Parts you can trust

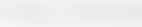

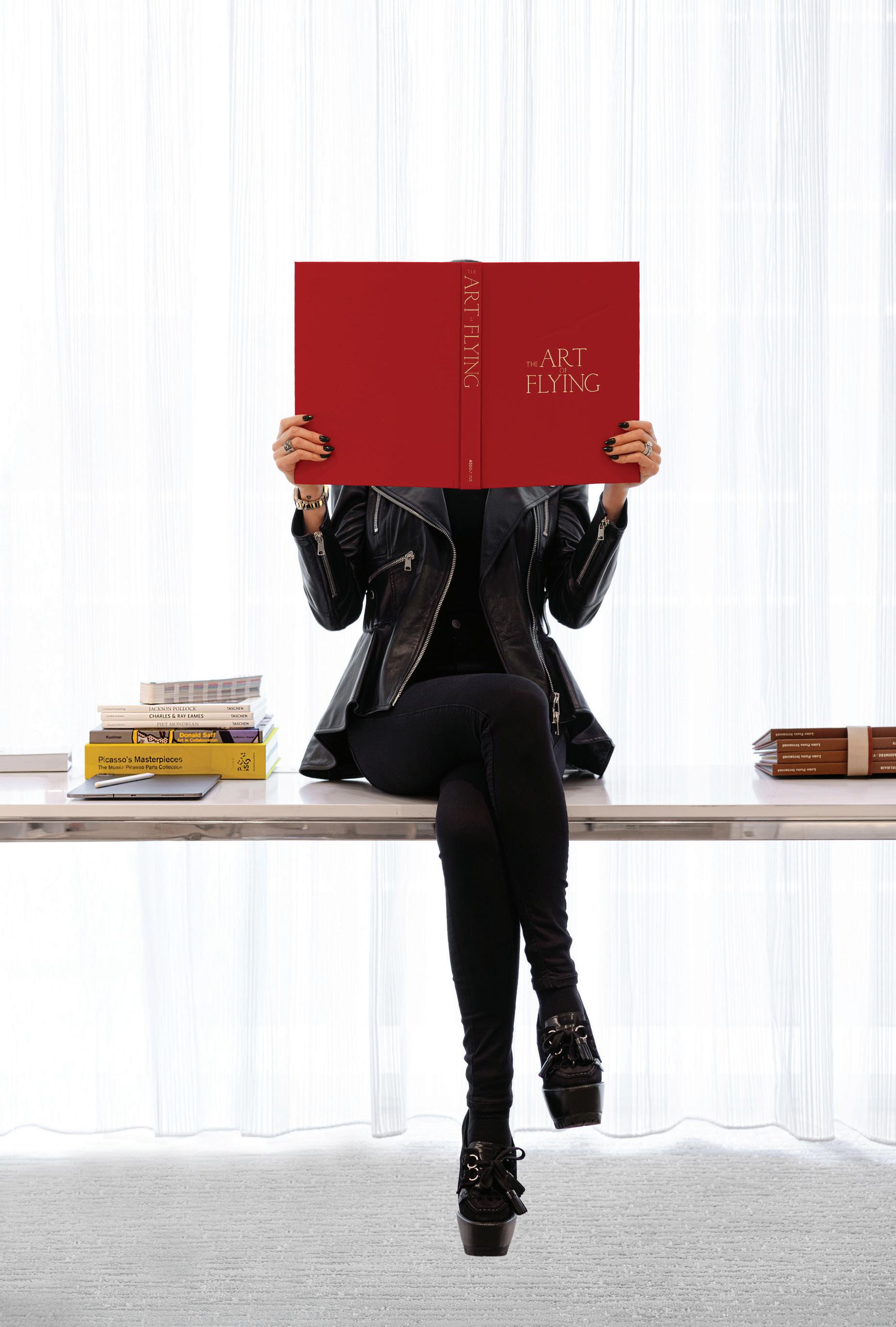

TROY PALMER - FOUNDER AIRCRAFT PARTS DISTRIBUTION

Parts you can trust

TROY PALMER - FOUNDER AIRCRAFT PARTS DISTRIBUTION

When the good times just keep coming, it is easy to forget that we’re all in a deeply cyclical sector. Things are so buoyant right now that one can lose sight of the fact that business aviation has its downs as well as its ups. Right now, however, the upside just keeps on trucking, and the signs are good for a solid end to 2025 and a good start to 2026.

That may be giving a huge hostage to fortune. One has to be mindful of the commentator’s curse. If you are a cricket fan, which, admittedly, not many in North America are, you’ll be well familiar with lines like: “Blogs is batting beautifully, closing in on his/her Test 50. Oh, oops, that’s the middle stump cartwheeling out of the ground.”

As evidence of how buoyant things are, consider the latest report from GAMA on the current state of the general aviation sector. The results for the second quarter of 2025, by comparison with the same period last year, show increased shipments for both business jets and piston aircraft. It also shows an increase in the overall value of aircraft shipments.

Sales of piston aircraft are up just over five percent, with 810 units shipped. Turboprops didn’t fare quite as well, showing a 4.3 percent decrease, but business jet sales were up almost 10 percent (9.9 percent), with 354 aircraft sold. The total value of aircraft deliveries in the quarter exceeded $12 billion, up 9.9 percent.

We are also hearing plenty of anecdotal evidence from our friends and supporters in the industry that more than bear out GAMA’s positive report. In this issue, Clay Healey, for example, the owner of AIC Title Service, reckons that although 2024 was the firm’s best year ever, they are already 15% up, year on year – “and we haven’t even got to the busy part yet!” he commented.

At the same time, the sector continues to innovate hugely. Sustainability continues to be a big driver. Brad Streeter, CEO of AERO Specialties, points out in this issue that demand for electric and hybrid ground service equipment is growing by leaps and bounds.

We are pleased to announce that we’ll be holding our NBAA-BACE Networking Event this year at the Hard Rock Cafe, Las Vegas, on Wednesday 15th October. We’d like to give a big shout-out to our event sponsors, without whom the party would not be possible. As usual, it is by invitation only, and our advertisers and sponsors have priority. For tickets, please contact our CEO, Max Raja.

There will be an open bar, and this year features the Club DJ along with a live band. Address: Hard Rock Cafe, Las Vegas; 3771 Las Vegas Boulevard, NV 89109.

all enquiries, please contact Max Raja at max@bizavltd.com or on +44 (0)203 865 3736

ANTHONY HARRINGTON

Troy

Darren Broderick, CEO of Asian

48 Forward thinking

Jane Stanbury talks with David Bienvenu, Global Leader, Maintenance Training, CAE

54 Vision of the future

Max Pardo, Founder and CEO of KiPcreating, on transforming visualisation and rendering

62 Going the extra mile

Waleed Muhiddin, AMAC Aerospace’s Chief Marketing Officer, on what drives AMAC’s continued success

68 Innovative ground supp ort

Brad Streeter, CEO, AERO Specialties, on how the company has transformed into a global force

Clay Healey, the owner of AIC Title Service, on a

and, potentially,

Louis Seno, Executive Director, Erika Ingle, Managing Director, and Brendan Lodge, Regional Director to the UK/ EU region, on the global reach and expertise of

Larissa Groesbeck-Fringo, Megan Kucel and Tommy Carter, on the teamwork and skills required to build on an already stellar reputation for

Mike Behm, Director of Business Development at Gentex Corporation, on how the specialist automotive supplier is looking to bring the best of automotive innovation to business aviation

JetBed Founder, Gary Bosstick, on the

76 Ranking highly

Dave Morgan, President, on the rise of Celtic Air Services

80 BMC25 gallery

Photos from the conference

84 World-class support

Mike Minchow, President, Duncan Aviation, on meeting the skills challenge

90 Supporting aircraft ownership

Nick Isbister, Director of Sales, Volare Aviation, on the company’s recent successes

With AvfuelZero, we guide your path to sustainability—assessing emissions, setting targets, creating a reduction plan and delivering clear reports.

Let our ESG experts simplify your journey to net zero so you can stay focused on the flight.

+1 (310) 488-9452 sarah@sarahlarranaga.com www.sarahlarranaga.com

Skylink Services Ltd is part of the Skylink Group of Companies. The company is well-established and provides ground handling services for General Aviation Aircraft in Cyprus. We began operations in 1992, filling the gap in the Executive Aircraft ground handling market, at both international airports of Cyprus, Larnaca and Pafos.

P.O.Box 43012, CY 6650 Larnaca - Cyprus

T: +(357) 24 84 09 00 • F: +(357) 24 66 58 05

E: flightops@skylink.com.cy

T: +(357) 24 64 33 34

F: +(357) 24 64 35 99

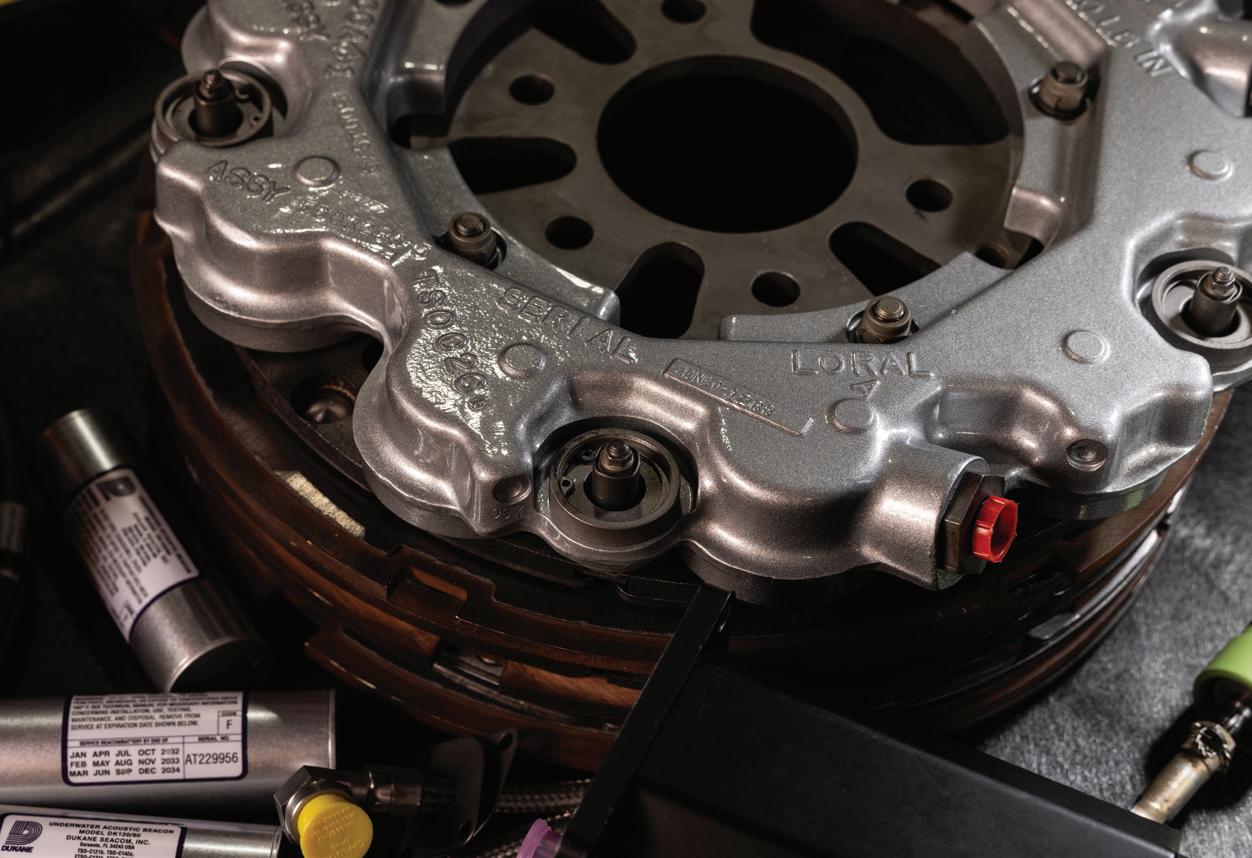

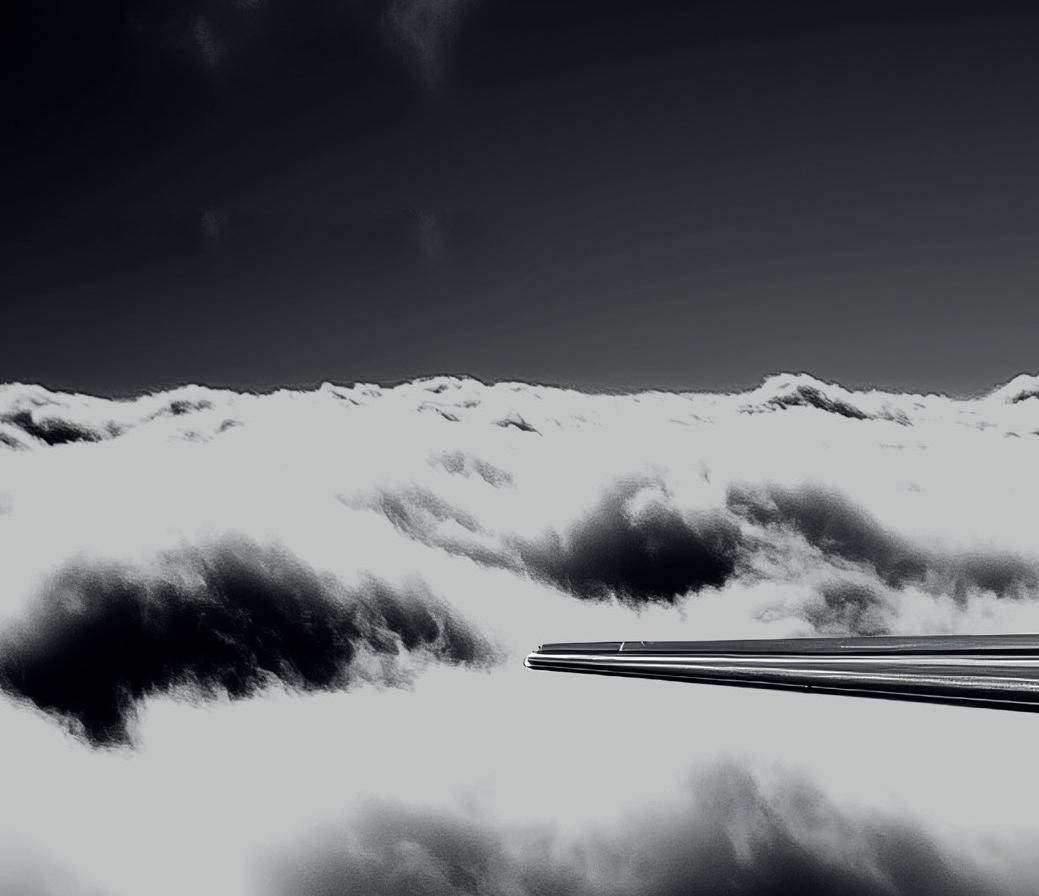

Troy Palmer, Founder, Aircraft Parts Distribution, talks to Anthony Harrington about what it takes to be the best in parts distribution

Aircraft Parts Distribution: Building Resilience and Speed into the Aviation Aftermarket

Business aviation thrives on precision and timing. When an aircraft is grounded for lack of a part, operators and MROs need a solution in hours, not days. Aircraft Parts Distribution (APD), founded in 2023 by industry veteran Troy Palmer, was built to answer exactly that challenge. In just two years, the company has emerged as a trusted supply-chain partner across Bombardier, Learjet, and Textron fleets, serving customers worldwide.

our shipping discipline ensures parts leave the warehouse without delay.

