Social Annual Report 2021

Bergschenhoek, May 1st 2022

We are taking on our responsibility for a sustainable future!

Sustainability is the core value on which our business is predicated. A rich history forms our basis. Our goals aimed at a sustainable existence are the concept for the future. By doing this, we are taking on our responsibility and doing our bit for a better world.

Our Corporate Social Responsibility policy is comprehensive and multifaceted, and is founded on the 3 P’s: People, Planet, Profit.

Within our organisation and with our products, we are making an impact and contributing to achieving the 17 Sustainable Sustainable Development Goals (SDGs).

The Sustainable Development Goals of the United Nations for 2030. In the Social Annual Report, we make a correlation with relevant SDGs and outline how we are making an impact.

In 2021, we were confronted with COVID-19 all over the world. This has also affected our organisation, our business operations and our performance. The measures that were taken have had an impact within our chain as well as in the execution of the work activities within the organisation. Flexibility and resilience within the organisations and close cooperation in the chain have led to a limited range of

consequences for the Group.

The scope of this report covers our businesses in the Netherlands.

We are proud to present the Social Annual Report 2021 and hope you enjoy reading it.

Board of Directors Bergschenhoek Groep B.V.

& CSR

Corporate Social Responsibility (CSR) is about finding a balance between the social (People), ecological (Planet) and economic (Profit) aspects of conducting business and minimising the negative sustainability effects of the organisation on society. Our goal is to interpret Corporate Social Responsibility in a way that best suits the organisation, thereby creating profit for stakeholders, the environment and the organisation and its shareholders.

The most important economic advantages of CSR are:

• The market for sustainable products and services is growing;

• Those who generates less waste and is more economical with energy and raw materials save money;

• Being a good employer leads to higher productivity and less sick leave;

• CSR improves the reputation of the company;

• CSR strengthens the innovative strength of the company.

How the organisation addresses the needs and interests of employees and other stakeholders. Among the topics are health and safety in the workplace, internship policy, working conditions, the company’s social engagement.

How the organisation deals with environmental impacts arising from its business operations and in the chain. Among the issues are CO2 emissions, waste separation and recycling.

How the organisation is reconciling social responsibility and sustainability with financial profits. Moreover, social and environmental gains are often synonymous with economic gains. Companies that conduct business in a socially responsible manner have an edge over their competitors.

We uphold the principles of Corporate Social Responsibility. We commit ourselves to:

• Responsibility: being accountable for the impact of our activities on the community, the economy and the environment.

• Transparency: being open about our decisions and activities that have an impact on the community and the environment.

• Ethical conduct: demonstrating ethical conduct at all times.

• Respect for stakeholders: respect, take into due consideration and respond to the interests of our stakeholders.

• Respect for legislation: Respect for laws and regulations that are in force.

• Respect for international behavioural standards: respect for international behavioural standards, in conjunction with respect for laws and regulations.

• Respect for human rights: respect for human rights and recognise their significance as well as their universality.

We shall map out the aspects of our CSR, establish clear CSR policies and corresponding goals, develop and maintain a CSR programme and management system and provide enough resources to be able to adhere to the CSR principles. Management and employees are expected to actively contribute to this. We will assess our CSR policy and objectives annually to ensure that they are still in line with our vision for the future.

The Meelick weir in the largest river in Ireland, the Shannon, was damaged during the heavy floods of 2009 and again in 2015 and 2016, when a footbridge was also damaged and subsequently closed.

solution for a new weir construction. Our engineers came up with a unique solution. During the kick-off meeting for the project with the local contractor and the end client Waterways Ireland, the response from Waterways Ireland after the technical presentation of our proposal was: “This is what we want! It’s great to work with such experienced engineers in our organisation as a source of support!

“This is what we want!”

The Meelick Dam connected the historic village of Meelick in the east of the Galway region with the village of Lusmagh in the west of the Offaly region and was part of the scenic Hymany Way and Beara-Breifne Way walking routes.

The dam was built in the 1800s as a part of the Shannon Navigation. The dam is more than 300 metres in length, features a dam construction with four sluice gates, and regulates and manages the water levels between the towns of Athlone with Ree lake (‘lough’) and the village of Meelick with Derg lake (‘lough’). Waterways Ireland, as the owner of this dam, would place wooden dams on this dam from a boat at least four times a year to raise or lower the water level of the Shannon River.

KWT had its sights set on this project for some time, and in 2019 it was officially commissioned to come up with a

This resulted in the fabrication of 25 weir valves, each 12 metres long, which could be operated directly by machine via a 2-metre high spindle drive structure on a new footbridge.

This yielded the following advantages for Waterways Ireland:

• Communities, which had been separated since 2015, were able to be reunited via the newly constructed steel footbridge.

• The KWT weir valves enable one person to raise or lower the water level of the Shannon by more than half a metre mechanically.

• Operating the 25 weir valves can be done in a safe, sound and ergonomic way.

• Structural safety was guaranteed by KWT by fabricating according to the EN 1090 standard ( which KWT has been officially certified for since 2021).

• Protection of the spindle drive structure by sliding HDPE plates over each other.

• Elevated footbridge that can also withstand future elevated water flows of >740 m3/sec.

• So in 2019, KWT was commissioned by local contractor LM Keating to undertake this fine solution for Waterways Ireland.

At the time of the project’s implementation, a change was made that called for not only the steel footbridge, but also the valve weir, to be made suitable to handle floating debris. Our first thought was that we should define floating debris as a few dead ducks, some twigs and grass. A KWT weir valve can easily cope with this, no problem at all.

However, after some further questions, it transpired that floating debris in the River Shannon is also seen in the form of a tree trunk, 80 cm in diameter and 10 metres in length, weighing 2,000 kilos and travelling at 2 metres per second towards the weir. This is comparable to an Audi Q7 speeding down a shopping street and driving right through the front door of your favourite shop. Well, that was of course something entirely different. In the end, they decided against this expensive option and a floating barrier was placed in front of the dam. It just goes to show

that the same criterion can be interpreted in completely different ways by various parties.

The 12-metre KWT weir valves were engineered with special software to demonstrate that the force/pressure in the material would not exceed 200N/mm2 . This is a requirement of the Euro Code EN 1090 that KWT uses, among other things, to demonstrate that the solution is structurally safe. The consequences of a breach, i.e. the Shannon River dropping by half a metre in level, could be very serious.

