Safeguarding a Smooth Ride

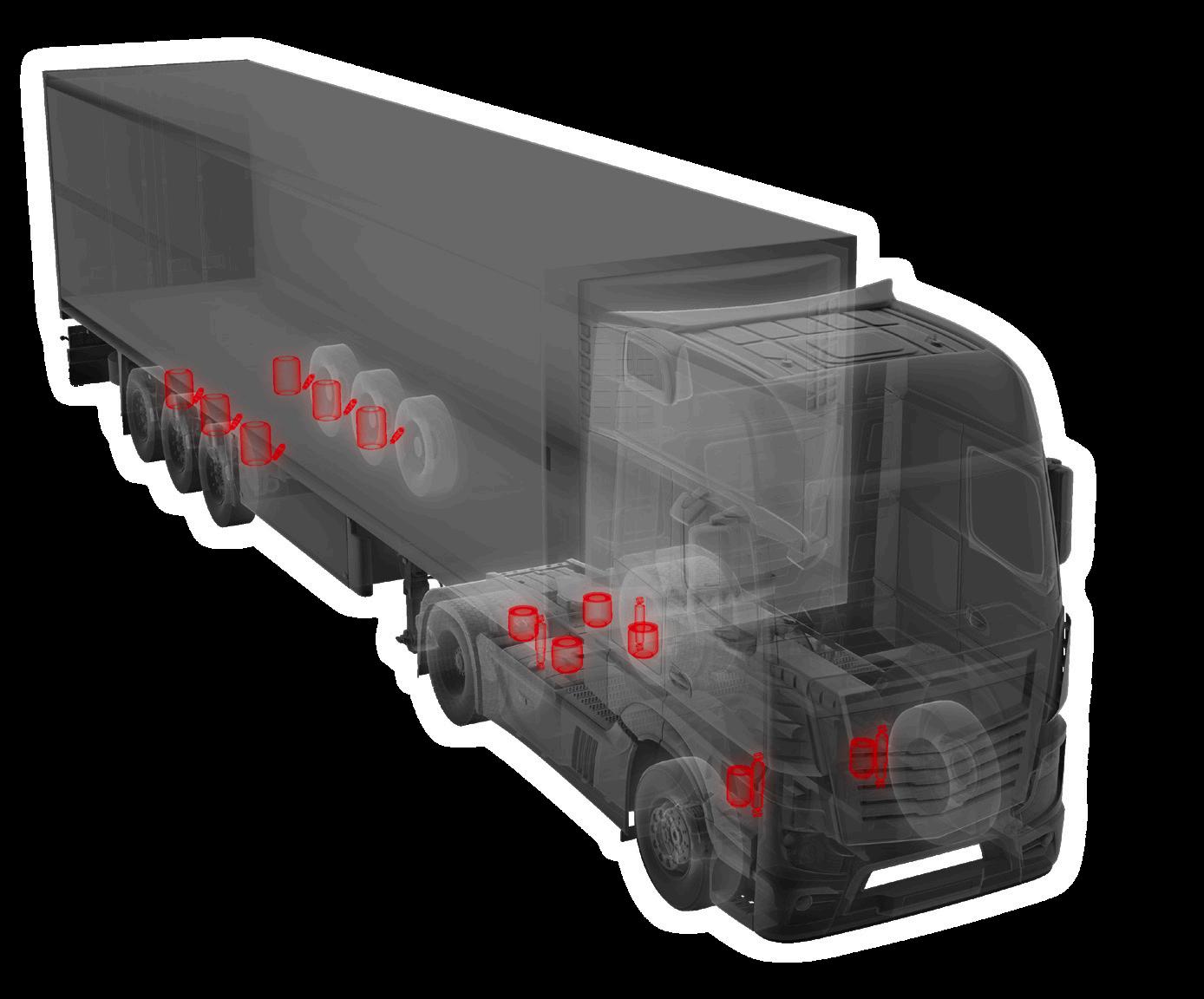

febi Air Springs and Shock Absorbers

Without suspension, driving would be extremely uncomfortable and unsafe. The constant connection between the vehicle and the road is necessary to transfer the forces of braking and acceleration, as well as the wheel forces in curves.

