Gernot Minke

Gernot Minke

Design and Technology of a Sustainable Architecture

Fifth and revised edition

Birkhäuser

Gernot Minke

Design and Technology of a Sustainable Architecture

Fifth and revised edition

Birkhäuser

Basel

Preface 7

1 Introduction 9

History 9

Earth as a building material: the essentials 11

Improving indoor climate 13

Prejudices against earth as a building material 16

2 The properties of earth as a building material 17

Composition 17

Tests used to analyse the composition of loam 19

Effects of water 22

Effects of vapour 26

Influence of heat 29

Strength 30

pH-value 32

Radioactivity 33

Shelter against high-frequency electromagnetic radiation 33

3 Preparing of loam 34

Soaking, crushing and mixing 34

Sieving 36

Mechanical slurrying 36

Water curing 36

Thinning 36

4 Improving the characteristics of loam by special treatment or additives 37

Reduction of shrinkage cracks 37

Stabilisation against water erosion 38

Enhancement of binding force 40

Increasing compressive strength 40

Strength against abrasion 45

Increasing thermal insulation 45

Lightweight loams 46

5 Rammed earthworks 50

Formwork 51

Tools 52

Method of construction 53

Shaping of openings 53

Wall construction techniques 54

Rammed earth domes 59

Drying 59

Labour input 59

Thermal insulation 59

Surface treatment 59

6 Working with earth blocks 60

History 60

Production of earth blocks 61

Material composition 64

Laying earth blocks 64

Surface treatment 65

Fixing fasteners to walls 65

Lightweight earth blocks 65

Special acoustic green bricks and adobes 66

7 Large blocks and panels 67

Large blocks 67

Earth-filled wall panels 67

Clay panels 69

Heating panels 71

Floor slabs 71

Floor tiles 72

Extruded loam slabs 72

8 Direct forming with wet loam 73

Traditional wet loam techniques 73

The “Dünne loam loaf” technique 75

The stranglehm technique 75

9 Wet loam infill in skeleton structures 80

Thrown loam 80

Sprayed loam 80

Rolls and bottles of straw loam 81

Lightweight loam infill 81

Infill with stranglehm and earth-filled hoses 82

Sprayed loam in steel-reinforced walls and ceilings 82

10 Tamped, poured or pumped lightweight loam 85

Formwork 85

Tamped lightweight straw loam walls 85

Tamped lightweight wood loam walls 87

Tamped, poured or pumped lightweight mineral loam walls 87

Pumped lightweight mineral loam floors 88

Loam-filled hollow blocks 88

Loam-filled hoses 90

11 Loam plasters 92

Preparation of substrate 92

Composition of loam plaster 92

Guidelines for plastering earth walls 94

Sprayed lightweight plaster 94

Lightweight mineral loam plaster 95

12

Thrown plaster 95

Plastered straw bale houses 95

Wet formed plaster 97

Protection of corners 97

Stabilised loam plasters 97

Characteristics of different loam plasters 97

Weather resistance, coatings and coverings 100

Consolidating the sur face 100

Paints 100

Making sur faces water-repellent 103

Lime plasters 104

Shingles, planks and other covers 105

Structural methods 105

13 Repair of loam structures 106

Occurrence of damage 106

Repair of cracks and joints with loam fillers 106

Repair of cracks and joints with other fillers 107

Repairing larger damaged areas 107

Retrofitting thermal insulation with lightweight loam 107

Residences

Vineyard residence, Mornington Peninsula, Victoria, Australia 148

Residence cum office, Kassel, Germany 150

Residence, Merrijig, Victoria, Australia 152

Residence, Helensville, New Zealand 154

Residence, Palo Alto, California, USA 156

Weekend house, Ajijic, Mexico 158

Desert Outpost residence, Paradise Valley, Arizona, USA 160

Artist’s residence, Boulder, Colorado, USA 162

Casa Martha, La Misión, Baja California, Mexico 164

Condominiums Los Maitenes, Peñalolén, Santiago de Chile, Chile 166

Residence at Valle Tucán, Emboscada, Paraguay 170

Barrel-vaulted residential buildings at Valle Tucán, Emboscada, Paraguay 172

Cultural, educational and sacred buildings

National Environment Centre at Thurgoona Campus, Albury, New South Wales, Australia 176