After the weir valves arrived in Ireland, they were transported by a Waterways Ireland pontoon on the Shannon River and installed by the contractor using a crane on a newly constructed concrete dam. KWT prepared special installation templates to specify where the chemical anchors were to be set in the concrete. This gave the contractor an insight into where the reinforced concrete needed to be placed so that the subsequent holes in the concrete for the chemical anchors could be drilled without too many problems and delays.

As KWT’s contacts with both the local contractor and with Waterways Ireland as the final client were very good, the three parties kept one another fully informed at all times,

constantly voicing their confidence that everything would be done to make this project a success for all the parties involved.

KWT delivered the weir valves on time and on schedule.

Waterways Ireland, together with the local contractor, installed the valve weirs according to the Installation Instructions prepared by KWT and completed the work on site before the construction site had to be closed for the start of the storm and fishing season.

The time had finally come on 24 September 2021. The Meelick Weir and footbridge in the River Shannon were officially opened by the Minister for Housing, Local Government and Heritage, Mr Darragh O’Brien, and

Minister of State for Heritage and Electoral Reform, Mr Malcolm Noonan together with the CEO of Waterways Ireland, Mr John McDonagh. As KWT, we had been specially invited to attend this.

“Meelick Weir is an iconic building and I am delighted that this restoration project has now been completed. The weir is an exceptionally important piece of navigation infrastructure, which means that the water levels of the Shannon River can be managed for navigation. The Dutch systems that are built into the weir also provide a safer working environment for our staff.” “This is the largest project ever undertaken by Waterways Ireland since we have restored the main line of the Royal Canal and I would like to pay tribute to my colleagues and KWT, who worked diligently to bring this ambitious project to completion under budget during very challenging times.” - John McDonagh

Bergschenhoek Groep B.V. is a family business, founded in 1919 and dedicated to continuity over the long term. In 2021, the Bergschenhoek Groep comprises the holding company Bergschenhoek Groep B.V. and a group of (inter) nationally operating production and trading companies within two divisions (hereinafter: the Group). The Air & Ventilation division and the Civil Engineering & Water Management division.

The Group develops, manufactures and supplies high-quality construction-related products that enable sustainable solutions are being provided. In this respect, great value is attached to cooperation with partners within the chain. The transfer of knowledge is part of this.

The environment where the Group operates is complex. Stakeholders set high standards. Assuming responsibility for legally sound behaviour and ethical entrepreneurship is important. Bergschenhoek’ has a good name and reputation to uphold and also acts accordingly, as all stakeholders expect us to be competent, honest and reliable.

In the CSR declaration, we commit ourselves to the principles of corporate social responsibility. CSR objectives are set out in the annual plans of the businesses. Businesses within the Group draw up a CSR annual report every year.

Sustainable entrepreneurship offers us opportunities. With our sustainable products, choice of materials, production methods, employee programmes and the RoFa Foundation, among other things, we shoulder our responsibility for People, Planet and Profit.

The Group has its headquarters in Bergschenhoek. The production companies and sales offices are located at various locations throughout the Netherlands as well as in Belgium, Bulgaria and a subsidiary in Malaysia. The Group works closely with the affiliated companies Climate Recovery in Sweden and Rekuperatory and Ventermo in Poland. Since the 1970s, the Group has distinguished itself as a manufacturer of steel products. The Dutch businesses are consequently affiliated with the Metal and Engineering sector. Apart from steel, plastics are also used in the products nowadays.

In view of the growing importance of good and responsible governance, a compliance programme has been introduced that applies to both board members and all employees within the Group. The compliance programme has been drafted according to the basic tenets for conducting business: integrity, ethics, transparency and loyalty. The programme covers compliance with laws and regulations in various areas including competition, good business practices, protection of personal data, and business communication. By doing business in a sustainable way the Group takes responsibility for the effects of its business operations on the environment, both internally and externally.

Bergschenhoek Groep B.V.

R-Vent Group B.V.

Air & Ventilation

R-Vent Netherlands B.V.

Bergschenhoek Luchtcomfort Vespi

Spiralite

R-Vent Natuurlijke Ventilatie B.V.

Bergschenhoek Civiele Techniek B.V. (BCT)

KWT Holding B.V.:

KWT Productie B.V.

KWT Waterbeheersing B.V.

KWT Construction Ltd. (Bulgarije)

KWT Milieu BVBA (België)

Rowat Asia SDN BHD *

Stakeholders such as employees, shareholders, suppliers, transporters, customers, (local) governments, educational institutions and schools, civil society organisations and local residents, all have an influence on our businesses. By engaging in dialogue with our stakeholders, we acquire information and knowledge to help us further develop our CSR policy.

The CSR reports prepared by our companies for 2021 are presented to the employees and the Board of Directors of the Bergschenhoek Groep and have also been made available to the other stakeholders. The consolidated report for the Bergschenhoek Groep is also shared with shareholders, directors and employees and has been made available on the website for the other stakeholders.

Compliance is a broad term for compliance with the applicable laws and regulations, (internal) procedures, contracts within the Group and the standards and values of a company. The basic tenets of our business are: integrity, ethics, transparency, loyalty.

The core values that are at the heart of this are shown below. In order to effectively put our basic tenets and core values into practice, a Compliance Programme has been adopted by the Group.

The SDGs (or Sustainable Development Goals) encompass seventeen goals to make the world a better place by 2030. The SDGs have been agreed upon by the member countries of the United Nations (UN), including the Netherlands. The goals were set on the basis of global input from organisations and individuals. The Sustainable Development Goals started in 2015 and will run until 2030. They serve as a global compass for challenges such as poverty, education and the climate crisis. They are the successors to the Millennium Development Goals (2000 to 2015). Behind the seventeen goals are a total of 169 targets. These make the goals out in concrete terms.