The aircraft on the ground doesn’t care whether the delay is caused by stock, paperwork, or a missed courier pickup. What matters is that we have the systems to eliminate those delays before they reach the customer.

AH: What kind of inventory does APD hold to stay at the top of the parts game?

Here we talk to the APD leadership team about the company’s origins, its approach to parts availability, and how it is navigating a global marketplace shaped by tariffs, compliance pressures, and evolving operator expectations.

AH: Let’s begin with APD’s origin and how it rose so quickly.

TP: The key is a balance of breadth and documentation. We stock for a wide range of business and regional platforms, including Learjets, Challengers, Globals, Citations, Beechcraft, Embraer, and Dassault. But inventory alone is not enough. Every part we sell is supported by an SV+ package with detailed photos, test data, trace information, and the required airworthiness certifications.

You can have the part in hand, but if the paperwork doesn’t check out, the aircraft still sits on the ground. Documentation is as vital as the component itself.

TP: I built my reputation on GlobalParts.aero, which I founded in 2002 and sold in 2021 to VSE Aviation. That journey gave me an intimate understanding of the challenges operators and MROs face: part scarcity, documentation gaps, logistical bottlenecks, and supply-chain risk. When I launched Aircraft Parts Distribution (APD) in 2023, the goal was clear: bring best practices, newer technology, and sharper responsiveness to the business aviation parts market.

Our leadership team is composed of seasoned veterans in sales, nance, warehouse operations, purchasing, and rotable support. at blend enables us to act not simply as a parts vendor, but as a true supply-chain partner, aligning inventory, shipping, and compliance strategies to operator needs.

AH: When an aircra is grounded and needs a part, time is everything. How does APD manage to respond so quickly — especially for rare or hard-to- nd components?

TP: We operate under an AOG-first philosophy. We aim to deliver quotes in under 15 minutes, and in-stock parts can often ship the same day. That speed is possible because we carry buffer inventory across major platforms, forecast demand using historic and live market data, and coordinate closely with repair and exchange partners. Just as important,

AH: How much does parting out older or retired aircra help maintain a diverse parts inventory? Are there multiple sourcing strategies in play?

TP: Parting out remains one of the most effective ways to sustain legacy fleets. We acquire and dismantle aircraft, harvesting high-value components that are certified and put back into circulation. This is further supported by the APD Fund, which enables outside investors to participate in aircraft acquisition and harvesting.

But this is only one part of the sourcing picture. We also maintain OEM agreements, work closely with repair stations, and manage consignment programs for operators and brokers. The result is a diverse set of supply channels, ensuring resilience even when one stream is constrained.

AH: What are the biggest logistical and compliance challenges in getting parts delivered quickly — especially internationally — and how does APD handle them?

TP: Shipping is where things o en go wrong, but it’s also where a disciplined process can save hours or even days. One of the most common causes of delay is an incomplete purchase order. e more detail customers provide up front, the faster shipments move. at means including service levels, carrier

“ When I launched Aircraft Parts Distribution (APD) in 2023, the goal was clear: bring best practices, newer technology, and sharper responsiveness to the business aviation parts market.”

“ “The real secret is discipline. Every part goes through multiple checks before it leaves our building. That way, the shipment isn’t just fast — it’s also right.”

account numbers, freight forwarder contacts, and complete end-user addresses. When those details are missing, shipments can stall before they even leave the warehouse.

Email communication is another key element. We encourage customers to keep PO numbers in subject lines, highlight service levels clearly, and include freight forwarders in threads. It sounds small, but when dozens of shipments are moving at once, clarity in communication prevents errors and saves valuable time.

Export compliance is another layer. International orders often require signed End User Agreements and, in some cases, the aircraft serial number. These documents confirm that shipments are not destined for restricted parties and often allow for more efficient routing, such as direct dropshipment from OEM to end user.

through slower approval channels. We also stress the value of having more than one carrier available, since strengths vary by region, and a bottleneck at one courier should never halt an AOG shipment.

Finally, cut-off times are a constant challenge. Many suppliers close their shipping desks by mid-afternoon, meaning orders placed late in the day risk slipping to the next morning. We mitigate this by preparing early where possible, but also by maintaining extended AOG shipping capacity — even into evenings, weekends, and holidays.

Carrier authorisation is also critical. When we are added as an authorised shipper on a customer’s DHL, FedEx, or UPS account, labels and customs documents can be generated instantly. Without that authorisation, shipments are forced

The real secret is discipline. Every part goes through multiple checks before it leaves our building. That way, the shipment isn’t just fast — it’s also right.

AH: Tell us about your auction platform and consignment inventory options.

TP: AeroAuction.com has become an important tool for operators looking to convert surplus or aged stock into cash. By running 30-day auctions with reserve backing, we create transparency and liquidity. Sellers get access to a broad buyer