Air springs and shock absorbers are the main components of chassis suspension. The spring carries the weight of the vehicle and allows the axle to move up and down to compensate for uneven roads and potholes.

Air Springs for Different Loads and Heights

Air springs offer the decisive benefit of being adaptable to the vehicle‘s current load condition with a variably adjustable air pressure. This increases comfort and driving stability and ensures that the load is treated lightly. Additionally, the adjustable frame height makes it easier to approach ramps of different heights and simplifies handling when changing trailers and swapping bodies.

Keeping Swinging Under Control

Since springs can swing, shock absorbers are needed. They dampen this swinging and maintain the tyres’ contact to the road.

The effect of worn and defective shock absorbers is that the driving behaviour of the vehicle deteriorates. The braking distance also increases due to poorer road contact of the wheels.

Range

» Extensive range with more than 750 components

Quality

» Material selection and quality testing in accordance with OE specifications

Reliability

» We offer a 3-year manufacturer guarantee and our products are available in 170 countries worldwide

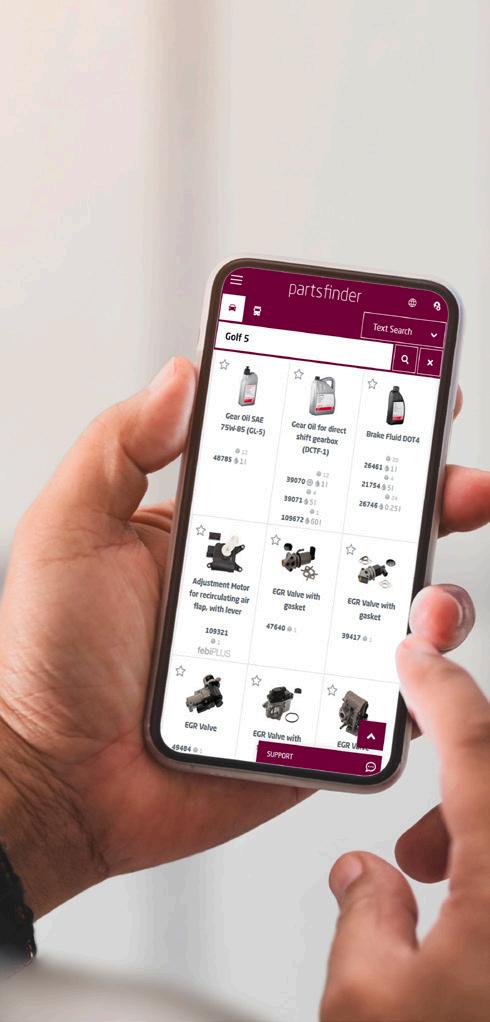

Offering You More

febi Truck‘s range of products is even wider: In addition to air springs and shock absorbers, we also offer cabin shock absorbers and cabin air springs. You can find all important information about these products at: www.febi.com/en/truck/chassis-cabin/

Perfectly in Touch

Advantages of febi Air Springs

Air springs are exposed to environmental conditions such as UV radiation, high and low temperatures, chemical substances, and mechanical stress – e.g. from dirt. Over time, the rubber hardens and small cracks form. If the air springs are not replaced in time, they can, in the worstcase scenario, burst.

Due to the appropriate selection of the rubber compound and optimal arrangement of the 2 to 3 reinforcing fabric layers, premature failure is avoided. Steam vulcanization ensures an optimal bonding of the different reinforcement layers with the rubber. The state-of-the-art production which is in accordance with TS 16949 leads to a durable and dimensionally stable product. Regular lifetime tests up to 3 million load cycles serve as proof of consistent quality and a long service life is granted.

A Special Construction

Due to their special design, convoluted air springs are used in areas with limited installation space, for example for lifting and lowering lift axles. For the suspension of the axles, normal air springs are mainly used. There are also single convoluted and triple convoluted versions for special applications.