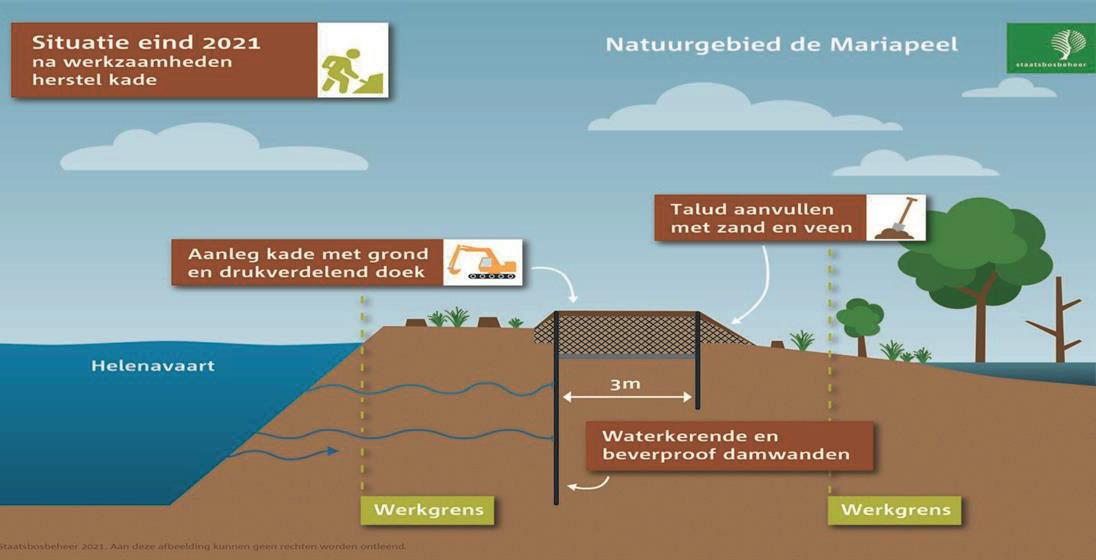

Flood-proof and Beaver-proof”

Water, meadows, sand ridges, birches, open plains and cranes. De Pelen is a paradise for nature lovers and hikers. De Pelen, on the border of North Brabant and Limburg, forms an impressive swamp.

The embankment on the edge of the Mariapeel was in a bad state, partly due to beavers digging holes in the embankment has been excavated. As a result, nutrient-rich canal water flowed into the acidic and nutrient-poor raised bog habitat. The supply of this nutrient-rich water will cause vulnerable bog fauna and flora to disappear and other species will displace the vegetation that the raised bog.

Staatsbosbeheer (the Dutch Forestry Commission), the Limburg Water Board and contractors have repaired the embankment with ROwat plastic sheet piling in a sustainable manner. So that it is safe and stable once again and canal water can no longer flow into the Peel.

Originally, the repair of the embankment was to be carried out earlier, but was postponed because of the presence of beavers. The Limburg Water Board issued an advisory report for the construction of 2 plastic sheet pile walls: Barriers that are vibrated several metres into the ground. These sheet piles will ensure that the embankment remains stable and is flood-proof and that means beavers will no longer be able to dig holes. The choice for ROwat sheet piling was made because of its use of recycled material and its sustainability compared to alternative materials.

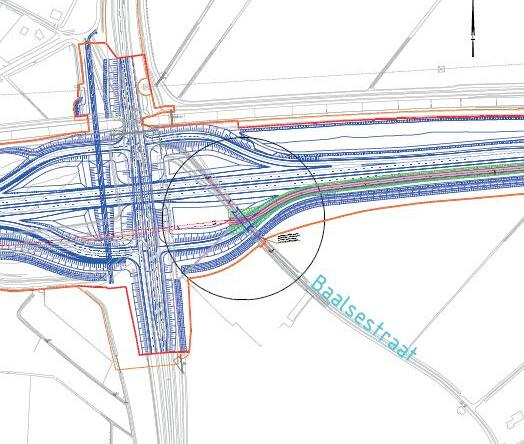

The ambition of the Dutch Directorate-General for Public Works and Water Management is to work in a climate-neutral and circular manner from 2030 onwards, for instance, by making use of circular construction. Bergschenhoek Civiele Techniek B.V. embraces circularity and, through contractors, has initiated the recycling of steel Super Cor tunnels for the A9.

In the period 2015-2021, the contractor joint venture IXAS Gaasperdammerweg B.V. extended the A9, between the Holendrecht and Diemen intersections, with additional lanes as well as the Gaasperdammer tunnel. During the construction of the tunnel and the park built on top of it, IXAS installed bicycle and pedestrian tunnels to provide temporary detours for the road network.

These tunnels are made of prefabricated corrugated steel sheets, which are assembled using bolted connections. Thanks to the prefabricated elements and bolted connections, the tunnels are designed so that they can be dismantled after a period of use and reused at another location.

Bergschenhoek Civiele Techniek B.V., saw an opportunity in Project ViA15 to reuse the Super Cor tunnels of the A9. The ViA15 project involves extending the A15, widening the A12 and widening the A15. Both IXAS and GelreGroen B.V., the contractor duo of a sub-project of Project ViA15, have since become enthusiastic about this circular idea as well.

For instance, the parties have agreed that Bergschenhoek Civiele Techniek will dismantle the tunnels in Amsterdam and rebuild them as part of the ViA15 project near Bemmel.

In awarding the ViA15 contract, the Directorate-General of Public Works and Water Management assessed contractors on the criteria of sustainability, risk management and minimising disruption to traffic. For GelreGroen B.V., the reuse of the tunnels fits in seamlessly with the sustainable design and realisation of the A15 motorway!

Employment

Gender pay gap

Sector average: 1,6%

Netherlands average: 7%

Internships

Sick leave absenteeism

2021 compared to 2020

Bergschenhoek Groep : +2,6%

BCT : -2,1%

KWT Productie : -0,8%

KWT Waterbeheersing : -5,9%

R-Vent Netherlands : +1,1%

The following is a summary of our social performance and successes achieved in 2021.

Internships and cooperation with education.

The Group is active in the provision of internships and works together with educational institutions in the region wherever possible. Four internships were made available over the course of 2021. Internships at intermediate vocational (VO), upper vocational (MBO) and university of applied

sciences (HBO) level with a focus on sales, production and engineering. In addition to internships, we offer (technical) schools in the area the opportunity to visit our company for guided tours and presentations. Limited use was made of this due to COVID-19 in 2021.

There is close cooperation with (partnerships between) schools and educational institutions in the vicinity of our companies. In addition, we have taken part in an initiative led by the Aeres University of Applied Sciences in Dronten, where research has been undertaken into improving agricultural water management.

The Group is affiliated with entrepreneurial and trade associations, employer organisations and professional groups, such as: VNO-NCW, FME, The Netherlands Royal Metal Union, VLA, LUKA, TVVL, Duurzaam Gebouwd, NEN, Ondernemend Lansingerland, Entrepreneurs’ Association Staphorst ICC, Entrepreneurs’ Association de Driehoek (Dronten), Kennispoort region Zwolle, NEVI, Federatie dunne plaat, Netherlands Water Partnership, Envaqua, IKN foundation, MVO Nederland, Bouwen met staal, Duurzame leverancier, Corrugated Steel Pipe Institute.