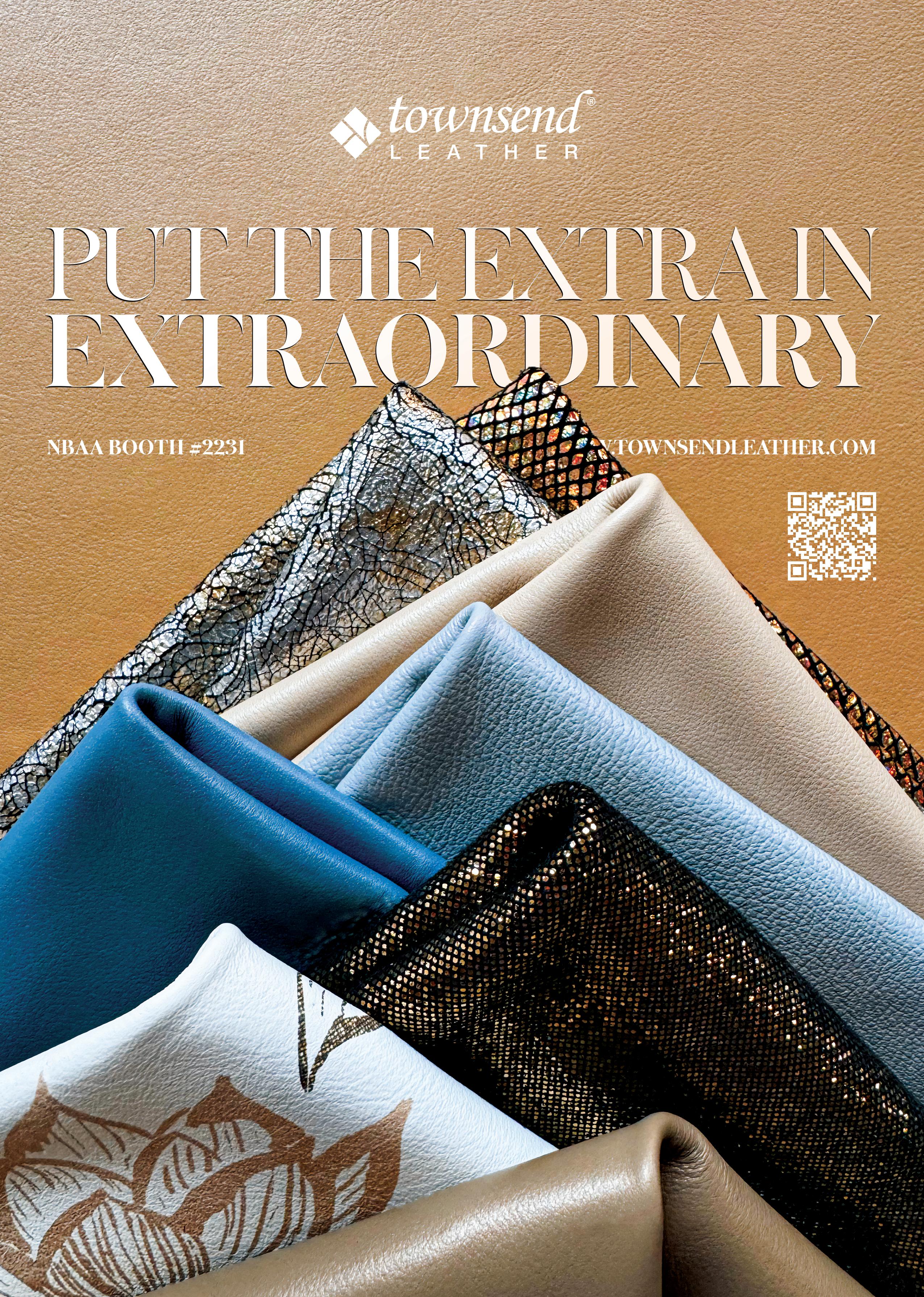

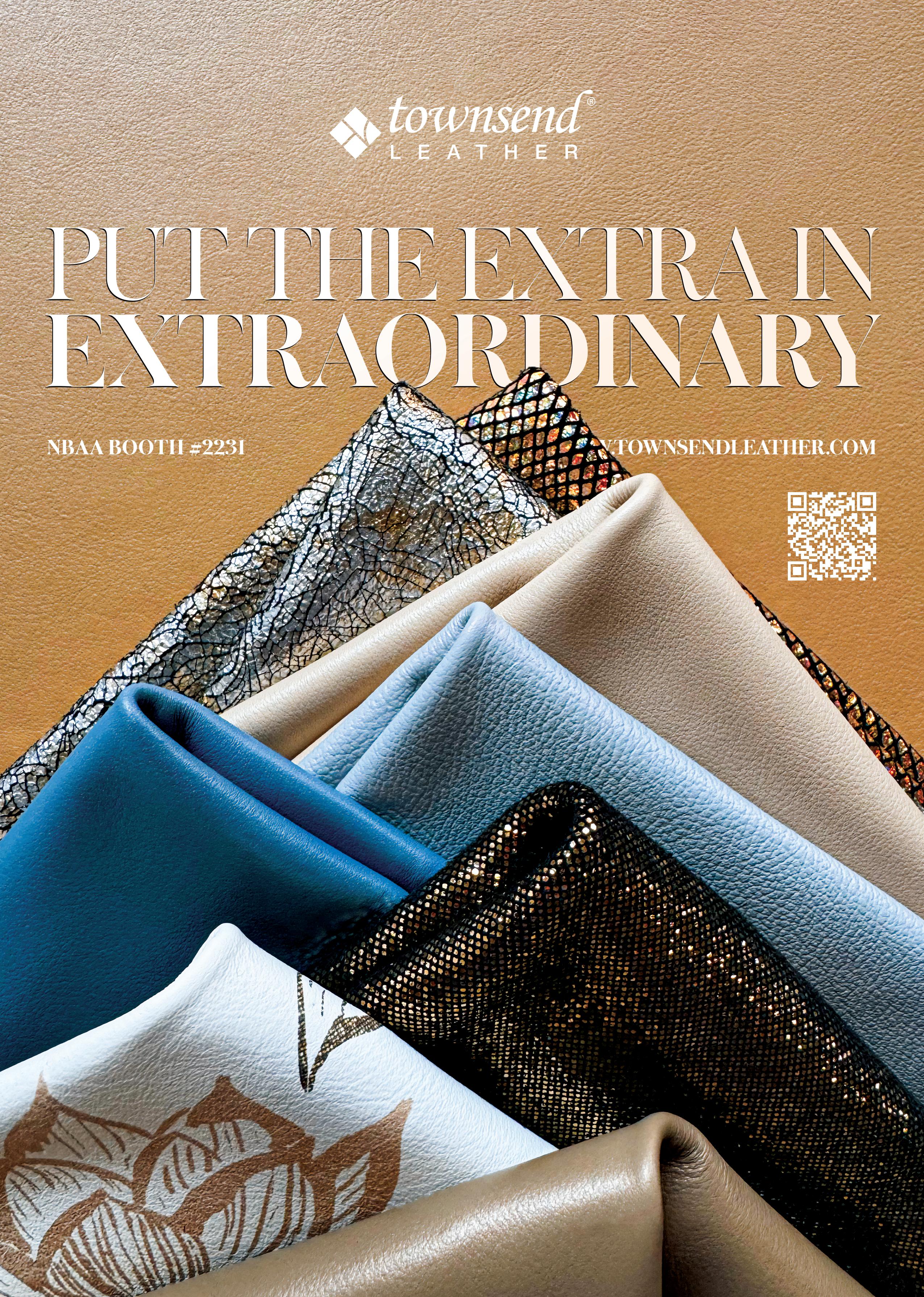

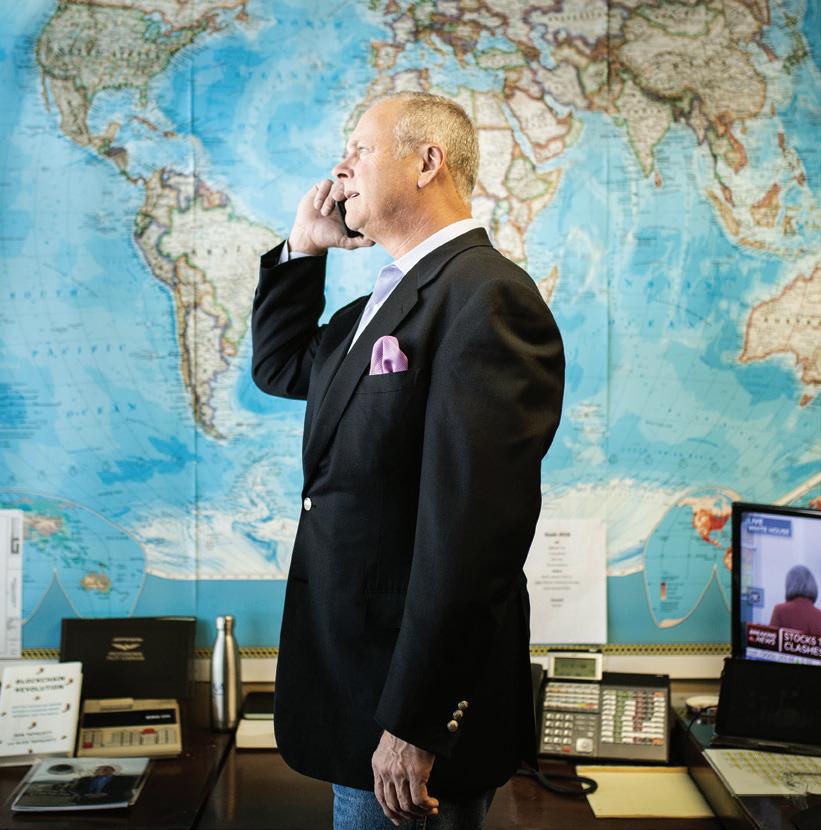

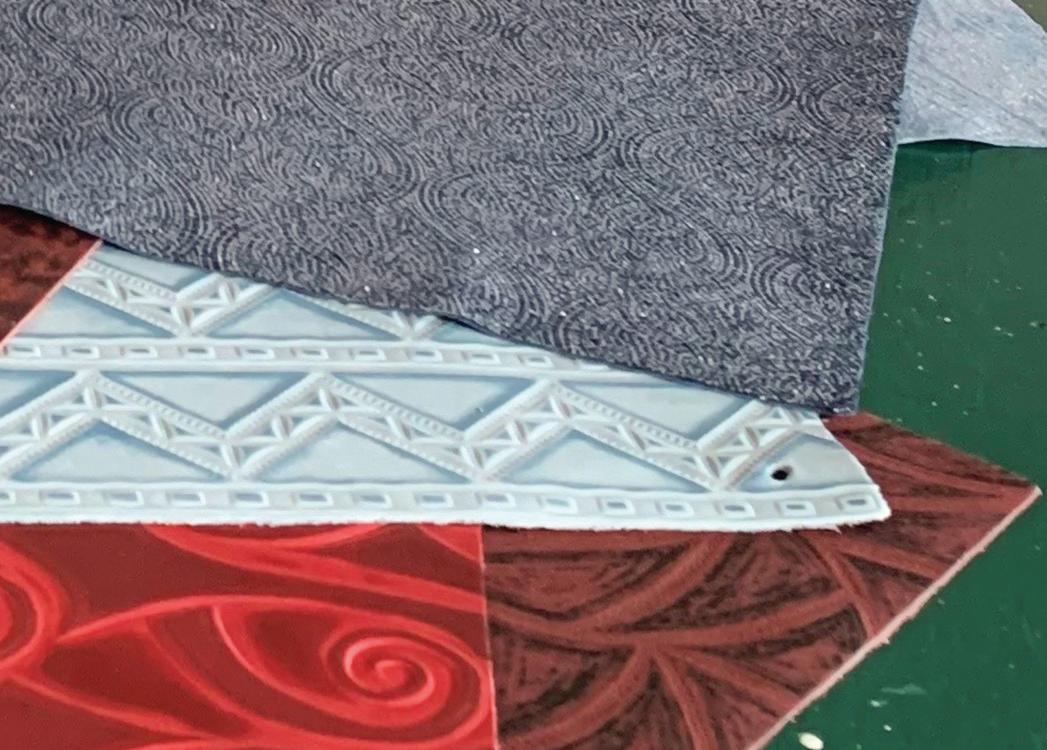

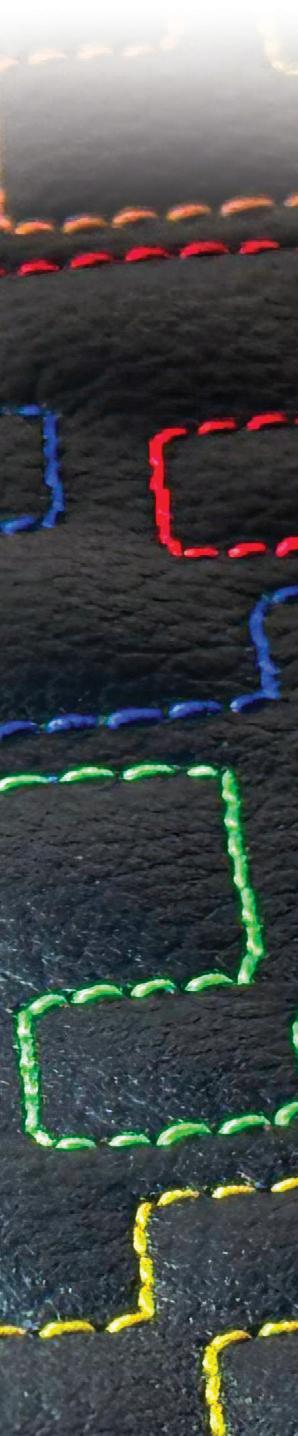

DISTINCTLY EMBOSSED. EXPERTLY CRAFTED.

Introducing Cestino; one of five new, tactile collections.This leather’s versatile texture, two-tone and hand-tipped finish boasts a luxurious, multidimensional appearance. Cestino is roller-embossed on center-cut hides with no plate lines.

Visit garrettleather.com to request samples.

base and clear reporting dashboards, while buyers gain a new channel for sourcing parts.

Alongside the auction, we offer a consignment program that allows operators to hand over inventory for us to inspect, catalogue, market, and sell. Parts on consignment are included in our AOG coverage, which means consignors benefit from 24/7 responsiveness without the operational burden. Predictable payouts — either monthly or 30 days post-sale — give operators clarity in cash flow, and flexible fee structures let them choose the model that suits their needs.

It’s about taking the hassle out of surplus. Our consignors don’t just see revenue; they see predictability and transparency.

AH: You clearly have deep relationships within the industry. Tell us more about that.

TP: Relationships are one of our strongest assets. Our le adership team’s decades of experience mean we have

longstanding ties to MROs, OEMs, and operators worldwide. Those connections allow us to arrange exchanges quickly, secure repair capacity when it’s scarce, and offer assurance that parts have passed through trusted channels.

Trust is everything in aviation. Operators give us their AOG calls because they know we won’t just source a part — we’ll stand behind it, documented and compliant.

AH: Finally, what do you feel sets APD apart most clearly in the market?

TP: We may be a young company, but we’ve been built on decades of experience. By marrying deep inventory and strong sourcing strategies with process discipline in shipping and compliance, we ensure that when an aircraft is down, the solution is close at hand.

The part, the paperwork, and the process — we bring them together so our customers can fly with confidence. |BAM

Darren Broderick, CEO of Asian Corporate Aviation Management, better known as ACAM, talks to Anthony Harrington about his ambitions for the group

AH: Darren, can you tell us about ACAM, where it all started, and your role in it?

DB: I am the founder and CEO of the whole Group, which consists of some 17 companies. We own 100 percent of the company, other than ACAM Pacific, which was formed a few years ago in Australia. I have 50% of that company, along with my partner there.

The Group is headquartered in Singapore and is a Singaporean company, although we now have a global reach outside of North America. We were established in Singapore 15 years ago.

As to the Australian operation, Dane Williams approached me three years ago to suggest we partner to found ACAM Pacific. I wasn’t really interested in starting an Australian operation myself at the time. When I last left Australia fourty years ago, the business aviation market was very quiet, but it has had something of a remarkable renaissance since and is now an extremely dynamic and exciting theatre to be involved in.

Dane is the Managing Director and I am the CEO. We operate three bases there. Our HQ is in Melbourne at the magnificent Melbourne Jet Base and we have operational bases in Sydney and on the Gold Coast.

AH: Can you tell us about your group HQ in Singapore?

DB: Singapore is the heartbeat of our companies where we have our 24x7 flight support and operations centre. We also have our 24x7 engineering and CAMO support teams

there. They are an extremely dedicated team made up of a melting pot of the industry’s finest professionals.

So, every query and request that comes into our operations anywhere in the world gets routed to the Singapore operations centre. If we get a flight request in the middle of the night in Europe, Asia or Africa, that is where it gets dealt with and solved.

AH: What can you tell us about your fleet of aircraft? Is it fairly mixed, and is it mostly managed aircraft versus your own wholly owned aircraft?

DB: We now have a fairly large fleet of aircraft, getting on for 40 in total. It is mostly managed and it is very varied, comprising everything from King Airs to Boeings and Airbus Corporate jets. As you can imagine, that makes the CAMO guys hate me. Whenever I tell them we’ve signed on a new jet, they say, “Tell me it’s a model we already have,” and mostly I tell them no, it’s a new one!

AH: What do you think makes ACAM unique?

DB: Where we differ from other operations is that we are very bespoke and work very closely with our clients. When principals are flying in to or out of the FBO’s, if I’m around, I’m at the FBO waiting for them. We have a really well-tuned team that is very hands-on, as am I.

From Singapore, we service South East Asia, including Indonesia, which is one of our strongest markets. I can say with confidence that we have the largest market share of corporate jets in Indonesia. We have our Dubai office, which

“ We now have a fairly large fleet of aircraft, getting on for 40 in total. It is mostly managed and it is very varied, comprising everything from King Airs to Boeings and Airbus Corporate jets.”

handles ACAM Middle East. That office also looks after our Africa operation, where we have managed aircraft in South Africa. We had some managed business jets in the Sudan, but for obvious reasons, they are now all based back in Dubai.

We have two companies in San Marino, where we work very closely with the Colindres family. We worked together with San Marino to develop a new set of Civil Aviation regulations for Commercial specialised operations, (CAR-SPO) similar to a commercial airwork operation. We are also in the advanced stage of finalising our San Marino AOC.

We have an excellent business that does flight calibration and inspection for airports all around the world. This involves routine calibrations and inspection of airport and enroute navigational facilities, airport lighting systems and any interference factors that may affect aircraft navigation on approach, landing and departures.

For example, Schiphol Airport in the Netherlands had an area of vacant land adjacent to the runway, where a solar farm to been placed there. What happened was that pilots found themselves distracted by the glare coming off some of the panels when the sun was at certain angles.

We have the contract to do flight calibration in Singapore, plus similar contracts around the world. We have contracts with Cambodia and several other countries all over Asia. We do flight calibration for the Kuwait government military bases and numerous contracts in Europe. We have another flight calibration aircraft in South Africa, based in Johannesburg that does all of the African continent Sub-Sahara. A lot of governments do not own their own flight calibration aircraft, so this is a lucrative business that we have built up from nothing.

AH: How are you doing with expanding your business jets profile in Europe?

DB: Two years ago we acquired a company in Germany that will be renamed to ACAM Germany, and we’ve signed up our second aircraft in the UK. We have other deals currently in progress that I can’t talk about at present, but the point is that we are moving further west, with an emphasis on bridging the Asian and European markets continuing the expansion of the company.

AH: And you’ve still got plenty of appetite for business?

DB: Absolutely. For me, business is not about making money; it’s an absolute passion. Aviation has been my life, I’ve been flying since I was 16, and at age 18 I had both my commercial helicopter and my commercial aeroplane licenses. I think I still hold the Australian record as the youngest person to achieve this.

My son does a lot of the travelling with me now. He’s 17 and following a business degree will be doing his flight training with Emirates. He’ll be joining the company at some point with a view to eventually taking over from me.

My philosophy has always been that hard work gets results, and I enjoy it thoroughly. My two mentors in business, the men who helped me to develop from a senior pilot to a businessman and entrepreneur, exemplified this. Both worked into their 80s. I was discussing deals with one of them right up to the day before he died. The other also died in his office. They both worked to the end and thoroughly enjoyed it! |BAM

Since unveiling The Omnia at its Luton FBO, Harrods Aviation has seen the name truly come to life. Inspired by the Latin for “all”, The Omnia embodies a complete, world-class service. Discreet luxury, refined design and attention to every detail.

Whether relaxing in the lounge, travelling with pets, or enjoying the services, The Omnia experience feels uniquely tailored, every time.

“ People tend to blow the impact of the discount out of all proportion. With mid to large private jets, if you are in the market for a new jet, you are going to buy it anyway, regardless of whether or not there is a discount.”

Clay Healey, the owner of AIC Title Service, talks to Anthony Harrington about a record year and, potentially, a good few years to come

AH: How has 2025 been for AIC Title Service so far this year, Clay?

CH: We are busy as hell. Last year was a great year for us, and we are up 15 percent year on year already. Plus, we haven’t even got to the really busy part yet.

AH: How much is this down to the recent extension to the 100 percent tax write-off on private jets?

CH: It might have had some effect in the US, but people tend to blow the impact of the discount out of all proportion. With mid to large private jets, if you are in the market for a new jet, you are going to buy it anyway, regardless of whether or not there is a discount.

At the high end, I can’t see the write-off having more than a 5 to 10 percent positive impact on transactions. Where it will have an impact is on the low end of the market, where people usually don’t have the same deep pockets. At the low end, if the discount had not been continued, it might have knocked sales back possibly 30 to 50 percent.

AH: What of the tariffs? Is that likely to dampen things going forward?

CH: I do not see the tariffs mattering much. The OEMs are going to have to eat most of the price increase in their new jets. This may amount to a three to four percent additional build cost for them, but I can’t see them trying to pass that increase on to potential buyers.

That said, I welcome the current push to get more of what we need built in this country. Globalised supply chains started because in the mid- to late 1900s, companies found out that US companies could get stuff made abroad for pennies on the dollar.

However, what we found out in spades with COVID was that when you outsource your supply chain abroad, you are

hugely vulnerable to supply chain disruption. If the flow of parts that you need stops for any reason, be it through a pandemic or through geopolitical factors, your product chain stops, and you’re in deep trouble.

So, from one perspective, globalisation might seem a really good idea, but it is sure as hell a seriously risky model to base your business on when you are producing stuff. The US needs to step back and say we are the one economy in the world that everyone wants to buy stuff from, so why are we not making everything here? Let the rest of the world produce whatever they want and sell it to whoever they want. The fact is that they won’t be selling much of it to us in the near future because we’ll be buying from ourselves!

As things are right now, if we didn’t buy from China, then China would be totally bust. What people tend to forget is that there is a hell of a lot of productive capacity in the US that has been mothballed for years. Sure, it will take a year or so to get that mothballed plant working again. However, once you’ve renovated the stuff that’s gone to sleep and have brought it back to full production, the whole area those plants are in starts to show economic growth again.

