, it is the highest-producing soy sauce facility in the world, with an annual output of more than 30 million gallons.

JOBS AT KIKKOMAN

MECHANIC AND MAINTENANCE SCHEDULER: Schedules and coordinates routine and non-routine maintenance and repairs. Obtains vendor quotes and submits work authorizations. Ensures that planned work is built. High school diploma and four-plus years of machine maintenance in a production environment preferred. $1,000 to $2,000 sign-on bonus.

PLC TECHNICIANS: Designs, programs, repairs and maintains programmable logic controller (PLC) systems. $2,000 hiring bonus.

GARBAGE DISPOSALS

InSinkErator | Racine -based InSinkerator is the world’s largest manufacturer of garbage disposals and instant hot water dispensers for home and commercial use. Founded in 1938, the company has subsidiaries in Australia, Brazil, Canada, China, Mexico, New Zealand and the United Kingdom.

JOBS AT INSINKERATOR

ASSEMBLER: Prepares workstations with necessary hardware and components for assemblies. Must work at a fast pace and know how to use hand tools. High school diploma and one year of experience in assembly, manufacturing and packaging are required.

ELECTRICIAN: Installs and maintains electrical work on plant electrical systems and equipment. The use of ladders, raised platforms, caged lifts and manual climbing on equipment is required. Plans and installs wiring circuits, distribution centers, switches and controls. State of Wisconsin indentured electrical apprenticeship and four years of electrical journeyman experience required.

GUMMY BEARS

Haribo | Hans Riegel founded Haribo in Bonn, Germany in 1920. The company opened its first U.S. office in 1982. Today, Haribo is available in more than 120 countries around the world and produces at 17 locations worldwide, employing more than 7,000 people. The company’s first North American manufacturing facility opened this year in Pleasant Prairie.

JOBS AT HARIBO

OPERATOR: Responsible for running and maintaining production and packaging equipment. Operates tanks, vats, boilers and kettles to prepare products. Ensures the machine is supplied with correct material needed to run and completes documentation. High school diploma and three years of progressive manufacturing or packaging experience required.

Responsible for the daily management and support of quality in operations and for strategic planning. Supports the implementation of food safety programs to ensure a food-safe product. Monitors quality complaints and works with operation teams to reduce complaints. Bachelor’s degree in microbiology, chemistry, food science, public health or related field required. Minimum of two years of experience in quality in a factory environment preferred.

8 STUFF SE | Fall 2023 A SUPPLEMENT OF BIZTIMES MILWAUKEE

COOL STUFF

MRI MACHINES

GE HealthCare | Chicago-based GE HealthCare designs, manufactures and distributes medical technology such as MRI machines, CT scans, X-ray machines and ultrasound machines. The company traces its roots back to 1893, when J.B. Wantz and C.F. Samms founded Victor Electric Company. As the company evolved, it began to provide tools for research of cells and proteins and large-scale manufacturing of biopharmaceuticals. GE HealthCare was incorporated in 1994 and has facilities in Milwaukee, West Milwaukee, Wauwatosa, Oak Creek, Waukesha, Muskego and Madison.

JOBS AT GE HEALTHCARE

CLINICAL PRODUCT SURVEILLANCE SPECIALIST: Ensures safe and effective products. Handles complaints and assesses risk by providing guidance on clinical workflow and how products are used to identify and navigate potentially dangerous situations. Bachelor’s degree or a high school diploma with five-plus years of experience in quality, clinical patient monitoring or product surveillance required.

ULTRASOUND HEALTHCHECK SPECIALIST: Works on-site collecting information on ultrasound assets and interviewing customers. Works with operations and finance teams to put together GE Ultrasound offerings for customers. Reports customer information to the technology planning team. Bachelor’s degree or a high school diploma with at least four years of experience in sales required.

GENERATORS

Generac | Founded in 1959, Generac provides advanced backup and prime power systems for home and industrial applications, solar and battery storage solutions and engine and battery powered tools and equipment. The company is headquartered in the Town of Genesee and has additional manufacturing facilities in Whitewater, Berlin, Jefferson, Oshkosh and Eagle.

JOBS AT GENERAC

ENGINEERING TECHNICIAN: Responsible for the planning, implementation and performance of advanced electrical, mechanical, audio and environmental tests of current and new product designs. Fabricates and leads assembly of test equipment and prototype products per blueprint specifications. Analyzes test data and prepares formal and informal test reports. High school diploma and five years of relevant work experience required.

FABRICATION MACHINE OPERATOR: Works under the direction of area supervisor to manufacture parts per plant specification utilizing fabrication equipment. Interprets drawings, schematics and machine specifications. Experience on equipment and automation consistent with metal fabrication, paint and assembly operation preferred. High school diploma required.

MINING EQUIPMENT

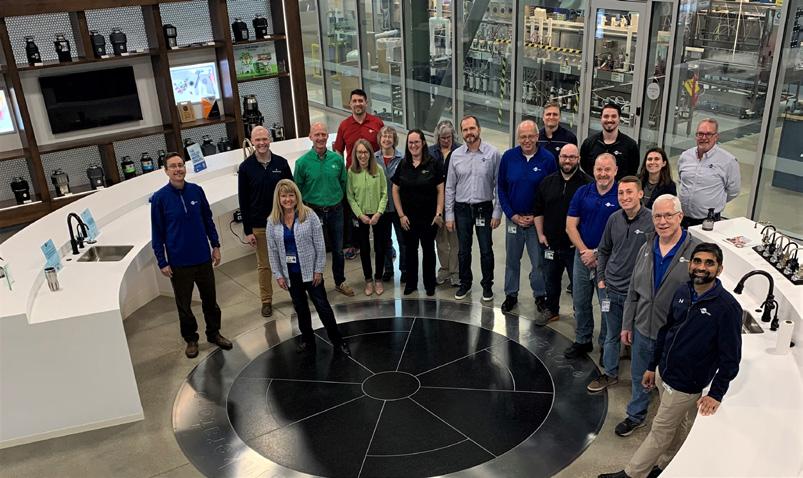

Komatsu Mining | Milwaukee-based Komatsu Mining is a subsidiary of Tokyo, Japan-based Komatsu Ltd. Last year, Komatsu Mining completed construction of a new $285 million campus in Milwaukee’s Harbor District that includes a three-story office building and a 430,000-square-foot manufacturing facility. The facility produces the major components of large mining machines, including electric rope shovels, hybrid shovels, draglines and blasthole drills.

JOBS AT KOMATSU

WELDER: Reads blueprints. Measures and cuts materials to specifications. Welds materials using the correct materials. Must be familiar with manual and mechanical welding techniques. A minimum of two years welding experience in a manufacturing environment is required.

MACHINE CELL OPERATOR: Sets up and operates a variety of machines within the department according to routing instructions and part drawings. Loads and removes parts on the machines. Starting wage is around $30 an hour depending on skill level.

9 stuff.biztimes.com | STUFF SE

WISCONSIN PRODUCTS SENT AROUND THE WORLD

Wisconsin has a long history of growing and making products, but these products aren’t just used in our state or just in the United States. Over the past five years, Wisconsin companies have exported to foreign countries an average of $23.4 billion worth of products. Not only do these international sales support jobs at local businesses, they also help grow the state’s economy by bringing money in from outside of the state, and the nation.

Take a look at some of Wisconsin’s top exports and which countries they go to. Some of the products – like milk and sausage – are ones you might expect, while others – like silica sands or lab reagents – are less well known.

Mexico

WHEY & MILK PRODUCTS

Annual Exports: $187.1 million

Rank and Percentage of U.S. Total: 1st | 17%

Top Export Destinations

China: $59 million

Canada: $30.9 million

Japan: $16.5 million

SOYBEANS

Annual Exports: $150.2 million

Rank and Percentage of U.S. Total: 15th | 4%

Top Export Destinations

Indonesia: $30 million

Vietnam: $25.8 million

Mexico: $21.1 million

SAUSAGES

Annual Exports: $150.7 million

Rank and Percentage of U.S. Total: 1st | 20%

Top Export Destinations

Canada: $91.5 million

Japan: $27.3 million

South Korea: $11.3 million

PREPARED OR FROZEN CRANBERRIES

Annual Exports: $97.8 million

Rank and Percentage of U.S. Total: 1st | 35%

Top Export Destinations

China: $15 million

Canada: $11.7 million

Netherlands: $9 million

A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 10

Canada

WISCONSIN PRODUCTS AROUND THE WORLD

United Kingdom

Belgium

Netherlands

Germany

SILICA SANDS

Annual Exports: $212.6 million

Rank and Percentage of U.S. Total: 1st | 39%

Top Export Destinations

Canada: $205 million

Mexico: $7.5 million

South Korea

Japan

COMPOSITE DIAGNOSTIC/ LAB REAGENTS

Annual Exports: $258.3 million

Rank and Percentage of U.S. Total: 12th | 2%

Top Export Destinations

Germany: $63 million

Canada: $47.1 million

China: $27.5 million

China

Vietnam

Indonesia

Australia

OUTBOARD MARINE ENGINES

Annual Exports: $427.5 million

Rank and Percentage of U.S. Total: 1st | 67%

Top Export Destinations

Belgium: $191.2 million

Canada: $59.2 million

Australia: $44.1 million

CIVILIAN AIRCRAFT, ENGINES AND PARTS

Annual Exports: $885.2 million

Rank and Percentage of U.S. Total: 18th | 1%

Top Export Destinations

United Kingdom: $186.6 million

Germany: $171.7 million

China: $121.2 million

11 stuff.biztimes.com | STUFF SE

career in a skilled trade is an amazing thing to have.”

learn on the job and to even attend class. Apprentices have little or no debt because tuition is a fraction of what it costs to attend college and many employers –who are the ones who sponsor apprentices – pay the tuition for their apprentices.

