47 YEARS OF EXCELLENCE

OUR JOURNEY

1977

Made India’s first Toilet Roll Machine (Online Slitting Type) for Sehgal Paper Mill

1982

Made India’s First Automatic Paper Napkin Folding Machine

1986

Received Bharat Ratna Visvesvaraya for making India’s First Automatic Paper Napkin Folding Machine

1988

Received recognition for Automatic Paper Napkin Folding Machine from NRDC

1999

Made India’s First Straight-Type Automatic Paper Napkin Folding Machine

2001

Made India’s First Coreless Toilet Paper Log Rewinder

2007

Made India’s First C Fold Paper Towel Machine

2011

Made India’s First Single Size Paper Napkin Machine with Bandsaw

2014

Made India’s First Double Deck Machine

2018

Made India’s First 4~6(Multicolor)

Printing Machine with Ceramic Rollers, Doctor Blade to achieve CMYK results

Made India’s first L Fold Machine

2020

Made India’s first Face Tissue machine along with fully automatic Toiler Paper Log Rewinder

2021

Made India’s First V Fold Machine

2023

Made India’s First N Fold Machine

BHARATRATNAVSVESVARAYAAWARD

Made India’s First Tissue Lamination Machine 1986 y HbGLShPdfI

Our journey began as the first manufacturers of Tissue Paper Conversion Machines in India. Sehgal Paper Mills established the first Tissue Paper manufacturing mill and conversion unit in 1975, and we provided the technology to convert their side cuts produced on paper mills into Toilet Paper Rolls (online slitting type) This made us pioneers in the Indian Tissue Conversion Machine industry.

ABOUT US

Birla Hi-tech Machines is a trailblazing Indian company specializing in the design, development, and manufacture of cutting-edge Tissue Paper Converting Machines. In 1977, Shri P.L. Birla founded Paper Conversion Machines, pioneering India's paper napkin machine manufacturing The company's debut of India's first toilet roll machine in 1977 Shri P L Birla's innovation earned him the Bharat Ratna Vishvesvaraya award in 1987 for creating India's first Automatic Napkin Folding Machine. With this achievement, the name Birla symbolized the beginning of a new era in the manufacturing of Paper Napkin Machines in India Building on this legacy his son, Mr Ashwani Birla, then led Birla Hi-Tech Machines to revolutionize the industry with high-production machines, leaving an enduring legacy of inspiration for many

At Birla Machines, we’re passionate about delivering solutions that are high-value, efficient, and ecofriendly Our dedicated team is constantly innovating and refining our products based on customer feedback, always striving to exceed expectations and set new industry standards We understand that in today’s fast-paced world, time is of the essence, which is why we’re committed to delivering faster turnaround times without sacrificing quality

As the tissue industry continues to evolve, we’re always looking for ways to stay ahead of the curve We believe that the key to success is staying adaptable, responsive, and customer-focused Our team is dedicated to providing outstanding service and support every step of the way, from initial design to final delivery and beyond

The history of the tissue industry is intertwined with the evolution of human civilization, and we’re proud to play a part in its ongoing development By working closely with our customers, we’re committed to promoting a healthy and sustainable tissue industry that makes a positive impact on society. At Birla Machines, we’re more than just a company we’re a partner you can trust to deliver exceptional results every time

At Birla Hi-Tech Machines, our commitment to delivering excellence permeates every facet of our operations. Our state-of-the-art technology, skilled workforce, and customer-centric approach combine to create products of unmatched quality.

Our machines are crafted with precision, utilizing the finest materials and components sourced from trusted suppliers. Through meticulous monitoring and continuous improvement, we ensure that each machine aligns with the highest industry standards.

OUR CUSTOMER BASE

Our Machines are installed in all states of India, a growing community of satisfied clients who rely on our products to drive their success. Birla Hi Tech is where innovation begins...