14

Customised design solutions 109

Joints 109

Special wall constructions 111

Intermediate floors 113

Rammed earth floorings 113

Inclined roofs filled with lightweight loam 115

Ear th-covered roofs 115

Ear th block vaults and domes 117

Ear then storage wall in winter gardens 129

Loam in bathrooms 129

Built-in furniture and sanitar y objects from loam 131

Passive solar wall heating system 132

15 Earthquake-resistant building 133

Structural measures 134

Openings for doors and windows 136

Bamboo-reinforced rammed earth walls 139

Steel-reinforced sprayed loam walls 139

Steel-reinforced adobe wall system 141

Domes 141

Vaults 141

Textile walls with loam infill 144

Steel-reinforced earth walls 146

School, Rudrapur, Bangladesh 178

Chapel of Reconciliation, Berlin, Germany 180

WISE Centre for Alternative Technology, Machynleth, Wales, UK 182

Primary school, Tanouan Ibi, Mali 184 Cemetery, Bushey, Hertfordshire, UK 188

The Village Nursery, Bellingdon, Buckinghamshire, UK 192

Centre for People with Disabilities and Dipdii Textiles Studio, Rudrapur, Bangladesh 196

Adobe Dome Music Space, Aiguá, Uruguay 200

Burkina Institute of Technology, Koudougou, Burkina Faso 204

Maison pour tous, Four, Isère, France 208

Commercial, hospitality and health buildings

Rivergreen Centre, Aykley Heads, Durham, UK 212

High Country Visitor Information Centre, Mansfield, Victoria, Australia 214

Mii Amo Spa, Sedona, Arizona, USA 216

Bayalpata Hospital, Acham, Nepal 218

Office pavilion Earthbox, Asunción, Paraguay 222

Alnatura Office Building, Darmstadt, Germany 226

Prototype building TECLA, Massa Lombarda, Italy 230

Dior Pop-up Store, Jumeirah, Dubai 232

Bibliography 236

About the author 239

Illustration credits 239

Subject index 240

This handbook was written in response to an increasing worldwide interest in building with earth. While in Europe and North America earthen architecture may never play the dominant role as in warmer regions, we nevertheless find an increasing tendency to build with loam also in cooler climate zones. One reason for this is the growing environmental awareness as well as the desire to live in a balanced and healthy indoor environment. Thus this fifth edition is timely and should encourage architects to explore the potential of this sustainable building material further. The publication provides a survey of all applications and construction techniques of earth as a building material, including the relevant physical data, while explaining its specific qualities and the possibilities of optimising them. On many accounts, earth can offer an interesting alternative to industrialised building materials. The data and expert knowledge contained in this volume may be used as guidelines for a variety of construction processes and possible applications by engineers, architects, builders and clients who seek to use humanity’s oldest building material for their purposes.

Earth as a building material comes in many different compositions, and can be variously processed. Loam, or clayey soil, as it is referred to scientifically, has different names when used in various applications, for instance rammed earth, soil blocks, mud bricks or adobe. This book documents the results of experiments and research conducted at the Preface

Forschungslabor für Experimentelles Bauen (Building Research Institute – BRI) at the University of Kassel in Germany from 1978 to 2011. Moreover, the specialised techniques that the author developed and the practical experience he gathered in the course of designing earth buildings in a number of countries have also found their way into this book.

This volume is loosely based on the German publication Handbuch Lehmbau (Publisher: Ökobuch Verlag, Staufen), first published in 1994 and now in its nineth edition (2017). Besides this English edition, the publication was translated into numerous languages such as Spanish, Russian, Japanese, Czech, Farsi, Arabic and Rumanian.