Apprenticeship also opens the door to other career options. Many graduates become leaders on the job site in a variety of different management positions. Some will eventually become apprenticeship instructors and teach our future skilled craft persons or become owners of their own companies. Reymond is already transitioning into a crew management leader, responsible for the performance of an entire crew.

ABC of Wisconsin has more than 2,000 active apprentices, so to be named the apprentice of the year is impressive. Reymond Rodriguez, however, was humbled after receiving the award in 2022.

“I felt amazing and appreciative. The moment was unlike anything I imagined,” said Reymond. “To have everyone there supporting me and seeing their joy, combined with mine, was amazing,” he said.

Reymond is in the ABC of Wisconsin Roofing Apprenticeship program and is employed by JRT Top Notch Roofs located in Milwaukee and Saukville, where their team handles various types of commercial roofing projects. He indicates that this opportunity has allowed him to grow as an individual and a worker.

“I feel blessed to have had the career and life that I’ve had. I’ve had great people help me and be by my side, whether it is at work or as a family.”

Apprenticeship is unlike any other kind of education. Employers, who are approved by the state of Wisconsin to be apprenticeship trainers, sponsor individuals into a program. Apprentices are not in it alone. Apprentices have mentors on the job and instructors who teach what they need to know.

ABC has 11 different programs, such as carpentry, plumbing, electrical, and HVAC. Apprentices are paid to

“I like that I learned so many things from so many people … different types of roofing and construction strategies from different perspectives. I love that it helped me become more than just a laborer. My apprenticeship helped me become a better leader,” Reymond said.

There are so many more stories like Reymond’s today, but that wasn’t always the case. For many years, the skilled construction trades did not receive the credit they deserved. For the past decade or so, that’s changed. More and more people are realizing, like Reymond, that the skilled trades are evolving, and the future is bright.

“A career in a skilled trade is an amazing thing to have. These trades are something to be very proud of.”

“A

Reymond Rodriguez

Reymond on a roofing jobsite with JRT Top Notch Roofs.

Reymond Rodriguez (middle) receives the apprentice of the year award. Also pictured, Josh Thull (left) and John Mielke (right).

BUILD YOUR CAREER $ 85,000 Median annual earnings for all trades in construction sector. Source: Wisconsin Technical College System Apprenticeship Completion Report for apprenticeship salaries soon after completion in 2019-20. This is the mid-point of all reported salaries, with half above and half below. Earn while you learn and be in demand Explore 11 trades at BuildYourCareerWI.org

STUFF blown u p

MILWAUKEE CONVENTION CENTER EXPANSION

A $456 million construction project is doubling the size of the downtown Milwaukee convention center, which was recently renamed the Baird Center under a naming rights sponsorship by the Milwaukee-based investment and financial services company. When the expansion project is complete in May of 2024, the Baird Center will have 52 meeting rooms, a 300,000-square-foot exhibit hall (that’s larger than five football fields), 22 loading docks, a 400-stall indoor parking garage and a spectacular new rooftop ballroom with outdoor terraces offering sweeping views of the city skyline. This construction project began in October of 2021. There are numerous workers and companies that have worked on the project and each offers their own unique career opportunities. Take a closer look at some of the jobs and companies making the expansion of the Baird Center a reality.

CONTRACTORS

Providence, Rhode Island-based Gilbane Building Co. and Fond du Lac-based C.D. Smith, both of which have operations in Milwaukee, are partnering to serve as general contractor to lead construction for the Baird Center expansion project. To complete a project, general contractors usually work with several subcontractors, each specializing in a specific area, giving them expertise to make sure the job is done right and on budget. Here are some of the companies that are working on the Baird Center project:

JP Cullen | Janesville, Madison, Milwaukee: Structural steel

JCP Construction | Milwaukee: Structural steel, structural steel labor, carpentry, concrete

CG Schmidt | Milwaukee: Carpentry

Klein Dickert | Pewaukee, Madison: Exterior aluminum and glass work, interior glass

Kapur | Glendale, Milwaukee, Madison, Burlington, Appleton, Rothschild: Deep foundations

KMI Construction | New Berlin: Masonry

CornerStone One | Brookfield: Plumbing work, underground plumbing

Lee Mechanical | Franklin: HVAC work

Source: Wisconsin Center District

Staff Electric | Menomonee Falls, Monona, Sturtevant: Electrical, low voltage

Michels | Brownsville, Milwaukee, Franksville, Green Bay, Madison, Neenah, Lomira, Wausau: Deep foundations

Rams Contracting | Lannon: Excavation and site preparation work

Langer Roofing & Sheet Metal | West Allis: Roofing work

Hetzel Tile & Marble | Menomonee Falls: Hard flooring

Thomas A. Mason Co. | Milwaukee: Soft flooring

Duwe Metal Products | Menomonee Falls: Miscellaneous metals - stairs

A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 STUFF BLOWN

UP

1 SEPT

4

2021

MAR 2023

OCCUPATIONS

It takes people with many different specialties to bring a construction project like the Baird Center to completion. Here are some of the jobs involved in the project along with a brief description and average yearly salary for the position in the Milwaukee area according to O*Net:

CONSTRUCTION LABORERS: This position performs physical labor on a construction site, including operating power tools and other equipment, preparing sites, digging trenches or setting braces, erecting scaffolding and cleaning up rubble and debris. You’ll work with others, spend time outside in the elements and often be on your feet. It is a job that requires communication, knowledge of construction, dexterity and strength, dependability and attention to detail.

WAGES IN METRO MILWAUKEE :

Low $47,410 | Middle $60,630 | High $88,750

BRICKLAYERS: This job is responsible for using mortar and other substances in building and repairing walls, partitions and other structures with materials like brick, structural tile or blocks. It is a job that requires both independence and cooperation along with attention to detail and integrity. You will need core strength, hand steadiness and the ability to see details at close range, plus construction and design knowledge.

WAGES IN METRO MILWAUKEE:

Low $47,410 | Middle $60,630 | High $88,750

CARPENTERS: Workers in this trade build, install and repair structures made from wood and other materials. Think of things like the framework of a building, stairways, window and door frames and floors. They may also install cabinets, siding or drywall. It is a job that requires measuring, cutting and fastening materials. You’ll need to get information, work with others and pay attention to details.

WAGES IN METRO MILWAUKEE:

Low $37,890 | Middle $52,950 | High $81,880

IRON WORKERS: This job is responsible for raising, placing and connecting steel and iron to form the basis of structures. It is a job that requires reading blueprints to determine locations and materials to use, connecting parts with rivets, bolts or welding and working with other trades to move materials into place. You’ll need to inspect materials, deal with potentially distracting noises and be comfortable working in high places.

WAGES IN METRO MILWAUKEE:

Low $54,080 | Middle $82,730 | High $107,590

OPERATING ENGINEERS: Responsible for operating equipment like graders, bulldozers, tractors, shovels and front-end loaders, this job excavates, moves and grades dirt, erects structures and pours concrete or other hard surface pavements. You’ll operate big pieces of machinery, coordinate actions with others and understand the consequences of a mistake could be extremely serious. In addition to operating equipment, you’ll also need mechanical and equipment maintenance knowledge.

WAGES IN METRO MILWAUKEE:

Low $52,080 | Middle $73,650 | High $93,930

stuff.biztimes.com | STUFF SE

2 AUG 2022 3 DEC 2022 5 AUG 2023

CAREER SPOTLIGHT

She had been pursuing nursing, but the field seemed increasingly unstable as COVID-19 cases rose during the pandemic. Bevilacqua was interested in business management, but she wanted something more specific.

She knew a lot of people who worked in construction, a field that had always piqued her interest, so she enrolled in Gateway Technical College’s construction management program. Bevilacqua graduated this spring.

Entering a traditionally male-dominated field was daunting at first. Bevilacqua feared she wouldn’t be taken seriously, but she wanted to take the risk and challenge herself.

“I wanted to graduate because I wanted to be educated and respected when I did come out in the field,” Bevilacqua said. “You have to go in believing that you’re just like anyone else.”

PAIGE BEVILACQUA

ENGINEERING TECHNICIAN/CONSTRUCTION INSPECTOR KAPUR & ASSOCIATES INC.

LIKE MANY PEOPLE, the pandemic forced Paige Bevilacqua to re-evaluate the course of her life.

ALEX SULLIVAN

ALEX SULLIVAN has always been creative. Growing up, she remembers dabbling in anything she could get her hands on; whether it be knitting, painting or sewing, you name it, she’s tried it.

Sullivan, who has attention-deficit/hyperactivity disorder, also hates sitting still. Her high school art teacher recommended that she channel her energy into something she’d never tried before: welding. Sullivan took a welding class at her high school and was hooked. “I was good at it. I liked making things come to life in their own, unique way.” she said. “It expanded to the point where I knew I could do this for a living.”

Sullivan started an internship at The Eaton Corp. in Waukesha while pursuing her degree in welding and fabrication through Waukesha

So far, the crews that Bevilacqua has worked with have been extremely welcoming and supportive. She currently works out of Burlington as an engineering technician and construction inspector at Kapur & Associates, a consulting engineering firm based in Glendale. Bevilacqua is in charge of managing and inspecting sites. She works outside with the crew, making sure they use the correct materials and stay on schedule. In the office, she organizes and enters her inspection notes. Bevilacqua’s job has changed the way she looks at the world. When she was a senior in high school, she figured her options for a career path were nursing or teaching.

