Muilte Contae Andun Mills 232 of County Down

02–23

24–45

46–49

50–59

60–67 68–73

74–83

84– 91 92–105

Gilford

Banbridge

Loughbrickland

Newry

Blackskull

Waringstown

Dromore

Hillsborough

Lisburn

Rural Linen Towns

Anahilt

Dromara

Katesbridge

Milltown

Rathfriland

Mayobridge

Hilltown

Kilcoo

Rostrevor

Kilkeel

Downpatrick

Crossgar

Ballynahinch

Saintfield

Carryduff

Ballygowan

Comber

Newtownards

Dundonald

Bangor

Millisle

Kircubbin

To those who worked in the 232 Mills of County Down.

Dóibh siúd a bhí ag obair sa 232 Muilte Contae Andun.232 Mills of County Down showcases the various different mills involved in the linen industry in County Down. Thomas Ferguson in Banbridge is the last remaining linen mill out of the 232.

Documenting and paying homage to the industry in which so many people dedicated their lives to. Delving into the various different mills of bleaching, spinning, weaving, beetling and cultivating flax as a crop.

Through archival records, personal accounts, and historical anecdotes, interviews and photographs this book paints a vivid picture of the industry’s significance in shaping the region’s economy and culture. Each chapter sheds light on the various towns and cities involved in the processing of linen. This book is dedicated to preserving local heritage and ensuring that the mills of County Down are remembered.

Flax Mill — Herbert J Martin (Henry Uprichard)

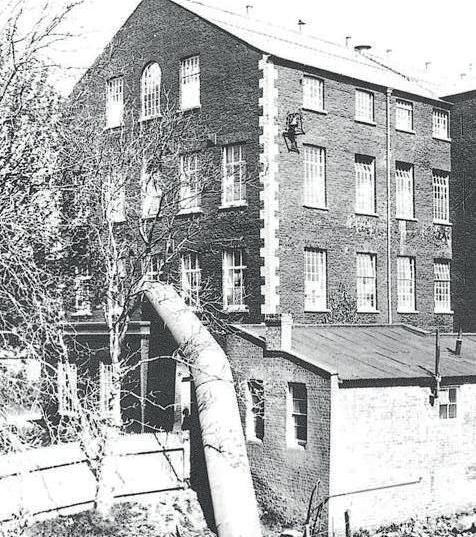

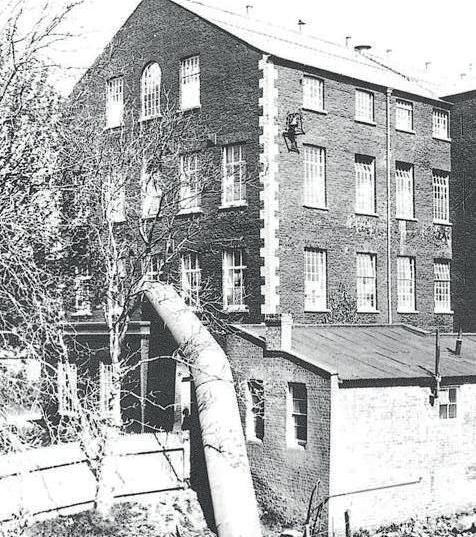

Spinning Mill — Dunbar McMaster & Co

Weaving Factory — Cochranes Row, Dunbar McMaster & Co

Bleach Mill — Banford Bleach Works Company

Bleach Mill — Thornhill Bleach Mill

Bleach Mill — William Foster Uprichard Bleach Works

Bleach Mill — Messrs William Smyth and Co Ltd

Bleach, Spinning and Weaving Mill — Hazelbank Weaving Co

Beetling Mill — Haughton

Flax Mill — Herbert J Martin (Henry Uprichard)

Spinning Mill — Dunbar McMaster & Co

Weaving Factory — Cochranes Row, Dunbar McMaster & Co

Bleach Mill — Banford Bleach Works Company

Bleach Mill — Thornhill Bleach Mill

Bleach Mill — William Foster Uprichard Bleach Works

Bleach Mill — Messrs William Smyth and Co Ltd

Bleach, Spinning and Weaving Mill — Hazelbank Weaving Co

Beetling Mill — Haughton

The town of Gilford dates from about the middle of the 17th century when the Magill family, after whom it was called, acquired the land. The Magills were of Scottish origin. Early maps show the village of Gilford confined to what is now the Main Street. It had a tuck mill and a corn mill located in the vicinity of the present Presbyterian Church Hall. Houses were built around the crossing place or ford and on Castle Hill which was the main road leading from Lurgan to cross the river and proceed to Loughbrickland. In 1691, Sir John Magill (Johnston) grandson of Captain Magill granted by lease, for ever, to Thomas Purdy the tuck mill and corn mill of Gilford, with a large part of the present town and all that ground on which the present spinning mill now stands. Thus begins the 1st recorded history of milling in Gilford.

Having purchased these premises, the Purdys set about the processing of linen and by the end of the first quarter of the 18th century had extended their interests in the area. The will of Thomas Purdy, dated 21st August, 1728 states that he left the mills and lands to his sons, James and John after the interest of his widow ended. He further left to his son, James, the bleaching yard or green. The document also states that prior to 1691, the mills had been leased to a Hugh Ridley "Clothier" and John Thompson "Glover."

Up until the last quarter of the 18th century the Purdy family retained their interests in the linen industry. Imports and exports were facilitated by the vast enterprise, for those times, of cutting the Newry Canal which was opened in 1737 and finally completed to Lough Neagh in 1741 at an estimated cost of £896,000. It is roughly one and a half miles from Gilford to the Canal at Madden near Tandragee.

From 1775, however, the Purdy family began to dispose of their property in Gilford, mills included, and transfer their commercial interests to Newry. By a series of assignments up to 1792, the corn mill, tuck mill and lands became the property of a leading linen merchant – George Law. Being in the linen trade and with his family connections in the industry, he gave Gilford the stimulus that was to attract the attention of other enterprising entrepreneurs, who came into the district, purchased existing mills, developed machinery and increased output. Money was to be made in abundance and those engaged in the industry became very wealthy. In addition to the trade facilities afforded by the Newry Canal which served as the principal means of goods transport, there were the properties of the Bann water which were excellent for the whitening of the linen and, of course, the easily accessible water power.

During his years in Gilford, George Law extended his business interests by building a new beetling mill to the south of the present Gilford Castle. He also erected a new weir and widened the mill race to generate more power and thus increase production. When he died in 1802, his property became the subject of a law suit in Chancery between members of the Law family. Eventually the property was purchased by his nephew, Hugh. With the increased industrial development, there was the ever increasing need for labour and accommodation of a sort.

Sir James Johnston granted 46 leases for the building of houses on Castle Hill between 1807 and 1811. It is interesting to note that in each case there is a covenant that the or his assigns should within one year, "erect on the said granted premises one dwelling house, 40 feet in front and well dash, rough cast and whiten the same every two years and put sash windows in the said dwelling house." Unfortunately nothing now remains of this early development.

In 1835–1836 there opened a new era in the industrial history of the locality. About 1834, Hugh Dunbar, late of Huntly Glen, near Banbridge, where he carried on a linen thread and brown linen manufacturing business, conceived the idea of erecting flax spinning mills and linen thread manufacturing on a large scale in Gilford. To do so he obtained free farm grants from Hugh Law of the Corn Mill; from James Uprichard of lands at Banvale to construct a tail race and from WM McCreight lands on the opposite side of the river to the proposed mill. The original partnership was formed by Hugh Dunbar and WA Stewart of Edenderry, Banbridge and business commenced on 4th February, 1836, in premises in Mill Street. The dyeing houses were located at the rear of the present library. Having obtained the necessary lands and water rights, building of the large mill complex commenced in 1837. In 1837 Stewart died and Robert Thompson entered into a partnership with Dunbar to form Dunbar Dickson & Co. Thompson died in 1839, and having bought out his share, Dunbar now formed a partnership with John Walsh McMaster from Armagh. In the same year, James Dickson, elder son of Andrew Dickson of Glenconway, Co. Antrim, together with John McMaster became partners with Hugh Dunbar in his several trades of flax spinning and thread and linen manufacturing. The firm began to trade under Dunbar McMaster and Co. for flax spinning and linen thread and Dunbar Dickson and Co. for brown linen. Dunbar himself became the exclusive owner of the lands, mill buildings, workers' houses

At the beginning of this partnership, the mills at Gilford were substantial enough to permit the commencement of the business but for some time longer until 1843, part of the business, that of the manufacture of brown linen continued to be carried out at the Huntly Glen, Banbridge.