While this is first and foremost a technical book, the introductory chapter also provides the reader with a short survey on the history of earth architecture. In this fifth English edition, the relatively recent technology of prefabricated rammed earth elements is introduced and the growing segment of clay panels is documented. The book’s final chapter depicts a number of attractive earth buildings from various regions of the world. These constructions demonstrate the impressive versatility of earth architecture and the many different uses of the building material earth. Within this chapter, several older built examples were replaced by seven new projects.

Kassel, March 2025

Gernot Minke

In nearly all hot-arid and temperate climates, earth has always been the most prevalent building material. Even today, one third of the human population resides in earthen houses; in developing countries this figure is more than one half. It has proven impossible to fulfil the immense requirements for shelter in the developing countries with industrial building materials, i.e. brick, concrete and steel, nor with industrialised construction techniques. Worldwide, no region is endowed with the productive capacity or financial resources needed to satisfy this demand. In the developing countries, requirements for shelter can be met only by using local building materials and relying on do-it-yourself construction techniques. Earth

is the most important natural building material, and it is available in most regions of the world. It is frequently obtained directly from the building site when excavating foundations or basements. In the industrialised countries, careless exploitation of resources and centralised capital combined with energy-intensive production is not only wasteful; it also pollutes the environment and increases unemployment. In these countries, earth is being revived as a building material. Increasingly, people when building homes demand energy- and cost-effective buildings that emphasise a healthy, balanced indoor climate. They are coming to realise that mud, as a natural building material, is superior to industrial building materials such as concrete, brick and lime-sandstone. Newly developed, advanced earth building techniques demonstrate the value of earth not only in do-it-yourself construction, but also for industrialised construction involving contractors. This handbook presents the basic theoretical data concerning this material, and it provides the necessary guidelines, based on scientific research and practical experience, for applying it in a variety of contexts.

Earth construction techniques have been known for over 9000 years. Mud brick (adobe) houses dating from 8000 to 6000 BC have been discovered in Russian Turkestan (Pumpelly, 1908). Rammed earth foundations dating from ca. 5000 BC have been

3 Loam saves energy and reduces environmental pollution

The preparation, transport and handling of loam on site requires only ca. 1% of the energy needed for the production, transport and handling of baked bricks or reinforced concrete. Loam, then, produces virtually no environmental pollution.

4 Loam is always reusable

Unbaked loam can be recycled an indefinite number of times over an extremely long period. Old dry loam can be reused after soaking in water, so loam never becomes a waste material that harms the environment.

5 Loam saves material and transportation costs

Clayey soil is often found on site, so that the soil excavated for foundations can then be used for earth construction. If the soil contains too little clay, then clayey soil must be added, whereas if too much clay is present, sand is added. The use of excavated soil means greatly reduced costs in comparison with other building materials. Even if this soil is transported from other construction sites, it is usually much cheaper than industrial building materials.

6 Loam is ideal for do-it-yourself construction

Provided the building process is supervised by an experienced individual, earth construction techniques can usually be executed by non-professionals. Since the processes involved are labour-intensive and require only inexpensive tools and machines, they are ideal for do-it-yourself building.

7 Loam preserves timber and other organic materials

Owing to its low equilibrium moisture content of 0.4% to 6% by weight and its high capillarity, loam conserves the timber elements that remain in contact with it by keeping them dry. Normally, fungi or insects will not damage such wood, since insects need a minimum of 14% to 18% humidity to maintain life, and fungi more than 20% (Volz, 2004, p.

60). Similarly, loam can preserve small quantities of straw that are mixed into it. However, if lightweight straw loam with a density of less than 500 to 600 kg/m3 is used, then the loam may lose its preservative capacity due to the high capillarity of the straw when used in such high proportions. In such cases, the straw may rot when remaining wet over long periods (see 10.3, p. 86).