For me, the US has turned the corner, and I don’t see us going back again, not for the next three and a half years, that’s for sure. Politicians on both sides need to realise that 80 percent

of the people in America want to see improved security and America making stuff that Americans buy. It’s that simple.

AH: We’re seeing a lot of deregulatory efforts from the current Administration, which appears to be pushing back against some of the previous administration’s policies. Is that good for business?

CH: Absolutely. Look, I am all for clean air and clean water, and I support sensible efforts to ensure that we have both. But no one needs over-regulation. What is driving the current wave of business in the US is that growth is back on the agenda. The business folks I talk to are confident that growth is going to happen. People are putting a lot of money into the facilities they are building, and if you do that, then you have to travel a lot more. That has to be great for business aviation.

What cracks me up is that people outside the US just don’t get how big, geographically, the US is. The State of Texas, for example, by itself is bigger than France, which is the largest country in the EU! Hell, New Hampshire, which is one of our smallest states, is bigger than Switzerland, and you could put New Hampshire into Oklahoma four times at least.

My point is that general aviation is so important, given the sheer scale of the USA. If you wanted to drive from Houston to Amarillo, it would take five hours just for a one-way trip. If you are serious about doing business across even one state, you need at least a small aircraft

AH: We saw what happened when people got ‘grounded’ because of COVID. As soon as the restrictions came off, there was a boom in private flying. That’s kind of normalised now. How is that playing for you?

CH: A ton of people bought planes in 2021. We were up 22 p ercent, year-over-year. That was a tremendous amount of growth for a single year. Think about it. All the aircraft bought during 2021 are now four years old or heading that way. That is about the time that people think of upgrading their aircraft. So, many of those planes are either already on the market or will soon be. That is part of the activity growth that we are already seeing in 2025.

AH: What is happening as far as new pilot training is concerned? Are we seeing enough numbers to counteract the shortfall that everyone is mentioning?

CH: All the flight schools I know of are really active. However, the cost involved in getting your licence is a huge obstacle. You are talking about people having to find around $100,000 for the training if you are going to go on to get an airline pilot’s license. Plus, you are going to have to put a load of money into renting a plane to get the hours in.

One of the real stupidities in all this is that after the Colgan Air Flight 3407 accident in 2009, which crashed near Buffalo, New York, with 50 deaths, the regulators raised the number of flight hours required from 300 to 1500. That was a fivefold increase and hugely unnecessary in my view. The crash itself wasn’t even about a lack of training.

I could see doubling it to 600, maybe. But raising the requirement to 1500 hours just guaranteed that we’d be short of pilots for years to come. I’ve been flying for decades, and I would guess my total flight time is only twice or two and a half times that figure. It is just not realistic. They over-egged it hugely, and it has really slowed down people from entering the industry.

AH: Clay, you’ve been leveraging technology massively in your platform for AIC Title Service. You started well ahead of the game. Is there any sign that the competition is catching up?

CH: Nope. I am seeing some web-based platforms out there. They are great for some things, but not for the technical knowledge that you have to pass back and forth between buyers, sellers, and everyone involved. You must have software that you can design and develop, and run off your own servers, and I’m just not seeing that.

If the competition started today, it would take them a decade to catch up to where we are now, and by that time, we’d be a long way further forward. So no, they are not even close.

Our Artificial Intelligence is working fantastically. We brought blockchain technology and AI into the platform, and that is really bleeding edge. My goal is to keep pushing for maximum efficiency in handling transactions and to keep growing.

This has huge benefits for our clients. One of our largest clients does around 600 transactions a year through us. They are quite clear that there is no way they could handle that number of transactions without our platform to help them. The brokers who want to achieve greatness have moved over to us or are moving over. Those who want to continue doing things the old way, God bless them and good luck.

AH: How is Eric Lewin getting on with AIC Global Solutions, your European arm?

CH: Eric is doing fantastically and has a lot of things going on. There are not as many aircraft deals in Europe, but we are picking up a nice share of that business. At the same time, there are a lot of transactions that Eric is doing that have nothing to do with aircraft. These are big-ticket asset transactions of all sorts, so he is doing a fabulous job there. |BAM

Louis Seno, Executive Director, Erika Ingle, Managing Director, and Brendan Lodge, Regional Director to the UK/EU region, talk to Anthony Harrington about the global reach and expertise of IADA-accredited dealers and certified brokers

AH: Thank you all for speaking with me today, Louis, Erika, and Brendan. IADA reinvented itself as an organisation in 2018 to stress its current focus on being international in scope, as opposed to its historic roots as a North America-focused association. How is that going?

Lou Seno (LS): I took up my present position in IADA on 1 January this year with a firm sense that we need to expand our international footprint. This is something IADA has been working on since we rebranded in 2018. Brendan came on board on 1 June to assist with this effort. He has a tremendous background in aircraft lending and transactions. We are now up to over 60 accredited dealers, by which I mean brokerage companies, and these companies include hundreds of IADA-Certified brokers.

AH: Could you tell us what sets IADA apart in the aircraft brokerage and dealer world?

LS: Certainly. IADA is the world’s only organisation providing independent accreditation and certification for aircraft dealers and brokers and verification for other professionals who aid business aircraft transactions. We vet professionals rigorously, no self-proclaimed expertise, only verified competence, so clients work with dealers and brokers that are held to the highest standards.

AH: That commitment to professionalism is clearly foundational. How do IADA clients deliver value to buyers and sellers in terms of aircraft inventory access?

Erika Ingle (EI): Through AircraftExchange.com, our exclusive, members-only platform, dealers and brokers list

Brendan Lodge

“ Via AircraftExchange and our IADA Quarterly Market Reports, our members give clients exclusive access to powerful market data, accurate valuations, and professional insights. This intelligence supports better pricing, smarter decisionmaking, and more efficient and faster transactions.”

- Brendan Lodge

premium aircraft before they reach the general market. Only IADA-accredited professionals can list, so users gain first access to top-tier inventory in a trusted environment.

AH: Excellent. Beyond exclusive listings, what kind of market intelligence does IADA offer?

Brenden Lodge (BR): Via AircraftExchange and our IADA Quarterly Market Reports, our members give clients exclusive access to powerful market data, accurate valuations, and professional insights. This intelligence supports better pricing, smarter decision-making, and more efficient and faster transactions.

AH: It seems the network offers real efficiency. Can you elaborate on how IADA speeds up transactions?

LS: IADA transactions move faster because they happen within an elite professional network. Working with accredited dealers and brokers and knowledgeable support providers reduces delays and complexity compared to dealing with unvetted parties. IADA transactions average 19% less time to complete compared to the industry average. As everyone in business knows, it is a truism to say that time kills deals. So, speed matters when you are looking to close transactions.

When owner pilots are looking to sell or upgrade to a new aircraft, they have the opportunity to work with IADAaccredited dealers. These owner pilots can have confidence that the brokers they are working with are aligned with their values and have ethical working standards.

AH: That level of reach and performance is impressive. Reputation and ethics must be central. How does IADA ensure ethical standards?

AH: Supporting member companies across the globe is key. How broad is IADA’s international network?

BL: IADA is truly global. Dealers and brokers do business in Europe, North America, Latin America, Asia Pacific, the Middle East, and Africa. As of mid-2025, our members account for about 17% of the world’s dealers, yet they represent more than half of the annual pre-owned aircraft dollar-volume transactions.

EI: And we’re keen to reach out to other industry groups, like GAMA, NBAA, EAA and other international aviation groups in Europe, Asia, and Africa. We have had great success with owner pilots. The Embraer Jet Operators Association is already affiliated with us, as is the Pilatus Owners and Pilots Association. We have others planned.

BL: Our members strictly adhere to a formal Code of Ethics, ensuring honesty, integrity, transparency, and full disclosure throughout each transaction. Accredited dealers and brokers are held accountable both by their peers and by IADA, a higher level of oversight that non-members simply can’t duplicate.

AH: Continuous development is crucial in a dynamic industry. How does IADA support ongoing professional expertise?

LS: Accreditation isn’t a one-time event; members re-accredit every three years, and engage in continuing professional development, including education via our IADA U platform. This ensures members remain current on best practices and industry trends.

AH: What overarching mission guides IADA today?

LS: Our mission is to be the recognised leader in setting

“ IADA transactions average 19% less time to complete compared to the industry average. As everyone in business knows, it is a truism to say that time kills deals. So, speed matters when you are looking to close transactions.”

- Louis Seno

A LEGACY OF EXPERTISE, INNOVATION AND RELIABILITY SPANNING 69+ YEARS. At Duncan Aviation, we understand that buying or selling a private jet is not just a simple asset transaction, but part of a bigger picture. As your vital advisors, we take the time to truly understand your goals and offer thoughtful insights, market intelligence, operational expertise, and comprehensive support solutions for your entire ownership experience. Our team’s dedication and vast network of industry connections ensure that every decision you make is thoroughly informed, aligning perfectly with your unique mission and aspirations. www.DuncanAviation.aero/aircraftsales

Global Wings, 2022 Gulfstream G500 On AircraftExchange.com

Elliott Jets, 2006 Cessna Citation XLS On AircraftExchange.com

standards for efficient, effective, and ethical business aircraft transactions. We serve business aircraft owners worldwide by promoting transparency, professionalism, and informed markets, ultimately to increase business aircraft ownership and usage globally. Our members clearly set the bar very high in our industry.

AH: In summary, what would you say are IADA’s defining pillars?

LS: We are setting the global standard for business aircraft transactions through five key pillars:

1. Exclusive Accreditation, only vetted professionals set a high trust standard.

Avpro Inc, 2020 Gulfstream G550 On AircraftExchange.com

2. Top-Tier Inventory Access, AircraftExchange provides premium listings.

3. Superior Market Intelligence, through reports and data tools.

4. Global Reach, connections across major aviation markets worldwide.

5. Ethics and Education, mandatory codes and continuing learning ensure excellence and transparency.

AH: Thanks so much, Lou, Erika, and Brendan. You’ve provided a comprehensive view of how IADA elevates the aircraft resale industry through accreditation, exclusive data-led strategies, global networks, ethical rigour, and professional development. It’s clear why IADA stands apart in this space. |BAM

“ When owner pilots are looking to sell or upgrade to a new aircraft, they have the opportunity to work with IADA-accredited dealers. These owner pilots can have confidence that the brokers they are working with are aligned with their values and have ethical working standards.”

CFS Jets, 2007 Piaggio Avanti P-180II On AircraftExchange.com

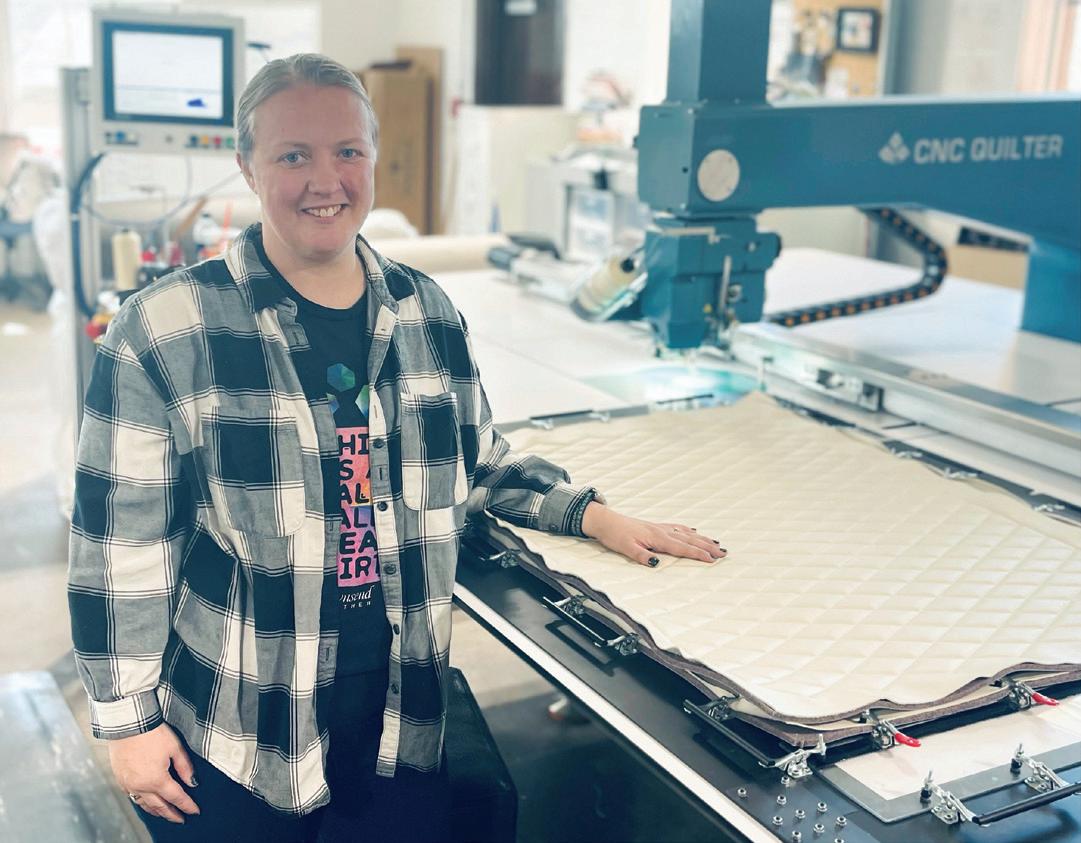

Larissa Groesbeck-Fringo, Megan Kucel and Tommy Carter, on the teamwork and skills required to build on an already stellar reputation for the company

Q: Megan, let’s start with you. How long have you been with the company, and what can you tell us about your role?