Completion of the Spinning Mills at Gilford took place in November 1841, and an extract from the Northern Whig of November 22, 1924, recalls the occasion, "19th November, 1841 was a great day in Gilford when one of the most splendid soirées ever held in this part of the country took place at the Works of Messrs. Dunbar, McMaster & Co. in the reading room and library belonging to the establishment. The proprietors, it seems, have just finished a large building for the manufacture of thread and this was appropriately fitted out and beautifully ornamented for the occasion. Upwards of 800 sat down to tea which was arranged in fine style under the able management of Mr. James Beck and company with a well selected committee.

After the company regaled themselves with a plentiful supply of good things of this life, dancing commenced and was kept up to a late hour. At occasional intervals lemonade was served with cakes and fruit. Several of the operators enlivened the company with song. A great many ladies and gentlemen from the surrounding neighbourhood and also from Belfast were present and seemed highly gratified with the proceedings of the evening. Mr. and the Misses Dunbar likewise honoured the soiree with their presence and appeared highly delighted especially Mr. Dunbar who, at all times, takes great interest in the welfare of his workers and spares no expense in making them comfortable. He has erected a hospital for the sick to the support of which he contributes very liberally. In fact, he has done everything which generosity and human feeling can suggest for the benefit of those employed at the Gilford works. Great credit is due to Mr. McMaster – one of his partners of the establishment. He used every exertion in his power to promote the comfort of the large assembly. The company retired at a reasonable hour, apparently highly delighted with the entertainment."

To accommodate the large number of workers encouraged to come to Gilford in search of employment mainly from Counties Monaghan, Fermanagh and Armagh, a huge house building project was begun. Altogether 180 houses were built in close proximity to the mill such were the numbers that came from the Keady district of Co. Armagh that Hill Street was known locally as "Keady Row." It was in this street that 2 houses were set aside and converted into a hospital for the sick of the town. From valuation field books many of these "two up, two down," type houses accommodated two families. It is not surprising that during the famine period, large numbers suffering from fever were accommodated in this well strategically erected hospital at the extreme north–east of the town. Though the records for the Banbridge Union Workhouse aren't complete it is known that a substantial number of people from the neighbouring townlands in the Lurgan Union died in the Lurgan Workhouse during the famine period. It was quite the task in supplying houses to accommodate the ever increasing population within the town of Gilford.

In a letter from an emigrant to his uncle, Mr. James Beck (mentioned in the report of the soiree), dated September 24th, 1848, from Dinsmore, Shilley Co. Cincinnati, he states:

"With great pleasure I received your letter dated 14th June, I received it the 10th July. It astonishes me to hear of the rapid improvement of Ireland; in my day there was no such factories as you are concerned in. And it also seems strange that Common work hands in that country get but £15 or £20 per annum and that Archabald and you get so large salaries.” It is certainly implied that the workers, despite the industrial advances, had poor wages, while management had comparable very much higher salaries.

In 1849, the following letter was circulated in the hope of establishing a market which would bring a degree of prosperity to Gilford and also attract business to the area.

Sir, A meeting of the Inhabitants of Gilford, will be held in the National School, on Saturday next, the 3rd of March, at the hour of 2 o'clock, for the purpose of adopting a requisition calling upon the Seneschal of said Manor, to convene a public meeting of the Inhabitants of Gilford and its vicinity to take into consideration the priority of having a weekly market established. Your attendance is particularly requested, Franklin McCreight Secretary, Gilford.

It astonishes me to hear of the rapid improvement of Ireland

Sewing Machine Gazette January 1881

Advertisement for Dunbar McMaster & Co

Coincided with the American Civil War between

Dunbar, Dickson & Co. were extremely valuable and goods stamped with the said trade marks commanded a much higher price.

During the 1840s the firm provided schools under the National Board of Education. Sites for the Roman Catholic and Presbyterian Churches were presented by individual members of the firm. In the case of the Church of Ireland, Mr. John McMaster was a large subscriber to the actual cost of the building and the parsonage on the Stramore Road was erected at his own expense. Mr. Hugh Dunbar himself did not confine his generous liberality to the provision of Churches and schools. He concerned himself with the temporal welfare of his workers. It is recorded that he was a man of extraordinary generosity. He had a list of 400 poor people whom he served weekly at his own house with financial assistance. Having died suddenly in 1847, while dispensing his alms, the piece of money he was about to give was still found in his hand after death.

In 1858, McMaster purchased the Misses Anne and Jane Dunbar's share for £20,662 and the lands, buildings, etc. for £25,000, the latter to be held by him as his property, the partnership paying him for the use; each partner was to have a separate interest in proportion to the sum bought in by him and at the end of eight years any surviving partner might by a year's notice dissolve the partnership and be paid the value of the shares.

The great linen boom took place during these years which, in fact coincided with the American Civil War (1861–65). Grade reached the highest peak. Sales in the year ending 31st March, 1866, amounted to over £1,000,000. McMaster and the Dickson Brothers became very wealthy men and it was during this period that the latter built Elmfield and Gilford Castles.

Built, literally over the River Bann, the water of which is famous for it’s bleaching power.

However disagreements took place and on 1st April, 1866, McMaster served notice on his partners that the partnership was dissolved from henceforth, the trade of "Dunbar, Dickson and Co" would be carried on by him in partnership with WM Spotten and James Douglas of New York under the style of "WM Spotten and Co. successor to Dunbar, Dickson & Co."

A famous law suit followed with the petition filed by Benjamin Dickson on 6th April, 1866, stating said business was carried on as well at the Gilford premises as also at certain warehouses and premises at Belfast, Dublin, London, Manchester, Glasgow and New York and by agents, travellers and correspondents in almost all parts of the world…that the goodwill and trademark and name, 'Dunbar, McMaster and Co.' and 'Dunbar, Dickson & Co.' were extremely valuable and that the goods stamped with the said trade marks commanded a much higher price in all markets than other goods of the same description. That stock in trade at the last half–yearly estimate was upwards of £500,000.

This petition came before the Lord Chancellor of Ireland 24th–28th May, 1866. It was decided that John Walsh McMaster was absolutely entitled to the goodwill and trademarks of the partnership. However, the next year the Court of Appeal overruled this decision on 28th June 1867. McMaster carried it to the House of Commons which finally reaffirmed the decision of the Lord Chancellor. Bonfires raged in Gilford at the verdict, giving testimony that the workers supported the claims of McMaster.

Gilford MillsMcMaster continued to live in Dunbarton House overlooking the Mill and died in 1872 at the age of 53. He left 12 children. His eldest son, Hugh Dunbar McMaster being named after the founder of the Mill. Six other sons were mostly engaged in the linen trade at home and abroad with the exception of one son who became a clergyman and ministered to his flock in England. McMaster is buried in Tullylish Old Churchyard. By his will, he left all his land, etc., to the eldest son, with Dunbarton, House (after life interest to his widow), and various other legacies.

In spite of difficult conditions, Hugh Dunbar McMaster carried on a very successful flax spinning and thread manufacturing business. Huge sums of money were used to improve the layout of the works, the erection of new buildings and the installation of plant and machinery. A large reservoir near the works was erected for fire extinguishing and was connected with hydrants and hose in every part of the mills, so that a conflagration that occurred in 1869 when £40,000 worth of property was destroyed, was not likely to happen again. Towards the end of the century, the Gilford mill complex was reckoned to be unsurpassed in the whole of the British Isles in the completeness of its resources for all the processes of the industry.

The economic success story of this industry in Gilford was such that it was necessary and commercially profitable to open a mill in Greenwich, New York, in 1880. It was managed by Mr. John McMaster and was called Dunbarton Mills. Workers emigrated from Gilford to man the mill and an examination of the population figures for the period will reveal that the town showed a decrease of approximately 50%. This can be attributed, in part to the attraction of the new mill in America. A Grocer's advertisement of the time indicates that he has undertaken an emigration agency. No doubt to meet the demands of those who decided to leave and find "better conditions" elsewhere. It is interesting to read that in "Industries of Ireland" Published 1891, when referring to Gilford Mill it states, "To all these advantages, as regards water for bleaching and dyeing and motive power, must be added cheapness of "labour. . ." No wonder there was a steady demand for work elsewhere.

In 1886, the firm became a limited company and Mr. Hugh Dunbar McMaster conveyed the whole of his property, lands, mills, etc. under certain covenants. In 1901 he decided to join the great linen thread combine in which Barbours of Hilden were prominent. Up until his death in 1908, he took the place of his father in the industrial and social life of the area. He was survived by his wife, Florence, a daughter of Major General Saxton of England and it was to her homeland she returned after her husband's death.

A large lampstand was erected after his death to his memory. This stood in a prominent position in the Square, but with the development of the road and widening of the streets, it was removed only to be re–erected without its lanterns and now stands rather inconspicuously in the corner of the lawn in front of the library.