County Technical College’s dual enrollment program for high school students. Eaton is a power management company that produces power chain management tools, fuel-efficient systems and commercial aircraft parts.

Sullivan finished the internship in June, shortly before graduating high school. At Eaton, she got a sense of what a career in welding looks like, confirming that, yes, she could definitely do this for a living. Sullivan honed her skills and produced some of her best welding work, embracing any challenges that came her way.

“I was used to low-heat welding, and Eaton needed heavy heat,” Sullivan said. “I didn’t know how I was going to do that, but I was able to put a lot of work into it and managed to get my welds up to par.”

Sullivan has big goals. In the future, she wants to weld for NASA. For now, Sullivan is still perfecting her craft, pursuing an associate degree in welding and fabrication at WCTC.

“With welding, if I don’t do it, I don’t feel like I’m breathing,” she said. n

A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 16

STUDENT WCTC

BEST ADVICE FOR SOMEONE INTERESTED IN THIS LINE OF WORK? “Take that first leap and see where you go. I think you’d be really impressed with yourself and where you can take yourself.”

BEST ADVICE YOU EVER GOT: “I’ve been told by my instructors that I’m going to do really great things in this field. That’s always a nice thing to hear!”

WHAT SKILL HELPS SOMEONE IN YOUR LINE OF WORK BE SUCCESSFUL? “Be a problem solver and an open minded, forward thinker.”

“They don’t really talk about the trades in high school, and the trades are such an important building block for this whole world,” she said. “I’ll be driving down the road and I’m like ‘Oh, wow, look at that water main … a regular person would just see a ditch and not think about what’s actually under it.” For Bevilacqua, it’s easy to pinpoint the best part of her job.

“Being able to drive by a site and know what it was to where it is now is so rewarding,” she said. “You know that you had a big part in making sure that job was complete.” n

SETH EHLERS

PROCESS & CONTROLS ENGINEERING TECHNICIAN MERCURY MARINE

WHEN HE WAS 20 YEARS OLD, SETH EHLERS discovered what he wanted to do when he “grew up.” He started his first job in metal work right before the 2008 recession hit. Ehlers had never worked in metals before, but he was determined to learn, evolve and be the best he could be. Soon after, the company let go of 75% of the staff and kept him.

BEST ADVICE YOU EVER GOT:

“Taking that first step and getting your foot in the door to better yourself.”

A GREAT LESSON YOU’VE LEARNED ON THE JOB: “Don’t be afraid to stand out and do things differently. Just because everyone else does something a certain way doesn’t mean that’s the only way it can be done, much less the best way.”

BEST ADVICE FOR SOMEONE INTERESTED IN THIS LINE OF WORK?

“Find a few companies to shadow at or ride along with. You can see what a typical day looks like in the trades and will get an idea if you’re truly interested.”

The company was short-staffed, so Ehlers went from department to department learning the ins and outs of each one, earning the nickname “the rover.” When the economy recovered and the staff grew, he was leading four departments. When Ehlers was put in charge of leading the design team of a multi-million-dollar machine, his passion for automation grew.

“I love figuring out how to make machines work. I have to learn everything about it, what I can adjust and what I need it to do,” Ehlers said. “With this, I learned it, took it over, and I flourished.”

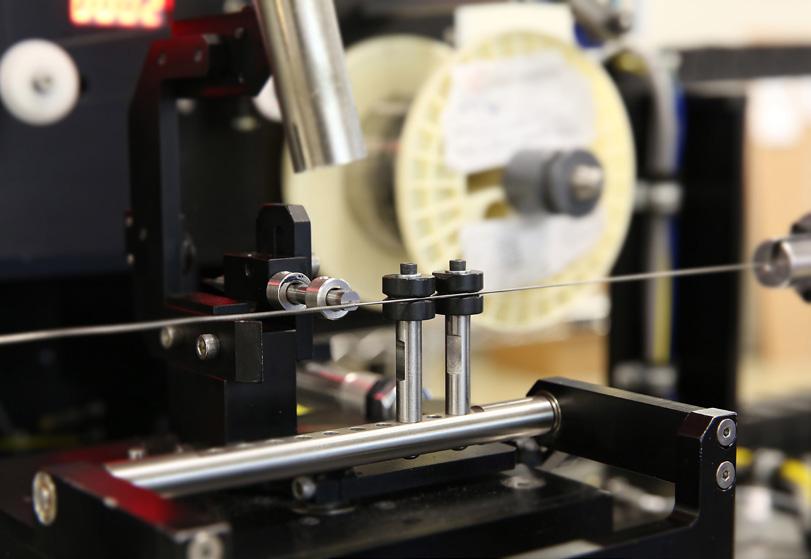

Ehlers wanted a job in which his career could advance, leading him to Fond du Lac-based Mercury Marine. The company produces outboard engines, sterndrives and inboard engines. The position he wanted required a degree so, at 31, Ehlers decided to enroll at Moraine Park Technical College. He graduated in May from the Quality and Advanced Manufacturing Technology program and is currently a process and controls engineering technician at Mercury Marine.

Ehlers works with robots, a previously uncharted territory for him. He programs automated robotic cells that grind, buff and polish stainless steel propellers for

WHAT SKILL HELPS SOMEONE IN YOUR LINE OF WORK BE SUCCESSFUL? “Keeping an open mind and always asking ‘why.’ Questioning and scrutinizing everything, in both my work and personal life, has helped accelerate my learning and understanding of so much in my life, and it has conditioned my brain to think more creatively when faced with difficult problems.”

Mercury Marine. The job is constantly evolving; he never gets bored.

“I’m addicted to the challenge. I don’t like standing there and pushing a button,” Ehlers said. “People joke and say the grass never grows under my feet because I’m always on the move.”

A typical day on the job could involve traveling to different plants to troubleshoot machinery, robotic applications or creating new programs by computer and by hand.

“Automation is a great career because there are so many facets like robotics, PLCs (Programmable Logic Controller) and networking. It’s always changing and challenging,” Ehlers said. “I want to figure out the things that nobody knows the answer to.” n

17 stuff.biztimes.com | STUFF SE

KYLEE THOMPSON

MUNICIPAL DESIGN ENGINEER INTERN KAPUR & ASSOCIATES INC.

KYLEE THOMPSON needed an elective class to fill her class schedule, so she decided to take a welding, drafting and print reading class. She loved everything about it, especially the design aspect. By her junior year of high school, she had taken every drafting course her school offered.

By senior year, Thompson was taking a few architecture courses at Gateway Technical College. She excelled particularly in math classes. Her professor took notice and asked her if she would consider transferring into the civil engineering technology program.

“Civil engineering was always just words I had heard growing up,” Thompson said. “I didn’t know what they did.”

Three months into her internship at Kapur & Associates, a Glendale-based consulting engineering firm, Thompson traded architecture for civil engineering.

At Kapur, Thompson is a municipal design engineer intern; she designs and plans the construction and maintenance of infrastructure projects. The job is anything but boring. Thompson has worked on designs for piping networks in water mains, parking lot expansions and – her personal favorite – road reconstructions.

“We had one project where we were boring under a state road and had to dig these 40-foot-deep trenches and then bore under it,” she said. “As someone who is a hands-on learner, my company has always been great with taking me to a site to go through it all so I can learn it that way, which makes it a lot easier to design it.”

The thing she loves most about her job is the journey to the finished product. From taking on an unfamiliar project and learning its ins and outs to knowing everything there is to know about it, Thompson appreciates the entire process.

“Seeing it go from nothing to developing into this project and knowing I worked on that is awesome,” she said.

Thompson plans to get her bachelor’s degree in civil engineering from Gateway and take the Principles and Practice of Engineering exam, which will allow her to become a licensed engineer and submit, seal and sign drawings and plans.n

BEST ADVICE FOR THOSE CONSIDERING THIS FIELD?

“Connect with companies or colleges in your area and see if you can take a tour to give you a better idea of the career you’re interested in.”

WHAT IS THE BEST ADVICE YOU’VE RECEIVED?

“It’s your life. You have to do what’s best for you.”

WHAT SKILL HELPS SOMEONE IN YOUR LINE OF WORK BE SUCCESSFUL?

“Communication. You’re going to be communicating with contractors, other engineers, different departments and clients. Also, a willingness to learn. You can’t come in expecting to know everything or be the best.”

MEDICAL-SURGICAL NURSE FROEDTERT PLEASANT PRAIRIE HOSPITAL

KRISTINA OVEROCKER began her career in health care in the early 2000s. After 9/11, she couldn’t fight the growing need to help people. This was coupled with a total lack of job security; Overocker had worked in the mortgage industry, which became less and less reliable following the terrorist attacks.

Before she was a registered nurse, Overocker was a certified nursing assistant at Froedtert Pleasant Prairie Hospital, where she still works today. Overocker graduated from Gateway Technical College’s nursing program in spring 2023 as a registered nurse.

“I got to a point where, with my family, I was stable enough to finish my goal of becoming a registered nurse and further my own educational goals,” Overocker said.

“I chose Gateway partly because of

18 A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 CAREER SPOTLIGHT

KRISTINA OVEROCKER

BEST ADVICE YOU EVER GOT: “Not every day is going to be a good day. I try my hardest to make it the best day for my patients. I may come home some days knowing that it’s not necessarily the best day for me or for them, but we’re going to try and make the next day better.”

