Importance of Tool Holders in CNC Machine

When it comes to CNC machines, tool holders play a critical role in achieving high precision and accuracy in machining. A tool holder is an essential component that holds the cutting tool in place and allows it to spin at high speeds during machining. Tool holders help maintain the cutting tool's position, control the runout, and reduce vibrations during machining.

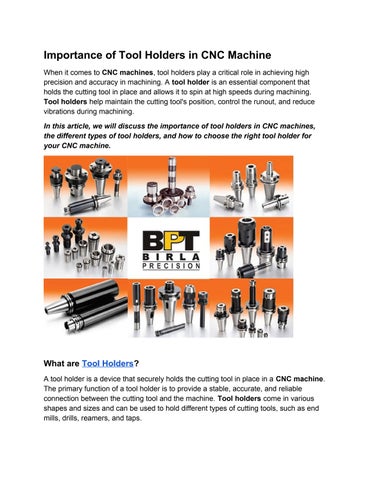

In this article, we will discuss the importance of tool holders in CNC machines, the different types of tool holders, and how to choose the right tool holder for your CNC machine.

What are Tool Holders?

A tool holder is a device that securely holds the cutting tool in place in a CNC machine

The primary function of a tool holder is to provide a stable, accurate, and reliable connection between the cutting tool and the machine. Tool holders come in various shapes and sizes and can be used to hold different types of cutting tools, such as end mills, drills, reamers, and taps.

Using tool holders in CNC machines has many advantages. They help to reduce vibration during machining, which is crucial for high-precision operations. Additionally, tool holders help to improve the quality of the finished product by providing greater machining accuracy, better surface finishes, and increased tool life.

Importance of Tool holder in CNC Machine

The importance of tool holders in CNC machines cannot be overstated. Tool holders play a critical role in achieving high precision and accuracy in machining. The use of tool holders in CNC machines helps to reduce the risk of tool breakage, provides more accurate cuts, and improves surface finishes.

The use of the correct tool holder can also help to reduce tool wear and tear, prolonging the life of the cutting tool. Tool holders can also reduce the risk of damage to the machine's spindle, which can be costly to repair.

Types of Tool Holders

● Hydraulic

Hydraulic tool holders are a type of tool holder that use hydraulic pressure to clamp and release cutting tools. They are commonly used in high-speed machining operations that require quick and accurate tool changes.

● Cone

Cone tool holders are a type of tool holder used to secure cutting tools in machining centers, lathes, and other machinery. They are named after their tapered shape, which allows for a secure and tight grip on the tool.

● HSK tool holders

These HSK tool holders do not have the retention knob (pull stud), and their unique feature is the hollow shank.

● Collar

Cone tool holders are a type of tool holder that is used to hold cutting tools in lathes, milling machines, and other machining centres. They are named after their tapered shape, which allows for a secure and tight grip on the tool.

● Sleeve pocket

Sleeve pocket tool holders are a type of tool holder that is used to hold multiple cutting tools in a single tool holder. They are often used in milling machines and machining centers, where a variety of tools may be needed to complete a job.

Factors that you should consider when choosing a tool holder!

Several factors must be considered when choosing a tool holder, including the type of material being machined, the size and weight of the cutting tool, the type of CNC machine being used, and the machining operation being performed. Other factors that need to be considered include the runout and accuracy requirements of the application and the recommended torque for tightening the tool holder.

Conclusion

Tool holders play a crucial role in achieving high precision and accuracy in machining. The use of the correct tool holder can help to reduce the risk of tool breakage, provide more accurate cuts, and improve surface finishes.

Birla Precision is a leading CNC tool holder manufacturer and supplier in Germany, providing high-quality products that are designed to meet the demands of the modern manufacturing industry. We also offer Precision Tool Holders such as, Cone, hydraulic, HSK tool holders, Collar, and Sleeve pockets at the most competitive price in the market!

Contact us today to learn more about our products visit us today!