Gilford Mill has survived the passage of time and the depressing economic ills of the linen industry but its past glory will not be easily forgotten. The thread produced here was world famous and gained many eminent awards at international exhibitions at home and abroad including a prize medal for "great general excellence" at London 1862, 2 medal in Dublin 1865 for "superior quality," a medal for "superior excellence" at Philadelphia 1876 and a special gold medal at the Toronto Exhibition 1880. The "British Trade Journal" of 1890 states: "The success of the firm as manufacturers of yarn and thread must be attributed in no small degree to the exceptionally favourable position of their works. They are built, in part, literally over the River Bann, the water of which is famous for its bleaching power.

The extremely fine white and even yarn required in making lace which sells in London at fabulous prices is spun and bleached in this district and is largely produced by this firm. So well appreciated is the river that linen is sent long distances, even, from Belgium to be bleached on the banks of the Bann. The fine quality threads spun for certain lace and embroidery may be inferred from the fact that a length of thirty–six thousand yards weighed only one pound. Commercially, Messrs. Dunbar McMaster & Co. were known all over the world. The looms of Europe wove yarns spun in Gilford. Gilling twines were exported to the Adriatic and Mediterranean countries, twine for salmon–fishing to British Columbia, carpet threads, book binders' thread, extra strong threads for leather and thick cloths, and fine threads for the sewing machinist and lace–maker were exported to United States, South and Central America, Brazil, Australia and the rest of the British Colonies."

The loom’s of Europe wove yarns spun in Gilford.

Even as early in its history in 1849, on the occasion of Queen Victoria's visit at Belfast, "Dunbar McMaster & Co" and "Dunbar Dickson and Co." were chosen to exhibit for the Royal viewing. "The Northern Whig" Tuesday 14th, 1849, reports that "Dunbar, McMaster and Co." exhibited the following:

Specimens of foreign flax – Riga, Dutch, Flemish, French and Egyptian. Hackled flax both Irish and Foreign. Full series of tow, linen yarns and sewing thread."Dunbar, Dickson & Co." had the following on exhibition:

4 pieces 4–4 extra stout unbleached mill spun linen. 10 pieces 4–4 extra stout bleached linen for family use. 10 pieces 4–4 stout mill spun linen: 1 piece sheeting 117 inches wide. Brown damask linen made up for North and South America.

Today the firm still remains in business. It is now Dunbar, McMaster Ltd. No longer is it the thriving industry of former years. However, it has survived the recession in the linen trade and in doing so will be in an advantageous position to benefit if the industry should expand, as predicted. No longer does it echo to sounds of 1,500 workers as in its early days of existing but in the 1980’s the labour force of 150 produced flax yarn that was exported to Greece, Italy, Belgium etc. The remaining hope is that once again it may find its best quality flaxes used in the process being grown at home, instead of being imported from Courtrai in Belgium.

The remaining hope is that once again it may find its best quality flaxes used in the process being grown at home.

Once the largest industrial undertaking on the Upper Bann, production ceased at Dunbar McMaster’s mill in the 1980s and the site currently lies semi–derelict awaiting a new use.

The site currently lies semi–derelict awaiting a new use.

Gilford Mills

2024

he worked

I worked at the bonding perm. cleaner there

Flax Mill — Eliza Heron and Robert MClements Scutch mill

Flax Mill — Mary McAneeny Flax Mill and Store

Flax Mill — George Crawford

Weaving Factory — Banbridge Weaving Co Ltd Office

Weaving Factory — Thomas Ferguson Damask Factory

Weaving Factory — Banbridge Weaving Comapny Ltd

Weaving Factory — Robert McClelland weaving

Weaving Factory — Smyth Weaving Company Ltd

Beetling Mill — Anthony Cowdy and sons Beetling Mill

Beetling Mill — Robert McClelland beetling mill

Beetling Mill — Uprichard and Lindsay Beetling Mill

Beetling Mill — Frederick Robert and Samuel McCaw Beetling mill

Bleach and Beetling Mill — William Smyth and Co Ltd Beetling Mill

Flax Mill — Eliza Heron and Robert MClements Scutch mill

Flax Mill — Mary McAneeny Flax Mill and Store

Flax Mill — George Crawford

Weaving Factory — Banbridge Weaving Co Ltd Office

Weaving Factory — Thomas Ferguson Damask Factory

Weaving Factory — Banbridge Weaving Comapny Ltd

Weaving Factory — Robert McClelland weaving

Weaving Factory — Smyth Weaving Company Ltd

Beetling Mill — Anthony Cowdy and sons Beetling Mill

Beetling Mill — Robert McClelland beetling mill

Beetling Mill — Uprichard and Lindsay Beetling Mill

Beetling Mill — Frederick Robert and Samuel McCaw Beetling mill

Bleach and Beetling Mill — William Smyth and Co Ltd Beetling Mill

Bleach Mill — Edenderry, Mill Mount

Bleach Mill — The Banbridge Bleaching Co

Bleach and Spinning Mill — Frederick Hayes and Co

The Company bears the name of the founder, Thomas Ferguson (27th April 1820- 24th February 1900), who was born in Clare, near the village of Waringstown in Co. Down, where his father John farmed. At that time the locality was a centre of Irish Linen hand weaving and this activity was commonly combined with farming. His father died in 1831, and he was orphaned, when his mother died in 1836. It is believed that the Rev. John Johnston (1786-1862) of Tullylish Presbyterian Church, became the guardian of Thomas, and his brother John. Thomas Ferguson’s guardian saw to the completion of his schooling and then arranged for him to be apprenticed to Brice Smyth (17961851) of Brookfield, Banbridge. This remarkable man, even though he was blind from smallpox as a child, was a very skilful hand loom weaver of fine linens, and a noted teacher of his trade. It was said Brice Smyth was also able to examine the brown webs as they were brought into his warehouse by the weavers, and in doing so he could have formed an accurate judgment as to whether, or not, the cloth had been correctly woven.

His apprenticeship completed, Thomas Ferguson left Brookfield sometime around 1845 and set up on his own as a hand loom weaver in Banbridge. It is believed he started business in a house in Church Square, in the town. In 1854, by then firmly established, he acquired a lease for 999 years of the site on which the Company operated for 137 years. The factory on this site was known as Edenderry Works.

In 1854, by then firmly established, he acquired a lease for 999 years of the site on which the Company operated for 137 years.

There he continued with his hand weaving business, until in 1866 he formed a partnership with his two brothers-in-law, James and Benjamin Dickson. Following the formation of this Company, Dickson, Ferguson & Co, the partners decided to build a new factory. Work was started in 1867 on the site which Thomas Ferguson had earlier purchase the lease, and the factory was equipped with steam powered looms with Jacquard machines for damask weaving.

In 1883 the two Dickson brothers retired from the business. The Company with its present title was incorporated in 1884 with Thomas and his sons, Howard and Norman, being the first directors with another son, Thomas S. as secretary. In later years three grandsons of the founder entered the Company while two great-grandsons and one great–great–grandson were all actively involved in the business. To find out more about the history of linen in Banbridge and Thomas Ferguson.

In December 1988 Thomas Ferguson & Co. Ltd. joined the Franklins Group. This was formed by another textile Company based in Banbridge Franklins International Ltd. Franklins is the premier badge, label and embroidery specialist in the UK and Ireland and was founded in 1835, in Coventry.

Franklins International Ltd supplies to youth organisations, commercial companies, charities, military, security and emergency services and manufacturers at local, national and international levels within the sports, industrial, fashion, career wear and promotional markets. In 1999 Franklins Group acquired Brownlow Textiles Ltd; currently known as Brownlow Linens. Brownlow is now a brand of Thomas Ferguson Co. Ltd.

In November, 2012 the John England brand came under the same ownership as Thomas Ferguson. John England (Banbridge) Ltd. is a designer and wholesaler of apparel and interior fabrics, and carries a wide range of unique off-the-shelf linens.

In January, 2015 John England (Banbridge) Ltd. joined Franklins Group. Now as a sister company of Thomas Ferguson both companies are working very closely together. John England exclusively sells fabrics by the metre and adds a wide choice of unique stock fabrics for the fashion and apparel, curtain, upholstery, theatrical linens, film productions, etc. to the range. It also designs unique fabrics along with our customers; to meet their specific requirements.

4th December 2023

Growing up, we thought there was for Irish linen.

We are the double damask weavers in the world. very last

4th December 2023

Frederick William Hayes was born on 11th June, 1802, the third son of William Hayes of Millmount. William Hayes came as a young man to Banbridge, took over the old Reilly corn mill at Millmount, in the townland of Edenderry and started a bleachworks there.