WHAT SKILL HELPS SOMEONE IN YOUR LINE OF WORK BE SUCCESSFUL?

“You have to have empathy, and you have to have compassion.”

affordability and partly for the reputation of the type and quality of the nurses that they produce.”

Overocker is a medical-surgical nurse, which means she focuses on caring for adults who are recovering from or getting ready for surgery. A typical day usually looks like this:

First, she’ll look through her patients’ files to preview the day ahead. After face-to-face introductions, her patients become her full priority.

“I move through my patients by taking care of who may be the most ill at that moment,” Overocker said. “Then, I work my way through the patients and make sure they get the absolute best care that they possibly can.”

The job requires a certain level of compassion and humanity that Overocker thrives on. She doesn’t do her job for herself. Making sure her patients get the health care they deserve is why she loves nursing.

“You have to understand that the person in front of you may be having the absolute worst day of their life, and you have to have

empathy for that,” she said.

Overocker encourages anyone seriously interested in nursing to jump right in.

“Whether you work in a hospital, a nursing home or assisted living, it doesn’t matter,” she said. “Get your feet wet, know that it’s hard work and know you genuinely have to have a passion for it.”n

future OWN YOUR

PRESENTED BY:

SAVE THE DATE !

Every year in October

A panel of CEOs from prominent local manufacturing organizations will share their insights and best strategies for how to grow the region’s manufacturing industry in both the present & the future.

19 stuff.biztimes.com | STUFF SE biztimes.com/mfg

Discounted registration for manufacturers

CHRISTINA GANNON

CHARGE NURSE AND PRN NURSE THE BAY AT BURLINGTON HEALTH & REHABILITATION CENTER AND LINCOLN LUTHERAN

WHEN THE COVID-19 PANDEMIC HIT, Christina Gannon felt like she was missing something. For 10 years prior, she had worked in the restaurant industry, which had been upended by government-mandated shutdowns and capacity restrictions to curb the spread of the virus. With no money coming in, Gannon decided to sign up for nursing school. As it turned out, a career shift was what she needed.

After completing her prerequisite courses and becoming a certified nursing assistant (CAN), Gannon earned her licensed practical nursing diploma from Gateway Technical College in April 2023. The process was long and, at times, difficult. She took the challenge head on, seeing it as an opportunity to better herself.

“We were in school for six hours a day, three times a week and the fourth day was a 12-hour clinical,” she said. “I probably spent 65 hours a week in physical class and working with my classmates on FaceTime … doing whatever we needed to do to be successful.”

20 A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 CAREER SPOTLIGHT A PRODUCT OF To participate: Email advertise@biztimes.com To request a copy: Call (414) 336-7100 Interested in more STUFF? Southeast Edition: Publishes in September 2024 A GUIDE TO SUPPLEMENT OF FALL 2023 DESIGNED, MADE AND BUILT IN SOUTHEASTERN WISCONSIN SEE PROFILES OF COMPANIES HIRING NOW ON PAGES 37-75 LEARN MORE ABOUT EXCITING CAREER OPPORTUNITIES could I make a career out of this? what is it? who makes it? STUFF BLOWN UP Baird Center page 14 COOL STUFF Made & Designed in Wisconsin pages 6-9 CHOOSING A TECH SCHOOL page 23 01-05 STUFF SE 2023 Front of Book.indd 8/25/23 3:45 PM A GUIDE TO DESIGNED, MADE AND BUILT IN SOUTHEASTERN WISCONSIN FALL 2023

“ The most rewarding aspect is helping people when they’re not able to help themselves and doing it in a very compassionate manner.”

BEST ADVICE?

“Advocate for yourself and utilize those teachers at school because I had some amazing instructors that still check in on me every week.

WHAT IS THE BEST ADVICE YOU’VE RECEIVED?

“Never quit. Keep that chin up high even on dark days.”

WHAT SKILL HELPS SOMEONE IN YOUR LINE OF WORK BE SUCCESSFUL?

“Time management. “

Now, she works as a charge nurse at The Bay at Burlington Health & Rehabilitation Center in Burlington and as a pro re nata nurse, or PRN, at Lincoln Lutheran, a Racine-based senior living facility. As a PRN, she works for hospitals only when the need arises.

“As a CNA, I would just assist the nurse with bathing, vitals and a range of smaller things,” Gannon said. “Now as a nurse, I’m the go-to. My aides need me, social workers and doctors are calling me, and families want updates.”

Gannon is the first to admit that her job is a heavy load; however, she couldn’t be happier with it. As a charge nurse, she works alongside other nurses and supervises the unit to make sure everything runs smoothly. As a CNA, she checks vitals, supplies medication, manages feeding tubes, and assists patients with personal care needs.

“The most rewarding aspect is helping people when they’re not able to help themselves and doing it in a very compassionate manner,” she said. “It’s important to help the patients and my staff get through the crazy day and just remind everybody to provide the best care that we can while we’re there for the day.” n

21 stuff.biztimes.com | STUFF SE

hiring entry level individuals that are excited to start a career in manufacturing. Grow your skills in our state-of-the-art facility as you craft world class orthopedic instruments. APPLY: GBIJ obs.com

BUILD YOUR CAREER We’re

KELSEA MEVIS

ROBOTICS PROGRAMMER AND TECHNICIAN EXACT AUTOMATION

BEFORE SHE WORKED FULL TIME as a robotics programmer and technician, Kelsea Mevis, like many other high school students, was contemplating her future. She wasn’t sure what she wanted to do. Did she want to go to college? Did she want to go to a technical school? One thing she knew was that she was interested in robotics.

Mevis, who has family members who work in the field, had always been curious about the ins and outs of robotics programming. Through Waukesha County Technical College’s dual enrollment program for high school students, Mevis was able to decide if a career in robotics was for her. In May, Mevis graduated with an Associate of Applied Science degree in Automation Systems Technology from WCTC with honors. She also received certifications in Programmable Logic Controllers programming.

While studying at WCTC, Mevis started working as an intern for Exact Automation, a Franklin-based robotics system integrator. She would

work during the day and go to class at night. Eventually, she worked her way to a full-time position.

“It was a good time for me to learn the field, participate in an assembly and understand the nuances of everything,” Mevis said. “As I progressed through school, I became more and more useful with the skills I learned, and I moved into robot programming as my main skill and developed that outside of school, too.”

At Exact Automation, Mevis does both service and project work. Every workday is different. One day, she’s programming and building the automation systems in-house. Another day, she’s packing up her tools and laptop for a service call or installation.

“With traveling, it’s great because I’m young and I don’t have a house or a family that I have to take care of,” she said. “It’s a good thing for me to do to further my career.”

What Mevis loves most about her job, though, is

BEST ADVICE FOR SOMEONE INTERESTED IN THIS LINE OF WORK?

“Having flexibility for traveling is huge for employers because it’s harder to find people who are willing to do that. If you put in that time, get experience and learn a lot, it pays off in the end.”

the constant challenge and teamwork. Facing a problem, finding a solution and giving customers what they need is endlessly rewarding.

“You really have to know your team, trust your team and work well together,” Mevis said. “We work alongside each other all day, so it’s rewarding when the whole team gets the job done together.” n

22 A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023 CAREER SPOTLIGHT

how to find the

TECH COLLEGE program for you

TECH SCHOOLS 101 – HACKS TO HELP YOU ON YOUR JOB TRAINING JOURNEY

Whether you know what trade you want to pursue or not, figuring out where to start your technical schooling or choosing from the bevy of options available to you can sometimes be the hardest part. To help you along the way, we spoke with experts who have counseled thousands of people just like you.

STILL EXPLORING?

If you’re interested in the trades but can’t decide on a specific area or program, experts suggest shadowing a student, teacher or employee in a field you’re curious about, touring a workplace, visiting a college career center, exploring websites for those colleges, or simply reading a few job descriptions to see if the tasks or responsibilities spark your interest.

You are not alone if you’re having a hard time deciding on a career path.

If you’re comfortable talking through your interests with someone, a great place to begin is speaking with a counselor at a college’s career services department, says Jenny McGilligan, director of CareerHub at Milwaukee Area Technical College.

Bradley Mitchell, a recruiter at Moraine Park Technical College suggests having a conversation with someone who works in the field.

“Learning right from the source about the good, bad and otherwise can really help you know if that eventual job will be a good fit,” he said.

SEARCHING ONLINE

Sheri Eisch, career counselor at Gateway Technical College, suggests taking some time to dig around on a college’s website to explore the degree and certificates offered, and the kind of jobs those credentials can lead to, including how much they pay. You can also find out if the program offers night and weekend classes that might better fit your schedule.

Some of the workers employers are looking for right now, in addition to nurses and other health care providers, include students with training in advanced manufacturing technology, automotive and diesel maintenance, carpentry, building trades, CNC production and programming, electrical technology, machining, plumbing, HVAC, robotics and welding.

HOW LONG WILL I BE IN SCHOOL?

How long your training takes will depend on what skill program you are pursuing. For certificate programs, the term can be as short as four to 10 weeks. Technical diplomas often take about one academic year to complete, while associate degrees often take about two.

Mitchell added that many students work while going to school and most trade schools have some flexibility with how you can take your classes or offer part-time enrollment.

“There will still be a limit as to how long you can take to complete an entire program, but most students are able to figure this out with their advisor,” he said.

