We are excited to announce that MacClancy and Sons Ltd has become Boss Products UK, a proud member of the Boss Industrial Group.

Located in Strathaven, Scotland, they are strategically positioned to serve clients throughout the United Kingdom and the Republic of Ireland.

This exciting new chapter allows the company to forge international partnerships and expand their reach, ensuring that manufacturing facilities in these regions have access to the safest and most innovative fire and explosion solutions available.

Their extended range of offerings now includes the cutting-edge Vigilex Explosion Protection Systems, Boss Process Compression Couplings, VDL Industrial Products and the Raptor Spark Detection and Extinguishing Systems.

With operations commencing on October 1st, 2024, Boss Products UK invites you to explore the exciting opportunities this development presents.

Boss Products supports industrial filtration and bulk material handling systems with a full line of integrated Fire and Explosion Mitigation

solutions – including Prevention, Isolation, Diversion, and Venting.

T +44 (0)7884 350337 james@bossproducts.co.uk https://bossproductsamerica.com

Publication Management

Thomas Reilly

Sales Manager

T 07539 070158 sales@bestpracticeuk.co.uk

Production

Robert Sharp

Production Manager production@businessandindustrytoday.co.uk

Accounts

Paul Whitaker

Accounts Manager

T 0121 824 4742 accounts@bestpracticeuk.co.uk

Editorial

Gina Burton Editor gina@freshmedia-uk.co.uk

Gina Burton Editor

Welcome to our February issue, where we dive into the latest advancements, practical insights, and groundbreaking innovations shaping the key sectors of UK industry.

This month we have chosen to recommend Quantex™, the leading brand of recyclable positive displacement pump technology. In this focus piece, we highlight Liquid Dosing, an area that Quantex is vastly experienced in. Many sectors benefit from Quantex’s unique attributes, providing hygienic, drip-free liquid dosing that eliminates cleaning and maintenance, with rapid changeovers that reduce downtime, as well as its ability to pump high viscosity products with particulates. Find out more about the Quantex QX25-HP among all other Quantex pumps, on page 4.

On page 22, we shine a spotlight on Lanes Group plc. This a focus piece explains how a drone survey carried out by Lanes Group plc is helping a major manufacturer investigate the drainage system on one of its sites in readiness for future development.

Other topics covered: Storage, Industry, Machinery, Health & Safety, Training, Air Compressors, Drives & Controls, Computers, Facilities Management.

Share any news to: gina@bestpracticeuk.co.uk

R M Fowler Limited specialise in linear guides and ball screws from one of the world’s leading manufacturers of linear technology NSK. They have large stocks of NSK linear products in their warehouse based in Knutsford, Cheshire and have precision cutting facilities available on-site to cut linear guides and ball screws to bespoke lengths quickly and efficiently.

Although rock salt has long been a common choice when it comes to clearing away ice and snow from outdoor surfaces due to its affordability, availability and ease of application the longer term effects of using it are far from ideal and outweigh any short-term benefits considerably. Rock salt does an unbelievable amount of damage. It also puts toxins back into the watercourse and damages most living things, including plants and animals.

As a country we have always overlooked the fact that rock salt is damaging to our environment and super corrosive to anything it contacts because we didn’t use it that often in the past. The problem we face is that due to global warming it is becoming colder in the winter. We can barely cope now when the ice

and snow arrive, even in short spells and we have never created a proper product to help in these situations as they didn’t arise so oftenUntil Now.

EcoGrit Concentrate is a biodegradable natural de-icer which doesn’t harm wildlife and is more economical as it does not damage the concrete and tarmac, removing the cost of repairing potholes year on year.

EcoGrit Concentrate is a safe de-icer, even if used in large quantities. It is made up in part by repurposing by-products from the cereal, animal feeds and brewing industries. It is a biodegradable, natural de-icer, harmless to wildlife, pets or humans. EcoGrit Concentrate actually protects metals it comes in contact

with rather than rusting them and works down to temperatures of -20 Centigrade. Our customers include English Heritage, National Trust, wildlife organisations, HMP - for the patrol dogs kennels - and the site where the police dogs are trained for Devon and Cornwall to name but a few.

Here at EcoGrit we are environmentally conscious and would like to serve the people by offering them education, insight, “peace of mind”, and the chance to make a positive difference on a monumental scale when winter weather patterns are becoming more unpredictable.

For more information visit our website www.ecogrit.co.uk

In this issue of Best Practice, we have chosen to recommend Quantex™, the leading brand of recyclable positive displacement pump technology.

Quantex is the innovative leader in singleuse, recyclable pump technology with a history rooted in product innovation. Owned by PSG, an operating company of Dover Corporation, Quantex’s mission is to innovate and improve its pump technology in order to drive big-impact, game changing fluid delivery solutions.

Many sectors benefit from Quantex’s unique attributes, providing hygienic, drip-free liquid dosing that eliminates cleaning and maintenance, with rapid changeovers that reduce downtime, as well as its ability to pump high viscosity products with particulates. From frozen beverage dispensing to refill machines in supermarkets, to dosing colour pigments into plastic resin manufacturing, this easyto-use, innovative and compact pump technology has a valuable impact.

To give an example of how its benefits help a specific application, let’s look at the demand for the food and beverage industry to add colour to its products during its manufacturing processes. Colour plays a crucial role in this market; it can influence consumer perception, enhance product appeal, and even create flavour profiles. As well as making a product more visually appealing, it can also be used to suggest flavour profiles, mask imperfections, and help comply with specific regulations.

Quantex has collaborated with some of the world’s largest companies in the Food & Beverage sector, delivering bespoke, off-the-shelf disposable pumps with custom fixtures and fittings.

Liquid Dosing

Adding flavour and colourants to food and drink via Liquid Dosing is an area that Quantex can bring great value. Take chocolate for example, where liquid dosing is used to create a variety of different products with the addition of colours, marbling, flavours and added ingredients such as fruit syrups or alcohol.

particulates if the chocolate has small caramel pieces, salt/sugar crystals, or fruit/ nut pieces that are less than 4mm in diameter.

Coloured chocolate is a visually appealing product that evokes reactions from consumers but it is a highly viscous product, and the final viscosity of chocolate depends on how the chocolate is treated, it’s additional ingredients and how it is manufactured.

Quantex can easily handle the high level of viscosity associated with chocolate due to the advanced transfer capabilities of the pumps. Using a positive displacement rotary action, with high vacuum and high-pressure capability, Quantex pumps can dispense or transfer chocolate solutions at lower temperatures than the ability of many other pumps.

Quantex Bag-in-Box pumps can be attached directly to the product packaging containing the flavouring or colourant solution. Their design also allows for the pumps to be easily and quickly replaced along with each new pack which reduces downtime. The pumps minimise mess and wastage, with reverse cycling to stop drips, and high vacuum for better bag evacuation for less product waste.

Lastly, when adding flavourings and colourants to liquid dosing, difficulties can arise such as when partially full or empty packs are swapped out and replaced, remnants of colour or flavour could be spilt, causing stains on machinery, equipment, products, or people. These product spills could be hazardous, but could also leave long-lasting, undesirable stains as well as rising costs caused by wasted products. With Quantex pumps that attach directly to the liquid pack, these risks are dramatically reduced making it much easier, safer, cleaner and quicker to handle liquid colourant.

For simple operation, no drips, and pump reliability, get in touch with Quantex below.