1000+

MachinesManufactured

150+ Clients

Countrieswhereourmachinesareoperating

Bahrain

Bhutan

Burkina Faso

Burundi

Ethiopia

Malaysia

Mozambique

Nepal

Nigeria

Oman

Romania

Rwanda

Somalia

South Africa

Sri Lanka

Suriname

United Arab Emirates

Uganda

Uzbekistan

Zimbabwe

Tissue Paper Rewinders

Paper Napkin Production Line

Paper Towel Production Line

Tissue Paper Jumbo Roll Flexographic Printer

Ancillary Machines

Accessories

INDEX

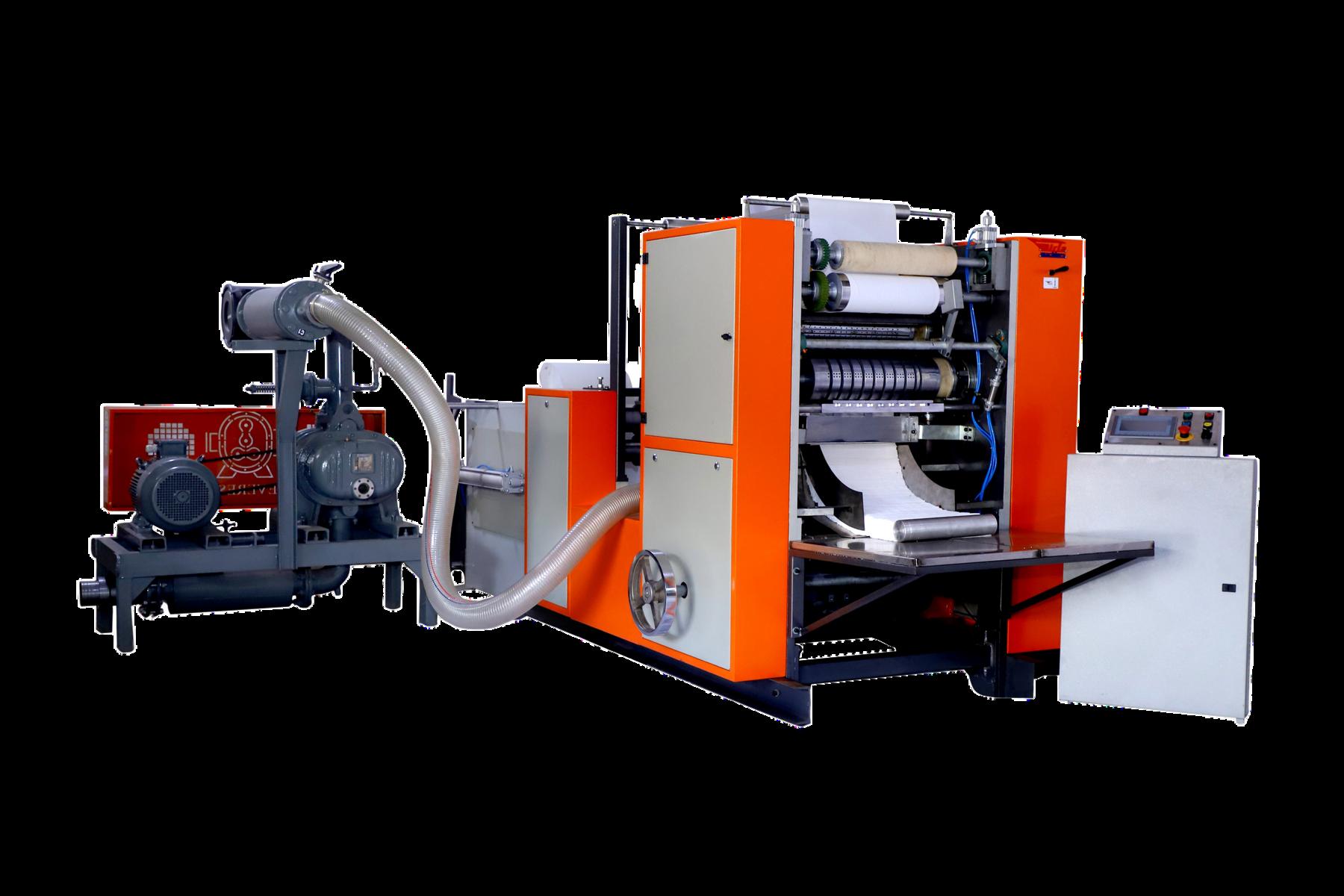

AUTOMATIC

TOILET PAPER LOG REWINDER

MainFeatures:-

Product diameter is controlled by PLC

The Gluing is performed automatically and uniformly

Core is automatically placed

Pneumatic arms are provided to load the Jumbo Roll on the unwind unit

Positive drive at unwind unit allows using lighter gsm paper easily

Pneumatic pressure is used over embossing unit

Options:-

Additional embossing unit

Additional unwind stand

Toilet Paper Log Rewinding

Attachment (JRT/HRT Roll

Rewinding)