DUAL CREDITS

If you’re looking to expedite things, many tech colleges also offer opportunities to earn college credits in high school, which can shorten the time you spend in school and save money.

High school students can even earn diplomas and degrees before graduating from high school, noted Katie Graf, director of high school partnerships at Gateway Technical College.

“Many incoming college students have taken dual credits at their high schools, or Start College Now credits at a local technical college during high school,” Graf said.

PAYING FOR IT

One of the biggest barriers to pursuing a degree, diploma or certificate can often be the cost, which, in addition to tuition, can include books, supplies, laptops, tools, supplies and specialty clothing.

Luckily, tech schools offer a variety of scholarships, grants, loans and financial aid programs, and there are staff available to help counsel you about your options. Some eligible students can even attend college tuition-free.

“I encourage everyone to fill out a federal financial aid application (FAFSA) to see your eligibility for grants and to apply for scholarships to help offset some of the costs,” McGilligan said. “Also, some employers offer tuition benefits to help you take classes.”

Gateway Technical College and other schools offer the Promise Program, which is geared toward high school seniors who need financial assistance. The program fills the gap between federal and state grants and the cost of tuition, so eligible students can attend tuition free. n

MEET THE EXPERTS

SHERI EISCH: career counselor at Gateway Technical College

KATIE GRAF: director of high school partnerships at Gateway Technical College

JENNY MCGILLIGAN: director of CareerHub at Milwaukee Area Technical College

BRADLEY MITCHELL: recruiter at Moraine Park Technical College

stuff.biztimes.com | STUFF SE 23

1111 Cedar Creek Rd, Grafton, WI 53024 (262) 204-3211

miba.com/en/product-areas/industrial-bearings

facebook.com/MibaIndustrialBearingsUSA

linkedin.com/showcase/miba-industrial-bearings

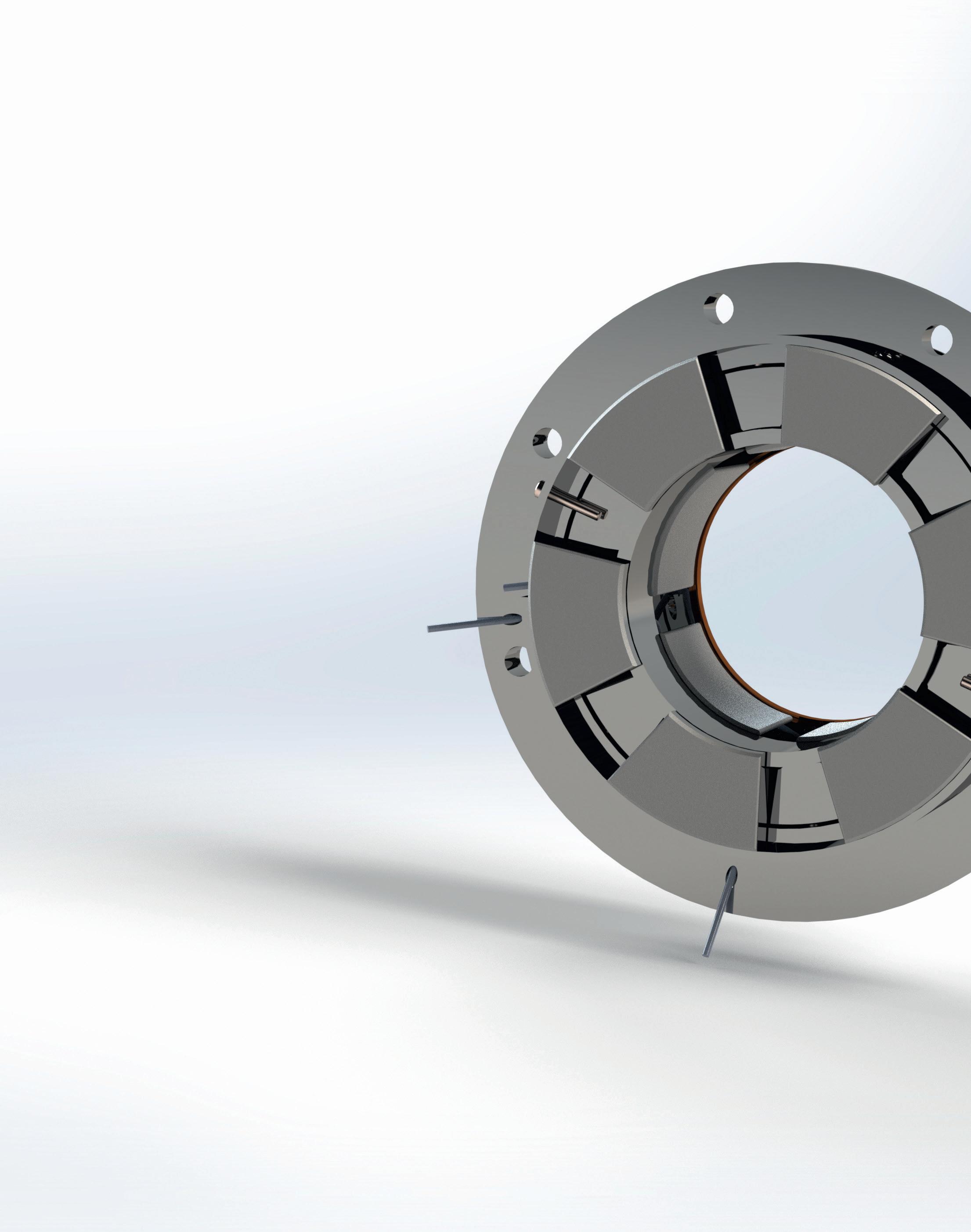

WHO WE ARE:

Founded 55 years ago Miba Industrial Bearings US is THE expert when it comes to turbomachinery bearings. Located in Grafton, WI, the site is part of the Miba Group, which generated 1 billion dollars revenue last year. While acting globally, the company has a strong local presence with 8 sites in the US and 30 sites worldwide. Having the financial stability and a strong foothold in the US; we are ready to expand and grow.

BENEFITS OFFERED DAY ONE:

• Health Insurance

• Dental Insurance

• Vision Insurance

• Flexible Spending Account

• Life Insurance

• Disability Insurance

• 401(k)

• Bonuses

Employees: 150

Year founded: 1968

President: Gregory Loisel

AD

STUFF WE MAKE: WORK HERE TODAY:

Miba Industrial Bearings US is one of the worldwide leading manufacturers of hydrodynamic bearings. These bearings are critical parts in turbines, generators, motors, pumps and compressors. Our bearings are used in power generation as well as in the oil and gas industry and the petrochemical industry. Without them, rotating equipment like turbines would stop turning. That is why these bearings are a key component to keep America running!

• Vacation (paid time off)

• Sick (paid time)

• Flexible Workplace (summer hours/flex time)

• Dependent Care Reimbursement Account

• Wellness Program

• Tuition Reimbursement

• Apprenticeships/Internships

Miba has a strong focus on its employees that is why we claim: “Our inspired people make the difference.” If you want to make a difference and keep America running, we are happy to welcome you here in Grafton, Wisconsin.

Text (414) 232-4273 or email andrea.slamka@ miba.com your resume today!