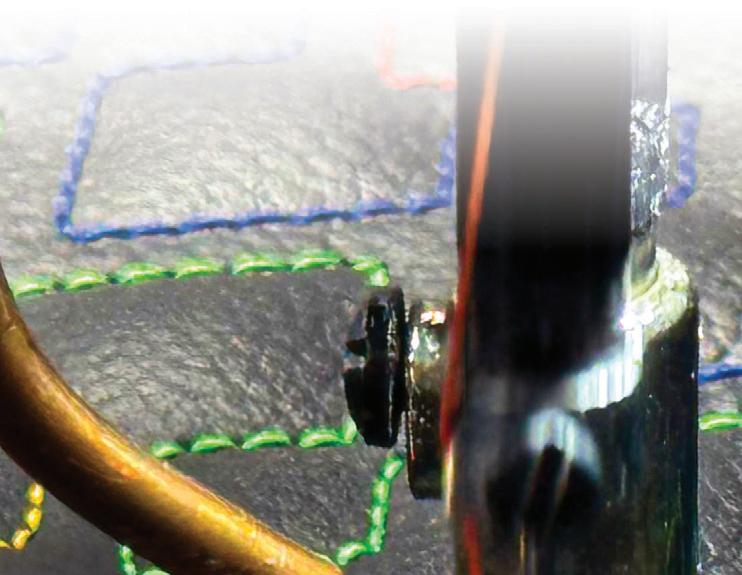

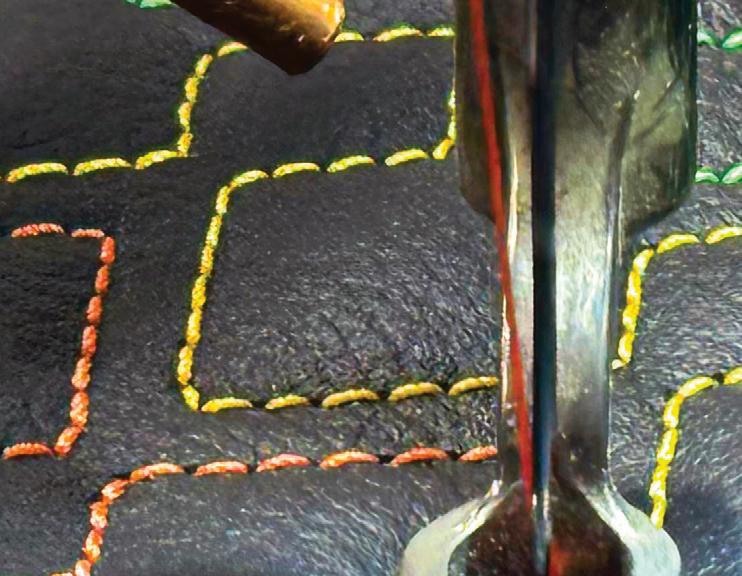

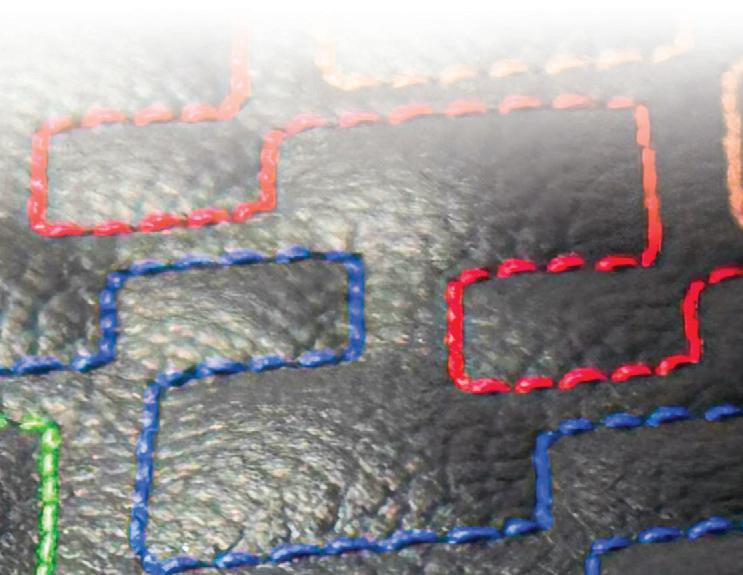

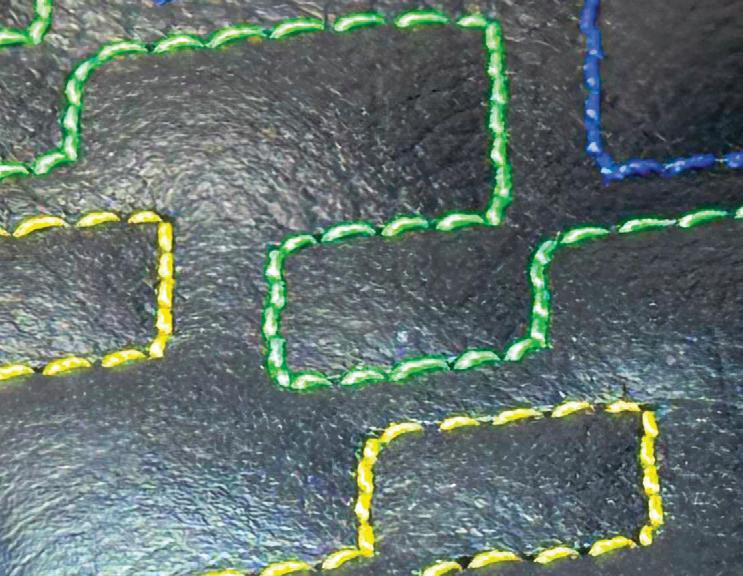

MK: I’ve been with Townsend Leather for eig ht years. I do graphic design and run our quilting machines, which prepare the leather by stitching a series of designs onto the leather with a foam backing that gives it dimensionality. Just last year, we got the newest technology out there, and it has really enabled us to expand our capabilities.

We do major work for OEMS, stitching new patterns into the leather, which we produce as panels. Everyone knows how to do diamond shapes, but I use my graphic design skills to create completely different looks in the leather. We can do different thicknesses of foam and create wholly new designs.

At the same time, we are also doing work outside of business aviation in the luxury motor coach market, as well as in the hotels and hospitality sector. We benefit hugely from wordof-mouth referrals, and it is really driving the business.

Q: I get that the latest quilting machine technology opens up new possibilities. What changes are you seeing in demand as a consequence?

MK: Until recently, designers and owners tended to

concentrate on seat backs for standard quilting diamond shapes. This would be just where the passenger’s back reclined against the seat. Now we are increasingly seeing demand for quilting patterns on the seat bottom panels as well, and we definitely expect to see more of this.

Q: I know Townsend Leather has a whole range of colours available. Are grey and beige still the favourite colours?

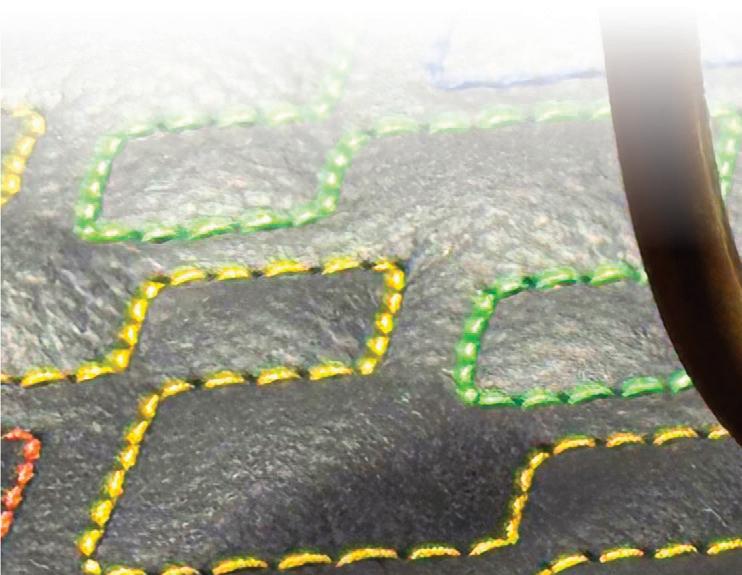

MK: We see constant demand for grey and beige. But we

can change things up with contrasting coloured thread to make things pop, or even use two or three different coloured threads on the same panel to create really interesting effects. Our machine allows us to switch the threads as required.

In all, we already have some 60 different patterns we can provide. Or we can design bespoke, abstract patterns inhouse. I will draw the pattern myself with the machine. The client can bring in a small picture of a design that they like, and we can produce that for them.

Q: Larissa, can you tell us about your role?

LG-F: I’ve been with Townsend Leather for going on 12 years now, in customer service, then in scheduling and now in project management in the cutting and quilting departments. A lot of my role is working with our team to come up with new and innovative ways to customise materials for our customers and to ensure we are meeting delivery lead times at the same time.

We want customers, such as designers and completion houses, to know that they can send us their schematics for the leathers they want to use, and we can do all the cutting for them. Upholstering requires all sorts of different cuts, and we can do all that for them here. That saves them hours of work.

We already do this for several of our OEM customers. This is a big step forward for the industry and for us.

Q: Being a natural product, leather has its flaws, yet customers expect to see a perfect finish. How is that achieved?

LG-F: That is Tommy’s role. Tommy has been at Townsend for about 10 years now, and most of that time has been him working in our Cutting department. I’ll let him talk about what this department does.

TC: We grade the hides on a table that simulates a stretch frame. It creates a vacuum that sucks the hide down and keeps it taut. Then we use a special pen to mark up all the blemishes and characteristics. Then the cutting machine scans the hide and places the patterns to be cut on the hide, and it then cuts these parts or patterns out of the hide, ensuring that it removes all the blemished parts. It is a process that allows us to use as much of each hide as is possible. It allows us to make better decisions than our customers in upholstery shops could if they were just hand-cutting the hide. It gives a fixed cost per seat or ship set, cuts down on shipping costs as we can ship these cut parts in smaller “pizza-sized” boxes than large boxes of rolls of hides, and it saves so much time in upholstery shops. They receive ready-to-stitch or assemble cut parts instead of hides they have to spend hours cutting themselves.

LG-F: Of course, by using more of the hide with the aid of the computer, we are also cutting down on waste. So this means that it reduces the number of hides that a customer will have to order when doing a refit or new completion on an aircraft

This industry is all about how many aircraft an OEM can deliver each year. They all have long order backlogs. So, they all want solutions that enable them to save time and expense. With what we do, they can make seats and panels quicker than they could without our cutting solutions.

I’d point out, too, that quilting is a need that impacts a number of industries, not just aviation. High-net-worth individuals buy top-of-the-range luxury cars. Some like the patterns they see in their cars so much that they want the same thing for their aircraft. We can work with a simple picture that they send in. We’ve even had people send in photos of their favourite handbag!

Q: How important are the big shows like NBAA for you when it comes to getting the word out about what Townsend Leather can do?

MK: Our Sales and Marketing Team will be showing a lot of brand new patterns we designed recently at NBAA on our booth. People who come to the stand will be able to see the wide range of quilted patterns. Also, we are premiering the quilted & perforated patterns that we can also now provide. It’s a great way to get immediate feedback from designers or to get them and their clients excited about new design possibilities.

LG-F: Most of the people that we meet at these shows are really important. What we see is that there has been a real change in the types of people who come to these shows. Fewer people are unconnected with the industry and are just enjoying the show. Most of those coming to the stand already have serious projects in hand or coming up, and they want to explore new ideas for upgrading aircraft interiors. |BAM

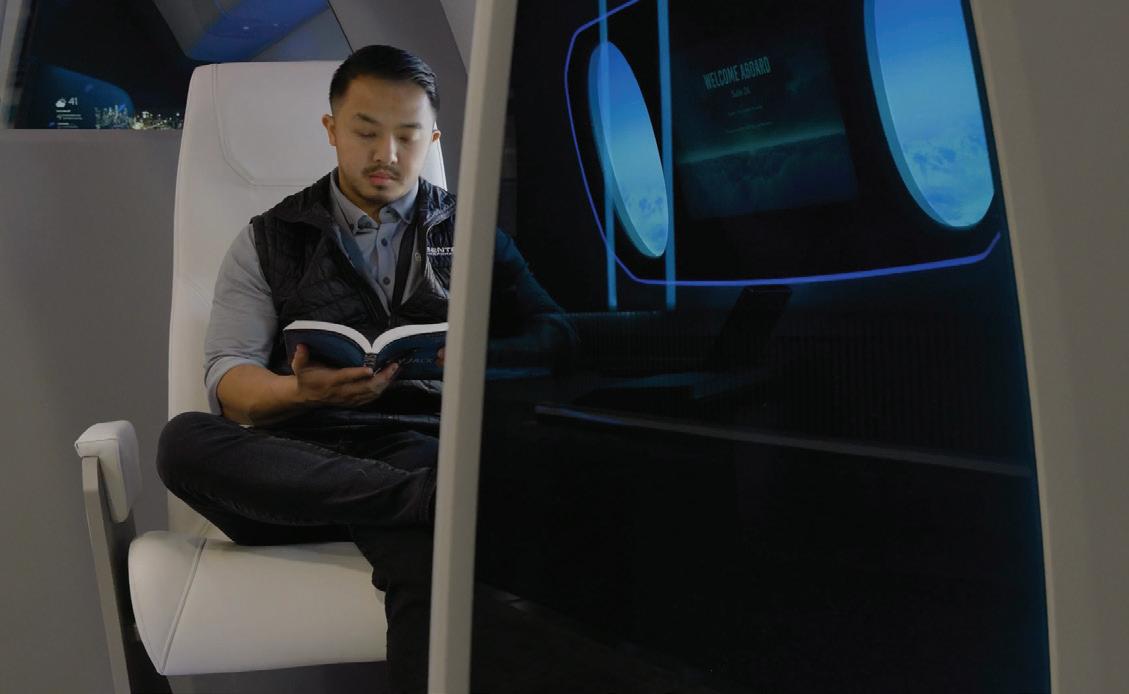

Mike Behm, Director of Business Development at Gentex Corporation,

on how the specialist automotive supplier is looking to bring the best of automotive innovation to business aviation

Introduction

Gentex is first and foremost a technology company, proficient in a wide range of core competencies that yield a unique fusion of technologies. The company is a long-time supplier of electro-optical technologies. It currently develops and manufactures custom, high-tech electronic products for the automotive, aerospace, and commercial fire protection industries, with growing competency in the medical field.

Within automotive, Gentex supplies nearly every major automaker with connected-car technologies and advanced electronic features that optimise driver vision and enhance

driving safety. It’s best known for inventing the automaticdimming rearview mirror, an active safety feature that combines sensors, chemistry, and algorithmic decisionmaking to detect and eliminate dangerous rearview mirror

glare. Today, Gentex ships over 44 million dimmable devices annually; however, its innovation doesn’t stop there.