T +49 (2065) 89205-0 info@psgdover.com www.psgdover.com/quantex

IntraLogisteX exhibitor Element Logic has completed the installation of Slovenia’s first AutoStore (another IntraLogisteX exhibitor) system at the Intersocks warehouse in Kočevje.

This automated storage and retrieval solution will support Intersocks’ growing logistics needs as the company continues to scale its operations.

Intersocks, a manufacturer of technical sports socks, produces between 20 to 30 million socks annually, including about 2 million pairs of Crocs, which are distributed to more than 1,000 stores in Central and Eastern Europe and to 63 countries worldwide.

The new logistics centre in Kočevje will serve as a central hub for storage and distribution, allowing for faster and more efficient customer service.

The AutoStore system’s design has the ability to expand as needed and will allow Intersocks to adjust to future market demands. According to company, the new system will enhance order capacity, goods handling, and fulfilment speed, setting new

standards in intralogistics for the company. Joachim Kieninger, director of strategic business development in Element Logic Germany, said, “We are proud to have installed the first AutoStore project in Slovenia. This technology will optimally support Intersocks’ logistics requirements and support its growth in the long term.”

Join more than 11,000 industry leaders

at Robotics and Automation Exhibition on 25th-26th March 2025. Explore cutting-edge technologies, connect with peers and discover the latest innovations shaping the future of manufacturing, engineering, and logistics.

Register now to secure your place at this premier event!

www.elementlogic.net/uk

In today’s fast-paced digital economy, businesses across multiple sectors are continually seeking cutting-edge solutions to enhance productivity and efficiency. At Workstation Specialists, we understand that high-performance computing is at the heart of modern innovation, providing the power needed to push boundaries in design, engineering, visual effects, research, and beyond.

For nearly four decades, Workstation Specialists has been at the forefront of delivering industry-leading workstation and rendering solutions. Our systems empower professionals in fields such as CAD, CAE, CAM, VFX, animation, and computational research to achieve their most ambitious goals with unparalleled performance and reliability.

Unlike mass-produced solutions that prioritise cost over quality, our approach is refreshingly different. Every system we produce is engineered by dedicated specialists who meticulously assemble, test, and optimise each unit to meet the exacting demands of professional applications. This ensures that every workstation

delivers peak performance, stability, and longevity, helping businesses maximise their return on investment while minimising downtime.

Our commitment to excellence extends beyond the hardware. We pride ourselves on delivering a superior customer experience, offering direct access to experienced engineers who provide personalised support and expert advice. Whether it’s optimising workflows, troubleshooting issues, or scaling up infrastructure, our team is dedicated to ensuring seamless operations for our clients.

As industries continue to evolve, the demand for powerful, purpose-built computing solutions has never been greater. At Workstation Specialists, we are proud to support UK businesses in achieving new heights of innovation and efficiency. By combining cutting-edge technology with unmatched expertise, we are setting the benchmark for high-performance computing solutions that drive success in the modern era.

T +44 (0) 1332 280 380 contact@wksmail.com www.workstationspecialist.com

SEMOTA is a hardware and software solution with a web-based application that enables the remote monitoring of any load cell, force, torque or pressure sensor, using our Wi-Fi enabled hardware.

SEMOTA Continuous Remote Monitoring provides dynamic dashboard views of your events, analysis and device control. Information can be captured and stored for review and in depth analysis. Linkage to common messaging systems deliver live alerts for device management. Tailor and build applications to suit your needs and devices. Read more below, then complete the form and we’ll arrange a demonstration.

THREE YEARS STORAGE

Whether your data is needed every day or every few seconds, SEMOTA is optimised to receive, compute, and return millions of data points across the globe.

Using SEMOTA point-and-click application development tools, create real-time dashboards to analyse data and control devices. Visualize data with SEMOTA stock graphs, charts, tables, indicators, maps, metrics, and control widgets or

develop your own using the HTML canvas and your own code. Share your data through public links, or by embedding dashboards into custom web applications.

EVENTS ENGINE

Add conditional and complex business logic to your hardware with triggered webhooks for M2M communication, and SMS, Email, Telegram, and Slack alerts to keep operators on-the-ball and informed.

SYNTHETIC VARIABLES

Transform raw data into insights with Synthetic Variables that compute complex math formulas and statistical expressions.

With SEMOTA cloud software, you can build applications to best fit the operator’s needs. SEMOTA administrators can configure permissions and restrictions to any end user or operator who interacts with dashboards, devices, and/or events. Need a user to be able to oversee multiple organisations? Not a problem. You can optionally add more users or organisations to your account and we can configure your users to best suit your application.

T +44 (0)1344 776666 info@interface.uk.com www.interfaceforce.co.uk

Automated Test & Measurement

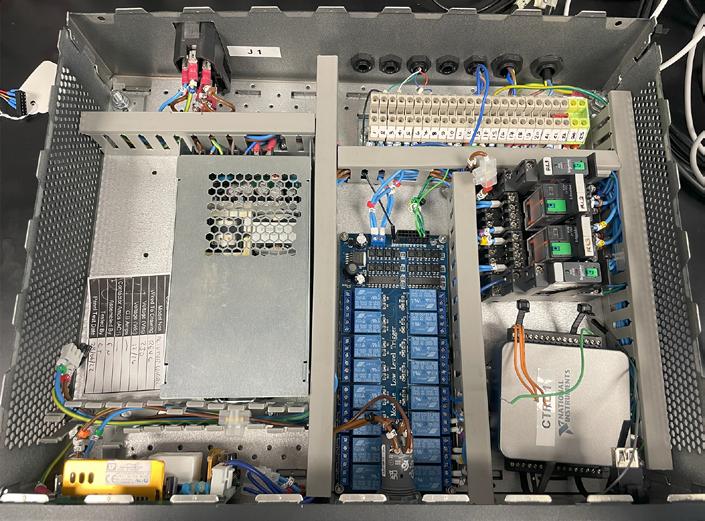

Abingdon Verification Instruments (AVi), a Test and Measurement company based in Oxfordshire specialises in the design and build of Automated Test Equipment (A.T.E.) solutions and general consultancy.

Who we are

Established in 2021, AVi is an ISO 9001 accredited company that upholds high quality standards. As a small business, AVi always responds quickly to customer needs, offering exceptional customer service and project management support.

Industries served include Environmental Monitoring, Battery and EV Technology, Electronic Manufacturing, and Med-Tech industries. With emerging opportunities in aerospace and SME start-ups involved in new product development.

Benefits of using a tailored system:

S Significantly reduced development time and cost.

S Faster time to market.

S Quicker test set-up times & improved accuracy.

S User interface to eliminate operator error.

S Unattended testing with results stored locally.

S Better data acquisition & reporting.

systems for evolving requirements and manageable equipment footprint.

Product validation is the cornerstone of product innovation, ensuring optimised performance, safety and the latest compliance with industry standards. An AVi solution dramatically improves your product verification processes through:

S Functional Testing: Ensure products perform as intended, using multiple simulated tests.

S Safety Testing: Safeguard risks to people, wildlife and the wider environment. BSI 9001 accreditation to oversee safety compliance.

S Environmental Testing: Assess products durability across a full range of factors including high temperatures or humidity, water ingress, shock and vibration and more.

Additional Electronics R&D services AVi also offers bespoke services in Electronics R&D, Embedded Systems Design, Schematic Capture, and PCB design and fabrication. Creating costeffective, flexible solutions for everyday products. These systems allow easy updates and enhanced functionality, reducing the need for costly hardware.