In 1834, Frederick William Hayes acquired glebe land at the rear of Seapatrick Parish Church and built weaving sheds close to the River Bann. He also built Seapatrick House at that time, on the Banbridge side of his new weaving premises. Seapatrick House was built in the style of the great Linen Houses of the period, incorporating a gate lodge and driveway from Lurgan Road, with a lawn sweeping down to a riverside driveway fronted by pillared double gates at the bottom of Kiln Lane. His wife, Isabella Boyd, was the daughter of the owner of the Belfast Foundry, and they had four sons and one daughter at Seapatrick House.

In 1840, Frederick William Hayes ceased production of linen cloth and started linen yarn spinning and thread making in the premises. The weaving sheds were single storey and stone built with "Northlight" roofing. The "Northlight" roof was very popular at that time in the construction of factory premises. It consisted of a series of inverted V structures, which, when glazed on the short side, provided a maximum of natural light for the weaving operators below. In contrast, further buildings at Seapatrick Mills were in keeping with the traditional mill buildings of the period, strong, stone built edifices three or more storeys high. During those early years, Frederick William Hayes established a good manufacturing base for his products, which were given the name "Royal Irish Linen Threads". He died on 13th October, 1853, aged 51 years and was interned in Seapatrick Churchyard. His eldest son, William Hayes, succeeded him in running the mills.

William Hayes married his cousin, Martha Mary Law of Hazelbank House, Lawrencetown, in 1855 and took up residence in Seapatrick House. During his period of management with F.W. Hayes & Company, he successfully extended the premises. It was recorded at the time that the firm occupied 60 acres and employed 700 people. To meet the needs of an expanding workforce, William Hayes embarked on a programme of house building. Rows of workers' dwellings were built on the right-hand side of Kilpike Road, from the junction with Lurgan Road. He also built a short terrace of management houses fronting the Lurgan Road, opposite the churchyard. A corner shop was provided at this point, which was controlled by the company, to meet the needs of the workers and their families. The company also built a new schoolhouse of character design, in dark stone, opposite the entrance to the mills, for the education of the children of the employees.

Rows of workers’ dwellings were built on the right-hand side of Kilpike Road.

Trading warehouses were established in major English and Scottish cities during the period and a selling agency, H.B. Shaen & Company was arranged in New York. William Hayes had four sons and two daughters. He died on 12th July, 1876 and was interned in a new burial plot in Seapatrick Churchyard. Although still a minor, the eldest son, Frederick William Hayes II succeeded his father in running the firm. The management team was strengthened by the recruitment of Charles Hugh McCall as general mill manager. A few years later Samuel George Fenton, a Belfast man, joined the firm to assist with the overall running of the mills.

Trade fairs were held regularly in major cities during the latter years of the nineteenth century.

F.W. Hayes & Company won gold medals for the excellence of their linen threads at Dublin 1882, Cork 1883 and Belfast 1895. Before the days of aerial photography, the mill and factory owners employed professional artists to paint an "impression" of their manufacturing premises. These pictures were later colour printed on large advertising show cards, for distribution to trading warehouses and overseas agencies, as well as being used on printed packaging materials.

F.W. Hayes & Company won gold medals for the excellence of their linen threads at…

In the early years at Seapatrick Mills Irish flax was the standard raw material for the manufacture of linen yarns for thread making. This was readily available from scutching mills, through established flax markets held in the provincial towns. As the years of the 1800's progressed, foreign flax was steadily coming in. Russian flax, flax from the Baltic States and Belgian flax were becoming popular with the mill owners of Ulster. The flax grown around the Belgian town of Courtrai eventually became established as the superior flax for linen manufacture. But the spinning and thread making machinery changed little over the period. Machines used for preparing, spinning and twisting the linen yarns were highly engineered. Most of the machinery used for these operations was manufactured in the Province, the leading makers being, Jas. Reynolds & Co, Linfield Road, Jas. Mackie & Sons, Springfield Road, and Fairbairn, Lawson, Combe, Barbour, Limited, Albert Foundry, Belfast. These firms had developed on the success of the linen industry. The machinery used by F.W. Hayes & Company for the polishing, winding, copping, spooling, and balling of linen threads was usually purchased in the Manchester area, where a substantial cotton thread industry was being supplied. These machines could handle both linen and cotton threads.

Many manufacturing operations were being done by hand at Seapatrick Mills in the second half of the nineteenth century. The preparation of the flax fibre for later preparing and spinning operations being a good example. The natural flax was taken through a series of combing operations, called roughing and hackling. Rows of men in the flax lofts pulled "pieces" of flax through blocks of combing pins to entangle the fibre and remove the ancillary "tow" from the main fibre, called "line". After the turn of the century, large flax hackling machines were introduced at Seapatrick Mills to considerably improve the efficiency of these operations.

Further building of houses for the workers in the mills took place around 1890. An attractive red brick terrace of ten management houses (Milfort Terrace) was erected on Lurgan Road, opposite the entrance to Seapatrick Rectory. A red brick terrace of 14 workers' houses (Bannview Terrace) was built at the other end of the property, on the road to Lenaderg. Finally, eight semi-detached houses (Seapatrick Villas) were erected opposite St. Patrick's Chapel-of-ease (the "wee" Church). In 1895, Frederick William Hayes II with his wife Lily, left Seapatrick House and took up residence at "Clareen", Sydney Parade, Dublin. He died there on 2nd April, 1896, aged 37 years and was brought back to Seapatrick Churchyard for burial. The last member of the Hayes threadmaking family to reside in the Seapatrick district was John Law Hayes, a younger brother of Fredrick William Hayes II. John Law Hayes was not involved in managing the family firm, but lived, with church benevolence, at Seapatrick Rectory until he died, unmarried, on 7th March, 1934, aged 74 years.

As the years of the 1800’s progressed, foreign flax was steadily coming in.

The most profitable years for the firm were the years of the American Civil War, 1860–65.

Samuel George Fenton became the first managing director of the Private Limited Company of F.W. Hayes and moved into Seapatrick House with his wife, Lillie Jane. Their first daughter, Dorothy Caroline Fenton, was born there on 2nd October, 1896. A second daughter, Irene Lillie Fenton was also born there on 22nd June, 1899. He was to take F.W. Hayes & Co., Limited, into the amalgamation of thread manufacturing firms that became The Linen Thread Co., Limited, before the new century dawned.

It was once claimed by a leading linen thread manufacturer that the most profitable years for the firm were the years of the American Civil War, 1860-1865. This can be understood when consideration is given to the amount of linen thread required to manufacture huge quantities of military ordnance, for two opposing armies in civil conflict, on that vast continent. In those years, manufactured supplies required on the American mainland were still largely bought from the British homeland. The profitable years of the early 1860s placed some leading textile firms in a strong economic position, looking for manufacturing development. A very high import tax on linen thread, imposed by the United States Government at that time, made the establishment of American thread mills a very lucrative proposition.

F.W Hayes & Company amalgamated with The Linen Thread Company in 1899, as did Dunbar, McMaster & Company, with both their Gilford and New York Mills, in 1901. Other British linen thread manufacturers who joined at that time were : Ainsworth & Sons, Cleator Moor, Cumberland; Robert Stewart & Sons, Antrim Street, Lisburn; and Crawford Brothers, Beith, Ayrshire. More than 30 years later the Group purchased the thread manufacturing interests of Lindsay, Thompson & Co., Limited, Flax Street, Crumlin Road, Belfast.

It was primarily intended that the new company would market the product brands of the amalgamated mills. The identity of the mills, the future development of their prosperous personal traditions and immensely valuable local skills would be preserved. However, in a few years, amalgamation had prompted both rationalisation and standardisation in the subsidiary mills. Early in the 1900s, thread manufacturing ceased at the Gilford Mills of Dunbar, McMaster & Company. The product brands were retained but the production of the sole sewing threads and shoe yarns was transferred to Barbours Hilden Mills, while Seapatrick Mills undertook the manufacture of the linen sewing threads, bookbinders threads and carpet threads. This programme also took place in the mainland mills. Gilford Mills became a yarn spinning and bleaching unit, their purpose, to augment the yarn supplies of the other group mills and to market a range of linen yarns to weavers and other industrial uses at home and overseas.

With the influx of new production, extensive building was undertaken at Seapatrick Mills. A new office block was built close to the churchyard wall to house both management and administrative staff, a works canteen, beside the main gate; a flax machine room; rove store; bundling room and an impressive new thread mill. This housed the thread polishing department on the ground floor and the thread making-up department on the second floor. The building incorporated a flat roof with a parapet wall, to allow the addition of a third storey, should this be required at a later date. Unlike the original mill buildings of Frederick William Hayes, which were largely stone built, all the new buildings were in a very attractive red brick finish.