8 Loam absorbs pollutants

It is often maintained that earth walls help to clean polluted indoor air, but this has yet to be proven scientifically. It is a fact that earth walls can absorb pollutants dissolved in water. For instance, a demonstration plant exists in Ruhleben, Berlin, which uses clayey soil to remove phosphates from 600 m3 of sewage daily. The phosphates are bound by the clay minerals and extracted from the sewage. The advantage of this procedure is that since no foreign substances remain in the water, the phosphates are converted into calcium phosphate for reuse as a fertiliser.

In moderate to cold climates, people usually spend about 90% of their time in enclosed spaces, so indoor climate is a crucial factor in well-being. Comfort depends upon the temperature, movement, humidity, radiation to and from surrounding objects, and pollution content of the air contained in a given room. Although occupants immediately become aware when room temperatures are too high or too low, the negative impacts of excessively elevated or reduced humidity levels are not common knowledge. Air humidity in contained spaces has a significant impact on the health of inhabitants, and earth has the ability to balance indoor humidity like no other building material. This fact, only recently investigated, is described in detail later in this section.

Research performed by Grandjean (1973) and Beckert (1986) has shown that a relative humidity of less than 40% over a long period may dry out the mucous membrane, which

can decrease resistance to colds and related diseases. This is so because normally the mucous membrane of the epithelial tissue within the trachea absorbs dust, bacteria, viruses etc. and returns them to the mouth by the wavelike movement of the epithelial hair. If this absorption and transportation system is disturbed by drying, then foreign bodies can reach the lungs and may cause health problems (1.16). A high relative humidity of up to 70% has many positive consequences: it reduces the fine dust content of the air, activates the protection mechanisms of the skin against microbes, reduces the life of many bacteria and viruses, and reduces odour and static charge on the surfaces of objects in the room.

A relative humidity of more than 70% is normally experienced as unpleasant, probably because of the reduction of oxygen intake by the blood in warm-humid conditions. Increasing rheumatic pains are observed in cold humid air. Fungus formation increases significantly in closed rooms when the humidity rises above 70% or 80%. Fungus spores in large quantities can lead to various kinds of pain and allergies. From these considerations, it follows that the humidity content in a room should be a minimum of 40%, but not more than 70%.

In moderate and cold climates, when the outside temperatures are much lower than inside temperatures, the greater degree of fresh air exchange may make indoor air so dry that negative health effects can result. For example, if outside air with a temperature of 0°C and 60% relative humidity enters a room and is heated to 20°C, its relative humidity decreases to less than 20%. Even if the outside air (temperature 0°C) had 100% humidity level and was warmed up to 20°C, its relative humidity would still drop to less than 30%. In both cases, it becomes necessary to raise the humidity as soon as possible in order to attain healthy and comfortable conditions. This can be done by regulating the humidity that is released by walls, ceilings, floors and furniture (1.17).

Porous materials have the capacity to absorb humidity from the ambient air and to desorb humidity into the air, thereby achieving humidity balance in indoor climates. The equilibrium moisture content depends on the temperature and humidity of the ambient air (see 2.29, p. 28). The effectiveness of this balancing process also depends upon the speed of the absorption or desorption.

Vineyard residence

Mornington Peninsula, Victoria, Australia

Architect: John Wardle Architects, Melbourne, Australia

Completion: 2002

Wall system: Rammed earth Floor area: 400 m²

The predominant elements of this residence, which is situated in a large vineyard, are the rammed earth walls. The living area extends out to the north veranda, the kitchen to an informal terrace area. The study opens up to the garden.

The principal bedroom, with its walls angling outward, evokes the impression of continuing into the landscape. The entrance screen reduces western sun into the living area. Cross ventilation is achieved throughout all areas.

Architect: Alfredo Navarro Tiznado

Design team: Kenia Esmeralda García Rosas, Hanna Appel Hernández, Giancarlo Reyes Olguin

Completion: 2021

Wall system: Rammed earth walls

Floor area: 310 m²

Casa Martha, the retirement home for an archaeologist couple, Martha and Bill, is located between the municipalities of Ensenada and Rosarito, in the urban area of La Misión. The plot has a size of 15 × 40 metres, on a terrain of rugged topography oriented towards the Pacific Ocean.