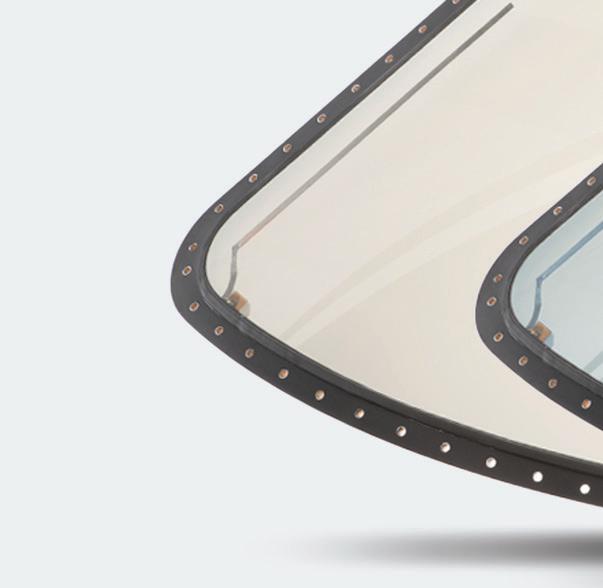

Within aerospace, the company is best known for supplying aircraft manufacturers with electronically dimmable windows that darken on demand to cut sunlight while still providing an exterior view. They improve the flying experience, aircraft design flexibility, and enable airlines to give their customers and crew more control over the view out of their windows.

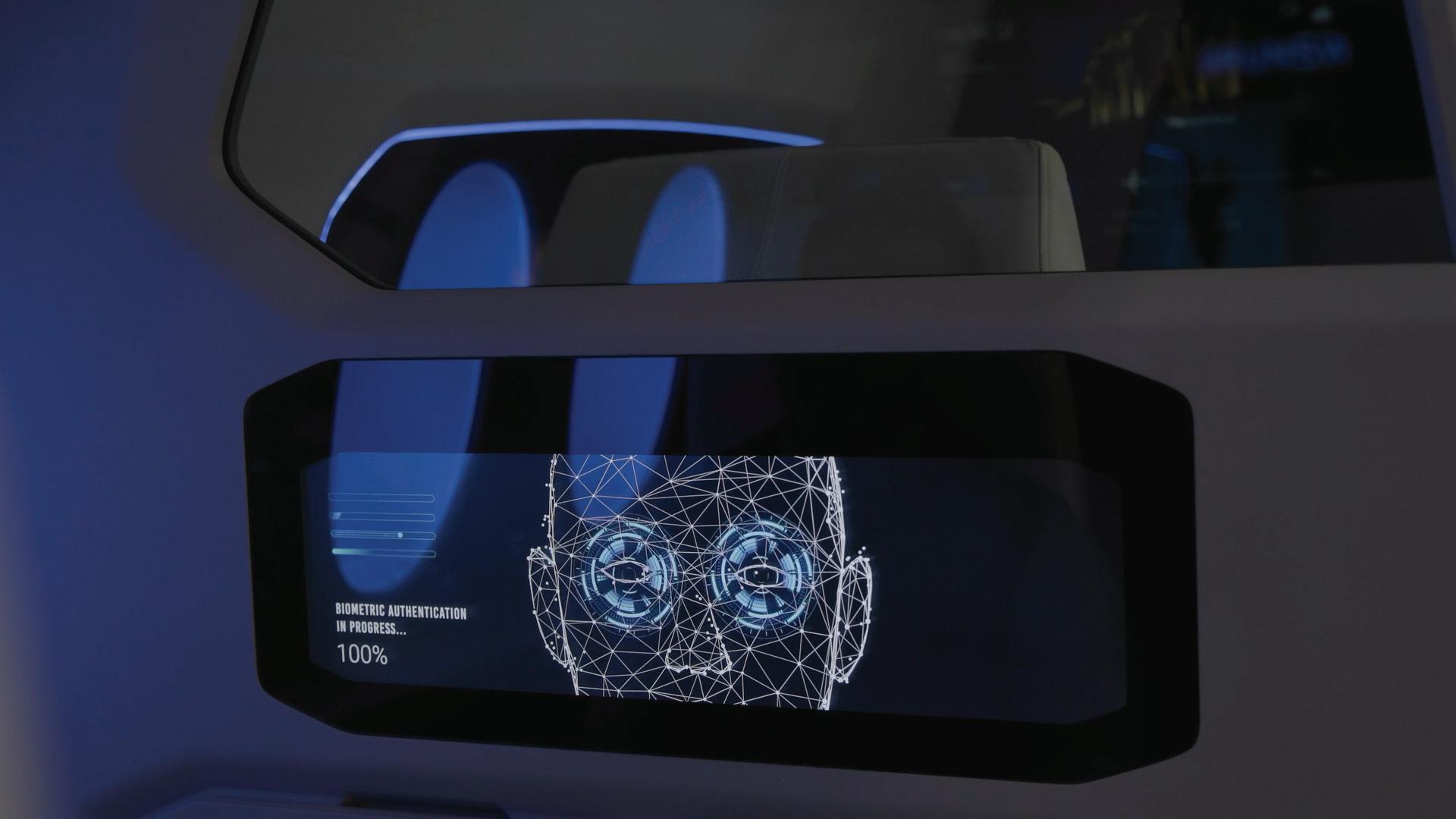

New to the Gentex aerospace portfolio is a unique glass laminating technology that yields durable, lightweight, ultra-

thin glass laminates engineered for aircraft cabin partitions, mirrors, and wood veneer applications. The company is also raising the in-flight experience with concept technologies, helping to drive innovation and improve the performance of the aviation industry, making air travel safer, more comfortable, and more efficient for passengers and crew members alike. Some of these technologies include biometric authentication, which allows for a personalised in-flight experience, and intelligent aircraft cabin lighting, providing light when and where it’s needed. Additionally, comprehensive environmental sensing units monitor cabin air quality for increased safety during the boarding process and during air travel.

“ “Without a doubt, at the top of the list are our electro-dimmable products. We have made huge advances in glass and film-based dimming technologies. We have been producing electro-optical products for the global automotive industry for many years.”

Q: In 2019, at EBACE, Gentex showed its first solution for electrically dimmable windows in business aviation aircraft with curved rather than flat windows. How is that progressing?

MB: Entering a new market is always challenging. We are extremely well known for our portfolio of innovative technologies for the automotive industry. OEM focus on launches of new platforms/aircraft, combined with shifts in priorities for the industry (SAF, range, etc), have added to the challenge but we remain confident that there are significant opportunities for premium cabin technologies with Gentex technology offerings.

As a result, we reprioritised and refocused and we now have a renewed push to increase our traction with the business aviation market.

Our general approach is to engage in conversations and then work up a proof-of-concept product, perhaps with partners. With the aviation sector, what we are looking for is to begin with the most persuasive and advantageous fits with our existing product lineup.

Without a doubt, at the top of the list are our electrodimmable products. We have made huge advances in glass and film-based dimming technologies. We have been producing electro-optical products for the global automotive industry for many years.

We supply nearly every automaker around the globe with vision, dimmable glass, sensing, and connected-car technologies that optimise driver vision while enhancing driving safety and

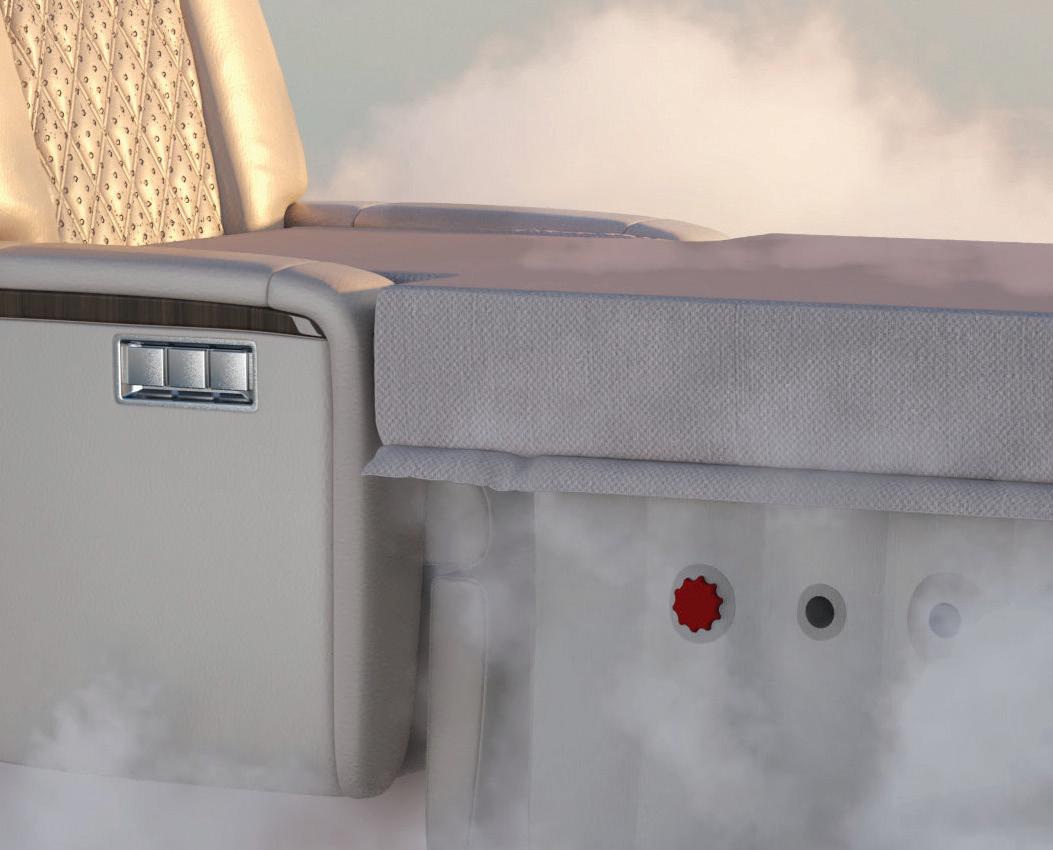

JetBedoffersthemostcomfortablein-flightsleepexperience, allowingpassengerstoliecompletelyflatwithoutgroovesor contoursinthemattress.ThenewJetBedBlueSeriesreducesthe packingsizeoftheJetBedwhennotinusebyapproximately70% foreffortlessstorage,makingitthemostcompactsleepsolution availableonthemarketbyfar.Whennotinuse,itstowseasilyin cabinorluggagecompartments,freeingupspacewithout compromisingcomfort.

comfort. We are well advanced in the technologies required to produce electrically dimmable curved aircraft windows.

Q: What other technologies do you see as being able to carry across from the high-end automotive sector to business aviation?

MB: To summarise our core skills, these comprise the ability to design and programme sophisticated sensor and biometric technologies to produce a range of outcomes that improve cockpit and cabin safety or enhance and personalise the passenger experience.

We have smart lighting products, and we also have camerabased motion sensing technologies. In the automotive industry, these tend to focus on driver safety and driver attention. There are obvious applications in the cockpit, where it would allow ground staff, for example, to see what the pilot was paying attention to. If the cabin crew were showing undue attention to a particular gauge, for example, that could be a concern, and so on.

We have biometric products that would allow a high degree of personalisation for VIPs in the cabin, including the owner and their family. Of course, such products raise concerns for business aviation regarding privacy and data protection and we are working with the industry to explore use cases that are safe and secure.

Q: What have you been doing to show your products to potential aviation customers?

MB: In recent aviation exhibitions, we’ve showcased our products in a bespoke aircraft fuselage simulator. This year, recognising that the big aviation exhibitions like NBAA and EBACE are undergoing some far-reaching changes, we are adjusting our strategy somewhat. The booths are now visited much more by experienced professionals who are part of the aviation sector. This makes for more specific and more productive conversations. We will be showing a range of products with real benefits to the business aviation sector on our booth (the West Hall — booth 1205). |BAM

“ Setup and takedown take just minutes, with beds inflating and deflating quickly from our lightweight, portable travel bag.”

JetBed Founder, Gary Bosstick, on the current status of the iconic JetBed

Quote from the Founder of JetBed, Gary Bosstick:

GB: As a pilot flying my own CJ3, I wanted my wife to feel truly comfortable when we travelled together. I quickly realised that even the most luxurious private jets lacked one key element: restful sleep.

Traditional berthing seats were uneven, uncomfortable for side sleepers, and big and bulky, which made them

impractical for crews to manage. That inspired me to create JetBed — a solution that brings the comfort of home and the luxury of a five-star hotel into your aircraft, that is simple to set up and compact enough for limited cabin storage.

Q: What sets JetBed apart from other in-flight sleep solutions in terms of size, convenience, and ease of use?

GB: Most private aircraft have limited cabin and storage space. Traditional berthing seats and bedding systems take too long to set up, create uneven sleeping surfaces that are uncomfortable for side sleepers (who make up over 90% of

travellers), and worst of all, they take up far too much cabin or luggage space when stored.

JetBed solves all of these challenges. Setup and takedown take just minutes, with beds inflating and deflating quickly from our lightweight, portable travel bag. Our patented design creates a completely flat sleeping surface, delivering restorative rest like no other product on the market.

With our latest innovation, the JetBed Blue vacuum bag, we’ve reduced the packing size of the JetBed by up to 70%, making it the most space-efficient sleep solution in the industry. Passengers and crews can focus on the journey, not the logistics.

Q: Can you walk us through the patented inflatable technology and how it achieves both firmness and durability while remaining highly portable?

GB: The magic of JetBed is in its patented inflatable design, w hich provides the firmness and uniform support you’d expect in your own bed at home. There are no grooves, gaps, or pressure points, just even weight distribution across the entire surface for exceptional comfort, whether you sleep on your back or your side.

Our patented vacuum bag technology allows JetBed to pack down far smaller than any other option on the market, making it the most compact sleep solution available. This unique combination of superior comfort and unmatched space efficiency is why JetBed has become the trusted choice for private aviation worldwide.

Q. Luxury is clearly central to JetBed — how do your linens and bedding choices help recreate a five-star hotel experience inside a private jet?

GB: Luxury isn’t just about appearance, it’s about the way something feels. At JetBed, every detail of our linens and bedding is crafted to bring the indulgence of a five-star hotel into the sky.

Our custom-fitted linens are hand-sewn in our California factory to precisely match the contours of each custom JetBed, including sidewall configurations, seat width, and spacing. The linen fabric itself is sourced directly from Milan, Italy, from the same supplier trusted by some of the world’s most

iconic luxury hotels, including One&Only Palmilla, George V Paris, and Hotel de Crillon.

To complete the experience, we pair these linens with comforters and pillows made in Nebraska by Ogallala Comfort from premium white goose down and natural milkweed fibre. These materials are naturally hypoallergenic, free from synthetics and chemicals, and are incredibly breathable, creating a cloud-like sleep experience at 40,000 feet.

Q: You’ve had some unique exposure recently, including being featured in MrBeast’s video — how has feedback from high-profile users and pilots shaped JetBed’s reputation?

GB: It’s been exciting to see JetBed featured in MrBeast’s video, but what matters most to us is the feedback we receive directly from the people who use our products every day: pilots, crews, and passengers.