For tailored solutions to meet your business needs, contact us: T 01865 408352 sales@abvi.co.uk https://www.abvi.co.uk

A new machine arrival and machinery moves prompts scrutiny of waste extraction system performance and ducting redirection at high quality print house.

Digital printing comes with benefits in quality, speed and a reduction in waste produced. A well-designed waste extraction system will usually cope with minor changes in quantity and location of printing machinery if unused ducting is left uncapped.

A detailed survey revealed a customer’s system running fast before ducting redirections and removal. Our calculations promised energy savings after modifications and rebalancing.

Case study benefits: Tidy roof space, Customer recovers 5 x job cost in one year, fan energy costs almost halved.

A detailed Waste System Survey can find out if, where and why a system is not operating effectively and efficiently. Modifications can rebalance a system ensuring continued smooth operation and, occasionally, energy savings and carbon footprint reduction.

If you suspect your Waste Extraction System is not running at it’s best due to age, modifications, additions and subtractions, contact

Paramount Waste and request a survey.

Paramount Waste, currently celebrating 25 years in business. T 01276 581392

Sales@ParamountWaste.co.uk www.paramountwaste.co.uk

Nitrogen Oxides (NOx) are chief villains in the battle for climate control; belonging to a family of gases that are formed during the combustion of fossil fuels. When Nitric Oxide (NO) reacts with other gases, for example with Ozone, it forms Nitrogen Dioxide (NO2), which is considered highly toxic to human health.

The reaction with Ozone is also an indicator for why Nitric Oxide (NO) is considered a climate active gas, that interacts with Earth’s protective Ozone layer. Human exposure to high levels of Nitrogen Dioxide (NO2), but also Nitric Oxide (NO) can cause airway inflammation, susceptibility to allergens and exacerbate preexisting lung or heart conditions.

Nitric Oxide (NO) is a biological marker of inflammation and is also produced by cells involved in the inflammation process. It is typically used to diagnose allergic/eosinophilic asthma. Legal ambient air limit value (annual average value for the European Union) for Nitrogen Dioxide (NO2) concentrations is 40µg/m³. Maximum occupational exposure1 limit is 950µg/m³. Indoor air limit value for maximum exposure is 250µg/m³ but the precautionary value 80µg/m³. The WHO defines 40µg/m³ as precaution limit.

The Department for Environment, Food & Rural affairs (DEFRA) has also reported soil chemistry and biodiversity changes across many UK habitats, through gas (dry deposition) and precipitation (wet deposition.) Anthropogenic Nitrogen Oxides (NOx) influence tropospheric chemistry, which directly cause photochemical smog and concentrated levels of urban ozone.

ECO PHYSICS AG offer worldleading measurements of Nitrogen Oxide (NOx), through trailblazing chemiluminescence analysers. These innovative analytical solutions are unprecedented in speed and sensitivity, with a cutting-edge range of sensitivities from 1% down to 1 ppt (part per trillion). Chemiluminescence Analysers use a unique thermally-stabilised semiconductor photodiode, to measure light intensity produced by reactions between Nitric Oxide (NO) with Ozone (O3). The light intensity correlates to the proportion of Nitric Oxide (NOx) converted to Nitrogen Dioxide (NO2) by the reaction.

We caught up with Dr Grischa Peter Feuersänger, Head of Sales & Marketing, to find out more about ECO PHYSICS, “ECO PHYSICS was founded in 1990

through a management buyout, by co-founders Dr Matthias Kutter and Dr Werner Moser and we now operate from our base in Duernten, Switzerland. We offer innovative analytical solutions for measurement tasks in the fields of environment, health and process control. With our interdisciplinary research and development team, we are delivering customeroriented and tailor-made products and services. The initial know-how focus was centred on the principle of the chemiluminescence, thus developing and manufacturing analysers for the ambient pollution and emissions. We have

perfected analytical technique in speed and sensitivity. Today we are proud to claim world leadership in the fastest and most sensitive chemiluminescence analysers and the broadest commercially available range.”

This Swiss-based innovative company has EN ISO 9001: 2015 quality management and EN ISO 13485: 2016 medical devicescompliance, offering quality assurance to customers across many industries. There is a new range of gas analysers and boxed set gas analysers available: nCLD AL, nCLD AL2, nCLD AL3/8555, nCLD EL and nCLD EL2.

The nCLD AL3/8555 is a nextgenerational modular gas analyser, offering state-of-the-art simultaneous measurements of NO, NO2, NOx, NH3 and NOxAmines. Even lower detection limits can be detected through the newly designed reaction chamber, enhanced gas flow paths, improved pressure and temperature stability. This analyser is adaptable to non-standardised applications, with the unit calibration running smoothly on an automated basis.

Contact T +41 55 220 22 22 info@ecophysics.com www.ecophysics.com

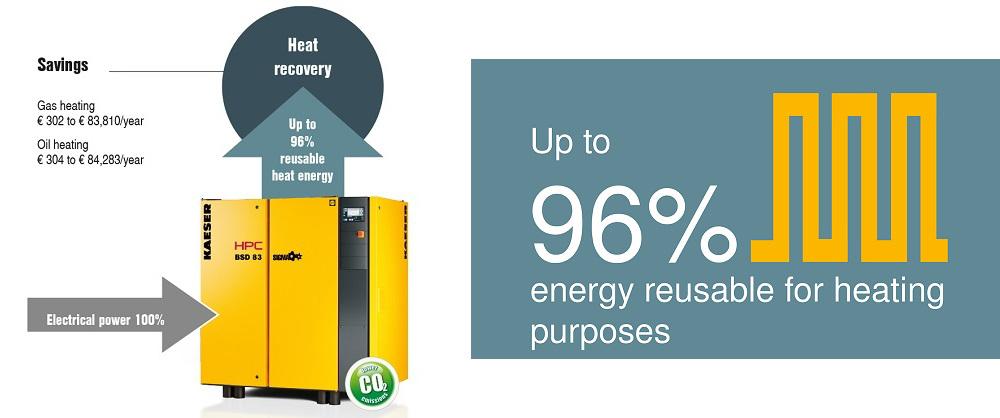

It is estimated that air compressors account for more than 10% of the total energy consumed by UK industry, but many of these are unfortunately old and inefficient.

There are several ways to increase energy efficiency, however, when it comes to compressed air:

First, choose a compressor with the best Specific Power – the energy efficiency rating of a compressor. Specific Power is the ratio of total energy used by the compressor and its compressed air output (at a stated pressure). The lower the Specific Power, the greater the efficiency, and the higher the energy and money savings.

Second, explore the merits of Heat Recovery. A rotary screw compressor converts 100% of the drawn electrical energy into heat. Up to 96% of this energy can be recovered. Energy costs can account for up to 80% of life-

cycle costs over the lifetime of a compressor. By using heat recovery, these costs can be significantly reduced.

Third, utilise energy-saving control. Some of the biggest energy savings in a system can be achieved with an air compressor master control system, which can identify wastage, make predictions and make necessary adjustments to ensure significant energy cost savings while delivering a reliable, consistent and efficient compressed air supply.

You can achieve all three of these methods with HPC KAESER compressors. With

market-leading Specific Power and Heat Recovery Systems and state-of-the-art Compressed Air Management Systems via the Sigma Air Manager (SAM4.0), saving energy has never been easier with HPC KAESER compressors.