Variable perforation length through ger box

Servo motor

Jumbo Paper Roll End Sensor Bandsaw

Our High-Speed Automatic Rewinder performs various operations, including perforation, embossing (optional), and rewinding, making it a versatile and indispensable tool for tissue paper manufacturers

The machine boasts advanced PLC technology and variable speed adjustments, ensuring precise and efficient operation. With its Touch Screen multi-menu type LCD screen operation control panel, operators can easily control the machine and rewind paper up to the desired diameter

Once the log has been rewound, our precision blade, which moves across the paper width with tail end glue application, cuts the log from the parent roll. The log is then transferred to the band saw, which cuts it into toilet rolls of the desired length

Perforation repeat

End product specification

/ 230mm ( As Per Requirement )

Each Log of 1400mm width , with each sheet length of 110mm

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Maximum Paper Width 1400mm / 1650mm Maximum Unwind Diameter 1200mm Maximum Rewinding Diameter 120mm

110mm

Motor with frequency drive 7 5 H P A C Control PLC ( Standard Make ) Unwind unit One ( Second Optional to make Four Ply Rolls )

Type Male to Rubber Type (Female Roller Optional) Capacity / 8hrs 1250 Logs / shift Weight 3000-3500Kg Space required 12 ' x 8 ' x 6 ' / 12 ' x 9 ' x 6 '

Embossing

TOILET PAPER LOG REWINDER

AUTOMATIC WITH JRT/HRT ATTACHMENT

MainFeatures:-

Product diameter is controlled by PLC

A seperate JRT/HRT Rewinding Unit it provided.

The Gluing is performed automatically and uniformly Core is automatically placed

Pneumatic arms are provided to load the Jumbo Roll on the unwind unit

Positive drive at unwind unit allows using lighter gsm paper easily

Pneumatic pressure is used over embossing unit

Options:-

Additional embossing unit

Additional unwind stand

Variable perforation length through ger box

Servo motor

Jumbo Paper Roll End Sensor Bandsaw

Our High-Speed Automatic Rewinder performs various operations, including perforation, embossing (optional), and rewinding, making it a versatile and indispensable tool for tissue paper manufacturers

The machine boasts advanced PLC technology and variable speed adjustments, ensuring precise and efficient operation. With its Touch Screen multi-menu type LCD screen operation control panel, operators can easily control the machine and rewind paper up to the desired diameter

Along with the features of Toilet Paper Log Rewinder a separate JRT/HRT Rewinding Unit is provided.

It’s important to note that by adjusting the slitting blade distance on the same rewinding unit, you can also produce JRT. To avoid the hassle of adjusting the slitting blades, we offer a convenient solution: you can have one product, either HRT or JRT (depending on which is in less demand), rewinding unit attachment on the same machine’s downside This allows for quick and easy switching between product types without the need for complicated adjustments.

Maximum Paper Width 1400mm / 1650mm

Maximum Unwind Diameter 1200

Maximum Rewinding Diameter

Perforation repeat

End product specification

200mm / 250mm ( For JRT / HRT ) 120mm

One ( Optional )

200mm / 230mm ( As Per Requirement ) ( JRT / HRT )

Each Log of 1400mm width , with each sheet length of 110mm .

For JRT / HRT :

1 ) Each Roll of 1kg weight , 200mm width HRT ( 35gsm Paper )

2 ) 95mm Roll of 250m JRT ( 16 / 32gsm Paper )

Motor with frequency drive 7.5 H.P.A.C

Control

Unwind unit

Embossing type

Capacity / 8hrs

PLC ( Standard Make ) .