The house comprises four levels in a terraced arrangement. The ground floor is the access level. The first floor is divided into two areas: a visitor’s area with two rooms and a study space that doubles as a painting and carpentry workshop or as a garage. There are also two small interior gardens. The second floor accommodates the core of the house – the entertainment room, dining room, and kitchen – with large windows and porches. Woven salt pine shutters provide protection from the prevailing winds while maintaining the privacy of the interior. They also create a play of light and shadow on the interior walls. At the back of the social area, a staircase leads to the third floor, where the master bedroom is located. This uppermost level has panoramic views onto the desert landscape.

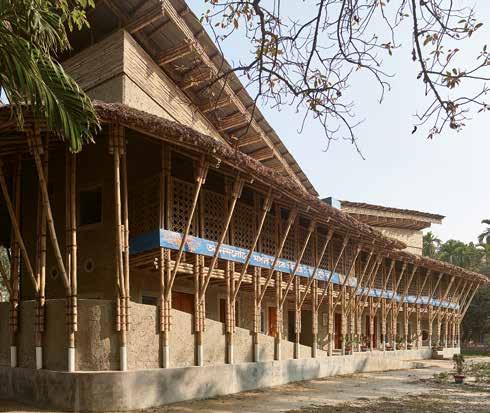

Concept and design: Anna Heringer

Project management: Stefano Mori

Consultants: Martin Rauch (earth), Andreas Guetling (roof construction), Emmanuel Heringer (bamboo roof)

Contractor: Montu Ram Shaw

Completion: 2020

Wall system: Cob

Floor area: 174 m² (rooms), 180 m² (ramp and veranda)

The two-storey-building accommodates a centre for people with disabilities combined with a small studio for the production of textiles, allowing women to find work in their village. It is called “Anandaloy” which can be translated as “place of profound joy”. The name strikes a positive note in a culture that traditionally shuns people with disabilities as punished by God. A large ramp leads to the first floor in order to be accessible for wheel chairs. The foundation was made of burnt bricks while the walls consist of locally sourced rammed earth using the cob technique that needs no formwork. Cob is an ancient building technology that is both simple and sturdy. Clay subsoil, sand, straw and water are mixed together to make a malleable mud that is then formed into monolithic walls. When the cob dries it becomes hard which results in very durable walls and columns. The columns, ceilings and the roof construction are bamboo. The ventilated roof has a lower layer of straw and is covered by metal sheeting. A special feature inside the building are the “caves”, spaces for self-learning and relaxing formed by hand from clayey soil lumps (also built in cob technique). Because the Anandaloy project mainly uses earth available nearby and bamboo from local farmers, the biggest part of the budget was invested in local crafts(wo)men. Thus, the building became a real catalyst for local development. Because of its sustainable and holistic concept, the centre received the Obel Award 2020.

Built examples

Aiguá, Uruguay

Design and supervision dome: Gernot Minke, Kassel, Germany

Organisation and supervision: Macarena Albarracin, Santiago Escarrá, Salta, Argentina

Completion: 2020

Vault system: Adobe masonry without formwork

Floor area: 38.5 m²

At a farm on the outskirts of the small town of Aiguá, a dome was built from adobe, designed for relaxation, meditation and music-making for up to 50 people. Due to its special acoustics, the building also serves as a recording studio for experimental music. The inner diameter of the dome is 7 m, the clear height in the middle is 5.40 m. The foundation and plinth as well as the circular entrance are made of locally available natural stones. The entrance has a diameter of 1.60 m, so the room has to be entered in a stooped position and its height is only experienced once inside. The floor slopes 20 cm towards the centre, so that no horizontal level is perceptible. This creates a special spatial impression, resulting in a sense of security and well-being. The top has an opening which is covered by an octagonal, pyramidical skylight, exuding a sense of being in touch with the cosmos.