After the amalgamation, the head office of The Linen Thread Company was established at 52 Bothwell Street, in central Glasgow. This building also held the sales department and accounting section. F.W. Hayes & Company had established independent trading warehouses and selling agencies at home and overseas, from the middle of the 1800's These were run down under the central marketing plan of the new company. In the next few years, The Linen Thread Company established sales outlets in all corners of the world for the distribution of yarns, threads and nets manufactured by the amalgamated mills. These roughly took the form of company owned stock warehouses in the British Isles and English speaking countries overseas, registered selling companies in the European sector and contracted franchise agents in other foreign markets.

Seapatrick Mills had long specialised in the manufacture of linen jacquard harness cord. This was used in the weaving factories from 1870 for the manipulation of punched cards on a jacquard weaving loom, to produce intricate damask patterns in the cloth. Linen harness cord was of heavy construction, having had a double twisting operation. It was found that a new product could be produced on the technology of the harness cord and in the 1920s Hayes Twisted Flax Fishing Lines went on the market. They were particularly successful in Norway, South Africa and Australia in the years ahead.

Seapatrick Mills had long specialised in the manufacture of linen jacquard harness cord.

The success of the amalgamation was being felt at Seapatrick and the Hayes Company undertook a further building programme, to update their housing stock, in the years leading up to World War I. Land was acquired, from the church authorities, opposite the entrance to the mills and 28 semi-detached houses (Hayes Park) were built. The plans for the estate were prepared by William Larmour, the Banbridge architect, to an idea put forward by one of the Barbour ladies of Hilden. This involved the building of English style cottages in grey ornamental block, with high pitch roofs and dormer-type windows. The cottages were laid out with large gardens and planted with trees, shrubs and hedges, giving the appearance of a garden village. The estate was served by a winding driveway. Samuel George Fenton, who successfully directed F. W. Hayes & Company for over forty years, died on 5th September, 1936, and was interned in Dundonald Cemetery. John Doherty Barbour, of Lisburn, became the new managing director.

30th September, 1962.

In 1954, The Linen Thread Company sold seven of the U.S. mills controlled by "The Linen Thread Co Inc." to an American textile organisation and undertook a programme of diversification into engineering and electrical goods manufacture. The name of the company was changed to Lindustries Limited, to reflect the changing trend and The Linen Thread Company was reduced to the status of "Textile Division" in the new Group.

In 1957, the Finlayson, Bousfield Mills at Johnstone, Renfrewshire, were closed down. This reflected a declining world market for linen threads, against the new synthetic threads in nylon and "terylen”. Alexander W. Fleming left Seapatrick Mills to take-up the post of manufacturing director in the Textile Division of Lindustries Limited. He was replaced by John Francis Pim, who handled his responsibilities in F.W. Hayes & Company with a youthful enthusiasm. This extended to starting Seapatrick Mills Recreation Club, that excelled on the football field, and at some pleasant dances organised in the village school.

Early in the l960s the American consultancy firm, Kinsey & Company was commissioned by Lindustries Limited, to carry out a survey on the activities and efficiencies of the home mills. From their report a decision was taken to close Seapatrick Mill on 30th September, 1962. After a progressive rundown of production operations and the transfer of machinery and material stocks to Hilden Mill, the premises became vacant, thus ending 120 years of thread making at Seapatrick.

maybe half an hour or a quarter of an hour before time to start, and then that was the final one at eight o’clock.

You wouldn’t have been late, maybe a few minutes.

There would have been no remarks passed. You went in and got your work and started right away.

Flax Mill — Scarva, Samuel Chambers Flax Mill 1918

Flax Mill — Legananny, Silverford Cooperative Flax Society 1925

Flax Mill — Drumsallagh, Sarah Magaw Flax Mill 1927

Flax Mill — Greenan, James Little Flax Mill 1876

Flax Mill — SC Cupples Flax Mill 1902

Flax Mill — Drumnahare, John McClelland Flax mill 1833

Flax Mill — Falkiner B Small Flax Mill 1914

Flax Mill — Ballymacaratty Beg, Thomas Woods Flax Mills 1906

Flax Mill — Scarva, Samuel Chambers Flax Mill 1918

Flax Mill — Legananny, Silverford Cooperative Flax Society 1925

Flax Mill — Drumsallagh, Sarah Magaw Flax Mill 1927

Flax Mill — Greenan, James Little Flax Mill 1876

Flax Mill — SC Cupples Flax Mill 1902

Flax Mill — Drumnahare, John McClelland Flax mill 1833

Flax Mill — Falkiner B Small Flax Mill 1914

Flax Mill — Ballymacaratty Beg, Thomas Woods Flax Mills 1906

By 1927 all of the flax mills had shut down, as flax production swiftly moved abroad, with importation of flax increasing.

Flax Mill — Carnmeen, James Henning Flax mill 1901

Flax Mill — Desert, John Edgar Flax Mill 1925

Flax Mill — Bessbrook Mills, 1973

Flax Mill — Castle Enigan, Andrew McMinn Flax Mill 1923

Flax Mill — Longhorne, Michael Torley Flax Mill 1921

Flax and Corn Mill — James McGaw Flax Mill 1874

Bleach Mill — Duncrue on the Halstead Co 1906

Weaving Factory — Thomas Gaffikin Weaving Factory 1925

Flax Mill — Carnmeen, James Henning Flax mill 1901

Flax Mill — Desert, John Edgar Flax Mill 1925

Flax Mill — Bessbrook Mills, 1973

Flax Mill — Castle Enigan, Andrew McMinn Flax Mill 1923

Flax Mill — Longhorne, Michael Torley Flax Mill 1921

Flax and Corn Mill — James McGaw Flax Mill 1874

Bleach Mill — Duncrue on the Halstead Co 1906

Weaving Factory — Thomas Gaffikin Weaving Factory 1925

Linen had been carried on at Bessbrook as early as 1760 by the Pollock family. The property was bought in 1845 by the Quaker Richardsons, whose connection with linen went back to 1654.

The first power flax-spinning mill in Ireland was in Bessbrook which subsequently became a substantial town with an estimated population in 1887 of 3,500.

To facilitate it the lake at nearby Camlough was enlarged (a fact already alluded to) and its water used to regulate the stream that supplied power to drive the mills for grinding corn, scutching flax and bleaching linens.

By the mid nineteenth century it was only in a few locations that the old irregular cluster of farm dwellings known as clachans, survive. Instead bogs had been drained, mountain slopes brought into cultivation and farmhouses built down laneways or sited at intervals along the new, straight main roads.

The clachans (e.g. at Clontygora, Cornamuchlagh, Ballynamadda, Lislea and Pollynagrasta) may have represented elements of the Pre-Plantation settlement pattern and in general they were located alongside the older roads which followed spring lines along the lower hill slopes: here farming communities could have benefited from rough pasture on the hills and cultivated land in the valley bottoms.

At one time, Bessbrook linen was among the finest in the world, and the linen mill provided most of the employment in the village. Tenement houses were constructed for the mill workers, many of which were of such good quality that they are still inhabited today. Each house also had an allotment garden for the growing of vegetables, and the area of the village where they were situated is still known as ‘The Gardens’, although the allotments themselves have been replaced by further housing. Most of the buildings in the village are constructed of granite, which is abundant locally.

In contrast, the large houses of the landlords set within wooded estates, parklands and gardens, represented the new features of the 19th century landscape. Examples are numerous but in our area we might name Heath Hall in Ballymacdermott townland, Killeavy Castle and Halls’ Narrow Water Castle.

Linen had been carried on at Bessbrook as early as 1760 by the Pollock family.

After a fire in 1839, the next carnation of the factory began in 1845 when the property was put on the market. Around this time the family which would leave a lasting impression on the mill and the community, the Richardson’s, were looking to expand their mill business and by 1846 the spinning mill was up and running.

In 1878 the company became known as The Bessbrook Spinning Co. Ltd, though the Richardsons were still firmly in control. In 1913 the company operated 20,000 spindles and 760 looms making it the seventh largest Irish spinning and weaving firm. The Spinning Company closed down in 1973 throwing most employees out of work. The Ulster Weaving Company carries on the linen business at Bessbrook until 1987 when it moved all production to its Belfast headquarters. The Craigmore viaduct on the Great Northern They can be seen in the background. Railways were important in linking customers and suppliers. A railway siding ran right into the works.

As with the rest of the Northern Ireland linen industry, at this time, the Bessbrook Spinning Company flourished over the next the 30-40 years, peaking around 1900.

In 1913 the company operated 20,000 spindles & 760 looms making it the seventh largest Irish spinning and weaving firm.

Peter Bradley writes of Bessbrook long ago. ‘I was born in Newry in 1917 but when I was very young the family moved to Hill Street (Quarry Road) Bessbrook. These houses together with Flynntown (Rock Row) were built to accommodate the labourers at the local quarry.