We do not provide any (financial) support to political or religious parties.

The businesses within the Group that fall within the scope of this report provide employment in 2021 for 199 FTEs, 219 employees. (2020: 174 FTEs, 191 employees).

In addition, in 2021 we hired an average of 31 FTEs within the businesses (2020: 26 FTEs) on a flexible and temporary basis. We work with certified agencies for this purpose, whereby the laws and regulations are followed. Over the course of 2021, we have given a number of employees from this flexible pool a permanent position.

The workforce rose by 22.5%. On the one hand, through the acquisition of Vespi by R-Vent Netherlands. On the other, through the expansion of our activities. The percentage of flex workers has fallen by 1%.

The diversity among our workforce is high, whereby our guiding principle is that everyone is entitled to be there and we respect each other as well as each other’s opinion.

Historically, the construction and production environment has been a man’s world. It is noticeable that the management boards of the operating companies do not have a balanced male/female ratio, but are made up exclusively of men. This is also largely true of the managerial team. Within the Board of Governors, we comfortably meet the 30% criterion of a balanced female/male ratio (50% women - 50% men).

As part of our recruitment policy, we are definitely open to female employees for all jobs. The percentage of female employees fell by 2% in 2021 compared to 2020. This is attributable to the acquisition of Vespi, where the majority of employees are men.

Under our terms of employment, it is frequently possible to work part-time, and this option has on average been made use of more extensively over the past few years. What is notable is that the group of female employees who work part-time is the largest. 4.5 times as many as male employees who work part-time.

We are committed to offering employees a permanent contract after a period of a temporary contract(s). 93.7% of the employees had a permanent contract in 2021.

The average age of our employees is relatively high. In 2021, the average age is 47 (2020: 49). 67% of our employees are older than 45 and 28% are 55+.

The average age of female employees is 47.74 years old (2020: 47), the average age of male employees is slightly lower at 47 years old (2020: 50). Compared to the sector, this is slightly higher. (Sector average age is 45 years old).

Generally speaking, our recruitment policy is aimed at rejuvenating our workforce, but in specific departments, the decision is made to go for seniority. Moreover, selection is also subject to availability, especially in the current labour market. The group of employees aged 45 and older was 3% lower in 2021 than in 2020 (2020 10% lower than 2019). The group of employees aged up to 35 years grew by 4% in 2021.

The recruitment policy is predicated on a meticulous process whereby the creation of a transparent image is paramount, both for the applicant and the company. No differentiation is made in the procedure on the grounds of (cultural) background, sexual orientation, religious faith or in any other respect whatsoever. The guiding principle for the company is diversity in balance.

Over the course of 2021, 20 employees left the company. The reasons for their leaving were diverse: a number of employees reached retirement age, a number of employees found other jobs elsewhere or with another subsidiary, one employee was granted a WIA disability benefit and two employees passed away.

In view of the age composition of our staff many employees will reach retirement age and end their employment service over the next few years. Furthermore, we have also noticed that the market has picked up, so that employees are more likely to take on a new challenge. This enables us to continue to rejuvenate our workforce, which is also desirable given the gravity and nature of the work involved. The challenge in this respect is how we can secure knowledge. Transfers between and within the businesses shall be facilitated wherever possible.

A very large group of our employees lives in the region (<30km), 43% of our employees live in the immediate vicinity (<10km) of our companies.

The Metaal & Techniek CLA applies to the Group. In the case of small entities, the CLA does not apply, but we do apply it with the aim of establishing equality among employees. Employees are required to join the PMT industry pension scheme. For employees who are not covered by a CLA, a company pension scheme is applicable.

specialised agencies to achieve this. When outsourcing work, we look for opportunities to outsource to socially marginised target groups. For example, BCT has outsourced the packing of fastening materials to Ambachtse Bedrijven.

The CLA and the pension scheme make it possible for older employees to take early (partial) retirement. Attention is devoted to this by means of personal information, pension scans, pension briefings and personal retirement plans.

Participation legislation and outsourcing to socially marginalised groups

It is only natural that we offer employees who are distanced from the labour market a place within our companies, and in doing so, we show our solidarity with the Participation Act. Also in 2021, there are two people with a work disability were employed by our businesses in 2021. We work closely with

Remuneration is paid on the basis of the CLA and the job classification system, whereby standard wages are paid above the CLA. The CLA is adhered to when it comes to salary raises, also for the non-CLA scales. A profit-sharing scheme is in effect for employees.

In 2020, we participated in the Eerlijke Beloning Scan (‘Fair Remuneration Scan’) of the FME. The guiding principle of the scan is that by law, women and men who do the same job and have the same qualifications must be paid the same.

We are committed to a fair wage policy and are convinced that we are paying fairly, but because we have not had this objectively assessed before, we decided to participate. The results of the scan make it clear that remuneration within the Bergschenhoek Groep is fair. There is no pay gap between women and men. (Sector gender pay gap 1,6%, Netherlands gender pay gap 7%).

It is notable from the scan that the representation of the number of women and men across the different salary positions deviates from the sector averages. It is also notable that within our group, fewer women and men fall into the lower salary positions, and more women and men than the sector average are employed in middle salary positions. Also, within our group, fewer women are in the higher salary positions. In order to establish diversity between women and men, we should therefore focus our recruitment policy on women in the higher position groups (managers and directors).

There are a range of staff participation bodies for employees. We work according to our core values, respect for each other and provide opportunities for open dialogue. Regular work meetings are held, either bilaterally, per department or team. By doing this, we safeguard a safe, healthy and pleasant work environment.

The Group has adopted an occupational health and safety policy in accordance with the Dutch Health and Safety Act. By means of a compulsory RI&E and accompanying plan of approach within the operating companies, all risks with regard to working conditions are mapped out and mitigated.

KAM (quality, working conditions and environmental officers) and prevention officers address working conditions by holding toolbox meetings, providing information and instructions on

how to work safely. Various training courses are also offered to employees in the field of safety.

Several studies were conducted in 2021, including hearing tests for employees in the production halls, welding fumes studies and noise studies, and based on the results, (improvement) measures are being taken where necessary. In addition, an inspection of repetitive work and the ergonomics and a climate scan were carried out in 2021. Improvements are being made.