Whether you are keen to be greener or you are a UK manufacturer looking to reduce overheads by thousands of pounds, switching to the most energy-efficient air compressors can help.

Find out how much you could be saving in energy costs with our new Energy Savings Calculator: www.hpccompressors.co.uk/calculator

Schmersal to exhibit the new ZQ901 pull-wire emergency stop switch for the first time at the SOLIDS 2024 trade fair

The Schmersal Group is expanding its range of safety switches for heavy industry and will be presenting the new ZQ901 pull-wire emergency stop switch for the first time at SOLIDS 2024. (Stand 5 in Hall5-L06).

Pull-wire emergency stop switches reliably secure conveyor systems and machines which lack a protective device or safety cover over a large area. The ZQ901 pull-wire emergency stop switch features a

cable length of up to 75 metres. The EMERGENCY-STOP switching command can be initiated at any point along the length of the cable.

What’s special about this new pull-wire switch is that the housing is made of robust stainless steel. It has the same design as the basic model (ZQ900) and the mounting points are the same, allowing the user to easily switch to the new switch type (ZQ901) for harsh environments.

The ZQ901 is suitable for ambient temperatures of –25 to +70 °C and complies with protection types IP65, IP67 and IP69 in accordance with EN 60529. The ZQ901 triggers in the event of rope pull or rope breakage, latches and can be reset manually to the operating state. In conjunction with a suitable safety evaluation unit, the pull-wire emergency stop switch can be used up to PL e in accordance with EN ISO 13849-1

ZQ901 pull-wire emergency stop switch

Schmersal is set to launch new versions of its SLC440COM-H/SLG440COM-H series safety light curtains and grids. With ranges of up to 30 metres (SLC440COM) and 60 metres (SLG440COM), they offer reliable hand and body protection and enable monitoring over greater distances with only minimal installation effort.

In addition, the safety light curtains and grids have a Bluetooth LE interface, which, with the ‘SLC Assist’ app developed by Schmersal, displays status notifications from devices and provides comprehensive diagnostic data. The new version of the ‘SLC Assist’ app now offers even greater functionality – as an example, the app can now also be used to calculate the required safety clearance to the danger area.

SLC440COM/SLG440COM series safety light curtains and grids secure danger areas and areas in applications such as presses, robot cells and palletising systems. Due to their increased ranges, the new versions of the SLC440COM/SLG440COM can now also be used to reliably protect

also suitable for hygiene-sensitive areas

The pull-wire emergency stop switch ZQ901 is suitable for transport and conveyor systems as well as production facilities — but also for hygiene-sensitive areas and the chemical industry. As machines and systems in hygiene-sensitive areas must comply with strict hygiene regulations, they’re often subjected to chemical cleaning processes. This being the case, the systems are exposed to aggressive media, corrosive cleaning agents and extremely hot high-pressure water jets several times a day. The robust stainless steel housing which characterises the ZQ901 and provides optimal mechanical and chemical protection in rough environments is a major advantage here. Thanks to cable lengths of up to 75 metres, the ZQ901 can be used with transport and conveyor systems, as well as other large-sized systems.

Visit us at www.schmersal.com/en/home

very large production systems, conveyors or the platforms of autonomous underground railways. With the help of deflecting mirrors, entire areas can also be secured and monitored with just one safety light curtain or grid. This solution reduces both the installation effort and the acquisition costs.

The Bluetooth interface and the app enable all status and diagnostic data regarding the operating status of the light grid/curtain to be called up on a smartphone or tablet in real time. The Schmersal app also offers extensive support for statutory testing and documentation, such as through an integrated operating hours counter and the capture of the switching frequency of the outputs.

The new version of the app now also includes a function for determining the safety

clearance to the danger area in accordance with EN ISO 13855. Thanks to the intuitive user interface, all essential data can be easily captured and the calculated results retrieved. The app also suggests specific products from the Schmersal range: A single click takes the directly to the corresponding product in the Schmersal online catalogue.

The ‘SLC Assist’ app from Schmersal is available for Android and iOS devices.

www.schmersal.com

Visitors to Eureka Training’s booth at The Business Show 2023 engaged with the company’s experts and experienced trainers who shared practical insights, best practices, and actionable strategies for success.

Eureka Training’s presence at The Business Show 2023 exemplified its dedication to staying at the forefront of emerging Health & Safety trends, blended learning programs and evolving business practices. By tailoring course delivery to best meet the client’s environment, practices and expectations, Eureka Training remains committed to empowering individuals and organisations to thrive in an increasingly competitive marketplace.

Eureka Training is an expert provider of workplace health and safety training, specialising in water safety, with RLSS DEFRA module 1 – Water & Flood Awareness training module (which is also accredited with the

Institute for Outdoor Learning), RLSS Aquatic Therapy Pool Rescue Award (ATPRA) and RLSS Open Water Lifeguard Qualification. With highly knowledgeable instructors, with over 30 years of expertise, Eureka is committed to ensuring the safety and well-being of individuals and communities with a mission to save lives at work, leisure and at home through training.

Eureka Training offers a comprehensive range of training programs for many environments and sectors as well Paediatric First Aid (complying with OFSTED framework for the Early Years), HSE compliant First Aid at Work (FAW) and Emergency First Aid at Work (EFAW), manual handling and fire safety courses that include Fire Marshal Training, Fire Safety Awareness Training.

If you’re interested in Training That Saves Lives, please see below: T 020 3871 1118 info@eurekatraining.co.uk https://eurekatraining.co.uk

Monometer foundry furnaces play a crucial role in the metal casting industry, providing the high-temperature environments necessary for melting various metals and alloys. Different types of furnaces are designed to cater to specific needs, efficiency, and types of materials processed. In this article, we will explore the four primary types of Monometer foundry furnaces: rotary, crucible, tilting, and reverberatory furnaces, detailing their features, advantages, and applications.

1. Rotary Furnaces

Rotary furnaces are designed with a rotating chamber that allows for continuous and uniform heating of materials. The rotation facilitates mixing of the charge, promoting efficient and faster melting than stationary hearth furnaces.

Key Features:

S Continuous operation, which enhances productivity.

S Ability to handle large volumes of metal up to 70 tonnes iron

S Suitable for both ferrous and non-ferrous metals.

S and producing alloys.

2. Crucible Furnaces

Crucible furnaces utilise a simple design where a crucible containing the metal is placed in a

heating unit. This method is effective for small batches or specific metal types.

Key Features:

S Can be fueled by electricity, gas, or oil.

S Available in various sizes for small or large operations.

S Typically made from ceramic or refractory materials that withstand high temperatures.

3. Tilting Furnaces

The tilting feature on Monometer furnaces is designed to pour molten metal easily. Tilting can be to various angles, allowing for precise control during the pouring process which minimises spillage and waste.

Key Features:

S Enhanced pouring capability due to their tilting design.

S Available in electric or gas or oil powered versions.

S Suitable for both ferrous and non-ferrous materials.

S Frequently used in foundries for casting larger components, such as engine blocks, car components , manholes, and industrial parts.

4. Reverberatory Furnaces

Reverberatory furnaces are characterised by their elongated rectangular shaped hearth and

the way they absorb heat from the furnace roof. The heat is directed onto the metal via reflected heat from the roof, allowing for large quantities to be melted simultaneously. They are designed with a large vertical loading door on the end of the furnace and a large hearth to deposit the metal to be melted

Key Features:

S Designed for bulk melting and holding applications.