I started school in Bessbrook Convent School in 1921 and in 1923 transferred to St Malachy’s Boys School where I completed my school Leaving Certificate in 1931. On my fourteenth birthday I was recommended by Mr Campbell who was the chief cashier of Bessbrook Spinning Company, to take employment as junior clerk in the Mill’s wages department.

At that time there were 2500 people employed by the company and my job was to stamp and date insurance cards and to post any mail. On Wednesday mornings I accompanied the chief clerk in the company’s Rolls Royce to withdraw the wages for the entire workforce. Two policemen, the chief clerk and me went into the Belfast Banking Company in Hill Street, Newry and the amount required would be withdrawn in cash.

In order to make it easier to make up individual wages, it was my job also to have a list of any individual coins or notes needed – shillings, florins, half-crowns, ten-shilling notes, pound notes and five-pound notes. The odd ten-pound note was also withdrawn but only very rarely because nobody ever earned as much as that in those days. The average earnings then was about one pound ten shillings per week. On returning to the Mill the wages were made up by the chief clerk on Wednesday evenings. They were stored in the main strong-room safe and paid out to the employees on Thursday mornings by Mr Honeyford.

The average earnings then was about 1 pound 10 shillings per week

While I was working in the wages office I attended night school in Newry Technical College where I studied shorthand and accountancy up to final balance. I then studied English and Latin in Stapleton’s Academy for two further years. I had an ambition to go into engineering and I left the Mill to complete my three-year course in ‘precision engineering’ and ‘workshop practice’ at Chester College of Technology. I then was employed by Cammill & Laird in the engine-repair shop and I worked there during the Second World War.

I returned to Bessbrook where I met and married Kathleen Kelly from Dorsey, Cullyhanna. We settled in Flynntown where we reared nine children. I was employed for a number of years by BICC where I worked as a machine-fitter. In Bessbrook we always had a number of good neighbours both in Rock Row and Quarry Row but the houses had no bathroom or flush toilets or hot water supply. In the early Seventies the houses were demolished to make room for the present Fr Cullen Park, where we finally settled.

John Feehan recalls how the hundreds of workers would arrive at the mill each day - “I remember the war type lorries of covered canvas, where everyone sat in lines in the back...they came from everywhere..Newry, Whitecross, Belleek, and Darkley....”

John himself walked to the mill where many a time he had to run the last few yards in order to beat the factory horn - “ I ran down Park Lane to be in time to get my clocking in medal ... (A coin the size of a large penny which had the worker’s individual details on it)...if you weren’t in before five to eight you were docked an hour’s wages...”

As an eager 17 year old, John Feehan spent a year at the mill just before it closed in 1971. John’s working day began at 8am and finished at 6pm, with breaks of half an hour for lunch and 15 minutes in the morning and the afternoon.

John worked in the “card” office where his job involved sorting the stiff-paper cards which were a vital part of the loom system. Carefully punched holes in the cards guided the looms along a predefined path. This area is now the army officer’s accommodation block.

to be in on time to get my clocking in medal…John Feehan

if you weren’t in before five to eight you were docked an hour’s wages.

Flax Mill — Tullycarn, William Liddell and Co Ltd 1927

Flax Mill — Coolsallagh, Thomas Taylor Scutch Mill 1924

Bleach Mill — Coolsallagh, John Stacker Bleachworks 1924

Weaving Factory — Ravernett Weaving Company 1927

Flax Mill — Tullycarn, William Liddell and Co Ltd 1927

Flax Mill — Coolsallagh, Thomas Taylor Scutch Mill 1924

Bleach Mill — Coolsallagh, John Stacker Bleachworks 1924

Weaving Factory — Ravernett Weaving Company 1927

By 1964 one third of Northern Ireland’s mills had closed. In 1973 William Ewart & Sons and William Liddell & Co merged to become Ewart Liddell and were acquired as part of the Coats Viyella Group. In the 1980s Ewart Liddell underwent a major modernisation programme. During the 1980s and 1990s the company’s luxury linen products could be found in stores such as Harrods, House of Fraser, Marks & Spencer and Bloomingdales in the US. The company’s international clientele continued to expand in the sales of linen tableware to airlines, including British Airways, Concorde, Qantas, Continental Airlines and Air New Zealand Hospitality clients included Raffles Hotel, Singapore, The Mandarin Hotel, Hong Kong, and the Ritz Hotel, London. At the turn of the century Coats Viyella put Ewart Liddell up for sale. Irish fashion linen supplier Baird McNutt bought the company renaming the company Liddell Limited. In 2004 the company was acquired by Hilden Manufacturing Ltd. In 2008 Vision Support Services acquired Hilden and Liddell. The Ewart Liddell factory no longer exists however the rich design heritage of Damask linen design has been preserved in the photographic glass plates archive currently housed in the Belfast School of Art, Ulster University.

In 1973 William Ewart & Sons and William Liddell & Co merged to become Ewart Liddell.

The earliest recorded date of 1919 can be found on an image of a design for the Hans Crescent Hotel.

The William Liddell Collection is an archive of 1600 photographic glass plates that were discovered during the dismantling of the EwartLiddell weaving factory in Donacloney, County Down, Northern Ireland in 2007. On first viewing the faint monochromatic image on the glass plate’s look like ghosts from bygone days of refined domesticity. However it became clear that these traces of linen splendour are but a hint of the unique and extensive record of an era of craftsmanship in both the design and production of Irish linen hidden within the William Liddell Collection. The discovery of the photographic plates has provided a rare opportunity to uncover and celebrate the often-understated artistic, design and technical skills of the generations of individuals working in the design offices of the textile industries in Ireland. The photographic plate preceded film and was used to capture images on a light sensitive emulsion of silver salts that coated the glass plate. The use of glass plates for photography declined after the 1910s yet this method of photography appears to have been used to record design work produced in the Liddell design office throughout seven decades of the twentieth century. The earliest recorded date of 1919 can be found on an image of a design for the Hans Crescent Hotel. The latest date recorded is 1972 on a design for South African Railways. This documentary practice appears to have effectively ceased after the William Liddell Company’s merger with the William Ewart Company in 1973 to form Ewart Liddell. It is extraordinary that this form of photographic record was kept and perhaps more astonishing that the observation of everyday affairs of a textile manufacturing design office were the subjects of such an extensive and persistent documentary endeavour.

Flax Mill — McDowell Fitzsimons Scutch mill 1922

Flax and Corn Mill — Magheralana Flax Mill 1834

Bleach Mill and Retting Works — Ulster Retting Ltd 1920

Weaving Factory — James Pennington Weaving factory 1921

Weaving Factory — Tullyherron, Waringstown Weaving Co 1927

Weaving Factory — Robert Liddell, 1923

Flax Mill — McDowell Fitzsimons Scutch mill 1922

Flax and Corn Mill — Magheralana Flax Mill 1834

Bleach Mill and Retting Works — Ulster Retting Ltd 1920

Weaving Factory — James Pennington Weaving factory 1921

Weaving Factory — Tullyherron, Waringstown Weaving Co 1927

Weaving Factory — Robert Liddell, 1923

Waring introduced weaving techniques from Holland and Belgium to the weavers of Waringstown.

Waringstown owes its existence, name and unique contribution to the development of the Irish linen industry to William Waring, who built Waringstown House, around which the village developed. Waring, who was anxious to introduce a prosperous industry that would employ local people, was among the first in Ireland to see the potential of linen. While the Irish wool industry, seen as a rival by the English, was almost taxed out of existence, the Irish linen industry was granted tariff protection and actively encouraged. Waring's vision was continued by his son Samuel, who was greatly impressed by the linen finishing techniques he saw on his travels in Holland and Belgium. On his return in 1688 these techniques were introduced to the weavers of Waringstown and the village soon acquired a reputation for the highest quality cambric and damask cloths.

At that time almost every house had it’s weaving shop attached with two or three looms.

1910

Double Damask Weaver, Waringstown.

An essential prerequisite to the Jacquard weaving process was a series of punch cards onto which the pattern, already hand drawn by the designer, was transferred as a series of holes. It enabled a primitive form of automation in weaving. The weaver could out the cards through the ‘engine’ in sequence by means of foot treadles. This caused selected threads to be raised so the pattern indicated on the punch cards was woven into the cloth. The Jacquard process enabled a hand-loom weaver to work on damask at home on his own rather than as before with as many as 16 helpers.