One ( Second optional to make Four Ply Rolls )

Male to Rubber Type ( Female Roller is Optional )

1250 Logs / Shift

For JRT / HRT :

500 Rolls of 1kg HRT ( Width 200mm gsm 35 )

700 Rolls of 250m JRT ( Width 95mm gsm 16/32 )

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Weight 3500-4000Kg Space required 12 ' x 8 ' x 6 ' / 12 ' x 9 ' x 6 '

AUTOMATIC

HIGH SPEED JRT/HRT REWINDER

MainFeatures:-

Product diameter is controlled by PLC

The Gluing is performed automatically and uniformly

Core is automatically placed

Pneumatic arms are provided to load the Jumbo Roll on the unwind unit

Positive drive at unwind unit allows using lighter gsm paper easily

Pneumatic pressure is used over embossing unit

Options:-

Additional embossing unit

Additional unwind stand

Variable perforation length through ger box

Servo motor

Jumbo Paper Roll End Sensor

Our High-Speed Automatic Rewinder performs various operations, including perforation, embossing (optional), and rewinding, making it a versatile and indispensable tool for tissue paper manufacturers.

The machine boasts advanced PLC technology and variable speed adjustments, ensuring precise and efficient operation With its Touch Screen multi-menu type LCD screen operation control panel, operators can easily control the machine and rewind paper up to the desired diameter.

Along with the features of Toilet Paper Log Rewinder a separate JRT/HRT Rewinding Unit is provided.

It’s important to note that by adjusting the slitting blade distance on the same rewinding unit, you can also produce JRT To avoid the hassle of adjusting the slitting blades, we offer a convenient solution: you can have one product, either HRT or JRT (depending on which is in less demand), rewinding unit attachment on the same machine’s downside. This allows for quick and easy switching between product types without the need for complicated adjustments

Maximum

Perforation repeat

End product specification

/ 250mm

/ 230mm ( As Per Requirement )

1 ) Each Roll of 1kg weight , 200mm width HRT ( 35gsm Paper )

2 ) 95mm Roll of 250m JRT ( 16 / 32gsm Paper ) Motor with

5 H P A C

( Standard Make )

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Paper Width 1400mm

1650mm

Unwind Diameter 1200

Maximum

/

Maximum

Rewinding Diameter 200mm

200mm

7

PLC

frequency drive

Control

type Male to Rubber Type

Female Roller is Optional ) Capacity / 8hrs 1600 Rolls of 1kg HRT ( Width 200mm gsm 35 ) 1400 Rolls of 250m JRT ( Width 95mm gsm 16/32 )

3500-4000Kg

required 12

Unwind unit One ( Second optional to make Four Ply Rolls ) Embossing

(

Weight

Space

' x 8 ' x 7 '

AUTOMATIC (SINGLE DECK - SINGLE SIZE)

PAPER NAPKIN MACHINE

MainFeatures:-

Air Shaft for Jumbo Paper Roll

Gear Box

Blade Sharpening

Integrated bandsaw to cut one lane into two stacks on the delivery deck

The separation between stacks is with the single napkin lift which is operated pneumatically

Electronic counting for absolute accuracy

Embossing provided is male to female type in either full or border pattern

Heavy Machine Structure

Options:-

Pneumatic Lift for Jumbo Paper

Roll

Web Guide

Static Eliminator

Mechanical Shaft for Jumbo Paper

Roll

Jumbo Paper Roll End Sensor

Semi-Automatic Paper Napkin

Bagging Machine

Our Automatic Paper Napkin Machine is designed to quickly and efficiently fold Jumbo Rolls into square or rectangular paper napkins. With its advanced system, this machine can handle printing, embossing, counting, and folding with ease

Thanks to its variable frequency drive, the speed of the automatic paper napkin folder can be easily controlled to match the requirements of your production line. Plus, the counting function can be easily adjusted to ensure that you’re producing the right number of napkins every time

For added convenience, we’ve included an extra remote control on the back side of the machine. This allows operators to adjust the machine’s speed while feeding paper at the beginning, ensuring that the process is smooth and efficient from start to finish

Working Paper

Parent

~ 200mm ( As Per Requirement )

Printing Unit As Per Requirement

Embossing Unit As Per Requirement

Parent Roll

Raw Paper Material 1 ~ 3 Layer Tissue Paper ( 18-36gsm)

Unwind Unit One or more ( As per Requirement )

Folding Size 1/4 (1/6 Optional)

Speed

300 to 600 Sheets Per Minute ( speed varies according to quality of paper , sheet size and printing area )

Installed Power 3kW, 440v A C , 50Hz

Air Pressure Required 5 P.S.I.