We offer over 375 air springs of all standard types for trucks, buses, and trailers including 18 convoluted air springs.

» Durable and dimensionally stable

» State of the art steam vulcanization

» Consistent quality guaranteed

» Regular lifetime tests to ensure a long service life

» No.1 in the Aftermarket for air springs

Variety of Air Spring Types

There are many different variants of air springs depending on the vehicle type and manufacturer. Sometimes the air springs come without accessories, sometimes with a plate, and sometimes with the piston and the plate. The designs are fundamentally different and adapted to the respective vehicle type with its specific mounting positions.

Selected Product Highlights

45759

To fit: Scania Series F, K, N, Series P, G, R, T Repl. no.: 1 903 608, 6700 N P02

To fit: BPW Repl. no.: 05.429.43.51.0, 881 MB P30

To fit: Evobus Citaro, Travego, Tourismo, Touro Repl. no.: 000 327 01 01, 644N

To fit: Volvo Trucks FH4, FH12, FH16, FH, FM4, FM7, FM9, FM12, FM Repl. no.: 21961456, 6608 N P01

To fit: MAN TGA, TGM, TGS, TGX Repl. no.: 81.43601.0151, 4882 N1 P01

To fit: Mercedes-Benz Trucks Repl. no.: 946 328 16 01, FD 200-19 1/4 M8

Produced to Perfection

Manufacturing of febi Air Springs

Material

Air springs are built using different materials:

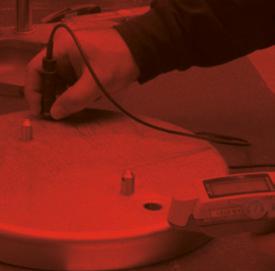

1. Rubber: a special mixture fulfilling the highest demands. Using the tensile test, the maximum force is tested to see when the rubber breaks. This ensures that only raw materials with the defined properties are used for production.

2. Cord fabric: used as a reinforcing element. Its woven structure gives the rubber the strength and durability against pressure and other forces.

Two complete layers of reinforcing fabric and additional reinforcement strips in certain, highly-stressed areas ensure high stability.

3. Plastic or metal components: In addition to the metal components with anti-corrosion coating, glass fibre reinforced plastics are also used for some pistons. They are not only very stable, but also very light compared to metal pistons and corrosion is not an issue.

Only high-quality materials are used for air spring production. Constant testing of the outer and inner dimensions, material hardness and specification, as well as the coating thickness must be in accordance with defined OE standards.

1 2 4

Production

To create an optimal wrapping of the air springs and thus a product of the highest quality, the material must be cut exactly to size.

Manual wrapping ensures the ideal arrangement of the rubber layers for a reliable and resilient product. Only highly experienced employees are allowed to carry out this essential work step, as it requires a great deal of skill and practice despite laser markings for the glued joints. As soon as the layers are rolled, the steam vulcanisation process starts.

Final Inspection

Air springs with a piston and cover are tested for leaks in a water bath. Regular service life tests with up to 3 million load cycles ensure for durability. Burst tests are used to check the materials and manufacturing quality. Every air spring is provided with a vulcanised sticker to ensure traceability.

As the final step in the production process, the febi sticker is applied, which contains the febi number as well as data on the permissible pressures and temperatures. The entire production process of febi air springs is carried out in accordance with the TS 16949 standard.

The febi logo and febi number can be found on the febi air springs rubber. An additional sticker with warning notices and the safe operating range of the air spring can be found on versions with plate. 3

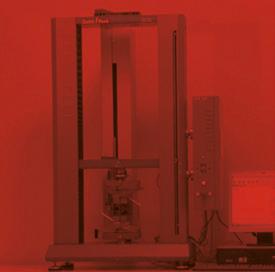

Steam Vulcanisation

There are different production methods in the air spring industry: vulcanization with an electric heating mould or steam vulcanization - or a combination of both. While the electric heating mould is only “cooking” the air spring, the steam vulcanization is curing the material. This leads to better vulcanisation and bonding of the different layers and a consistent hardness of the complete rubber. It also reliably prevents individual layers from peeling away.

febi air springs are produced using steam vulcanisation via a partner production with decades of experience with this method.