The dome was built during a two-week workshop directed by the author with the assis-

tance of Macarena Albarracin and Santiago Escarrá. It was built up utilising the “acoustic adobes” developed by the author. These have rounded edges to diffuse the sound reflection and are walled up at an angle of approximately 20° to the outside to reflect part of the sound upwards, thus reducing the focusing of the reflected sound towards the centre of the room. In addition, the joints have been recessed to improve sound absorption. In order to achieve the statically optimal cross-section of the dome, the rotational guide developed by the “Research Laboratory for Experimental Building” at the University of Kassel was used, which defines the correct position for each adobe. On the

outside, the dome was first covered with a two-layer earth plaster and then sealed with a fleece-reinforced acrylic paint to make it weatherproof. The last layer of the transparent paint was mixed with sand and clay powder to achieve a clay-like appearance and to provide additional protection against ultraviolet radiation.

The floor is made of rammed earth, its surface is divided into eight fields and a central octagon by wooden strips. The top layer of the floor consists of an approximately 2-cmthick earth render, which has been stabilised with some lime and cement.

Architect: Kéré Architecture, Jaime Herraiz

Completion: 2020

Wall system: Cement-stabilised rammed earth

Floor area: 1000 m²

The Burkina Institute of Technology is based on a system of repeated modules, housing classrooms and auxiliary functions, arranged orthogonally to define a rectangular courtyard. The orthogonal layout of modules allows the campus to be expanded incrementally according to its needs. The modules are staggered, allowing air to flow through the central void, creating a cool space where students can relax and interact.

The walls are made of cement-stabilised local lateritic clayey soil poured into the onestorey-high formwork and then rammed by a special vibrator. Due to the special mixture, which contains a high content of large particles, it was sufficient to use for stabilisation only 4.5% of cement by mass, which corresponds by volume to 100 kg per m³. The basic mixture contains per volume 57% of soil, 29% of crushed granite 05/15 and 14% of coarse sand. The formwork was removed after 4 weeks.

The roof profiles, repeated regularly, create a dynamic rhythm and form a chimney at the back of each module where warm air can be released. Suspended ceilings, made of local eucalyptus wood, brighten the interior spaces.

During the rainy season, water is channeled into a large underground tank and stored there. It is later used to irrigate the extensive mango plantations on the campus.

Office pavilion Earthbox

Asunción, Paraguay

Architects: Equipo de Arquitectura (Horacio Cherniavsky and Viviana Pozzoli)

Structural engineer: Emilio Richer

Rammed earth consultant: Yago GarcíaEnríquez

Completion: 2018

Wall system: Rammed earth walls

Floor area: 45 m²

This pavilion was built by Equipo de Arquitectura for themselves. A single continuous wall wraps around a basic square plan. It opens up to create the entrance to the office and bends around a little restroom next to it. A pre-existing guavirà tree was integrated into the design, rises from the patio, and creates a division between working spaces and kitchen. Outside, a flame tree screens the earthbox from the sun.

The 30-cm rammed earth walls hold the weight of the roof, resting on only 20 cm of their width and thus exploiting the structural qualities of this material. The remaining 10 cm on the perimeter hide the ceiling slab when seen from the outside.

All of the furniture and doors are made of recycled wooden formwork that was used to cast the concrete slab that covers the office. The library shelves are detached from the walls and suspended.

Earth, in common use for architectural construction for thousands of years, has in recent years attracted new attention as a healthy, environment-friendly and economical building material. An impressive number of buildings has been realized not just in hot and dry regions but also in the colder climates of Europe and North America. Technical innovations such as prefabricated rammed earth components, clay panels or earth walls from a 3D printer facilitate the use of this sustainable material.

This manual, now in its fifth and revised editon, describes the building technology of rammed earth. The physical properties and characteristic values are explained in a hands-on manner: With proper moisture protection, earth buildings are very durable, and in particular the combination with wood or straw allows a wide spectrum of design options. Thirty international built examples demonstrate the range of applications for this fully recyclable material.

ISBN 978-3-0356-2766-4