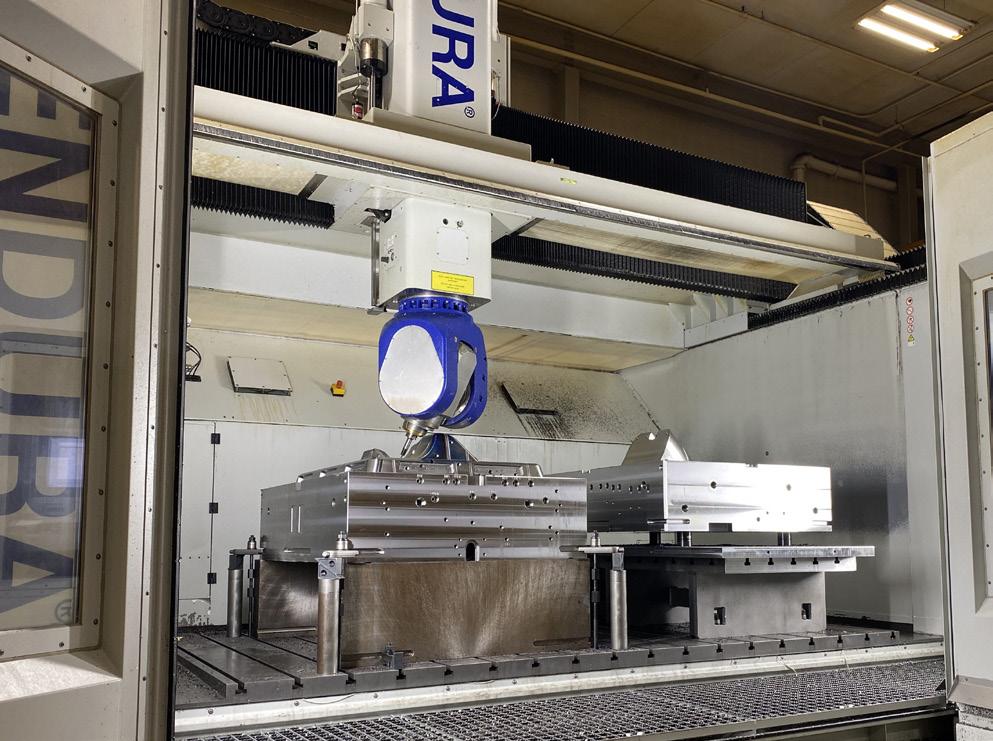

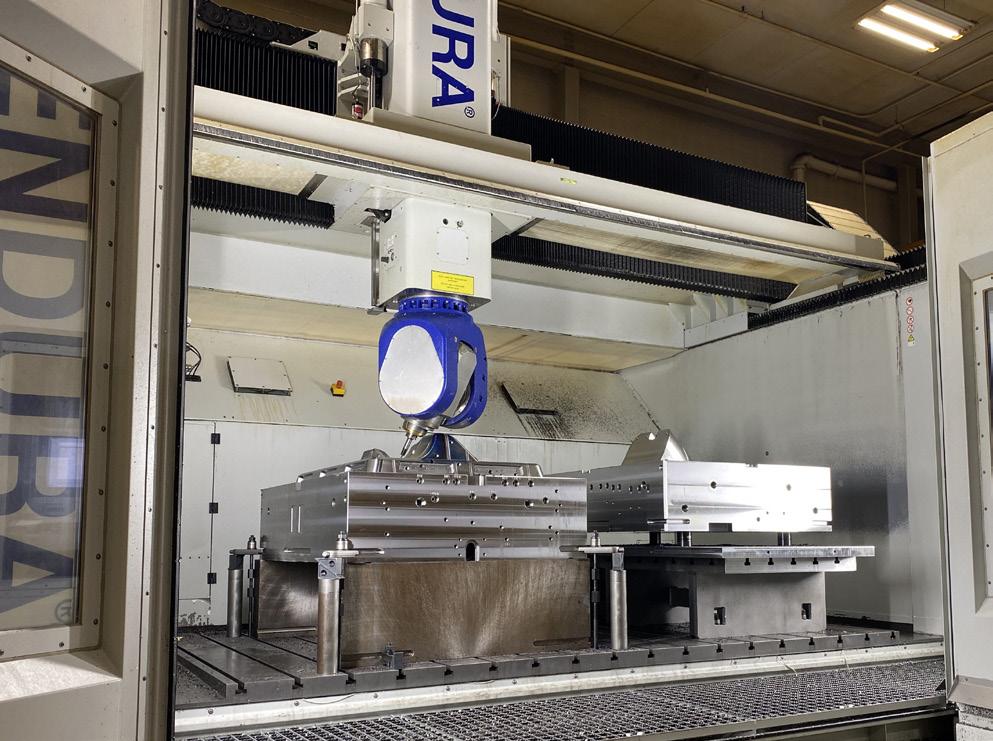

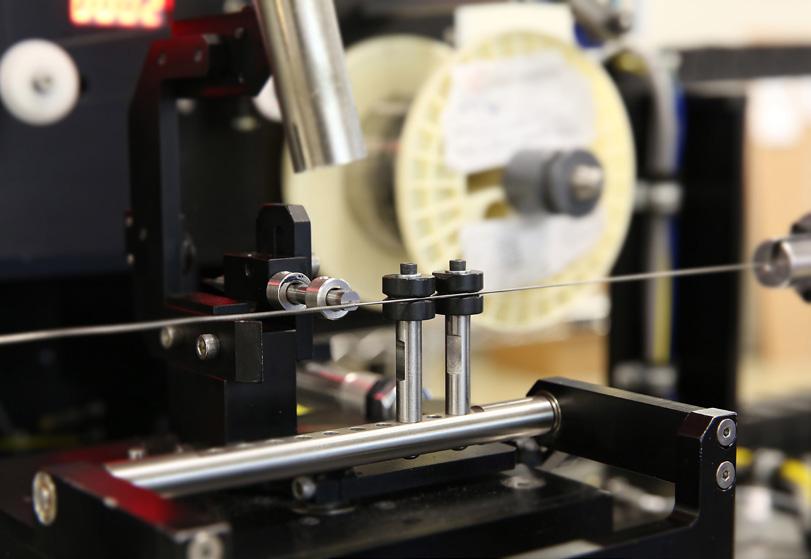

OUR BEARINGS KEEP AMERICA RUNNING! WHAT DRIVES YOU? • Part-Time Employment while in program • Uniforms • Access to 3-5 axis CNC Lathes, Mills (vertical / Horizontal). • Access to manual machines • Graduate from the GPSEd program with passing grades • 3-year commitment following Graduation and acceptance of full time employment Andrea Slamka +1 (262) 2043211 andrea.slamka@miba.com Miba Industrial Bearings U.S. Grafton, WI Miba responsibilities: Students responsibilities: We are hiring Youth Apprentice Opportunity Contact us:

BREAKING DOWN THE SUPPLY CHAIN

Dozens of companies often contribute to making products available for us to buy at a store or order online. Issues at any one of them, or the transportation between them, can disrupt product availability. These issues create plenty of job opportunities. Companies employ people in supply chain management jobs to make sure they have the right materials available at the right time to make the products that consumers want. They also need employees to figure out the best and most efficient way to ship those products to stores and consumers.

RAW MATERIALS TRANSPORTATION PHASE

The products we use every day start as raw materials like metal, plastic resins, food commodities or fabrics.

Raw materials are transported to factories by a variety of methods, including boat, train, airplane and truck.

MANUFACTURING TRANSPORTATION

Most manufacturers don’t actually make the final product we see. Instead, many companies specialize in making components or parts that go into a final product.

Each method of transportation has benefits and drawbacks. An airplane may be faster, but costs more. A train may be cheaper, but a truck can take the product to a specific destination.

CONSUMERS ASSEMBLY & DISTRIBUTION TRANSPORTATION

When consumers finally buy products, it is the end of a complex process that benefits from companies knowing what to make and how to ship it.

RETAIL & E-COMMERCE

Once products are finished, they are shipped to retailers or warehouses for distribution.

Many companies employ people to coordinate shipping and receiving products and materials. These people don’t work directly on products but are critical to keeping a business moving.

All of the parts and components made by factories eventually come together for final assembly and distribution.

The need for people working in supply chain management is growing as companies look to save money moving products as efficiently as possible. The U.S. Bureau of Labor Statistics estimates supply chain jobs in Wisconsin will grow 32% by 2030, with median salaries around $62,870. Four-year and two-year schools including Marquette University and Waukesha County Technical College have programs in supply chain management.

26 STUFF SE | Fall 2023 A SUPPLEMENT OF BIZTIMES MILWAUKEE SUPPLY

CHAIN

HOT NOWjobs

NOT EVERY JOB requires a four-year degree, especially jobs in construction, maintenance, production and transportation. These 45 jobs all require an associate degree at most, although some do involve longer periods of on-the-job training. Each job has a median salary of at least $40,000 per year and employment in each is expected to grow faster than employment in the state overall by 2030.

27 stuff.biztimes.com | STUFF SE EDUCATION TYPICALLY REQUIRED No formal educational credential High school diploma or equivalent Postsecondary non-degree award or some college, no degree Associate degree Bachelor's degree ON-THE-JOB TRAINING NEEDED None Short-term Moderate Long-term Apprenticeship

SOURCE: Department of Workforce Development OCCUPATION EMPLOYMENT 2020 % PROJECTED GROWTH BY 2030 TYPICAL POSTHIRE TRAINING ANNUAL MEDIAN INCOME CONSTRUCTION AND EXTRACTION OCCUPATIONS 126,068 8.0 $53,760 Construction laborers 20,509 11.9 $40,430 Electricians 12,704 11.2 $64,220 First-line supervisors of construction trades and extraction workers 12,371 9.1 $73,250 Plumbers, pipefitters and steamfitters 8,874 7.7 $65,570 Operating engineers and other construction equipment operators 8,663 8.0 $64,730 Painters, construction and maintenance 5,918 6.7 $45,910 Highway maintenance workers 5,774 6.6 $46,910 Roofers 3,118 7.5 $46,000 Sheet metal workers 2,858 7.6 $59,470 Septic tank servicers and sewer pipe cleaners 1,040 13.2 $48,070 Excavating and loading machine and dragline operators, surface mining 935 15.1 $50,940 Structural iron and steel workers 921 10.8 $68,640 Glaziers 869 7.9 $55,810 Floor layers, except carpet, wood and hard tiles 617 13.3 $53,060 Insulation workers, mechanical 589 8.8 $66,660 Elevator installers and repairers 463 8.2 $94,310 Plasterers and stucco masons 440 6.8 $40,480 Miscellaneous construction and related workers 301 12.0 $40,120 Earth drillers, except oil and gas; and explosives workers, ordnance handling experts and blasters 282 7.1 $50,440 INSTALLATION, MAINTENANCE AND REPAIR OCCUPATIONS 117,423 7.5 $48,880 Maintenance and repair workers, general 34,082 6.7 $43,920 Industrial machinery mechanics 12,417 25.5 $55,500 Heating, air conditioning, and refrigeration mechanics and installers 5,477 7.7 $53,190 Mobile heavy equipment mechanics, except engines 2,139 17.1 $54,220 Maintenance workers, machinery 2,054 12.8 $57,010 Installation, maintenance and repair workers, all other 2,048 9.1 $43,410 Farm equipment mechanics and service technicians 2,026 11.3 $42,980 Aircraft mechanics and service technicians 1,332 8.2 $62,040 Medical equipment repairers 949 9.2 $49,150 Coin, vending and amusement machine servicers and repairers 942 11.5 $40,890 Millwrights 676 13.6 $62,990 Mechanical door repairers 433 20.3 $45,810 Electric motor, power tool and related repairers 288 9.7 $47,600 Recreational vehicle service technicians 267 24.7 $40,570 Avionics technicians 207 13.0 $42,640 PRODUCTION OCCUPATIONS 319,263 2.9 $39,030 First-line supervisors of production and operating workers 24,080 8.6 $63,390 Welders, cutters, solderers and brazers 17,005 12.6 $46,530 Machinists 9,978 13.0 $40,070 Extruding and drawing machine setters, operators and tenders, metal and plastic 3,948 7.3 $42,950 Multiple machine tool setters, operators and tenders, metal and plastic 2,722 12.8 $43,490 Computer numerically controlled tool programmers 1,164 32.0 $55,360 Dental laboratory technicians 897 18.0 $41,430 Jewelers and precious stone and metal workers 600 12.2 $52,080 Crushing, grinding and polishing machine setters, operators, and tenders 477 7.8 $41,070 Chemical plant and system operators 225 8.9 $63,380 Petroleum pump system operators, refinery operators and gaugers 119 14.3 $65,520