The use of Personal Protective Equipment and hearing protection is mandatory and these are provided free of charge. Provisions are made to put employees to work in a sustainable way and with the minimum amount of strain as possible.

Accidents are reported and dealt with according to the guidelines. There were 13 workplace accidents and/or hazardous situations in 2021. In 2021, 5 accidents fall under class C (no sick leave) and 8 accidents under class A (with sick leave). The Injury Frequency (IF) represents the number of accidents with injuries resulting in sick leave and fatalities that occurred in a given year. Converted to 1 million working hours that have been worked. In smaller companies, a single accident can consequently lead to a very high IF.

The IF in 2021 for R-Vent Netherlands amounts to 24.7 (2020: 17.1), BCT 0 (2020: 68,4), KWT 0,3 (2020: 0).

Attention is paid to the sustainable employability of employees within the businesses. This takes the form of projects and activities in the areas of development, health, vitality and cooperation. In doing this, we focus on the employees’ ownership of sustainable employability in addition to the range of interventions that are initiated. Our employees have started out with enthusiasm in the past few years and are taking responsibility for their own personal development, physical and mental vitality so that they can do their work with a lot of pleasure and energy and find the right balance between work and private life.

Widespread attention is paid to Sustainable Employability through rotations and exchanges, safety, occupational health and working conditions. We offer our employees training courses and further education, because we believe it is very important for employees to develop themselves sustainably by expanding their skills, professional knowledge and competencies. Workshops were held in 2021 in the areas of Physical strain and Job Satisfaction.

In 2021, 14 employees made use of the bicycle plan.

We have a well-functioning absenteeism policy (in-house management model) in which brief follow-ups by managers, HR and the company doctor are responsible for ensuring proper handling and reintegration. The Group has its own healthcare network that can be mobilised both preventively and reactively. It features an approach whereby selected and specialised healthcare providers focus on the sustainable employability of employees. In 2021, the company healthcare package mainly used in-house physiotherapy, vitality talks and workplace studies.

The rate of absenteeism in 2021 varied between 0.24 and 6.61% (2020: 0.47 and 7.41%). A portion of the absenteeism percentage is Covid-19 related. Furthermore, there was an outflow of employees in 2021 due to precautionary measures/ quarantine in connection with Covid-19.

Bergschenhoek Groep B.V.

Bergschenhoek Civiele Techniek B.V.

Netherlands B.V.

We consider it very important that employees develop themselves in a sustainable way in terms of professional knowledge and competencies. In 2020, we introduced a digital Bergschenhoek Academy, which offers E-Learning courses to expand professional knowledge and competencies. This Academy will be extended further over the coming years.

By 2021, a plethora of training courses were followed in the areas of professional knowledge, competencies and safe working practices. Apart from that, there were also a number of personal coaching programmes. Wherever possible, we have made use of subsidies through the OOM foundation to achieve this.

Structural and incidental conversations take place between managers and employees, and the human resources is involved when needed. These conversations focus on the performance and development of the employees. In 2020, a new Conversation Module was developed for this purpose and implemented in early 2021. The WHTV conversation is key in this respect. Focusing on Job Satisfaction, Attitude, Job performance and Professional knowledge (Werkgeluk, Houding, Taakuitvoering en Vakkennis).

We respect human rights. Among other things, a ban on discrimination has been included in the staff regulations, complaint procedures have been drawn up and confidential counsellors are on hand. The rights of employees are respected by enforcing the CLA, the Staff Regulations and the Compliance Programme.

In the Compliance Programme, procedures have been laid out for our way of handling issues, codes of conduct have been introduced and a Compliance Manual has also been drawn up. With these, we want to prevent corruption and make sure that we do business fairly according to the rules. For advices or to report problems, a whistle-blower’s scheme has been set up. Training courses on the subject of compliance are held on a structural basis for key functionaries.

No complaints were filed in 2021 concerning working conditions or work discrimination. The confidential counsellor was not consulted in 2021.

In the chain assessment of suppliers, we also assess the aspect of human rights, specifically child labour and working conditions.

“Care for people and the indoor climate”

How do I provide ventilation for a sustainable residential/care complex with 65 apartments?

We have the answer.

R-Vent Dampdicht (vapour-free) insulated pipes and accessories fitted with R-Vent Safe. This prevents any unnecessary loss of temperature and leakage of air. Combined with an energy-efficient HRV system that works in conjunction with the heat pump.

In the heart of the village of Peize, in a rebuilt, characteristic farmstead, you can find the De Hoprank care complex with several forms of living, service and care under one roof.

Since March 2020, construction company Roosdom Tijhuis, commissioned by Interzorg, has been building this new, sustainable building with 65 apartments and communal areas. The ventilation system is made up of air handling units (AHA units) with an HRV coupled to a heat pump.

Care centre De Hoprank is intended for short-term or permanent residence, for day care or intensive care. One of the advantages that De Hoprank offers is that its residents can stay living there (as long as possible), even when their care needs change. Right in their own familiar surroundings. Of course, a good building with a healthy indoor climate is also an essential part of this!

Cooperation between the supplier and the installer for the right solution.

Van der Weerd Installatietechniek from Franeker asked Bergschenhoek Luchtcomfort to help come up with ideas for this project. Due to the sustainability requirements, the use of an HRV system in combination with a heat pump, and its control by the building management system, several challenges arose during the design phase. Thanks to good communication and coordination, this ultimately led to a wonderful overall design for the ventilation system. From the AHA units to the complete duct system.

In De Hoprank care complex, a variety of R-Vent products have been used, which have been seamlessly integrated in the design phase by the R-Vent engineering department. This meant that not only was the construction of the unit by Installatietechniek Van der Weerd and the assembly by Friamco B.V. possible within a short space of time, but the careful design ultimately also contributes to the optimum functioning of the entire ventilation system in combination with the other systems in place.

For example, one of the R-Vent AHU units is mounted on the roof and synchronised with the heat pump system.

R-Vent Safe components were used to ensure that the ventilation system is energy-efficient and quiet.

This made it easy to make all connections of the system airtight. This also involved using R-Vent vapour-proof insulated pipes and accessories to prevent condensation. The result is that with as little energy as possible and a low level of noise production, each room has its own separate intake and extraction of ventilated air. Important for a comfortable stay for both residents and care staff.

The first 20 apartments of De Hoprank were handed over in March 2021. Once De Hoprank is finished, there will be a new, sustainable building with 65 apartments and communal areas where it is a pleasure to meet each other.