Flax Mill — Drumbroneth, John Mulligan Flax mill 1920

Flax Mill — Lurganbane Flax Mill

Flax Mill — Ballyvicknacally, McConvilles Mill 2024

Flax Mill — Ballyvicknacally, David Mussen Flax Mill 1927

Flax Mill — Church Street, Murphy and Stevenson Scutch Mill 1924

Flax and Corn Mill — John Graham and Sons 1926

Weaving Factory — Murphy and Stevenson Ltd Weaving 1920

Weaving and Shirt Factory — Brewery Lane, Harrison Brothers 1867

Bleach and Beetling Mill — Ballymaganlis, William McMurray 1897

Beetling Mill — Whiteabbey Bleaching Co House Beetling Mill 1907

Bleach Mill — Drummiller

Flax Mill — Drumbroneth, John Mulligan Flax mill 1920

Flax Mill — Lurganbane Flax Mill

Flax Mill — Ballyvicknacally, McConvilles Mill 2024

Flax Mill — Ballyvicknacally, David Mussen Flax Mill 1927

Flax Mill — Church Street, Murphy and Stevenson Scutch Mill 1924

Flax and Corn Mill — John Graham and Sons 1926

Weaving Factory — Murphy and Stevenson Ltd Weaving 1920

Weaving and Shirt Factory — Brewery Lane, Harrison Brothers 1867

Bleach and Beetling Mill — Ballymaganlis, William McMurray 1897

Beetling Mill — Whiteabbey Bleaching Co House Beetling Mill 1907

Bleach Mill — Drummiller

been in my family for years. So it has.

Fields & river where flax was processed

Fields & river where flax was processed

McConville’s water powered Scutch Mill close to Dromore Co. Down provides a unique insight into the ancient craft of the scutcher who separated the fibre from the flax plant. Eugene McConville kindly showed us around his flax Mill on Tuesday. Eugene has a wealth of information about flax and the processes involved in harvesting flax and preparing it for sale into the Mills who turned it into yarn. He kindly donated samples of flax in various stages of the processes involved in scutching for our education programme. If you are interested in visiting the Mill tours can be booked by contacting McConville’s Mill.

1940 up to 50 people were employed locally

Felix McConville, the grandfather of the present owners, came to Dromore in 1870 from his birthplace in the townland between Annaclone and Rathfriland. He married a lady called Mussen, whose family had been involved in growing flax in the Dromore area for many years, and it was here that the McConville connection began.

The present mill was constructed around the turn of the century with the large mill wheel used to drive the machinery coming from nearby. The wheel, cast in Geoghegan’s foundry in Lenaderg, had previously been used to drive a beetling mill on the River Bann. Beetling, the final process in the production of linen, is the smoothing of the cloth by the action of hammers, made of ash planks, falling on the cloth at regular intervals.

The process to produce linen begins many months before however, and in its day was a labour intensive industry providing employment to many people in rural Ulster.

The flax, once harvested, is stored for around 14 months. After storage, it is taken out and ‘retted’ i.e. soaked in large pools for about nine days to help separate the fibres from the inner core. Once taken out and dried, it is crimped to make it more pliable, and then placed in the scutch machine.

On opening the sluice gates the water begins to flow bringing the large wheel into life. By a series of belts and cogs the main spindle, containing sets of spokes, begins to spin. The still hard flax is inserted by hand into the spinning spokes and the transformation occurs. The hard inner core, known as the shives, breaks off leaving the soft and pliable flax behind. The flax now has the same consistency as fine silken hair resulting from the scutching process. It then began its journey to market and in the early 1900’s there was a flax market in the town of Dromore but this was thought to have closed in the 1920’s so the flax was taken to Banbridge and Ballynahinch.

The main mode of transport would have been the horse and cart and in latter years the lorry, but there was a considerable amount of flax taken to Belfast on the old Newry to Belfast railway.

Felix McConville demonstrating the process of scutching.

Richard McConville, Eugene’s son, carried the business on from his brother and in the industry’s heyday, around 1940, up to 50 people were employed locally. The present owners still have the accounts books for wages, and the names of the mill workers read like a directory of the town. Characters such as Tommy Kernoghan, Fergy McGrath, Oliver Bickerstaff, James Dewart, Ned Fairley, Len Bostan to name but a few. Some of the workers, who were mere boys at the time, still live and work in the town.

The flax industry suffered however in the late 1950’s and 60’s with the increase in synthetic fibre production and the mill all but closed. There has been, in recent years, a resurgence of linen especially by it’s utilisation in the designs of Paul Costelloe and other Irish designers. This brought media attention to the small mill when the BBC programme, the Clothes Show, featured the present owners explaining the flax growing process.

The flax industry suffered however in the late 1950’s and 60’s with the increase in synthetic fibre production and the mill all but closed.

The Flax, now, it would blossom out into a wee

Flax Mill — Aghandunvarren, Phillip Jordan Flax Mill 1907

Flax, Corn and Saw Mill — Miller Marquis of Downshire 1834

Weaving Factory — Hillsborough Woolen Company 1860

Distillery and Weaving Mill — Hillsborough Linen Company 1919

Flax Mill — Aghandunvarren, Phillip Jordan Flax Mill 1907

Flax, Corn and Saw Mill — Miller Marquis of Downshire 1834

Weaving Factory — Hillsborough Woolen Company 1860

Distillery and Weaving Mill — Hillsborough Linen Company 1919

In 1876, a change was made in the factory production from woollens to linens

The Mill of Hillsborough Linen Company, Limited, was situated at a distance of about a mile, English, west of Hillsborough, and less than half a mile from the railway station. The buildings were, three storeys and two storeys high, they covered about two acres, and on 26 acres there are 52 workmen’s houses. Altogether, the premises consisted of about 140 statute acres, including the grazing farm. There was 318 looms, with the latest improvements. The manufactures included towellings, diapers and damasks. Yarns spun from Irish and Belgian flax were chiefly used. The products were sent to the markets of the United Kingdom and to the United States and Canada. An engine 135 horse-power, drove the machinery in summer. In winter a turbine wheel, equal to 70 horsed-power, was used as an auxiliary.

The buildings used were originally a distillery, that were operated by Mr. Hercules Bradshaw; a celebrated man of the turf. A short time after the demise of Mr. Bradshaw the distillery was acquired by a Limited Liability Company and changed into a woollen factory. A second limited liability company was formed while the concern was in full operation. It bought out the first company and continued to work until 1876, when a change was made from woollens to linens, the company re-organised and its name altered to the Hillsborough Linen Company, Limited. Some of the shareholders of the first company have stock in the present successful enterprise.

Mr J.J. Pimm of Lisburn, is managing director, and Mr. Arthur Pimm secretary. Mr Arthur Pimm resides at Culcavy Cottage, in handsomely planted grounds. About 300 people are employed in the factory, of this number more than half are females.

At the entrance to the factory there was a school under the National Board of Education. It was chiefly attended by children of the company’s operatives. The first storey of the school-house served as a reading and recreation room. It was established by the company for the workmen, who managed it by committee. For generations the mill provided the means of existence for a large proportion of the local population and this was often readily acknowledged.

Herbert Bell of Tullynore, Hillsborough, had his own recollections of many of these people and their work:

I went to work in Culcavy Factory in 1931/32. I was learning weaving. for a short period, then working at bleaching yarn, and later I was operating a cropping machine in the cloth office. The older person on the large machine was George Cunningham; he was reared at Chimney Hall, Lisburn Road. The cloth inspector was Waring McCleery from Moira, and he was married to a Uprichard.

I was learning weaving for a short period, then working at bleaching yarn, & later I was operating a cropping machine.

Annie McClenaghan nee Ball provides a lifetime recollection of work in a linen mills, starting with Hillsborough Linen Company. I started work in Hillsborough Linen Company as a Weaver at the age of 14. This was the main work place for most of the girls and women of the village and my mother introduced me into the intricacies of the trade. It was hard work and the youth of today would probably be horrified by the conditions under which we toiled, the noise, dirt and the cold.

This was the main work place for most of the girls and women of the village.

We put in a six day week, Monday to Friday 8am to 6pm and Saturday 8am to 12.30pm. More than welcome was the cup of tea we got at our loom at 10am. When 12.30pm arrived it was lunch break, but we had to be back at work at 1pm. For some it meant a `piece’ (sandwiches) consumed on the premises, but a few managed to run home for a quick bite. The weavers’ tools were a haddle hook (held in your mouth all day) and scissors (held in your hand all day). The women staved off the dirt by wearing an overall to save their clothes. If your loom stopped functioning the men would be called on to do the repairing or fixing, but as time meant money to the weaver the women sometimes became just as adept at the fixing and carried their own tools. I remember one method I was involved in was the supply of small cuttings of dry rabbit skin glued and put in the shuttle to stop the weft breaking. Another task was cleaning the looms every Friday. We were the producers of the best damask table cloths, tea towels and deck chair covers, the latter of which would cut the hands off you.

More than welcome was the cup of tea we got at our loom at 10am.

