Welded connections will normally be used when fabricating large primary elements like a large plate girder or composite sections in the shop. Quality welding is best done under controlled conditions. Welded connections are also preferred when fabricating complex trusses from HSS members, as common methods of attachment such as plates and angles are more suited to connecting members with webs and flanges. Welded connections present different issues for concealed versus exposed structures. Chapter 6 on Architecturally Exposed Structural Steel will address issues of aesthetics and cost implications for welded joints. Welded connections: Plates can be spliced together using two basic types of welded connections. Groove welds (left) are used where the two plates must be maintained in line. Thicker plates will use a double Vee weld, (top left), whereas thinner plates will use a single Vee weld. If it is not important to align the plates, then lap welds can be used (right). If the load on the lap joint is small, a single fillet or edge weld can be used (top right). For higher loads it will be necessary to use a double fillet weld (bottom right). For plate elements that are to be joined in line, groove welding can produce a clean-looking connection if side plates are not desired. Depending on the finish requirements the welds can be left “as is” or ground smooth. Grinding should be reserved for special high-profile applications as it is expensive and time consuming. Grinding also weakens the weld by removing weld material.

al

.

x

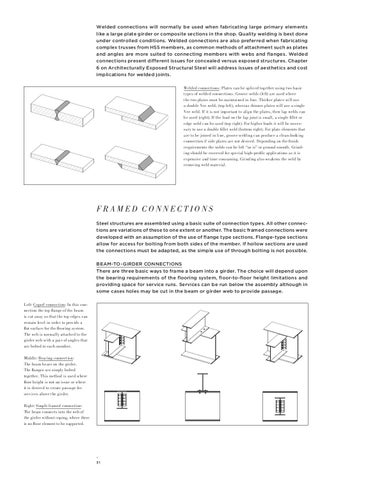

FR AMED CONNECTIONS Steel structures are assembled using a basic suite of connection types. All other connections are variations of these to one extent or another. The basic framed connections were developed with an assumption of the use of flange type sections. Flange-type sections allow for access for bolting from both sides of the member. If hollow sections are used the connections must be adapted, as the simple use of through bolting is not possible.

.

BEAM-TO-GIRDER CONNECTIONS There are three basic ways to frame a beam into a girder. The choice will depend upon the bearing requirements of the flooring system, floor-to-floor height limitations and providing space for service runs. Services can be run below the assembly although in some cases holes may be cut in the beam or girder web to provide passage.

s

r

e

Left: Coped connection: In this connection the top flange of the beam is cut away so that the top edges can remain level in order to provide a flat surface for the flooring system. The web is normally attached to the girder web with a pair of angles that are bolted to each member. Middle: Bearing connection: The beam bears on the girder. The flanges are simply bolted together. This method is used where floor height is not an issue or where it is desired to create passage for services above the girder. Right: Simple framed connection: The beam connects into the web of the girder without coping, where there is no floor element to be supported.

– 31