Transmission

Timing Belts

Speed Regulations Variable Frequency Drive

Weight 2000-3500Kg

Space Required 16 ' x 4 ' x 6 '

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Width 400mm

Diameter

1200mm

Roll Core Inner Diameter 76mm

PAPER NAPKIN MACHINE

AUTOMATIC (DOUBLE DECK - SINGLE SIZE)

MainFeatures:-

AirShaftforJumboPaperRoll

GearBox

BladeSharpening

Integratedbandsawtocutone laneintotwostacksonthe deliverydeck

Theseparationbetweenstacksis withthesinglenapkinliftwhichis operatedpneumatically

Electroniccountingforabsolute accuracy

Embossingprovidedismaleto femaletypeineitherfullorborder pattern

HeavyMachineStructure

Aslittingunitwhichcontainsone setofslittingknives

PneumaticLiftingArmstoload

JumboPaperRoll

Options:-

Pneumatic Lift for Jumbo Paper

Roll

Web Guide

Static Eliminator

Mechanical Shaft for Jumbo Paper

Roll

Jumbo Paper Roll End Sensor

Semi-Automatic Paper Napkin

Bagging Machine

Our Automatic Paper Napkin Machines are designed with efficiency, reliability, and ease of use in mind. With their high-speed paper folding capabilities, these machines are a valuable asset for tissue paper manufacturers who need to produce large quantities in a short amount of time

Our machines are engineered to deliver consistent, high-quality results with minimal downtime They are equipped with advanced features such as variable frequency drives and remote control options to help you maximize your production output and minimize your operating costs.

Air

Space Required

400 to 600 Sheets Per Minute per deck ( speed varies according to quality of paper , sheet size and printing area )

440v A.C. , 50Hz

atm 1 / 4Hose

Belts

Frequency Drive

' x 6 5 ' x 6 '

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Working Paper Width 660mm

440mm

Per

)

Unit As Per Requirement Embossing Unit As Per Requirement Parent Roll Diameter 1200mm Parent Roll Core Inner Diameter 76mm Raw Paper Material 1 3 Layer Tissue

)

Unit One

more

Folding Size 1/4 Speed

~

( As

Requirement

Printing

Paper ( 18-36gsm

Unwind

or

( As Per Requirement )