S Uses either natural gas or oil or electric rods for heating.

S Excellent for melting large chunks of aluminium, Can be used with copper melting with oxy-fuel burners

Each type of Monometer foundry furnace offers distinct advantages and applications crucial to various metalworking and casting processes. Understanding the capabilities and best uses for rotary, crucible, tilting, and reverberatory furnaces can help foundries and manufacturers choose the right equipment to meet their production goals and enhance their efficiency. By investing in the appropriate furnace technology, businesses can improve their output and maintain high-quality standards in their metal casting operations.

T +44 (0)1702 472201 www.monometer.co.uk

At Go True North, we specialise in helping organisations unlock their potential. We achieve this through Lean Innovation and Operational Excellence. By applying Lean Process Improvement principles, we streamline operations, reduce waste, and foster continuous improvement.

Whether you’re ready to take the next step in your business journey, transform your business or simply have a question, we’re here to help. Connecting with you is what drives us – so don’t hesitate to reach out.

Please visit gotruenorth.uk

Prefer to chat? Reach us directly at +44 (0)7488 899506 during our UK business hours.

At Go True North we believe that efficiency is key to success. Drawing from our extensive experience in lean methodologies, we help businesses streamline operations, reduce waste, and achieve sustainable growth.

Lean efficiency in action

Recently, we worked in the water industry with a Regional Water Company. By applying lean principles, we improved their maintenance delivery, resulting in an increase in efficiency and 10% maintenance contract cost reduction.

Your path to success

Ready to optimise your operations?

Let’s work together to make lean efficiency the cornerstone of your business success. Visit our website or contact us today for a consultation.

T 07943 448605

neil.betts@gotruenorth.uk

https://gotruenorth.uk

Cirrus Research plc; leaders in noise monitoring for more than 50 years.

At Cirrus Research, we have designed our range of simple-to-use sound measurement equipment, including sound level meters and noise dosimeters, and our vibration monitoring instruments to help you protect your people and the environment against the risks associated with excessive noise and vibration.

As one of the world’s leading designers, manufacturers and suppliers of noise measurement instruments, Cirrus Research plc is the

name you can trust to provide accurate, reliable and easy-to-use equipment that will stand up to scrutiny, and allow you to reduce the devastating effects of excessive noise, not only in the workplace, but also on the environment.

Our equipment is designed in-house by our team of acoustic experts and manufactured in the UK, so you can be sure of its technical excellence and reliability.

Whether you’re looking for a Class 2 Decibel Meter to conduct an occupational noise investigation, or a Class 1 Sound Level Meter for an environmental noise survey,

you can be sure that Cirrus Research has an instrument to meet your needs.

Cirrus Research’s commitment to quality is evident in its adherence to international standards, ensuring that its products not only meet but exceed the rigorous requirements set forth by regulatory bodies.

Find out more by speaking to our experts. T +44 (0) 1723 891655

sales@cirrusresearch.com www.cirrusresearch.com

Manosun is a brand-new innovative company that designs and manufactures an innovative range of quality industrial hand protection available for all industrial applications.

Developed in 2020 from the aftermath of the first COVID-19 lockdown, Manosun is the brainchild of Steven Patterson with the support of his factory sponsor. Located in the North East of England in South Shields, Tyne & Wear, Manosun works closely with its manufacturers in China to bring product development and innovation to the UK market.

Breaking the mould of traditional offerings, Manosun’s core range of hand protection is designed to bring a change to the end-user experience with industrial gloves, gauntlets and sleeves that offer a safe and perfect fit for anyone that requires Personal Protective Equipment.

Steven added, “Manosun have the ability to work on small MOQ’s from our sponsor factory in China and the ability to develop new products for an ever-changing work environment offering products where ‘not all solutions

are off the shelf.’ From ARC, Impact, FR. CUT and General handling applications, our products are the ideal solution for a range of industries from Utilities, Oil & Gas, Electronics and Automotive, to Maintenance, Hot Handling, Circuit Boards, and Renewable Energy.”

Of course, its not just its versatile application that makes Manosun’s products stand out from the rest. Their longlasting durability is down to the high-quality materials that are used for all its products. Every product offers extra flexibility and dexterity that ensures minimal hand fatigue, and because of its 360° breathe technology, all products have the ability to keep hands cool while working.

“We also offer case quantities that is much lower than any of our competitors, and because we are a company on the rise that has the capabilities to develop and tweak products to make them more suitable to our client’s requirements, we can deliver a more personal service that is tailored to suite the end-user. As we continue to grow throughout the UK, we will be advertising to employ our field sales team for the North (Scotland) and the South,” stated Steven.

For more information, please see below: T 07468 904409 steven.patterson@manosun.co.uk www.manosun.co.uk

Fatal injuries are a relatively rare occurrence and yet according to RIDDOR, a staggering 135 workers were killed in work-related accidents during 2022-2023 across Great Britain. These were caused by falling from height, being struck by a moving object or moving vehicle across construction, agriculture, forestry and fishing.

The Health and Safety Executive (HSE) is the national regulator for workplace health & safety and repeatedly stresses the importance of H&S training for the following reasons: S Developing a positive H&S culture, where best practices are integral in all workplaces S To prevent injury or illness

This applies to all businesses, including small and mediumsized companies and ranges from cascading H&S policies, identifying workplace hazards, to appointing workplace first aiders.

Addressing H&S advice Westley Lansdowne Safety Consultancy is a Leicestershirebased company headed by director Thomas Sproston, with a mission to provide expert H&S advice to SME’s.

With targeted expertise in complex safety in applications such as defence, aerospace and transport, Tom has brought his knowledge to the forefront and provides robust support within occupational safety.

Products, processes and premises Clients of Westley Lansdowne can receive support with any of the three P’s, with Tom offering particular guidance for nuclear, rail, aerospace and instrumented safety system standards.

To find out more today about safety consultancy, contact Tom on the details below and quote WLSC BP682: Contact 07476 245559 www.westleylansdowne.co.uk

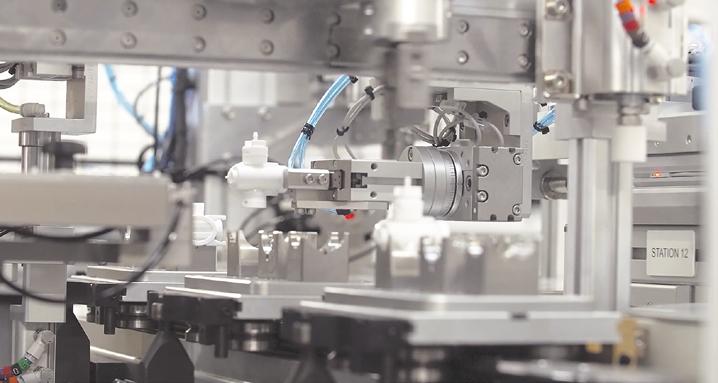

UK machinery safety

Machinery safety is a top priority across all industries to safeguard safe working practices. Despite best safety practices, HSE reported that tragically 135 workers were fatally injured at work during 2022/2023 (RIDDOR), with construction, agriculture/forestry/fishing and manufacturing reporting the highest fatalities. Machine hazards in manufacturing can range from machine guarding, electrical hazards, poor maintenance, mechanical hazards, to equipment malfunctions, and many more, with the onus placed on companies to become more stringent with the health & safety and regular inspections of machinery operations.

