K12

Problem solving and decision-making techniques.

K13

Influencing and negotiation models and techniques.

S2

Identify problems and provide solutions.

S16

Influence and negotiate with stakeholders to shape and agree goals and outcomes.

B5 Works flexibly and adapts to circumstances.

B6 Works collaboratively with others across the organisation and stakeholders.

“Problem solving involves identifying a goal, carrying out actions to reach the goal and overcoming obstacles that interfere with reaching it.”

(Munakata, 2006)

Breakout room discussion points:

• Which behaviours do you think are most important for effective problem-solving (e.g. persistence, adaptability, creativity, collaboration, resilience, any others)?

• To what extent do you feel you demonstrate the behaviours you have discussed - what are your strengths and what might you want to develop further?

• Can you think of someone you know who is a great problemsolver? What specific behaviours make them stand out?

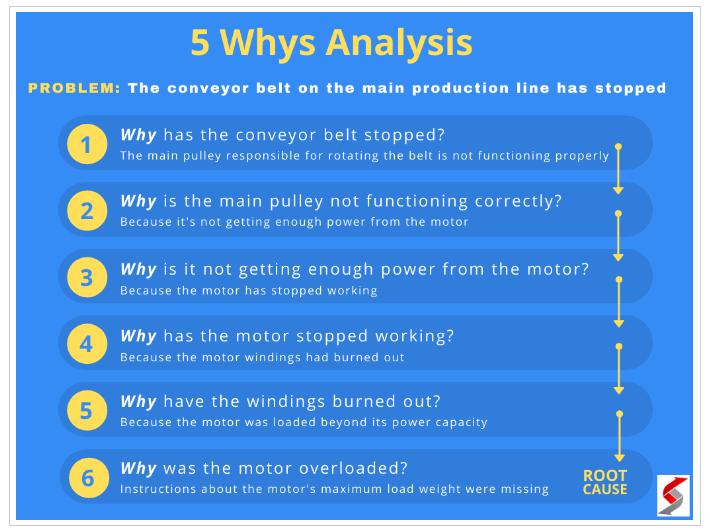

5 Whys Analysis (source: The Business Analysis)

The 5 Whys technique was initially invented by Sakichi Toyoda, the founder of Toyota Industries Co. and father of the Japanese industrial revolution. However, the credit for bringing the 5 Whys to mainstream implementation goes to Taiichi Ohno, the pioneer of the Toyota Production System.

According to the Toyota company website:

Whenever a problem cropped up, Taiichi Ohno encouraged his staff to explore problems first-hand until the root causes were found. “Observe the production floor without preconceptions,” he would advise. “Ask ‘why’ five times about every matter.”

Toyota believes in the ‘go see and clarify’ approach. When an issue occurs with a manufacturing machine, the solution is not found by looking at some historical data or a manual. A deduction is made by understanding the problem, questioning employees working there, inspecting them, and then making a decision.

Continuous implementation of practices like 5 Whys has made Toyota the world’s largest automaker.

The origins of PDCA

PDCA was popularized by W. Edwards Deming, the American statistician and management consultant who played a significant role in Japan's post-war economic recovery. However, its roots trace back to the scientific method and earlier iterations like Walter Shewhart's Plan-Do-Study-Act (PDSA) cycle.

You might wonder why we're still talking about a concept from the mid-20th century. The answer lies in its versatility and effectiveness. PDCA isn't tied to any specific industry or type of problem—it's a universal approach to improvement that can be applied in manufacturing, software development, personal productivity, or virtually any other domain.

This technique based on “6 Thinking Hats” was developed by Maltese psychologist Edward de Bono (1933 – 2021). It is a communication and reasoning tool to see from new perspectives by applying lateral thinking.

This method is used in coaching to help individuals or teams change perspective, think more effectively and make more informed decisions. It also enables coachees to discover unexpected skills or capabilities within themselves.

Description of the method

The method uses six different coloured hats to represent 6 different thinking styles:

1. First of all, the white hat for facts and figures. It represents an objective, neutral and unbiased point of view which answers the question: what are the facts?

2. The black hat for the negative side and potential risks. It is the “devil’s advocate” and answers the question: for each of these solutions, what are the risks and drawbacks?

3. The yellow hat applies a direction of thinking with a logical positive focus and on potential benefits. Like the black hat, comments are constructive, positive and try to make other members’ ideas concrete. However, it represents optimism and answers the question: for each of these solutions, what can be implemented?

4. The red hat represents passion, emotions and feelings. It doesn’t have to justify itself to the other hats. It answers the question: how do you feel?