Power 3.7kW,

Installed

Pressure Required 5

Timing

Transmission

Variable

Weight 3000-3500Kg

Speed Regulations

16

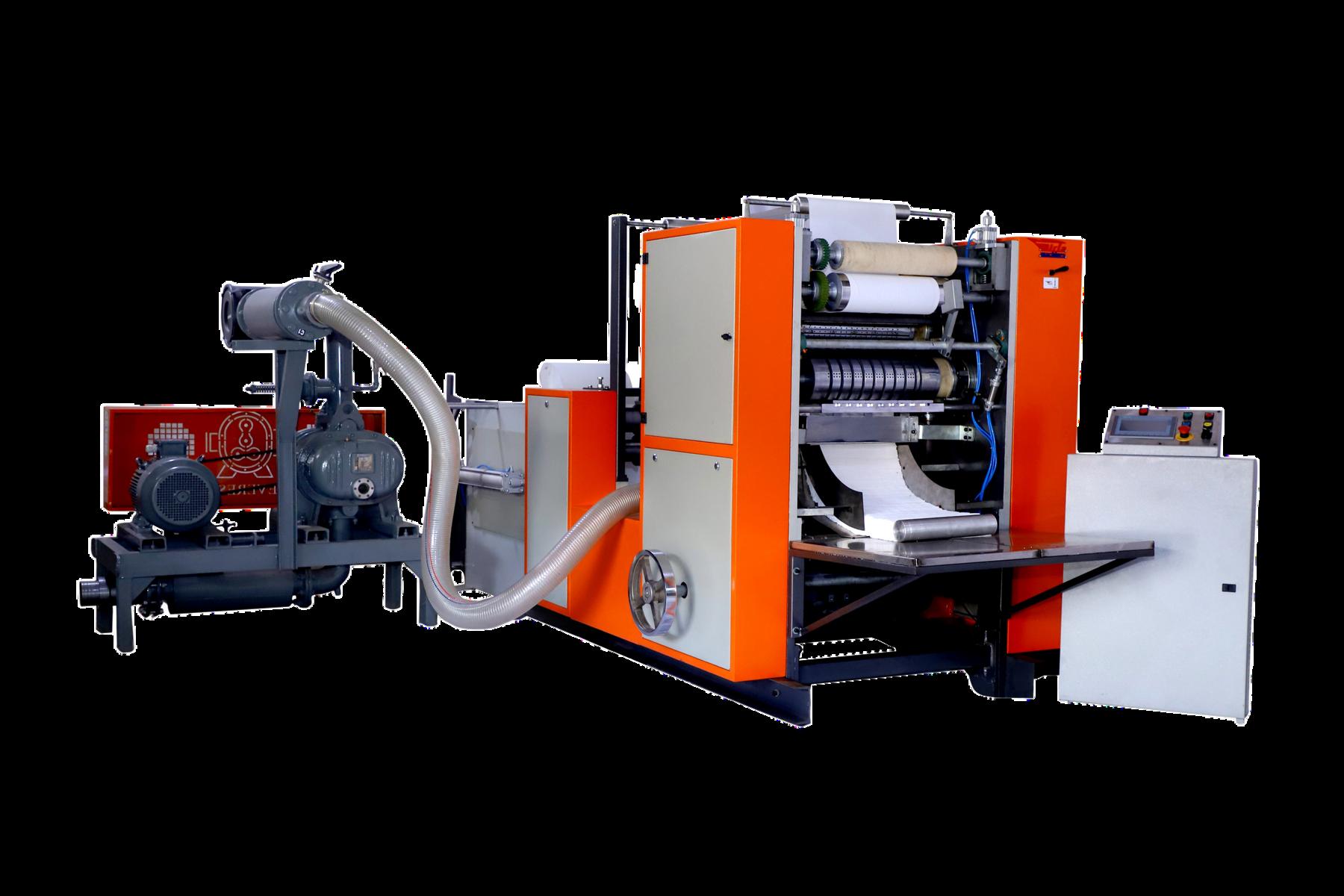

MULTI COLOR PAPER NAPKIN MACHINE AUTOMATIC (SINGLE DECK - SINGLE SIZE)

MainFeatures:-

Air Shaft for Jumbo Paper Roll

Gear Box

Blade Sharpening

Integrated bandsaw to cut one lane into two stacks on the delivery deck

The separation between stacks is with the single napkin lift which is operated pneumatically

Electronic counting for absolute accuracy

Drying Chamber

Web Guide

Heavy Machine Structure

Embossing provided is male to female type in either full or border pattern

Options:-

Pneumatic Lift for Jumbo Paper

Roll

Static Eliminator

Mechanical Shaft for Jumbo Paper

Roll

Jumbo Paper Roll End Sensor

Semi-Automatic Paper Napkin

Bagging Machine

Our advanced Automatic Paper Napkin Machine is equipped with cutting-edge technology that allows it to produce tissue paper napkins in multiple colors, ranging from one to six colors, and can even be customized to meet specific customer requirements for additional colors The machine uses a state-of-the-art Ceramic Rollers with Doctor Blade technology, resulting in superior printing quality and precision. With our advanced printing capabilities, you can achieve exceptional results based on the CMYK color model Our machine provides a cost-effective and efficient solution for those who require high-quality, multi-colored tissue paper napkins in large quantities.

~ 270mm ( As Per Requirement )

Printing Unit As Per Requirement

Embossing Unit As Per Requirement

Parent

Parent Roll

Raw

Air

~ 3 Layer Tissue Paper ( 18-36gsm )

Unwind Unit One or more ( As per Requirement )

Folding Size 1/4 (1/6 Optional)

300 to 450 Sheets Per Minute ( speed varies according to quality of paper , sheet size and printing area ) Installed

7kW, 440v A C , 50Hz

P.S.I.