CO2 Footprint Bergschenhoek Groep scope 1&2 in kilotonnes

n this chapter, we set out our environmental performance over the year 2021.

We are conscious of our footprint and have taken measures to minimise it. On the one hand, we have focused on conserving energy by using energy-efficient resources and dealing with energy conscientiously, and on the other hand by relying on sustainable energy sources (through the purchase of European and Dutch guarantees of origin (wind)). Thanks to the installation of solar panels, we generated 214,060kWh of our own energy.

The total CO2 emissions scope 1 & 2 have risen in 2021 in comparison to 2020, despite the reduction in emissions from lease cars, due to the expansion of our activities and increase in turnover, but also because of the increase in the percentage of gas consumption. Calculated in terms of turnover, CO2 emissions were reduced by 22%, calculated in terms of employees, CO2 emissions were reduced by 0.2 tonnes.

Bergschenhoek Groep

The Bergschenhoek Groep falls under the audit requirement as stipulated in the European Energy Efficiency Directive (EED). As a follow-up to 2017, another EED audit was carried out at R-Vent Netherlands and KWT in the year 2020. BCT has no EED audit requirement because BCT submits reports using the CO2 performance ladder.

On the basis of the audits, an energy savings potential was drawn up for each company/branch. It made us aware of which measures can be applied in the production process, including behavioural and organisational measures that require minimal/no investment, which have subsequently been put into practice. In addition, the decision to make resources more sustainable was made at times that came naturally. This has helped to lower our footprint.

On the basis of the 2020 audit, measures have been drawn up to be able to analyse the gas and electricity burden profiles in more detail in the future, whereby further opportunities for savings may be achieved. On average, there are no company-specific measures that have a high potential. That said, we will continue to look for further opportunities to save energy.

The lease vehicle fleet of the Group is being made more sustainable by regularly adjusting the CO2 emissions per standard for new vehicles, within the scope of the market.

From 2021 onwards, efforts have been made to provide fully electric lease cars for passenger transport.

The number of fully electric cars has grown in 2021. The total emissions from the lease vehicle fleet in 2021 for Dutch companies are lower than in 2020. The average emissions in 2021 per lease car is 4.6% (2020: 5.75%). The average emissions per lease car were reduced by 1.15 tonnes of CO2

In 2022, a plan for making our buildings more sustainable will be drawn up on the basis of a maintenance audit and sustainability scan.

No environmental incidents occurred in 2021.

Overview CO2 Footprint 2021 Bergschenhoek Groep B.V.

Overview CO2 Footprint 2021 Bergschenhoek Civiele Techniek B.V.

Overview CO2 Footprint 2021 R-Vent Netherlands B.V.

5.3 Total overview CO2 footprint scope 1 and 2

5.4 CO2 emissions from the purchase and sale of goods CO2 emissions are purchase and/or sales-turnover related (distance, type of products, quantity)

With the addition of activities and an increase in production turnover, the percentage of waste has risen. 2021: 507,475 kg waste (2020: 413,500 kg). By separating waste more carefully, a significant growth has been achieved in the percentage of waste suitable for recycling. 2021: 83% (2020: 71%).

Within the Group, an LCA has been established for the products corrugated steel SPIROsol pipes and ROwat plastic sheet piling, which are available via the National Environmental Database. Sustainable products have been added to the range.

Steel products are recyclable, this also applies to our sustainable plastic products. Many of our products can also be used for other purposes or refurbished over the course of time. For this reason, certain products are also taken back after their technical service life. We comply with the legal requirement concerning e-waste for electrical appliances at R-Vent, through Wecycle. Products that we put on the market are consequently recycled in a responsible way.

Most of the water consumption is attributable to household water use. KWT consumed in the production process water (spray welding), working at home due to COVID-19 is likely to have an influence on the reduction of the average household water consumption.

The most sustainable form of packaging is no packaging at all. Many of the products are suited to being marketed without packaging, but not all of them. Packaging is needed to conserve and protect products, to transport products safely or to provide customers with information regarding the products.

The materials we offer in packaging are supplied in recyclable material such as cardboard and LDPE and VCI packaging foil. We notice that there is an increasing need for packaging for specific products, e.g. for keeping pipes dust-free or providing protection against corrosion. No packaging is collected. The packaging that is used is easy to sort and dispose of or reuse.

NB: The water consumption of Bergschenhoek Groep B.V. is incorporated in the water consumption of R-Vent Netherlands B.V.

In this chapter, we set out our economic performance over the year 2021.

The Group does not report on financial results in the annual social report. The financial results are reported in a consolidated annual financial report and filed with the Netherlands Chamber of Commerce in accordance with Dutch law.

The turnover in 2021 compared to 2020 grew by 22.2%.

The purchase volume of the businesses is categorized into machinery and equipment, raw materials for production (including metals, plastics, rubber, PUR), trade goods, packaging materials, services and miscellaneous materials such as office supplies, personal protective equipment, workwear, automation tools, etc.

We are aware that the origin of purchased goods is important and believe that our suppliers should also have a sound CSR policy in place.

When purchasing from countries outside the EU, Iceland, Norway, Liechtenstein and Switzerland, prior to a potential transaction there is a procedure for a legal check to be carried out to ascertain whether the sanction policy of the European or US government is being followed. There was no need for a check in 2021.

In order to ensure that the CSR values of the Group are upheld in the supply chain, suppliers have been asked to endorse and comply with the Suppliers Code of Conduct for CSR Bergschenhoek Groep (Suppliers Charter). In the period 2015-2020, a large percentage of suppliers (83-87%) signed this code of conduct.

In the Suppliers Charter, attention is called for:

• Conducting business fairly and honestly

• Improving social, ethnic and environmental aspects

• Employees’ rights

• Health and safety in the workplace

• Environmental conservation

• CO2 emissions

• Compliance with legal requirements

A CSR audit questionnaire is used to assess the extent to which our suppliers comply with the code of conduct, which forms part of the supplier assessment. Suppliers are audited on a regular basis.

The products produced and marketed by the Bergschenhoek Groep companies also contribute to a healthy living environment and ecology.

• Healthy indoor climate (R-Vent Netherlands B.V.)

• Surface water management (KWT Waterbeheersing B.V.)

• Water storage (BCT B.V.)

• GWW sustainable solution (BCT B.V.)

Customer satisfaction

Customer satisfaction is monitored by the operating companies in a number of ways. Feedback from customers is taken to heart and included in the process discussions so that services can be improved.