Jobs IN Detail

WHILE PRODUCTION, CONSTRUCTION, maintenance and transportation jobs are expected to grow across the board in the coming years, these four jobs are among the fastest growing with the most annual openings available, giving you an even better chance to land a job. Take a look at these job descriptions to get a better idea of what each occupation does, what training is involved and what your pay could be. You can learn more about each job and all of those listed in “Hot Jobs” on page 27 at onetonline.org.

HEATING, AIR CONDITIONING, AND REFRIGERATION MECHANICS AND INSTALLERS

TO BE SUCCESSFUL IN THE HVAC INDUSTRY, you’ll need to have a mix of strong technical and communication skills. Heating, air conditioning and refrigeration mechanics and installers often need to test electrical circuits and components, study blueprints and designs, repair defective equipment and lay out and connect electrical wiring. But first, workers must communicate with customers to figure out what problems they’re having and lay out a detailed plan of action.

Jobs available within this industry include air conditioner technicians, HVAC installers, refrigeration mechanics and more.

In addition to having strong people skills, those considering a job as a heating, air conditioning or refrigeration mechanic must be apt at critical thinking, troubleshooting problems and reading technical documents. A strong knowledge of building and construction methods, tools and engineering science and technology is also required.

To gain a career in this field, most people typically need one to two years of training, including on-the-job experience and informal training with experienced workers. Training at a vocational school or through an apprenticeship program are also options.

This job category is projected to grow by 7.7% in Wisconsin by 2030, and projections show 40,100 job openings in the state by 2031. In the Milwaukee area, mechanics and installers can expect to make an average of $63,450 annually, with some making as much as $104,860. n

STRUCTURAL IRON AND STEEL WORKERS

IF YOU’VE EVER DRIVEN BY A CONSTRUCTION SITE and found yourself fascinated by the workers who precisely put in place the framework of a building, you might want to consider a job as an iron and steel worker. Iron and steel workers are the people who operate cranes, hoists and other moving or lifting equipment to install metal structural components. In order to do this, they must first review project blueprints.

To excel in this career, you’ll need to have good coordination and strong critical thinking skills. You’ll also need to be an active listener who’s able to give others your undivided attention. If math is one of your stronger subjects in school, that could directly translate into being an iron and steel worker. Knowledge of building and construction, machines and tools and a general interest in safety policies and procedures are also helpful attributes.

This occupation typically requires a high school diploma. Some previous work-related skill is usually needed, but iron and steel workers can gain this experience through an apprenticeship program last-

ing anywhere from a few months to a year.

This job category is projected to grow by 10.8% in Wisconsin by 2030, and projections show 7,500 job openings in the state by 2031. In the Milwaukee area, structural iron and steel workers can expect to make an average of $82,730 annually, with some workers making as much as $107,590. n