The dreaded internal safety inspections

Automated assembly lines have now become standard practice across many warehouse and distribution, manufacturing and food & beverage companies, freeing up staff to carry out other important tasks. Needless to say, one area that hasn’t changed much is the dreaded ‘inspection clipboard,’ with lots of tick boxes. It can often be a cumbersome job but putting it off can cause machinery failure, leading to costly downtime and in worst case scenarios, injuries or fatalities.

But what if there was another option?

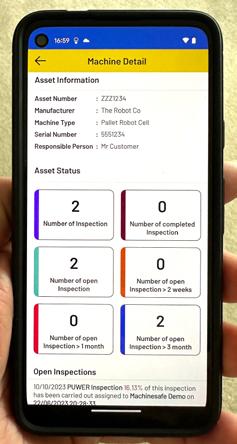

Introducing MachineSafe safety and compliance software

The MachineSafe safety and compliance software platform has been designed to fit a gap in the market for the inspection process by machinery safety engineers. With a rich background in conducting PUWER inspections, UKCA Marking, CE Marking and Machinery Risk Assessments, the MachineSafe engineers used this expertise to develop the platform. Managing Director, Jon Rowen is a member of the BSI Safeguarding of Machinery Committee and is well versed in the mechanics of machine safety protocols.

Benefits of MachineSafe

We spoke to Jon to get a further insight into the benefits of MachineSafe for end users, “Our web and tablet-based platform affords optimised safety and compliance inspections of machinery and equipment across industries such as warehouse and distribution, manufacturing and food and beverage. The platform takes away the burden of inspections, which is a pain point for many companies across the UK. It is perfect for OEMs, machinery end-users and consultants who need timely machinery inspections and audits for stakeholders or customers, even for auditing new machinery at the manufacturers before it is shipped to your company.”

“With inspection modules such as: Prevision and Use of Work Equipment Regulations Assessment (PUWER), Risk Assessments, New Machinery Audits, MachineSafe Audit, CE/UKCA Marking, electrical, pneumatic and hydraulic systems. Users can also add their own inspections to the MachineSafe platform for their own use.”

User-friendly and streamlined

The MachineSafe app can be easily downloaded from Google Play but for companies who would like more information, there are Zoom demonstrations, followed by in-person ones if required.

Following assessments and inspections, the data can be switched to a Cloud Platform and pdf reports can be printed, for ease and convenience.

That’s not all.

MachineSafe offers training for upskilling teams on PUWER inspections, risk assessments and compliance support, as required.

“PUWER (Provision and Use of Work Equipment Regulations) places duties upon individuals and companies who own, operate or control work equipment. PUWER also places responsibilities on businesses

and organisations whose employees use work equipment, whether owned by them or not. The purpose of a PUWER inspection is to identify whether the equipment can be operated, adjusted and maintained safely and that any deterioration (for example, any defect, damage or wear) can be detected and remedied before it results in unacceptable risks.”

“The MachineSafe PUWER module is available as a stand-alone module or is included in our Enterprise subscription is the ideal tool to manage and document your PUWER inspections.”

“All MachineSafe subscriptions include all the core inspection modules, with templates available at the touch of a button. End-users can simply choose the subscription package that suits their requirements. The platform latest release now includes UI enhancements, Improved inspection templates and CE/UKCA marking plugin and our engineers are constantly looking at how to improve the platform going forward.” concluded Jon.

The age of technology

Industry 4.0 pushed advancements in automation, robotics, smart systems, AI, machine learning, big data analytics and IoT across many industries. The advent of Industry 5.0 however, is all about placing worker wellbeing at the epicentre of production processes and using new technologies to provide prosperity beyond jobs and growth while respecting the production limits of the planet. For many industries, this could translate to technology ‘freeing’ up staff to carry out other important tasks and MachineSafe is at the forefront of streamlined inspections, placing workers at the heart of safety.

For more information or to request a demo today, please see the details below: T +44 (0)1793 547018 info@machinesafe.co.uk https://machinesafe.co.uk

Oriental Motor, a leader in precision drive technology, has announced the launch of the AZX Series, an advanced range of high-precision servo motors. The AZX Series promises unparalleled performance and flexibility, catering to a wide range of industrial applications where precision and reliability are paramount.

The AZX Series is designed to offer the precision and reliability of advanced servo motors. With superior control and feedback features, the AZX Series is an ideal solution for applications requiring precise movement and high torque at high speeds. This makes it perfect for demanding industrial environments where accuracy and performance are critical.

Key Features of the AZX Series include:

S Battery-free absolute encoder: the AZX Series is equipped with Oriental Motor’s patented ABZO sensor, a mechanicaltype multi-turn absolute sensor that retains positioning information even when powered off. This eliminates the need for external sensors and batteries, reducing maintenance and operational costs.

S High torque and speed: the AZX motors deliver high torque at high speeds, making them suitable for positioning applications with extensive travel, such as ball screw or belt driven applications. The motors achieve superior performance in the high-speed range compared to conventional models.

S Ease of integration: the AZX Series maintains the same basic operations as the existing AZ Series, allowing for seamless integration into existing systems. This compatibility extends to networkcompatible drivers that support EtherCAT, EtherNet/IP and ProfiNET, simplifying wiring and reducing installation errors.

S Enhanced positioning and control: the AZX motors feature built-in positioning operation functions and various sequence capabilities, which can be configured using the MEXE02 support software. This simplifies the programming and enhances the operational flexibility of the host system.

Industrial ventilation systems play a critical role in maintaining a safe and comfortable working environment, protecting workers from exposure to harmful substances, and preventing the buildup of contaminants.

Founded by Mark Ashby (Son) and Bob Ashby (Father) in June 2017, Clean Air Environmental is extremely committed to quality and as such, imports equipment from all over Europe and the UK, to ensure successful solutions are achieved every time.

Clean Air Environmental specialises in the engineering of industrial ventilation systems and provides a comprehensive service consisting of consultancy, design, supply, installation, and commissioning of industrial ventilation systems and services. The systems are engineered to integrate seamlessly into a facility and is predominantly designed for use in industrial manufacturing (automotive, aerospace, food manufacturing etc.), universities, colleges and schools. Offering intelligent designs and creating effective results, Clean Air

Environmental systems enhance air quality, providing healthier clean air for students, workers and operatives.

“Our services are solutions led rather than product led, so we can design the best ventilation systems that will meet our client’s exact needs,” mentioned Mark.

Clean Air Environmental places meticulous attention to detail in the design and site installations, ensuring that the company only use the best products, equipment and installation engineers.

For more information, please see below.

T 07715 432051 mashby@ cleanairenvironmental.co.uk www.cleanairenvironmental.co.uk

Applications and benefits include the fact that the AZX Series is designed for long-term reliability without the need for complex tuning. This makes it ideal for diverse applications across industries such as medical, automotive, and food processing.

It’s also a very cost-effective solution. By eliminating the need for batteries and reducing wiring requirements, the AZX Series offers a cost-effective alternative to traditional servo and stepper motors. Last but not least, following the kaizen principle of continuous improvement the AZX Series reflects Oriental Motor’s commitment to innovation and quality in precision drive technology.