The shareholders of the Bergschenhoek Groep set up the RoFa Foundation in 2011 and provide financial support on an annual basis. The RoFa Foundation bears a great deal of social responsibility and the businesses indirectly make their contribution to this. The RoFa Foundation has a great deal of social responsibility and the companies are indirectly contributing their share to this.

Because children are the future!

In 2020, ambassadors from various Bergschenhoek companies signed up with the RoFa Foundation. It was limited to a first meeting on account of COVID-19. We will further define the role of the ambassadors this year. With the help of the ambassadors, we want to further shape the cooperation between the RoFa Foundation and the Bergschenhoek companies and hoped to be able to start with that in 2021. For more information: www. rofafoundation.nl

The long-standing support for the SOS Sovata Foundation has also been continued in 2021. In addition, the Bergschenhoek Groep offers its companies the opportunity to sponsor local social initiatives. Applications are assessed on the basis of the CSR policy and relevance. In many cases, the sponsorship activities are sports-related. Such as the long-standing main sponsorship of B.V.C.B., Bergschenhoek football club and the sponsorship of the local football clubs in Staphorst and Biddinghuizen.

Within the Group, an active subsidy policy is pursued. For development, training courses (OOM foundation), a reimbursement of wage costs and a refund of the severance pay were received in the 2021 subsidy reporting year.

In addition, an EIA subsidy has been received for LED lighting and HR heaters.

Each company in the Group has established its own challenges for 2022 in the annual plan and outlined these in the CSR report. These plans are based on the multi-year strategy for the CSR policy approved by the management board of the Group.

Challenges can be found in all CSR areas of People, Planet, Profit and the SDGs. Making an important contribution to a healthy indoor climate with our high-quality products on the basis of our mission and vision.

People

Working conditions

Inclusive organisation

Knowledge development and retention

Planet

CO2 neutral entrepeneurship (scope 1&2)

We ensure that there is a healthy indoor climate, good working conditions and terms of employment that focus on the sustainable employability and job satisfaction of our employees.

We pursue an active personnel policy aimed at diversity and inclusion.

We pursue an active policy of developing knowledge for 3-5 years.

Reduction in emissions

Making the delivery and supply chain sustainable

Reduction in water consumption

Reductie of waste streams (refuse, reduce, reuse, recycle)

Making buildings sustainable

Circular production and business

We reduce our emissions and compensate them where we are (not yet) able to reduce them to 0.

By 2030, emissions from the lease vehicle fleet will be zero, and emissions from machinery, equipment and transport will be reduced by 50% compared to 2022. And for energy use, efficiency is to reduce CO2 emissions in the delivery and supply chain by 50% by 2030, on the basis of the opportunities within the EED.

We are putting plans in place to reduce CO2 in the chain by 50% by 2030.

We will set targets to reduce household water consumption.

Our waste streams from production and trade will be circular by 2030

We are drawing up plans to make the buildings fully sustainable by 2030.

By 2030, 50% of the products we sell will be circular.

This report contains Information Elements from the GRI Sustainability Reporting Guidelines. The cross-reference table, chapter 9, shows which GRI indicators have been incorporated into this report. The report has been internally reviewed and not verified externally.

This report has been based on the annual social reports of the following businesses (100% subsidiaries) in the Netherlands that fall under the Bergschenhoek Groep B.V:

• Bergschenhoek Civiele Techniek B.V.

• KWT Productie B.V.

• KWT Waterbeheersing B.V. / KWT Productie B.V.

• R-Vent Netherlands B.V.

Occasionally, other businesses are also included in the reporting. This is then explicitly stated.

For any questions or comments about this Social Report, please contact Corine Rook, CEO Bergschenhoek Groep B.V. (c.rook@brghoek.nl).

G4-28

G4-EN16 G4-EN19

Direct greenhouse gas emissions (Scope 1), by weight

Indirect greenhouse gas emissions from energy (Scope 2), by weight

G4-DMA

G4-LA4

G4-DMA

G4-LA5

G4-LA6

G4-LA7

Total number and rate of employee turnover per age group, gender and region

Benefits provided to full-time employees that are not available to part-time employees, per significant business location

Return to work and retention percentages after parental leave, per gender

and

G4-LA8 3.3 Health and Safety

G4-DMA

G4-LA9

G4-LA10

Percentage of total workforce represented in formal joint management-worker occupational health and safety committees

Rates of injury, work-related illness, lost days and absenteeism and number of work-related fatalities, by region and per gender

Employees with a high risk or higher incidence of work-related illness

Agreements on occupational health and safety matters are laid down in formal agreements with

G4-LA11 3.4 Training and education

G4-DMA

G4-LA12

Average hours of training per year per employee per employee category Programmes for competency management and lifelong learning that assure the sustained employability of staff and help them to accomplish their career goals

Percentage of employees who are regularly informed about performance and career development

3.5 Diversity and Opportunities

3.7 Chain assessment on working conditions

Percentage of new suppliers/parts of the supply chain that have been assessed on the basis of the working conditions criteria

G4-HR2 3.9 Investment and procurement policy

Percentage of total number of significant investment agreements which contain human rights clauses or where compliance with human rights has been verified. Total hours of staff training on policy and procedures

that the right to exercise freedom of association and collective bargaining may be at significant risk, as well as the measures which have been

G4-DMA G4-HR5 3.12 Child labour Activities in which a significant risk of cases of child labour is ascertained,

G4-DMA

G4-HR6 3.13 Forced and compulsory labour

Activities in which a significant risk of cases of forced or compulsory labour has been ascertained, as well as the measures that have been taken in order to eradicate forced or compulsory labour 6.2

G4-DMA

G4-HR9 3.16 Assessment

Total number and percentage of the activities that have undergone a human rights assessment as well as an impact assessment 6.2

G4-DMA

G4-HR10

G4-HR11 3.17 Chain assessment on human rights Percentage of new suppliers/parts of the supply chain that have been assessed on the basis of the human rights criteria Actual and potential significant negative impacts on human rights in the supply chain, and measures taken

G4-DMA

G4-HR12 3.18 Human rights complaints procedures

Number of complaints concerning human rights that have been submitted, handled and resolved through formal complaints procedures 4.5

Civil society

G4-DMA

G4-SO1 3.19 Community

The nature, reach and effectiveness of all programmes and methods that determine and manage the impact of activities on communities, including the location, activities and exits

G4-DMA

G4-DMA G4-S07

Total value of financial and in-kind contributions to political parties, politicians and related institutions per country

G4-DMA

Chain assessment on the impact on the community

Percentage of new suppliers/parts of the supply chain that have been assessed on the basis of the working conditions criteria

Complaints procedures for the impact on the community

Monetary value of significant fines and total number of non-monetary sanctions for failure to comply with laws and regulations

Type of product and service information that is required to be provided for procedures and the percentage of significant products and services subject to any such information requirements

3Ps People, Planet and Profit is the mix of three elements that, to a greater or lesser extent, give a company its CSR label. The prerequisite is that they are fully in balance. If they are not in balance, other elements will suffer from the dominant element. If, for example, the main focus is on the generation of turnover, this will then be at the expense of the employees and the environment. The 3 Ps were devised by John Elkington, a consultant in sustainable development.