Flax and Spinning Mill — Largymore 1888

Flax, Spinning and Bleach Mill — Taghnabrick 1929

Weaving Factory — Lisnagarvey Linen Co 1927

Weaving Factory — Linenhall Street Weaving Factory 1911

Weaving Factory — The Back Lane Barracks 1929

Weaving Factory — James Ward Coulson Damask Factory, 1885

Weaving Factory — Lisburn Weaving Factory 1927

Weaving Factory — Jonathan Richardson Weaving Mill 1866

Weaving Mill — Milford Weaving and Finishing Co 1925

Spinning Mill — Island Spinning Co Limited Flax Spinning Mill

Spinning Mill — Robert Stewart and Sons Flax Spinning 1926

Spinning Mill — William Barbour and Sons Ltd 2006

Beetling Mill — Alex Martin Beetling Mill 1924

Flax and Spinning Mill — Largymore 1888

Flax, Spinning and Bleach Mill — Taghnabrick 1929

Weaving Factory — Lisnagarvey Linen Co 1927

Weaving Factory — Linenhall Street Weaving Factory 1911

Weaving Factory — The Back Lane Barracks 1929

Weaving Factory — James Ward Coulson Damask Factory, 1885

Weaving Factory — Lisburn Weaving Factory 1927

Weaving Factory — Jonathan Richardson Weaving Mill 1866

Weaving Mill — Milford Weaving and Finishing Co 1925

Spinning Mill — Island Spinning Co Limited Flax Spinning Mill

Spinning Mill — Robert Stewart and Sons Flax Spinning 1926

Spinning Mill — William Barbour and Sons Ltd 2006

Beetling Mill — Alex Martin Beetling Mill 1924

Beetling Mill — Jonathan Richardson Beetling Mills 1866

Beetling Mill — Taghnabrick 1870

Beetling Mill — Lisnagarvey Richardson Sons and Owden 1927

Bleach Mill — Richardson and Sons and Owden Bleaching Mill 1925

Bleach Mill — Richardson and Co Beetling and Bleach Mill 1879

Bleach Mill — Kilmakee Bleach Mill 1925

The site on which Lagan Valley Island was built once played a significant role in Lisburn’s industrial past. Previously the site for the Island Mill Spinning Company, famous for the production on linen through it, production at the mill came to an end in 1983. When this happened, Lisburn and Castlereagh City Council (then Lisburn Borough Council) purchased the site, and with funding assistance from the National Lottery to the Arts Council of Northern Ireland, regeneration of this site began.

The land was gifted to the people of the area by the Richardson family, leading linen bleachers and manufacturers in the area and descendants from a Quaker family who settled in Ireland at Lisburn in the early 1700s. The Richardsons owned three linen production plants in the area: The Island Spinning Co (now LCCC Headquarters) Millbrook Bleachworks (now housing) and The Glenmore Bleachworks one of the largest of its type in Ireland. The family lived at two large estates in the Lambeg area: Glenmore House (now apartments) and Aberdelgy (now a Golf Course).

The Richardsons owned three linen production plants in the area: The Island Spinning Co, Millbrook Bleachworks (now housing) and The Glenmore Bleachworks.

John Barbour moved from Scotland to Co. Down, Ireland in 1784 to establish a linen thread making business at the Plantation, Lisburn. At the same time his son, William, bought a derelict bleach green at Hilden and set up business. Later, the thread works were transferred to Hilden and as early as 1817 it was employing 122 workers.

In 1823 William Barbour bought a former bleach mill at Hilden and built a water-powered twisting mill. The Linen Thread Company was founded 1898 and it quickly became a large international company. In fact it became the largest linen thread mill in the world, giving Lisburn a richly deserved international reputation.

By 1914 it employed about 2,000 people and until recently some 300 workers were still employed there, with the work-force dropping to just 85 in recent years. Among the company's varied products were nets, which could be made into snares and fishing nets. The company built a model village for its workforce in Hilden, which consisted of 350 houses, two schools, a community hall, children's playground and village sports ground.

By 1890 the mill had 30,000 spindles 8000 twisting machines & used 200 tonnes of coal and 100 tonnes of flax per week.

By the end of the 19th century, William Barbour’s mill at Hilden was considered the largest linenthread manufacturer in the world. In 1898 the Irish, Scottish and American Barbour companies were merged into the Linen Thread Co, Ltd. When war broke out in 1914, around 2000 people were employed at the Hilden Mill and with their help the mill produced linen thread that was used to stitch war-time parachutes, uniforms, boots and knapsacks.

In 2006 the company annoucned it’s closure, the employees, some of whom have worked at the factory for over forty years, said they were 'disgusted' at the decision and felt let down by the company. The factory's senior shop steward, Jackie Ross, said the staff were devastated. Speaking after the start of the consultation process between staff and Coats Barbour, Mr Ross said: "They call it restructuring but it is a total closure. We were given a business plan to turn the company around in two years but we weren't even given that opportunity. This year we made a small profit and to our mind, if we had another year, we could have made this a very successful business.”

"We thought we had a promise two years ago about the future, but it wasn't worth the paper it was written on," said a very angry Mr Ross. "They are taking away the Barbour name," said Mr Ross. "They are taking away the heritage from the people of Lisburn. To them 85 is just a faceless number but they are not faceless to us. Those 85 workers are families, couples, brothers, sisters, fathers and sons. Workers at Barbour feel let down, disappointed and betrayed."

"We have, however, been compelled to restructure our business because of the industries we serve. The declining local market and the demand for lower costs from our customers makes it inevitable that we cannot continue to operate at Hilden and remain competitively serving our customer needs. We have to reshape our business to support our customers. We must meet their demands for quick, responsive supply whilst facing the challenges of a highly competitive global market. Doing nothing, in the face of these industry changes, is not an option."

It became the largest linen thread mill in the world, giving Lisburn a rich international reputation.

Lisburn Mills

They are taking away the

Barbour name.

We thought we had a promise two years ago about the future, but it wasn’t worth the paper it was written on.

of globalisation moves must be made to diversify the economy.

Particularly in areas where the textile industry has been so prevalent.

87 88 89 90

Flax Mill — Ballymurphy James Carlisle Flax Mill and stores 1918

Flax Mill — Cargygray Campbell Hook Flax Mill 1916

Flax Mill — Cluntagh Charles Rush House Flax Mill 1929

Flax Mill — Magheraconluce James McCormick Flax Mill 1929

Flax Mill — Growell

87 88 89 90

Flax Mill — Ballymurphy James Carlisle Flax Mill and stores 1918

Flax Mill — Cargygray Campbell Hook Flax Mill 1916

Flax Mill — Cluntagh Charles Rush House Flax Mill 1929

Flax Mill — Magheraconluce James McCormick Flax Mill 1929

Flax Mill — Growell

Cluntagh Charles Rush House Flax Mill 1929

“In this townland, on the river rising at Lough Aghery, there is one flax mill occupied by William Kearns it has a breast wheel 13 feet in diameter.”

1834 & 1929

In 1929 Magheraconluce and Cluntagh, the last two flax mills closed down.

Flax Mill — Tullindoney Flax Mill 1921

Flax Mill — Dromara Flax Mill 1926

Flax Mill — Crossgar, The Mill on the Rock 1969

Flax Mill — Rathfriland Road, William Dodds Mill 1911

Flax Mill — Aughnaskeagh, William John Corbett Flax mill 1914

Flax Mill — Tullinisky, William Heron Flax Mill 1970

Flax Mill — Carne Flax Mill 1836

Flax and Corn Mill — Kinallen, Earl of Clanwilliam Flax Mill 1928

Flax and Corn Mill — Kinallen, Johnston Flax mill 1914

Flax and Bleach Mill — Dromara, Bertie Dodds Mill 1926

Weaving Factory — John Thompson Weaving factory 1891

Flax Mill — Tullindoney Flax Mill 1921

Flax Mill — Dromara Flax Mill 1926

Flax Mill — Crossgar, The Mill on the Rock 1969

Flax Mill — Rathfriland Road, William Dodds Mill 1911

Flax Mill — Aughnaskeagh, William John Corbett Flax mill 1914

Flax Mill — Tullinisky, William Heron Flax Mill 1970

Flax Mill — Carne Flax Mill 1836

Flax and Corn Mill — Kinallen, Earl of Clanwilliam Flax Mill 1928

Flax and Corn Mill — Kinallen, Johnston Flax mill 1914

Flax and Bleach Mill — Dromara, Bertie Dodds Mill 1926

Weaving Factory — John Thompson Weaving factory 1891

1836–1918

They had 16 employees in their last year.

William John Corbett

David Johnston

S G Graham

James McIlroy

S J Walker

Sandy McVeigh

James Biggerstaff

Oliver Biggerstaff

Thomas Johnston

William Smartt

John McIlroy

William McLoughlin

Sandy Johnston

Mrs John Biggerstaff

Sadie Johnston

Minnie Graham

The flax industry has a long association with Dromara with the bleach green at Woodford dating back to before 1810 and there are linen trade connections to this site going back to 1758.