MrBeast’s pilot said JetBed would be “essential for surviving 100 days living in an aircraft” and described sleeping on it as “like sleeping on little baby clouds.” That sentiment echoes what we hear from customers worldwide.

Pilots & Flight Attendants tell us JetBed simplifies their work by cutting down the time needed to prepare sleeping arrangements mid-flight. Passengers say it’s life-changing,

giving them the ability to rest as deeply in the air as they do at home. This real-world feedback has helped build JetBed’s reputation as the gold standard for in-flight comfort.

Q. What new developments are you working on, such as the travel bag, and how will they improve the JetBed experience for customers?

GB: Innovation has always been part of JetBed’s DNA. The launch of our JetBed Blue Bag was a major milestone, reducing the packed size of JetBed by up to 70% so it takes up minimal cabin or luggage space when stored, a critical factor on private jets with limited storage.

Looking ahead, we’re developing a next-generation bag that will hold not just the JetBed, but also its linens, pillows, and comforter, all without increasing the packed size. This all-inone solution will make storage and setup even more seamless for crews and passengers. Additionally, we are steadily designing JetBeds for the newest aircraft we’ll see entering the market in the future.

In the past year, we’ve also expanded our product line to include duvets, comforters, and pillows, giving customers a complete bedding system designed exclusively for private aircraft. Each innovation brings us closer to our goal: making sleep at 40,000 feet as effortless and restorative as it is at home. |BAM

“ MrBeast’s pilot said JetBed would be “essential for surviving 100 days living in an aircraft” and described sleeping on it as “like sleeping on little baby clouds.” That sentiment echoes what we hear from customers worldwide.”

“ Our 2025 CAE Aviation Talent Forecast predicted that 416,000 new maintenance technicians will be required by the global aerospace sector by 2034, and of these, 69,000 will be needed in business aviation.”

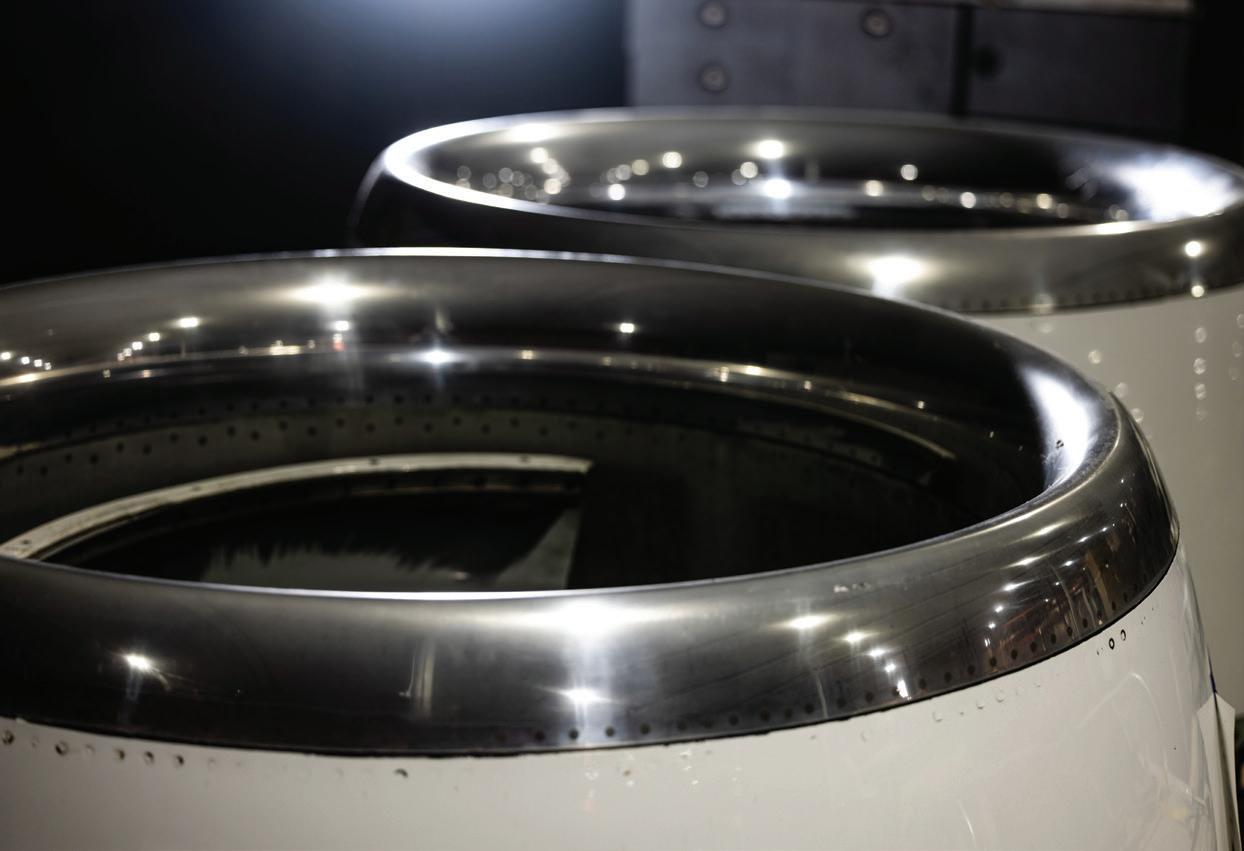

CAE is recognised worldwide for its leadership in aviation training, has a strong reputation for designing and manufacturing full-flight simulators, and today trains more pilots than any other company. However, the technology-forward company also provides business aviation maintenance training. Jane Stanbury talks with David Bienvenu, Global Leader Maintenance Training, CAE, to find out more

JS: I’m more familiar with CAE from the pilot training perspective. Can you tell me more about why and how CAE supports business aviation maintenance training?

DB: In addition to pilots on the civil aviation side, we also train air traffic controllers, commercial aircraft cabin crew, and maintenance technicians. Our 2025 CAE Aviation Talent Forecast predicted that 416,000 new maintenance technicians will be required by the global aerospace sector by 2034, and of these, 69,000 will be needed in business aviation. We are committed to supporting this requirement through a comprehensive maintenance training portfolio that better prepares technicians for their roles and covers a full suite of OEM programs, including Bombardier, Dassault, Embraer, Gulfstream, and more.

We teach entry-level aircraft maintenance technician courses, as well as in-depth initial training courses on specific aircraft Courses range anywhere from three days to five-plus weeks for a complete aircraft tip-to-tail initial course. We also offer several professional development courses to help aircraft technicians improve their leadership skills.

JS: CAE is very much a technology-led company; It’s clear from the state-of-the-art full-flight simulators (FFS), the company’s ability to incorporate gaminglevel displays into them, and the introduction of a new AppleVision Pro tool. How is the use of technology translating to maintenance training?

DB: Beyond the use of actual aircraft parts and hangarbased instruction, CAE is producing innovative ways to accelerate a student’s ramp-up time so they can become an effective technician sooner rather than later. Technology is at the core of CAE’s approach, and we are employing advanced simulation tools to support our customers. These allow

technicians to practice diagnosing and resolving malfunctions in a safe, controlled environment before working on an aircraft. It also gives them more opportunity to practice, as physical aircraft are not always available for training.

We have integrated virtual reality (VR) technology into our maintenance technician training programs. This enables us to create detailed digital twins of aircraft, allowing trainees to virtually become familiar with aircraft systems, components, and procedures in a fully immersive, simulated environment. This accelerates understanding, builds skills, and confidence in a safe setting. During a theoretical portion of a course, we can now bring an entire aircraft “into” the classroom and show levels of detail that, before VR, were very difficult to achieve. This high-value solution is transforming the aviation maintenance industry.

JS: How are customers responding to this new training methodology?

DB: Customers love being able to bring an aircraft into the classroom environment. The special orientation that VR allows makes objectives such as component locations, removal, and installation tasks much simpler to deliver. Students enjoy being able to access parts of the aircraft that they usually couldn’t during routine maintenance. As business jets become increasingly advanced with integrated avionics and connectivity systems, technology-driven training ensures that maintenance teams are always prepared for evolving aircraft designs.

CAV Systems delivers proven ice protection solutions for Hawker and other leading business jets. Engineered for performance, safety and reliability.

CAV’s relationship with Hawker stretches back over 50 years, when we designed and manufactured TKS® panels for their first business jet... 20 years later, we became responsible for the entirety of the Hawker’s leading edge sections.

Today, we are the only company equipped to overhaul TKS® panels and Hawker leading edge sections to the original specifications. We combine proven history with innovation, keeping your aircraft flying safely, efficiently and reliably.

customerservice@cav-systems.com sales@cav-systems.com

JS: You refer to the high number of maintenance technicians the industry will require. How do you work with OEMs to help them support their customers?

DB: We are exploring a number of options, and the relationship between CAE and Bombardier demonstrates a good example of how we’re thinking differently about training. We are collaborating on the development of a modular maintenance training program, which aims to optimise the time required to train Bombardier Service Centre maintenance technicians.

There is a need for more trained personnel on the ground and in the field. A key challenge is that it currently takes a considerable amount of time to train new technicians, and even longer to train them across multiple aircraft platforms. The new modular solution developed for Bombardier reduces training time by consolidating courses for an entire aircraft family since they share many components and features. This is designed to speed up the acquisition of basic knowledge across the family of aircraft types and then become more tailored to each specific model.

JS: How does CAE ensure regulatory compliance and certification for its maintenance training?

DB: Maintenance training must meet strict aviation authority standards. This is why CAE aligns its programs with regulatory organisations, such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency), as well as OEMs and partner MROs, to refine our programs continually. For operators managing global fleets, this assures that personnel are qualified regardless of where the aircraft flies. CAE also works closely with OEMs to maintain type-specific authorisations.

As regulations evolve, CAE updates its curricula, so technicians remain current with airworthiness directives,

service bulletins, and new maintenance procedures. The result is a training framework that provides both legal compliance and real-world operational competence.

JS: What can we expect from CAE business aviation maintenance training in the future?

DB: CAE’s maintenance training continuously adapts to meet or exceed the needs of its customers. We are investing more in technology-based training, maintenance career development programs, and innovative training methodologies that accelerate training and make it more accessible in more places around the globe. With technology such as maintenance simulations and VR, CAE is continuing to push the boundaries of how technology can benefit learners in a way that appeals to the next generation. In addition, we can provide technician training at all of CAE’s business aviation training centres around the globe, as well as at the customer’s location on request, and even online.

For operators, this means ease of access and reliability, as well as trained maintenance personnel, which reduces the risk of unexpected aircraft-on-ground (AOG) situations, keeps flight schedules on track and ensures aircraft availability for demanding clients. Training with CAE also supports cost efficiency, as accurate troubleshooting and preventative maintenance minimise unnecessary part replacements and downtime.

For technicians, CAE training delivers career opportunities. Earning OEM-authorised and regulator-approved qualifications enhances employability, mobility, and career progression. Ultimately, we are responsible for keeping business aviation moving safely and efficiently, and our maintenance training provides a foundation of technical excellence, regulatory assurance, and professional growth.|BAM