5. The green hat stands for creative ideas and new perspectives. It represents unlimited creativity and the fertility of ideas, and answers the question: What are the possible solutions, including the most far-fetched?

6. Last by not least, the blue hat is all-encompassing and focuses on the whole process. It represents structured thought and acts as a guide. The process is prevented from getting stuck or sidetracked. Use it to answer the questions: What is the best solution? How should it be implemented?

Kepner-Tregoe decision analysis (source: Purple griffon)

The Kepner-Tregoe Method is highly regarded in the fields of management and IT for its systematic methodology to tackle complex issues. The method emphasises a clear definition of the problem, analysis of the problem's cause, identification of possible solutions, and making and implementing decisions. The process can be broken down into four main steps:

• Situation Appraisal

• Problem Analysis

• Decision Analysis

• Potential Problem (Opportunity) Analysis

The Kepner-Tregoe Method is praised for its rational and measured approach to decision-making and problem-solving. It helps teams cut through confusion and ambiguity to get to the heart of issues quickly, making it a valuable tool in any organisational context where critical thinking is essential.

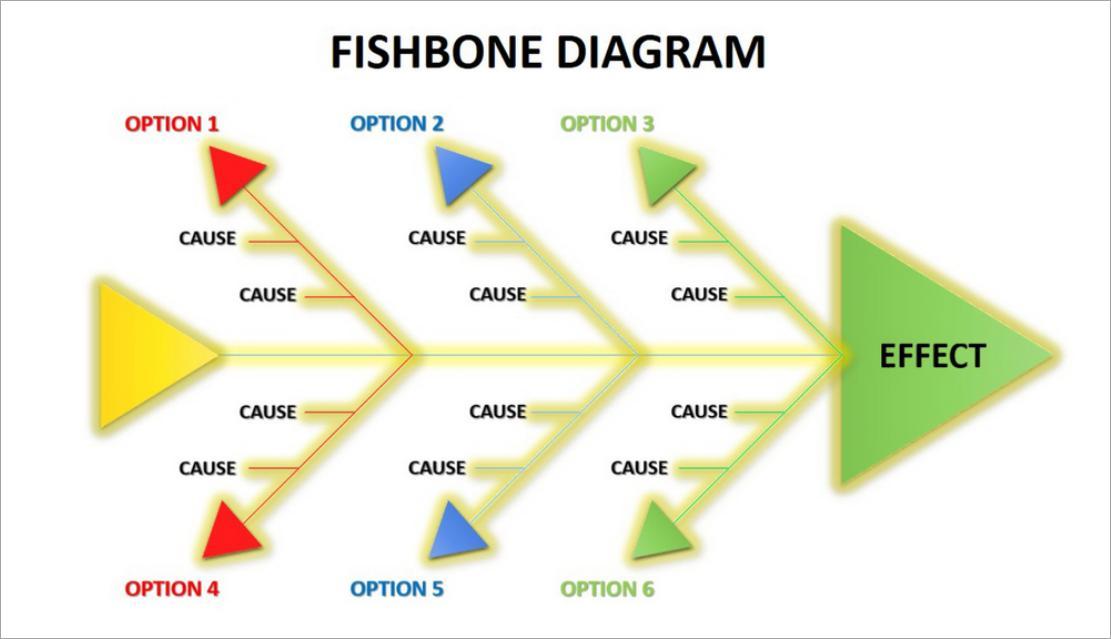

The Japanese professor at the University of Tokyo, Kaoru Ishikawa invented the fishbone diagram in the 1960s.

At the time, Japan was re-inventing its manufacturing and automobile sectors by introducing the concept of quality management in regular business processes.

Kaoru Ishikawa is known to use the fishbone diagram for the first time while working with the Japanese company of Kawasaki.

This quality management tool was named the Ishikawa diagram in honour of its creator. Later, it was nicknamed the fishbone diagram due to its similarity with the skeleton of a fish laid on one of its sides.

A fishbone diagram is also known as the cause-and-effect diagram, as it helps in finding the root cause of the problem in the business processes of an organisation.

In the diagram, the head of the fish depicts the problem, and each bone of the spine depicts the potential causes of the problem.

Thus, a visual representation of the problem and its potential causes can help quality management professionals who are working to solve the problems in the business process of their organisation to successfully identify the root causes of the problem. This root cause analysis tool also helps in brainstorming and finding the right solution to eliminate the problems faced by the organisation.

Taking this forward…reflection prompts

• Which behaviour/s will you focus on developing in your practice in the coming months?

• Which models/techniques might you use?

• How could this link to the wider culture, policies or learner experience?

• What might you need (or who might you need to involve) to make this happen?