28 A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | Fall 2023

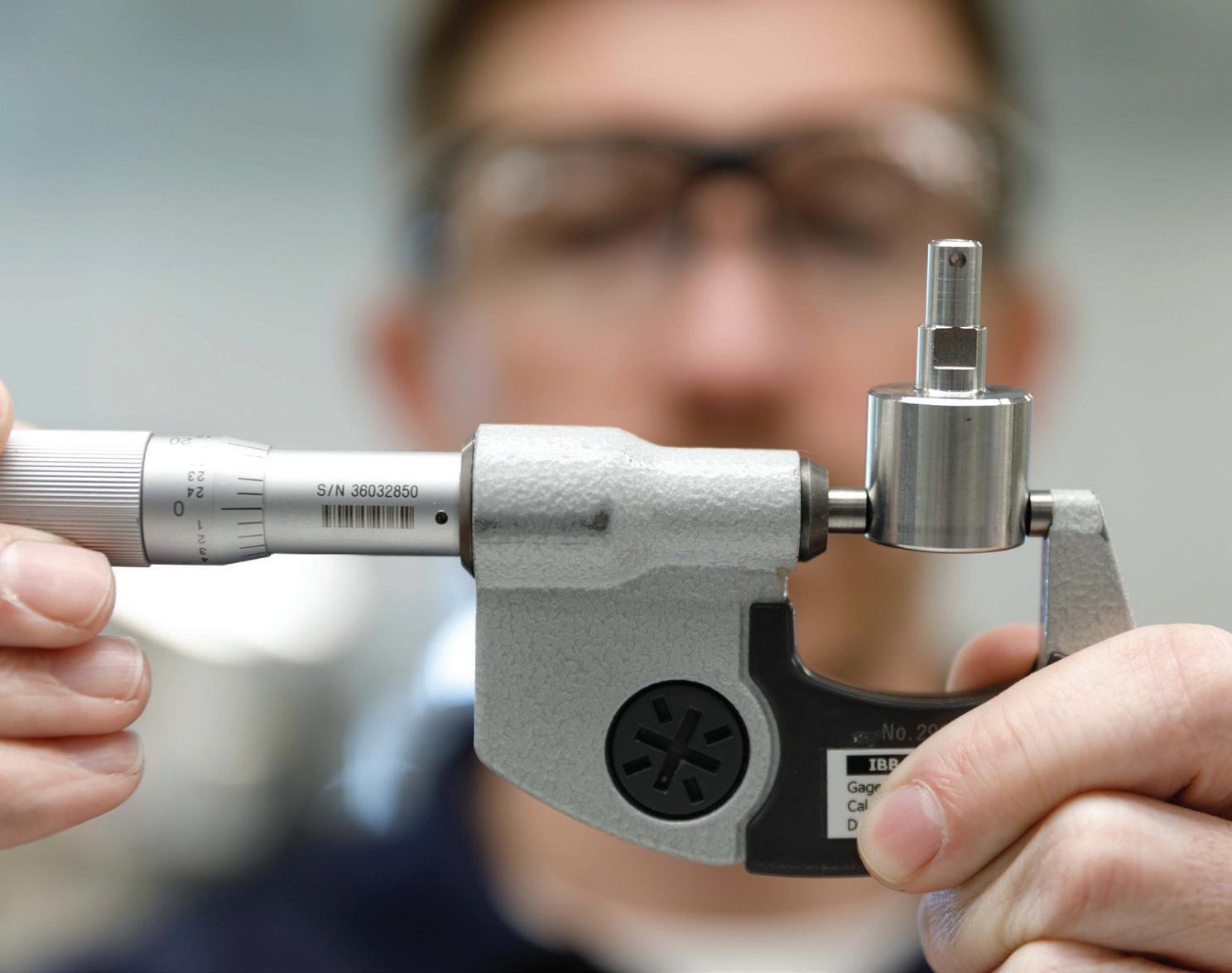

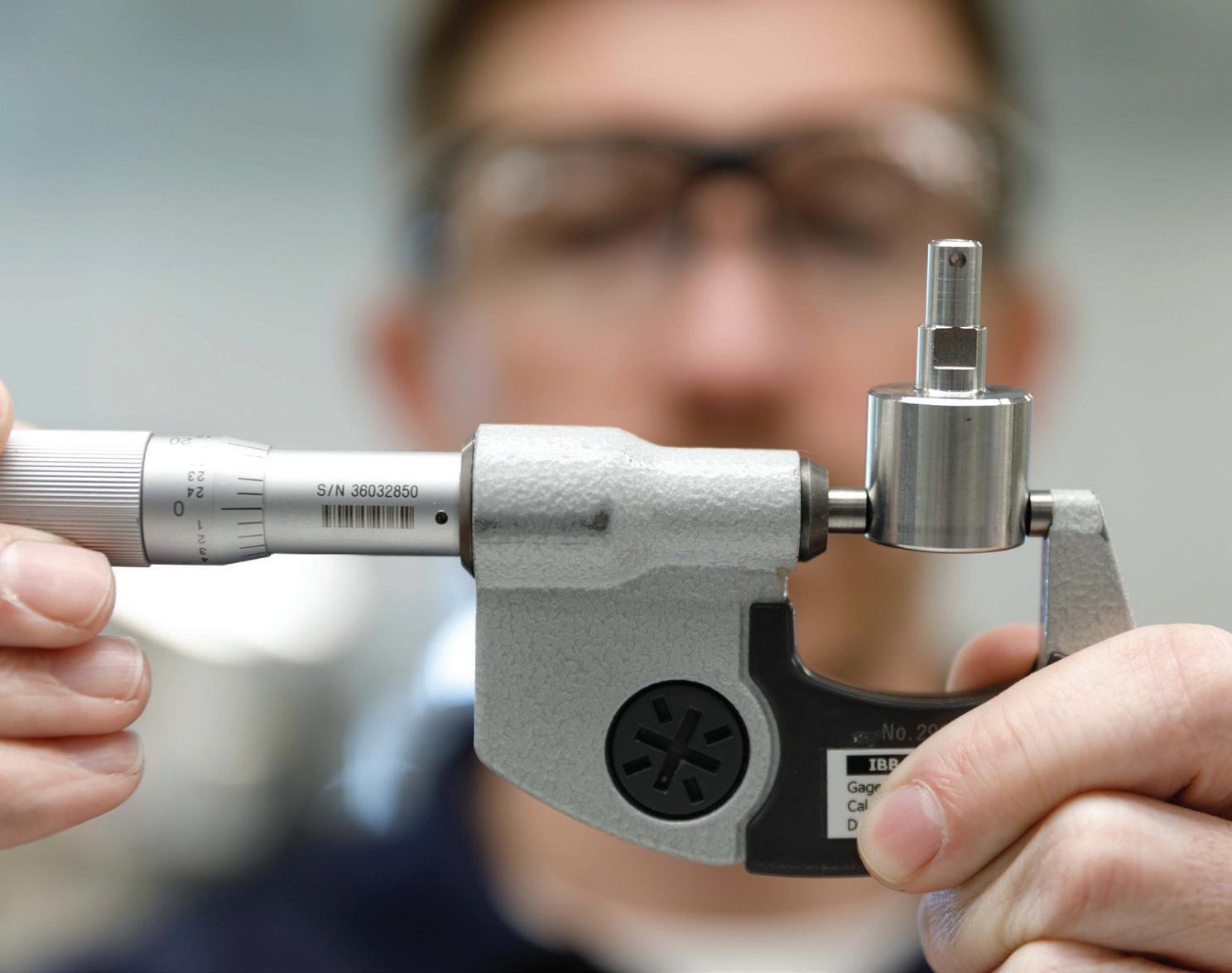

MACHINISTS

STRONG ATTENTION TO DETAIL, deep understanding of mathematics – including algebra, geometry and statistics – a creative mindset and overall interest in design are all qualities that make a good machinist. This occupation involves setting up and operating a variety of machine tools to make precision

ELECTRICIANS

ELECTRICIANS INSTALL, MAINTAIN AND REPAIR electrical wiring, equipment and fixtures. This work is critical as poorly installed electrical wiring and fixtures can be hazardous. Daily work activities might include making construction diagrams, threading wire or cable through ducts or conduits, repairing electrical equipment, digging holes or trenches and fabricating parts.

Electricians will also need to work from ladders, scaffolds or roofs; use a variety of equipment including power construction tools; test electrical systems; and diagnose malfunctioning systems or parts. To be a good electrician, you’ll need to love working with your hands, have a strong knowledge of math, mechanics and design and have a fundamental understanding of business and management principles.

Job titles in this category include control electrician, wireman and electrical troubleshooter.

This is yet another career that requires strong attention to detail. You’ll also need critical thinking, time management and communication skills. Necessary technological skills include knowledge in Autodesk AutoCAD, accounting software and analytical software like Construction Master Pro.

Most electricians require training in vocational schools, onthe-job experience or an associate degree. Electricians usually need three to four years of training, which could also be gained through an apprenticeship program. They must also pass a licensing exam.

This job category is projected to grow by 11.2% in Wisconsin by 2030, and projections show 79,900 job openings in the state by 2031. In the Milwaukee area, electricians can expect to make an average of $78,120 annually, with some workers making as much as $106,320. n

parts out of metal. Job titles in this field include CNC machinists, tool room machinists and gear machinists. Machinists may also fabricate, modify or repair mechanical instruments and fabricate and modify parts to make or repair machine tools.

Day-to-day tasks might include designing fixtures, tooling or experimental parts to meet special engineering needs; machining parts to different specifications; programming computers or other electronic equipment; studying sample parts, blueprints or drawings; and calculating the dimensions of certain parts. To succeed as a machinist, you’ll need knowledge in several software programs, such as Autodesk AutoCAD and Armchair Machinist, and strong critical thinking skills.

Most machinists require training at a vocational school, onthe-job experience or an associate degree. Machinists usually need one or two years of training, which could also be gained through an apprenticeship program.

This job category is projected to grow by 13% in Wisconsin by 2030, and projections show 37,500 job openings in the state by 2031. In the Milwaukee area, machinists can expect to make an average of $45,590 annually, with some workers making as much as $64,120. n

29 stuff.biztimes.com | STUFF SE

APPRENTICESHIPS by

the numbers

APPRENTICESHIPS OFFER A UNIQUE OPPORTUNITY to get started in a career. They give you a chance to learn from experienced workers, take classes and earn money along the way. In Wisconsin, apprenticeships require a contract between the apprentice, the employer and the state that details how long your training will be, how many hours you will spend in the classroom, what skills you will learn and the wages you will receive.

MORE AND MORE YOUNG PEOPLE ARE SIGNING UP FOR APPRENTICESHIPS. A decade ago, the average age of someone signing a contract was 29. In 2022, the average age was down to 27.1.

APPRENTICESHIPS BY THE NUMBERS A SUPPLEMENT OF BIZTIMES MILWAUKEE STUFF SE | 2023 30

9, 08 1 15 ,7 85 14, 783 14,230 14,719 13 ,799 12,263 9 ,68 1 11,3 21 9, 87 0 10 ,633 10 ,5 21 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022

in Wisconsin ACTIVE

Apprenticeships

ACTIVE

2012 2022 2014 2020 2016 2018 Average age at time of contract registration

THERE ARE DOZENS OF DIFFERENT APPRENTICESHIPS YOU CAN DO IN WISCONSIN in a wide variety of jobs, from construction jobs like carpenter, painter or plumber to industrial jobs like a machinist, tool and die maker or maintenance electrician. There are also apprenticeships in service trades for jobs like barber and even funeral director. Here are the top 10 most popular apprenticeships based on the number of active contracts.

do Apprentices Make? do Apprentices HOW MUCH

APPRENTICESHIPS: EARN whileLEARNyou

ONE OF THE MOST APPEALING ASPECTS OF AN APPRENTICESHIP IS THE OPPORTUNITY TO EARN WHILE YOU LEARN. Not only will you earn money while working as an apprentice, but you also earn money while in class for instruction related to your trade. An apprenticeship contract includes a set schedule of wages as time passes and your skills grow. The specific hourly rate is determined by the rate paid for that same trade and by what part of the state you are in. To the left is a look at the range of how much select trade apprentices make in southeastern Wisconsin.

31 stuff.biztimes.com | STUFF SE the MOST POPULAR Apprenticeships 2,6 78 1,99 5 1,22 1 1,12 6 65 0 59 1 540 45 5 38 4 361 Construction Electrician Plumber Carpenter (Construction) Operating Engineer Sheet Metal Worker Construction Craf t Laborer Steamfitter (Construction) Industrial Electrician Iron Worker Electric Line Worker

Electrician Plumber, Fire Sprinkler-fitter, Steamfitter Sheet Metal Worker Bricklayer, Blocklayer, Stonemason HVAC Installer Servicer Carpenter Cement Mason $36.74 $40.95 $39.25 $40.41 $36.74 $39.88 $33.52 $36.18 $31.02 $33.92 $26.14 $30.09 $29.17 $29.97

Co $ t of Living the

Basic Budgeting: How much do I need to make to live like I want?

LIKE GOVERNMENTS AND BUSINESSES, IT IS IMPORTANT FOR INDIVIDUALS AND FAMILIES TO HAVE A BUDGET SO THEY UNDERSTAND HOW MUCH MONEY THEY MAKE AND SPEND EACH MONTH. FORTUNATELY, APPS LIKE MINT CAN HELP YOU TRACK YOUR BUDGET, BUT IT IS ALSO GOOD TO KNOW WHERE YOUR MONEY IS GOING WITHOUT THE HELP OF TECHNOLOGY.

WHERE YOU LIVE MATTERS:

The cost of many common items in your budget will be different depending on where you live. The Economic Policy Institute estimates housing for one person in metro Milwaukee costs around $663 per month while it is around $1,000 in Chicago and $2,350 in San Francisco. Here’s a look at how some common costs compare across metro areas.

What makes up your budget?

At its heart, a budget is about how much you make and how much you spend. Every month, there are certain costs you can plan for like rent, utilities, groceries and food, and transportation costs like gas for your car. There are also unexpected costs like medical bills if you get hurt or car repairs if you’re in an accident. You should plan some extra cushion in your budget to account for these, to save for bigger purchases in the future or for things you want to do like going to a Milwaukee Brewers game or attending a concert. It may seem like it is a long way off, but you should also plan to set some money aside for retirement.

What changes my budget?

The amount of money you spend each month on some things, like rent, may not change very much. Other costs may go up and down depending on your activities. For example, utilities charge you based on how much natural gas or electricity you use, so if you have to heat or cool your home a lot, your costs may go up if those items are not included in your rent. The amount you spend on food may also change if you eat at restaurants a lot since they are generally more expensive than cooking at home.

How do I save money?

Source: Economic Policy Institute budget calculator

If you want to save money for bigger purchases like a house, a new car or a nice vacation you will need to spend less than you make each month. There are lots of ways to save money on regular costs including splitting housing with roommates, buying generic products instead of name brands, buying in bulk, not using credit cards or at least making sure you pay off your balance every month to avoid interest costs.