Pierce Ferris, UK Divisional Manager at Oriental Motor, comments: “The launch of the AZX Series is a significant milestone for us. It provides our customers with enhanced flexibility and performance, allowing design engineers the option to utilise both stepper and servo technologies. The battery-free design and high torque capabilities at high speeds make it a versatile and cost-effective choice for a wide range of applications.”

For more information: info@oriental-motor.co.uk www.orientalmotor.eu/uk/

Precision and efficiency are essential in the dry bulk soldis handling industry, which is why DMN-WESTINGHOUSE offers 8 distinct rotor options for rotary valves. Each rotor is designed to enhance process performance and safety. The correct rotor boosts reliability, ensures hygienic handling, and improves product flow in diverse applications.

How the correct rotor impacts performance Selecting the right rotor is vital for efficient rotary valve operations. Beyond regulating product flow and dosing materials, the right rotor prevents expensive downtime.

In demanding environments where wear resistance and corrosion protection are crucial, a wellmatched rotor to the application reduces maintenance costs and optimises long-term system and production reliability. Let’s look at DMN-WESTINGHOUSE’s 8 unique rotor solutions.

Key rotor options for diverse needs

1. Fixed Vanes: An all-round component ideal for powders and granules, offering stable flow with reduced friction. Suitable for pharmaceutical, food, and chemical industries.

2. Replaceable and Adjustable Blades: Flexibility to replace blades easily without

dismantling the entire rotor. Suitable for abrasive or sticky materials.

3. Resilient Edge: Reinforced blades specifically for wear resistance, reducing air leaks and extending rotor life in heavy-duty applications.

4. Semi End Disc with replaceable and adjustable blades: Offering added protection against wear, it’s perfect for abrasive materials, with easy blade replacement without rotor disassembling.

5. End Disc Fixed Vanes: Explicitly designed for palletised products, minimising end cap wear.

6. Reduced Capacity Closed End: Handles challenging materialsstickiness or particle size - with improved transport accuracy.

7. Scalloped Pockets: Ideal for sticky products, reducing build-up and ensuring even distribution.

8. Fine Dosing: Precise control for sensitive materials such as sensitive products, perfectly fitting for the food and pharmaceutical sectors.

DMN-WESTINGHOUSE helps you select the best rotor for your process, considering aspects like material properties, hygiene, and operational efficiency.

T +44 (0)1249 818400 dmn.uk@dmnwestinghouse. com

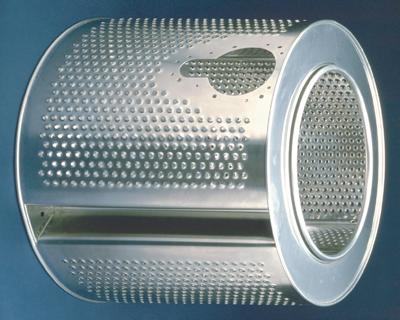

As the largest perforating company in the world, RMIG has over a century’s experience in the perforation industry. This impressive size and experience means RMIG has a local presence in a range of markets, providing accessible contacts for customers no matter what their query.

RMIG is dedicated to being an innovative and reliable solution provider in the perforation industry, as well as being recognised as a benchmark for customer service and optimised logistics.

RMIG’s perforated sheets

can be used effectively within a number of areas, and RMIG has six dedicated market sectors covering Industrial Processing, Food Processing, Buildings and Interiors, Multimedia and Communication, Automotive, and Household Appliances.

One particular area of Industrial Processing is medical and pharmaceutical, where RMIG’s perforated materials are able to give firm tolerances during their manufacture, and are well suited for use in sterile environments. RMIG’s perforated products also have numerous uses in the petrochemical sector, from industry specific applications such as filtration, to oil and gas exploration, as well as more general applications such as walkways in processing plants.

Additionally, RMIG works with biomass drying applications. The demand for alternative sources of sustainable and renewable energy is always growing. RMIG’s Bridge Slot sheets are the most effective way of drying woodchip to an optimum moisture content, ensuring boilers operate efficiently to benefit farming and agriculture.

The RMIG Bridge Slot sheets play an essential role when it comes to the design and manufacture of biomass drying floors. The combination of sheet thickness and opening size allows RMIG’s sheets to be used either as a

Dematic has recently completed a modernisation of an AutoStore™ system for Manutan, Europe’s leading specialist in the distribution of equipment and supplies for enterprises and local authorities. With 25 subsidiaries across 17 European countries, Manutan selected Dematic to be the integrator of its existing AutoStore solution at its Gonesse logistics site, just outside Paris. The system utilises 60,000 storage bins and 68 robots.

Boosting productivity and efficiency

Following a 9,000-square-metre extension of its logistics centre in 2021, which included the installation of an AutoStore system and increased the total surface area of its warehouses to 50,000 square metres, Manutan wanted to

continue its transformation when it joined forces with Dematic to transform its AutoStore system by boosting site performance and sustainable practices at the location.

Results that align with customer CSR goals

The project adheres to Manutan’s corporate social responsibility (CSR) goals. With the optimisation of available warehouse space and the modernisation of its equipment, Manutan has initiated new processes and tasks to reduce any unutilised space and the use of unnecessary materials in product packaging. New settings for the carton closers and greater use of envelopes to replace parcels are helping to cut down on the overall volume of shipments. The transport optimisation, with a reduced number of trucks, directly contributes to Manutan’s FRET21 carbon neutrality objective.

For more information on Dematic, please visit: dematic.com and follow us on: LinkedIn, Facebook, and X.

suspended floor in wood chip drying containers and trailers, or as drive-on drying floors in outdoor buildings. The bridge slot opening size determines the products that can be dried, which range from fine oilseed rape through to larger grains and cereals, as well as logs and wood chip drying.

In the production of perforated dishwasher filters, RMIG offers the complete service from perforating and forming, including surface treatment, right up to final assembly complete with plastic rings and funnels.

RMIG also has decades of experience in the manufacture of perforated sieves using highly developed technical methods and strict quality control systems to guarantee customers are receiving the best possible product.

T +44 (0)1925 839610 info.uk@rmig.com www.rmig.com/en

Wieland Electric presents samos© PRO MOTION, a compact safety controller with integrated motion functionality

Wieland Electric is literally bringing movement to its safety portfolio: With samos© PRO MOTION, the technology company presents a new allin-one safety controller with integrated motion functionality. A total of six TÜV-certified motion function blocks ensure that up to 60% fewer modules are required and therefore more space is available in the control cabinet than with comparable providers. Among other things, the compact, programmable controller enables safe standstill monitoring, even with vertical and slow-moving axes, and also scores points with an anti-vibration toolbox for macro and micro vibrations

Whether mechanical engineering or intralogistics – wherever reliable

standstill, speed, direction and position monitoring is required, the compact safety controller from Wieland Electric with up to 70kHz motion inputs on the base module is suitable. The integrated motion function modules include safe standstill monitoring (SSM), which can be implemented with both a speed window and a position window. The limits of the position window or hysteresis can be defined very easily using intuitive configuration options, allowing vertical and slow-moving axes to be monitored reliably and continuously, for example in construction cranes, lifting platforms, high-bay warehouses or presses, T 01483 531213 www.wieland.co.uk

Gransden UK, formally known as Lock N Pop UK Ltd, is the sole UK and Ireland distributor of the Lock N Pop pallet stabilisation systems, primarily known for reducing plastic pallet wrap and enhancing pallet stabilisation. The UK based company has been supplying the Lock N Pop solution to customers across the industrial and food and beverage applications for over 25 years.