GDPR General Data Protection Regulation

“Bergschenhoek” The Bergschenhoek Groep companies

Bergschenhoek Groep B.V. Holding company

BCT Bergschenhoek Civiele Techniek B.V., subsidiary of Bergschenhoek Groep B.V.

ERT (BHV in Dutch) Emergency Response Team

CE marking

Many industrial product groups can only be traded in the European Economic Area (EEA) if they have a CE marking. CE marking certifies that the product complies with the legal requirements on safety, health and the environment

CLA Collective Labour Agreement

CO2 Carbon dioxide

CO2 Footprint

An overview of the CO2 emissions of the organisation arising from the use of fossil fuels for the organisation's own transport, electricity (indirect) and heating

CO2 performance ladder The Performance Ladder (level 1) encourages companies to be aware of their own CO2 emissions - and those of their suppliers - and (level 2) to constantly seek out new opportunities to reduce emissions resulting from their own business operations and projects. The ladder then motivates companies to implement these measures (level 3) and (level 4) to share the knowledge they have gained in a transparent way and (level 5) to actively search for ways to further reduce emissions together with colleagues, knowledge institutions, civil society organisations and governments. The CO2 performance ladder fosters the aspirations of businesses to actively reduce CO2 by means of a notional bonus (up to 10%) when tenders are selected, which in turn recognises their sustainability efforts

Corrugated Steel Pipe Institute International association of corrugated steel pipe manufacturers

COVID-19 is an infectious disease caused by a new strain of coronavirus.

Cox Geelen Cox Geelen B.V., a former subsidiary of Bergschenhoek Groep B.V.

the Group Bergschenhoek Groep B.V. and its subsidiaries in the Netherlands (operating companies/ businesses)

SE Sustainable Employability

The Sustainable Supplier the platform for organisations that want to conduct business in a safe and responsible manner

EED European Energy Efficiency Directive (2012/27/EU)

EIA Energy investment allowance (EIA)

Envaqua the trade association representing ambitious water and environmental technology companies

ESF European Social Fund

Federatie dunne plaat (Netherlands Thin plate Federation) A chain organisation in the field of metal plating.

FME Organisation for entrepreneurs in the technology industry

GRI Global Reporting Initiative

KAM Kwaliteit - Arbeid - Milieu in Dutch Quality control - Occupational health and safety - Environment

The Netherlands Royal Metal Union Entrepreneurs' organisation for small and medium-sized enterprises in the metal industry

KOMO KOMO is an independent non-profit foundation and was established in 1962. The purpose: to make the flow of construction work clear and the quality of construction and infrastructure transparent. KOMO does this by issuing certificates after it has been ascertained objectively and by external, independent experts (accredited certification bodies) that a product, realisation process or service continuously satisfies the requirements as stipulated in a relevant Assessment Directive (BRL in Dutch) which was agreed upon in advance with all parties.

KWT KWT Waterbeheersing B.V. and KWT Productie B.V., subsidiaries of Bergschenhoek Groep B.V.

LCA Life cycle analysis of a product

LUKA Nederlandse Vereniging van Luchtkanalenfabrikanten (Netherlands Association of Air Duct Manufacturers)

CSR Corporate Social Responsibility

Nederlands Water Partnership (NWP) is a network of internationally oriented Dutch organisations working in the water sector.

NEVI knowledge network for procurement, contract and supply management

PEFC Programme for the Endorsement of Forest Certification schemes. It is an international independent quality mark for the promotion of sustainable forest management.

PME Pensioenfonds Metaal&Techniek (Metal & Tech pension fund)

PZ Human resources

R-Vent R-Vent Netherlands B.V., a subsidiary of Bergschenhoek Groep B.V.

RI&E Every employer must have an occupational health and safety policy. The basis of this policy is formed by the Risk Inventory and Evaluation (RI&E). The RI&E is a list of potential risks. With this list, companies can map out which risks they encounter in their own company.

Scope 1

Scope 2

Scope 3

Scope 1, direct emissions, are emissions generated by the organisation itself, such as emissions from its own gas consumption and emissions from its own vehicle fleet

Scope 2, indirect emissions that arise from the generation of electricity that the organisation uses, such as emissions from power plants that supply electricity. The CO2 performance ladder includes business air travel and business use of a private car up to scope 2

Scope 3, indirect emissions of CO2 arising from the business activities of another organisation. These concern emissions from sources that are not owned by the organisation and over which it has no direct control. For example, emissions caused by the production or extraction of purchased raw materials or materials and outsourced activities such as goods transport. Also, the indirect emissions as a result of business-related travel with private vehicles and business air travel fall within scope 3.

SDG The 17 Sustainable Development Goals 2030 of the United Nations

IKN Foundation A partnership that aims to gather, organise and share knowledge about the waste water chain

VCA** SCC stands for Environment, Health and Safety (EHS). With an SCC certificate, the company lays the foundation for working in a safe and healthy way every day.

VLA Vereniging leveranciers van Luchttechnische Apparaten (Association of Suppliers of Air Technology Equipment)

Operating companies Subsidiaries of Bergschenhoek Groep B.V.

WHTV conversation Conversation about Job Satisfaction, Attitude, Job performance and Professional knowledge

Boterdorpseweg 10, 2661 AC Bergschenhoek

Postbus 45, 2650 AA Berkel en Rodenrijs

T: (010) 524 26 00

E: info@brghoek.nl

I: www.bergschenhoek-groep.com

© No part of this publication may be reproduced without written permission. No rights can be derived from the contents in this publication. Bergschenhoek Groep B.V., May 2022