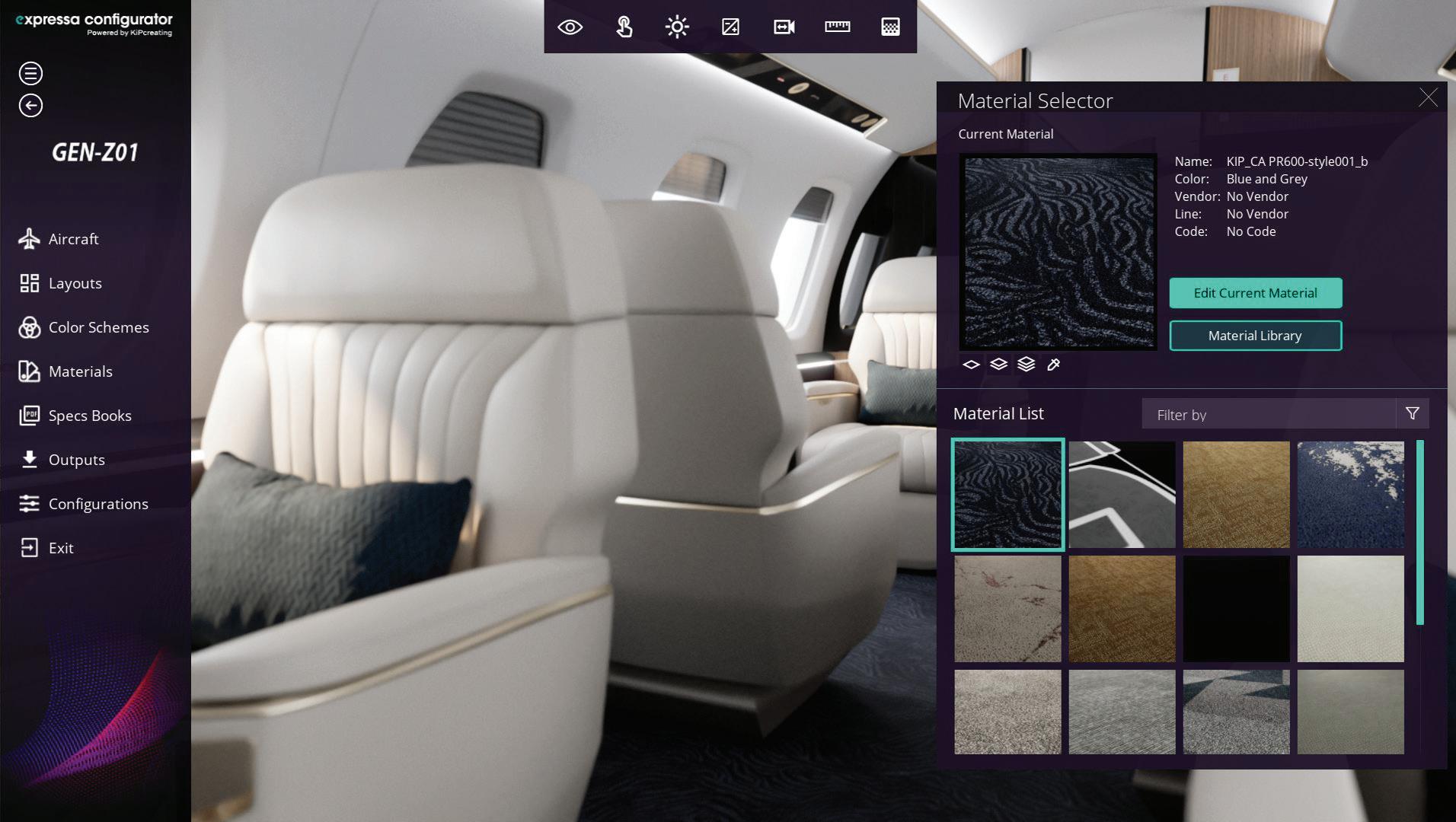

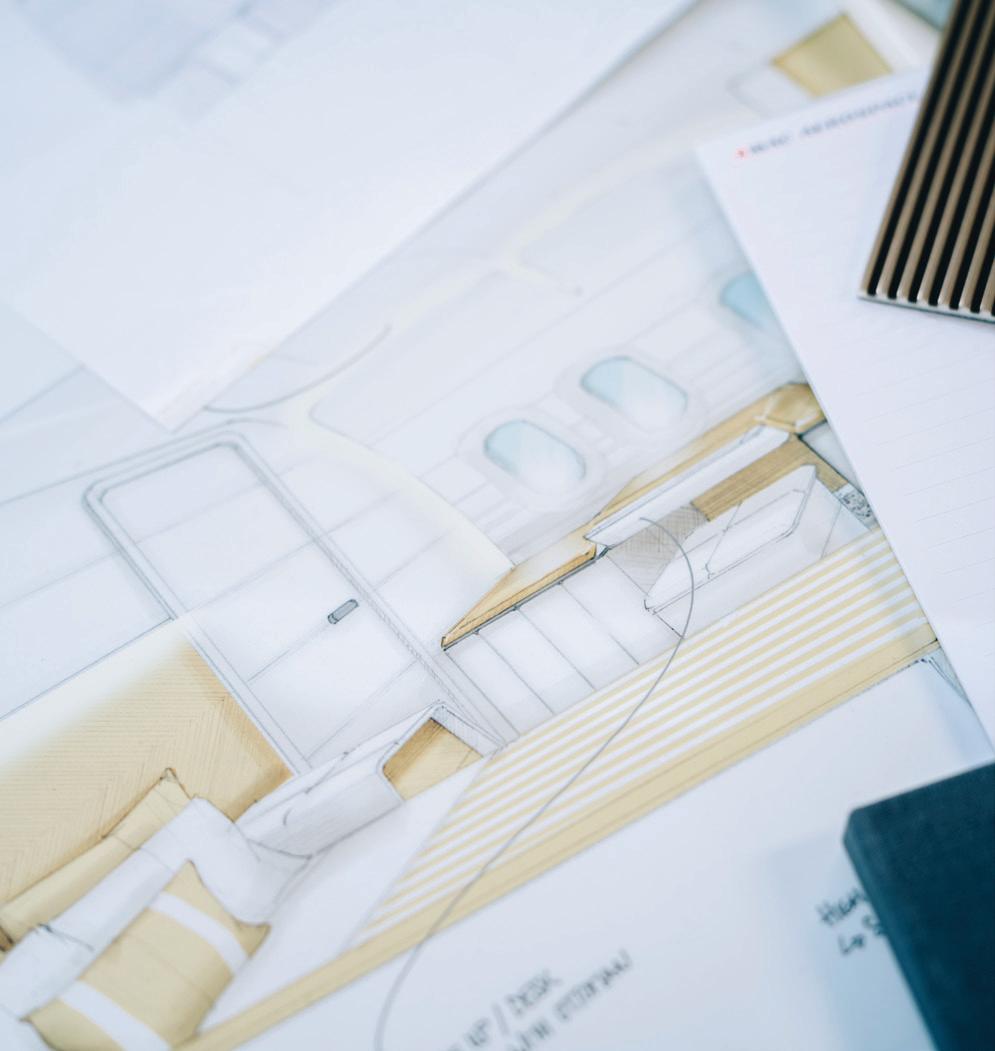

Max Pardo, Founder and CEO of KiPcreating, on transforming visualisation and rendering across multiple industry sectors

Q: Max, what got you started in the demanding field of 3D visualisation and rendering?

MP: I originally trained as an engineer and exp ected to spend my working life calculating complex systems. However, I discovered that my true passion was in computer graphics. That was something that had fascinated me since childhood, and my first computer.

What seemed at first like a detour became the foundation of KiPcreating, where I could merge creativity with problem-solving. Over the past 20 years, that passion has grown into an awardwinning studio, trusted by leading names in aviation. Looking back, I feel fortunate to have followed my instincts, building

not only innovative visualisation tools but also long-term partnerships with clients I now call friends.”

Q: Tell us a bit about KiPcreating and the industries you work with, particularly business aviation.

MP: KiPcreating is an award-winning visualisation and s oftware studio with deep roots in business aviation. We’ve been fortunate to work with leading names in the industry. This includes OEMs like Bombardier, Boeing Business

Jets, Embraer, and Pilatus, along with operators such as NetJets. We also collaborate closely with completion centres, including Comlux, AMAC, and Greenpoint, as well as design leaders and suppliers like Yves Pickardt, Aurora Saboir, F/ List, and SkyStyle, just to mention a few.

What defines us is not just what we deliver, but how we partner. We don’t work for clients — we work with them, as collaborators. Whether it’s an OEM, a completion centre,

“ By leveraging real-time visualisation technology, we give our clients the ability to make informed decisions faster, saving valuable time and resources.”

or a design studio, we see ourselves as an extension of their creative and technical teams.

To achieve this, I have assembled a multidisciplinary team of CGI artists, filmmakers, software developers, and designers. Together, we’ve set new standards in photorealistic rendering, configurators, and immersive experiences for aviation.

The result is a studio that combines technical precision, creative storytelling, and a passion for elevating client visions. That’s why we’ve been recognised with multiple International Yachts & Aviation Awards and why leading players trust us to help bring their aircraft and design concepts to life.

Q: Can you tell us a bit about how you work with customers to help them shape their vision of what they desire?

MP: At KiPcreating, collaboration is at the heart of e verything we do. Every project begins with a kick-off meeting where we capture the client’s vision, and then we build a clear delivery plan together. This includes collecting references for mood boards, defining structured design revision stages, and scheduling real-time visualisation sessions where clients can see progress and provide feedback instantly.

We know changes are inevitable, which is why our process is designed to be structured yet flexible. Our goal is not only to deliver a great image, movie, or configurator, but to make the customer journey enjoyable and stress-free.

To support this, we have developed proprietary tools that make the revision process both fun and effective. By leveraging real-time visualisation technology, we give our clients the ability to make informed decisions faster, saving valuable time and resources.

Most importantly, we are not distant AI agents; we work with our clients as an extension of their office. We are known for being fast, accurate, and above all, design-sensitive. Our team brings together industrial designers, architects, senior 3D artists, and software developers, so we approach each project from multiple angles. This combination of technical precision, design expertise, and human collaboration is what makes our process unique.

Q: How does your approach differ from the way the industry uses current traditional 3D visualisations?

MP: Traditional 3D visualisation is still surprisingly slow and rigid. Many companies continue to work as we did 20

Engineered MadeGermany and in Passion. with

Experience the power of electric drive, engineered

From BBJs to all Gulfstreams and Globals to smaller aircraft such as Dassault Falcons, Pilatus and Learjets, this state-of-the-art electric tug is suitable for all. With a capacity of up to 75 tons, it offers powerful performance in a very compact form. The fully automatic nose wheel pick-up and radio remote control streamline your ground handling. The robust hydraulic lifting platform ensures a firm and secure hold of the nose wheel at all times. Designed for maximum maneuverability and efficiency, each Mototok is agile, energy efficient and perfect for tight hangar spaces. This next generation tug is revolutionizing the way you move your fleet of aircraft on the ground. Get ready to elevate your operations!

years ago, building everything from scratch and relying on long render times. The process is time-consuming, and the biggest frustration for clients is that iterations take far too long. Every change adds days or even weeks, which disrupts the customer experience and risks losing momentum in critical design or sales discussions.

Balancing speed and quality has always been a challenge with traditional methods. Clients today face tighter deadlines and higher expectations than ever before, and the traditional workflow simply cannot keep pace. Delivering the level of realism they want within the time they need has become almost impossible without new approaches.

Revisions are particularly painful. Often, implementing changes takes longer than creating the initial visuals. Because visualisation is typically the last link in the production chain, we absorb the accumulated delays and have to deal with demanding last-minute changes. Traditional workflows make that extremely difficult.

The impact on our industry clients is clear. Their customers expect immediate results and shorter timeframes, and traditional visualisation methods simply cannot keep up. The industry is shifting toward more interactive and agile solutions, and those who remain tied to old workflows are increasingly struggling to meet modern expectations. At KiPcreating, while

we still support traditional methods when necessary, we have introduced new tools to drastically reduce these timeframes and make the process more efficient for our clients.

Q: How is KiPcreating innovating to change the game?

MP: At KiPcreating, innovation has always been in our DNA. We built our first aircraft configurator back in 2007, running on an iPad with pre-rendered content, which was groundbreaking at the time. By 2014, we took a bold step forward, developing one of the first fully 3D real-time configurators that achieved photorealistic quality almost indistinguishable from traditional rendering. That vision has matured into what we now call Expressa, a platform that delivers real-time visualisation at a quality level that not only matches but often exceeds traditional renderings.

The real breakthrough is that Expressa gamifies the customer experience with a user-friendly, intuitive interface. It combines speed and photorealism in real time, enabling clients to create consistent content for design, marketing, and sales. Under the hood, our proprietary technology modifies gaming engines with extensive custom coding, allowing us to create exclusive interactive modules.

But perhaps the most important innovation is that Expressa is more than just a configurator; it is an ecosystem. We have built

“ The results speak for themselves. Expressa allows teams to work 80 to 95 times faster compared to traditional workflows.”

a growing aircraft digital twin database, material libraries, a material editor, and cloud-sharing functionality. This allows OEMs, designers, completion centres, and suppliers to coexist and collaborate effectively within a shared digital environment. And to make it widely accessible, we developed a subscription business model that keeps the platform affordable for teams of any size.

The results speak for themselves. Expressa allows teams to work 80 to 95 times faster compared to traditional workflows. That means fewer repetitive tasks, less burden on creative teams, and more focus on design innovation. Even professionals without a 3D background can use the tool confidently. The quality of the output is consistent, photorealistic, and in many cases indistinguishable from reality, while reducing content production costs by up to 95 percent.

This is more than a tool; it is a shift in how the industry works. Expressa allows OEMs, operators, designers, and suppliers

to collaborate in real time, conducting spec sessions with customers that can compress what used to take four weeks of back-and-forth into a two-hour session.

That is how we see the future of aviation visualisation: faster, more collaborative, more effective and... in real-time.

Q. What can you tell us about how Expressa functions and how it addresses the drawbacks of traditional visualisations?

MP: Expressa was designed to eliminate the pain points of

You’re free to focus on what comes next. You’re on your mission and you know: You’re on top of compliance, safety, ops… All of this has become super easy and intuitive.

NGFT covers everything for a Biz-Jet or Rotary Wing Operation: Dispatch, Crew Management, Documents, Audit, Compliance, Safety, FlightLog, Duty Times, Flight Risk Assessment, WBT Courses for all crew ... of course AI is fully integrated.

www.ngft.com contact@ngft.com

traditional visualisation. Where older workflows are slow and rigid, Expressa brings speed, flexibility, and consistency without ever compromising quality.

In terms of speed, Expressa allows real-time navigation through any aircraft, with the ability to make changes on the fly while maintaining photorealistic realism. Clients can instantly render still images or movies directly within the software, delivering in minutes what once took days or weeks.

Flexibility is built into every module. With drag-and-drop materials, real-time swaps, and our Colour Scheme Creator, clients can test and visualise options immediately. Animated objects like tables, doors, or seats can be adjusted live, and interactive lighting modules allow day-to-night transitions or individual light control. At the end of a session, Expressa even generates a PDF report with mood boards and selected visuals, which can be shared seamlessly through cloud collaboration.

Consistency and quality are equally important. Our aircraft models are extremely precise, and our lighting is calibrated to guarantee a natural, realistic look in every output. All materials are based on Physically Based Rendering standards, which ensures fidelity in texture and colour. Clients can even import new materials and create custom libraries, always guided by our tutorials and best practices. This means the results are consistently photorealistic, even under the tightest deadlines.

But perhaps the most striking impact is the client experience. The first word we hear most often is simply, ‘Wow.’ Real-time navigation makes the design process engaging and enjoyable, transforming what was once a rigid review into an immersive journey. One client told us, ‘I am having so much fun working with the configurator that it doesn’t feel like work.’ That is exactly the outcome we want: to make life easier for our clients and help them close deals more effectively while enjoying the process.

The proof is in real-world results. One recognised OEM shared with us a customer review, where the buyer described it as the best purchasing experience they had ever had. What was once a four to five-week process was condensed into a two-hour meeting, thanks to Expressa. That is the difference this platform brings to the industry.”

Q: Can you summarise the transformation that this brings to the industry?

MP: Expressa is not just a configurator; it is transforming the way business aviation operates across sales, design, and collaboration.

From a sales perspective, it shortens customer decision time, increases closing rates, and eliminates much of the back-and-forth that used to slow down the process. Most importantly, it enhances the overall customer experience. What once took weeks of approvals and revisions can now be done in a single interactive session, where customers walk away with a clear, photorealistic vision of their aircraft.

For design teams, the change is equally powerful. Expressa eliminates repetitive tasks, freeing up time for true creativity and innovation. If a customer has an internal team, the platform makes them more productive without disrupting existing workflows. If they do not, Expressa still empowers them with an intuitive interface, ready-to-use aircraft libraries, and extensive material options to design with confidence.

Collaboration also reaches a new level. With cloud functionality, OEMs, suppliers, operators, and designers can all work within the same ecosystem. Materials and content can be shared across stakeholders, allowing suppliers to showcase their products and increasing opportunities for sales and partnerships.

Accessibility is another game-changer. We provide both offline and online configurators. The offline version is ideal for professional use, running on a laptop and producing the highest level of photorealism, while the online version is designed for exposure and initial customer interaction, often serving as a lead-generation tool. Many of our clients use both, starting with an online experience and then moving to a professional offline session for final decisions.

Looking ahead, we believe Expressa will become the new standard for how aircraft interiors and exteriors are imagined, sold, and delivered. It is not just a visualisation tool but a professional ecosystem that will benefit the entire industry. And as we integrate the latest AI capabilities, combining our precise digital twins with the power of automation and new levels of interactivity, Expressa will continue to push the boundaries of what is possible in aviation design and sales. |BAM

“What makes our Gosport facility essential for in-region customers is our ability to deliver exactly what they need.

At StandardAero, our focus is on providing the highest levels of technical expertise and customer service so operators can fly with confidence. For me as the new VP/GM