Transmission Timing Belts

Speed Regulations

Frequency Drive Weight 3500-4000Kg

Space Required 22 ' x 4 ' x 8 '

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Paper Width 400mm

Working

Diameter 1200mm

Roll

Core

Diameter 76mm

Inner

1

Paper Material

Speed

Power 3

Pressure Required 5

Variable

FACE TISSUE MACHINE

MainFeatures:-

Pneumatic lifting arms to load

Jumbo Paper Rolls

Pneumatic Paper Driving

Stepless speed adjustment

Equipped with high-quality vacuum pump for stable running of the machine and for stable folding

Heavy Machine Structure

Options:-

Embossing Unit

Perfume Unit

Air Shaft for Jumbo Roll

Jumbo Paper Roll End Sensor

Face TIssue Box Pasting Machine

AUTOMATIC

The facial tissue machines are the pinnacle of efficiency, reliability, and ease-of-use. With precision-engineered slitting cylinders, jumbo rolls are expertly cut into the perfect size before being interfolded into overlapping rectangular facial tissue sheets The machine’s variable frequency drive ensures optimal speed control, while the counting can be easily customized to meet specific requirements.

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Working Paper Width 400mm Jumbo Roll Maximum Diameter 1100mm Jumbo Roll Stands Two Jumbo Roll Core Inner Diameter 76mm Vacuum Pump 5kW Fold Size 100mm Product Specification 100mm* 200mm x 2 Main Drive 3 H P Speed 1100-1250 Sheets Per Minute Installed Power 7 25kW, 415v A C , 50Hz Air Pressure Required 5 P S I Control PLC Standard Make Weight 3000-3500Kg Space Required 14 ' x 6 ' x 7 '

AUTOMATIC

N-FOLD PAPER TOWEL MACHINE

MainFeatures:-

Pneumatic lifting arms to load

Jumbo Paper Rolls

Pneumatic Paper Driving

Stepless speed adjustment

Equipped with high-quality vacuum pump for stable running of the machine and for stable folding

Male to Male Embossing unit

Heavy Machine Structure

Options:-

Air Shaft for Jumbo Roll

Jumbo Paper Roll End Sensor

Paper Towel Bagging Machine

Bandsaw

The N Fold Paper Towel machines are the pinnacle of efficiency, reliability, and ease-ofuse. With precision-engineered slitting cylinders, jumbo rolls are expertly cut into the perfect size before being interfolded into overlapping rectangular paper towel sheets. The machine’s variable frequency drive ensures optimal speed control, while the counting can be easily customized to meet specific requirements.

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Working Paper Width 440/660mm Jumbo Roll Maximum Diameter 1100mm Jumbo Roll Stands One Jumbo Roll Core Inner Diameter 76mm Vacuum Pump 15/19kW Fold Size 210mm Product Specification 220*210 x 2/22*210 x 3 Main Drive 5/7 5 H P Speed 700/1050 Sheets Per Min Installed Power 19 5/21 5 kW, 415v A C , 50Hz Air Pressure Required 5 P S I Control PLC Standard Make Weight 4000 kg Space Required(Machine Only) 14 ' x 6 ' x 7 '

AUTOMATIC

L FOLD (CUBE) NAPKIN MACHINE

MainFeatures:-

Air Shaft for Jumbo Paper Roll

Gear Box

The separation between stacks is with the single napkin lift which is operated pneumatically

Electronic counting for absolute accuracy

Embossing unit having metal to paper ball type in either full or border pattern

Heavy Machine Structure

Options:-

Pneumatic Lift for Jumbo Paper

Roll

Web Guide

Jumbo Paper Roll End Sensor

Semi-Automatic Paper Napkin

Bagging Machine

The Automatic Cube (L-Fold) Paper Napkin Machine is a versatile and efficient machine used for folding Jumbo Rolls into L-Fold or rectangular paper napkins. The machine system includes features like printing, embossing, counting, and folding Its high-speed folding capability is controlled by a variable frequency drive, and the counting can be adjusted as per the requirement. The machine is also equipped with a static eliminator, which ensures high-quality production Moreover, an extra remote is provided on the back side of the machine, allowing the operator to control the speed while feeding paper at the beginning, making it easy to operate.

Working Paper Width 270mm (As Per Requirement)

Printing Unit As Per Requirement

Embossing Unit As Per Requirement

Parent Roll

Parent

Raw Paper

17 19 gsm

Unwind Unit One or more (As Per Requirement)

Folding Size 1/3

Speed

800 Sheets Per Minute(speed varies according to quality of paper, sheet size and printing area)

Installed Power 2 2kW, 440v A C , 50Hz

Air Pressure Required 5 P S I

Transmission

Speed Regulations

Timing Belts

Variable Frequency Drive

Weight 2500-3500Kg

Space Required 16 ' x 4 ' x 6 '