Precision & Stability

Advantages of febi Shock Absorbers

Shock absorbers are safety-relevant parts intended to guarantee driving stability and comfort in equal measure. Thanks to the special shock absorber oil, precise damping performance and a high level of driving stability over a wide temperature range even under extreme conditions is granted. The production is in accordance with the TS 16949 standard and the use of high grade production materials, like high temperature resistant seals, as well as salt spray tests and durability tests of more than 1 million cycles, ensures for long-term durability.

febi collaborates exclusively with certified suppliers. This way OE matching quality can be ensured across the entire product range.

We have considerably extended our range of hydraulic shock absorbers and, with more than 375 products, febi offers one of the most comprehensive ranges in the Independent Aftermarket.

» Constant damping over a wide temperature range even under extreme conditions due to the extremely temperature-stable shock absorber oil

» Long service life due to high temperature resistant seals

» The use of high-grade production materials and durability tests ensures longevity

» febi shock absorbers are of OE quality and are produced according to the TS 16949 standard

febi Shock Absorbers for Every Need

All febi shock absorbers are oil filled gas shock absorbers. Shock absorbers differ in external dimensions, minimum and maximum length, specific damping characteristics, and mounting types. There are mounting eyes or pins corresponding to the vehicle-specific mounting points. The piston rod is effectively protected by a durable metal protective cover.

Selected Product Highlights

Shock Absorber

Tasks of Chassis Shock Absorbers:

» Driving comfort & brake performance

» Dampen swings

» Prevent build up

» Prevent after-swinging

» Ensure wheels stay in contact with the ground

To fit: Schmitz Cargobull Repl. no.: 016 508

To fit: Mercedes-Benz Actros I+II+III, Arocs, Atego I+II, Axor I+II Repl. no.: 000 320 15 30

To fit: MAN HOC, Lion´s City, Lion´s Classic, Lion´s Coach, Lion´s Regio, Lion´s Star, NL, R, SG, SL, SÜ, ÜL Repl. no.: 81.43701.6924

To fit: Renault Trucks Kerax, Premium Repl. no.: 1629405

To fit: IVECO Euromover, Eurostar, Eurotech, Stralis Repl. no.: 0 4121 4818

To fit: Scania Series 4 Repl. no.: 1 861 117

febi 20338 febi 20366 febi 20444 febi 20293 febi 20387 febi 20353The Shock Absorber

in Detail

Shock absorber oil

Piston rod and seal

The smooth surface of the chrome-plated piston rod in conjunction with the special seal guarantees efficient sealing, and therefore a longer service life. The seal ensures reliable sealing even under demanding operating conditions and high temperatures.

Rubber bushings and protective cap

The rubber bushings consist of optimal rubber to meet the required hardness. The protective cap is made of steel and are extremely durable to protect the piston rod reliably.

Shock absorber tubes and piston and base valves

The shock absorber tube is very sturdy, so the shock absorber does not deform even under extreme loads. The piston and base valve are made of durable, sintered material which guarantees precise damping characteristics and therefore a high level of driving safety for a long time.

febi shock absorbers are always equipped with special shock absorber oil with the needed properties. Additives improve the viscosity index of hot and cold oil, lower the pour point and reduce wear. Special polar additives modify the coefficient of friction between moving parts and ensure a low foaming tendency, low air release, zero aggressivity towards copper, high temperature stability and rubber compatibility.

Force Displacement Curve

Each shock absorber has a certain Force Displacement Characteristic to meet the certain demands of each vehicle in regards of weight and damping force. In the graph the push-in force of the piston rod F (N) is shown in comparison to the push-in speed V (m/s). febi shock absorbers always have the right characteristic to ensure a good connection to the road and thus a safe and comfortable ride.