The Lock N Pop pallet stabilisation solution simply saves money by removing the costs associated with palletised goods moving or collapsing in transit to endcustomers. The primary focus on streamlined production process efficiency and the end transit journey to high street shelf, distribution centre or even across international waters or airspace has been paramount and has afforded Lock N Pop goldstandard industry recognition.

Lock N Pop pallet stabilisation uses a cold, water based cohesive, that is carefully applied inline to the cases, bags, shrink-wrap trays etc. immediately before

palletisation. The cohesive has high shear strength characteristics which binds the products together, resulting in a stable pallet. However, the additional bonus is that the cohesive combines this high shear strength with a low tensile strength, meaning that the items can easily be separated.

For more information, contact Gransden UK Ltd: T 01728 726621

M 07516 683314

locknpop@gransden.org www.locknpop.co.uk

Oakway Storage, a leading provider of warehouse design solutions, is proud to announce the launch of its latest product: flexible warehouse protection.

This innovative solution prevents accidents and damage to people, racks, property and machinery. Above and beyond traditional steel-fabricated protection, the Oakway Storage solution returns to its original shape after impact, reducing shock and damage, whilst also increasing floor space through a cleverly designed minimal footprint.

According to the Health and Safety Executive (HSE), over 5,000 reported accidents involve workplace transport every year in the UK. This alarming statistic underscores the importance of implementing safety measures to prevent workplace accidents and injuries.

The new product features a flexible design that absorbs the impact of a forklift or other heavy equipment without causing damage to vehicles, floors or the

An innovative Pallet Live Storage installation can play a key role in supporting grocery retailers as they strive for market leading growth, according to Edward Hutchison, Managing Director of BITO Storage Systems.

Providing up to 50% more storage capacity than traditional racking on the same footprint, a Pallet Live Storage (PLS) system can contribute significantly to accommodating sufficient stock to help grocery retailers meet growing demand.

Supporting a retailer’s need to maintain customer service in tandem with achieving sales growth is one of the biggest challenges placed on a distribution centres (DC), particularly when it comes to handling the sheer volumes involved and fast turnaround required by everyday bulk stock lines, such as soft drinks.

Pressure intensifies when these lines experience peaks, such as during a hot summer – particularly in large cities or on the coast. If one store runs out of soft drinks on a very hot day, there’s a good chance that others in the region will experience a similar issue. All will want more but storage limitations mean there’s a chance that not every store will get the amount they require, which will impact negatively on the grocery retailer’s level of customer service.

Maximising the amount of storage that can fit within the constraints of a DC, to provide

efficient order fulfilment for retail stores, will help to avoid such situations. For those grocery DCs that need greater flexibility to meet a variety of demands from customers within a limited space, PLS offers a dense storage and order picking system that contributes to innovative, efficient and agile grocery logistics operations. On a relatively small footprint, pallets can be located ‘in the air’ on several levels of inclined roller lanes, with delivery lanes for pallet loads of bulk stock lines – such as soft drinks – on the ground floor. This provides dense storage and rapid access to orders.

The flexibility in such a design allows products that need to be sent immediately to stores to be picked directly from the flow lane and transported to Goods Out. If the ground floor delivery lanes are getting close to empty,

protection itself. This popular feature offers cost-effective protection over a longer period than traditional steel protection.

Oakway Storage offers a full range of warehouse fit-out solutions, including pallet racking, mezzanine floors, shelving systems and complete turnkey project management, with a reputation for delivering full warehouse fit-outs, fast.

For more information about Oakway Storage, including the flexible warehouse solutions, please visit the company’s website at: https://oakwaystorage.co.uk or call: 01604 792255.

then stock stored in the lanes above can be brought down and pushed through to the other side of the lane for order pickers to continue their pick.

Operating on the FIFO (First In First Out) principle, PLS ensures product rotation, which is important for grocery store replenishment, ensuring the first product sorted by the ‘best before’ date is picked. A further benefit is that PLS can accommodate seasonal items on the flow lanes in the upper levels, allowing the grocery DC to take advantage of quiet time to get those products out to stores early.

Gaining the capacity to stock items in sufficient quantities to avoid running out, thus allowing the DC to react on customer demands quickly and deliver straightaway irrespective of the amount ordered by a store, even when bulk products a hit, peak makes the investment in PLS well worth it. A PLS system supplier with an experienced team of experts should be able to work closely with the client to develop competitively priced, customised solutions and work around existing operations to deliver projects on time.

For further information on pallet live storage, please visit: www.bito.com

A drone survey carried out by Lanes Group plc is helping a major manufacturer investigate the drainage system on one of its sites in readiness for future development.

The unmanned aerial vehicle (UAV) survey provided a highly detailed digital map of the factory site near Peterborough, which engineers can use to plot drainage assets with impressive precision.

It was carried out by Lanes Group Rail (LGR), Lanes Group’s rail division, in just one day when a conventional groundbased survey would have taken up to four days.

Significant cost saving

LGR Business Development Manager

Bill Waring said: “The aerial mapping surveys we carry out are fast becoming an essential element of site investigations across all sectors, including rail.

“In many cases, they can be carried out by a team of one, rather than the three or four operatives needed to work at height from ground level. It’s a significant cost saving, especially when time saved is factored in.

“Drone surveys also provide a hugely rich array of data that can be manipulated in many different ways to more accurately plot and understand the topography and built assets across large areas of land.

“They don’t just allow surveys to be carried out more quickly, more safely and with less site disruption. They also allow data

then be prepared more quickly and more flexibly for analysis.”

Eliminates site disruption

LGR’s drone survey unit holds the required Civil Aviation Authority commercial operating permission and is on the drone survey framework for Network Rail.

Lanes drone pilot and surveyor Adam Blakesley carried out the survey of the factory site that manufactures ground engineering infrastructure assets.

He flew a DJI Matrice M300 drone fitted with the latest 4K video camera to capture all the required data across an area covering 68,000m2. Esri Site Scan software was then used to process the images captured.

Adam Blakesley said: “We can stitch together many thousands of images taken during the drone flight into highly accurate orthomosaic images of the site. We can also create 3D models and point cloud images.

“These allow clients to view structures in very close detail without having to work at height, which may involve working from access platforms or erecting even more costly and disruptive temporary scaffolding.

“The advantages can be even more pronounced on rail networks. With the right precautions in place, drones can be flown over live rail assets with no disruption to services, negating the need to carry out surveys during engineering possession time.”

Flexible data analysis

The data gathered can be combined with other mapping software to plot assets across large areas with a great degree of accuracy.

This include WinCan drainage survey software used by Lanes CCTV survey teams, allowing data captured via drones to be merged with digital maps of underground drainage systems.

LGR has more than 30 years’ experience of working in the rail industry on national rail and Transport for London networks, while Lanes subsidiary UKDN Waterflow (LG) holds a Principal Contractor Licence (PCL) from Network Rail.

The ability to deliver drone surveys adds significant value to LGR’s capabilities and services, which include: conventional CCTV drainage surveys; track drainage and culvert cleaning and replacement; drain, sewer, and culvert lining; and vegetation control.

It also complements engineering services provided to the rail industry by Lanes Professional Services. They include drainage system investigation and design, and hydraulic engineering project management.

Talk to Lanes Group Rail about its drone survey service – for rail, commercial and industrial clients.

T 01708 528770

bill.waring@lanesgroup.co.uk https://www.lanesgroup.com