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

Diameter 1200mm

Roll Core Inner Diameter 76mm

Material

FLEXOGRAPHIC PRINTER

MainFeatures:-

The tightness of the product can be pneumatically adjusted, keeping diameter of finished product with one accord

Drying Chamber

Printing Registration can be easily managed at the delivery end

Air shaft for jumbo paper roll

Heavy Machine Structure

The Automatic Printing and Rewinding Machine comprises of an unwind unit, a printing unit, and a rewinding unit (Surface Type) The Jumbo Paper rolls are first unwound and then fed into the printing unit (Flexo-Graphic Type) for printing The printed paper then passes through a drying chamber to ensure the ink is dried thoroughly before being rewound on the surface type rewinding unit. This efficient and reliable machine is perfect for those in need of high-quality printing and rewinding of paper rolls.

Maximum

Maximum

Maximum

Drying

Printing Unit

415v)

Per Requirement ) Speed

Rewinding

Meter Per Minute

type

Drive

' x 6 ' x 6 '

Note: Keeping pace with time, specifications may differ.

Note: Machine is customizable as per customer requirement

paper width 300mm~820mm

Rewinding Diameter 1000mm

Unwind Diameter 1200mm

Chamber 4kW(on

1~4(As

80

Surface

Variable

required 12

Speed Regulations

Frequency

Weight 2500-3000Kg Space

ANCILLARY MACHINES

Face Tissue Box Pasting Machine

Bandsaw

Box Size As Per Requirement Power Required 1kW Speed 10-12 Boxes Per Minute Glue Tank Capacity 500ml Each Pneumatic Pressure Required 5 P.S.I. Control PLC Standard Make Maximum Cutting Length As Per Requirement Minimum Cutting Length 100mm Installed Power 1 5kW, 440vA C ,50Hz Speed Regulation Variable Frequency Drive Weight 800kg Space Required 4 ' x 4 ' x 7 '

ACCESSORIES

400mm Foot Operated Sealing Machine

Semi-Automatic Paper Napkin Bagging Machine

Semi-Automatic Paper Towel Bagging Machine

400mm Foot Operated Sealing Machine

Semi-Automatic Paper Napkin Bagging Machine

Semi-Automatic Paper Towel Bagging Machine

OUR VALUED CUSTOMERS

QUALITY ASSURANCE

At Birla Hi-Tech Machines, our commitment to delivering excellence permeates every facet of our operations Our state-of-the-art technology, skilled workforce, and customer-centric approach combine to create products of unmatched quality.

Our machines are crafted with precision, utilizing the finest materials and components sourced from trusted suppliers. Through meticulous monitoring and continuous improvement, we ensure that each machine aligns with the highest industry standards.

AFTER-SALES & SERVICE

We take pride in our comprehensive approach to customer satisfaction Open lines of communication, prompt responses, and effective solutions define our interactions with clients. Your success is our priority, and our products are designed to support your growth and profitability

Our dedicated team of experienced technicians under the guidance of Ashwani Birla is committed to providing thorough training for the machine until your satisfaction is fully assured We understand the importance of your confidence in our service, and we are dedicated to ensuring that you feel completely comfortable and confident in operating the machine. Rest assured, we'll be by your side every step of the way, offering guidance and support to ensure your seamless integration with our technology. Your success is our priority, and we're here to make sure you achieve it.

Choose Birla Hi-Tech Machines for machines that embody reliability, durability, and performance. Join a growing community of satisfied clients who rely on our products to drive their success Your journey towards efficiency and excellence begins with us

BRANDS USED IN MANUFACTURING

OFFICE 92, DSIDC Complex, Scheme 1, Okhla Industrial Area, Phase - II New Delhi 110020 (INDIA) FACTORY Village - Pali, Power House Road, Near Maruti Nandan Dharam Kanta, Faridabad121001 EMAIL ashwanibirla@gmail.com info@papernapkinmachines com CUSTOMER CARE NUMBER +919868119798 WEBSITE www.birlahitechmachines.com

400mm Foot Operated Sealing Machine

Semi-Automatic Paper Napkin Bagging Machine

Semi-Automatic Paper Towel Bagging Machine

400mm Foot Operated Sealing Machine

Semi-Automatic Paper Napkin Bagging Machine

Semi-Automatic Paper Towel Bagging Machine