DIFFERENT TYPES OF GEARS & THEIR APPLICATIONS

When pair of these components are fitted ogether, they are put to use in a process that transfers rotations and powers from the driving shaft to the determined shaft. The historical background of gears is ancient, and Archimedes refers to their use in ancient Greece in the BC years.

A gear is a specific mechanical component that may be identified by its teeth carved around a surface that is either round, hollow, or cone-shaped and has comparable dispersing.

5

1. MITRE GEAR Thesearethemostfundamental typeofbevelgears,andtheirspeed ratiois1.Theycanswitchthe directionofpowertransmission withoutaffectingthetransmission rate.Theymayhavealinearor helicalconfiguration.Sinceit generatesthrustforceintheaxial direction,spiralmitregear typicallyhasathrustbearing attachedtoit.Angularmitregears arethesameasstandardmitre gearsbutwithshaftanglesthatare not90degrees.

2.SPUR GEAR Parallelshaftsareusedto deliverpowerusingspurgears. Alloftheteethonasetofspur gearslieinastraightlinewith respecttotheshaft.Whenthis happens,thegearsgenerate radialreactionloadsonthe shaftbutnoaxialloads. Spursareoftenlouderthan helicalgearsoperatingwitha singlelineofcontactbetween teeth.Whenonesetofteeth makescontactwiththemesh, theothersetofteeth acceleratestowardthem.The torqueistransmittedmore smoothlyinthesegearsas severalteethmakecontact.

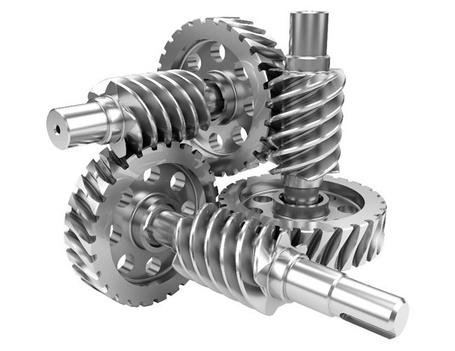

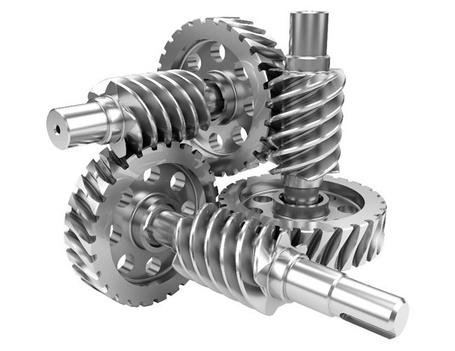

The bevel has a pitch surface shaped like a cone and has teeth running along the side of the cone. These are used to transfer force between two shafts in a system. They are arranged in the following categories: helical bevels, hypoid gears, zero bevels; straight bevels; and mitre.

Spurs are often louder than helical gears operating with a single line of contact between teeth. When one set of teeth makes contact with the mesh, the other set of teeth accelerates toward them. The torque is transmitted more smoothly in these gears as several teeth make contact.

3.BEVEL GEAR

4.HERRINGBONE GEAR Theoperationofa herringbonegearcanbe comparedtothatofkeeping twohelicalgearstogether. Therefore,anothernameforit isadoublehelicalgear.Oneof thebenefitsofthisisthatit offersprotectionagainstside thrust,incontrasttohelical gears,whichcausesidethrust. Thisparticulartypeofgear appliesnothrustforcetothe bearings. Spursareoftenlouderthan helicalgearsoperatingwitha singlelineofcontactbetween teeth.Whenonesetofteeth makescontactwiththemesh, theothersetofteeth acceleratestowardthem.The torqueistransmittedmore smoothlyinthesegearsas severalteethmakecontact.

5.INTERNAL GEAR These pinion wheels join with outer cogwheels and have teeth carved into cylinders and cones. These are used in gear couplings. Involute and trochoid gears have various internal and outer gears to manage problems and impedance. Bolton Engineering Products Ltd brings you a range of gears in the UK, be it spur gears, mitre gears, bevel gears, and so on. Spursareoftenlouderthan helicalgearsoperatingwitha singlelineofcontactbetween teeth.Whenonesetofteeth makescontactwiththemesh, theothersetofteeth acceleratestowardthem.The torqueistransmittedmore smoothlyinthesegearsas severalteethmakecontact.

ALLMAINS SERVEDWITH BOTTOMLESS ICEDTEA www.bepltd.com/collections/metric-spur-gears-supplier-uk BUSINESS ADDRESS: UNIT 5 PEAKS PLACE BUSINESS PARK, ROSSINI ST, BOLTON, BL1 8GJ, UNITED KINGDOM