SMARTER transformation

by

The Launch of the Mass Timber Centre of Excellence

It’s time to rethink what Scottish timber can do

Accelerate to Zero Beacon: Robert Hairstans, Edinburgh Napier University & NMITE

by

The Launch of the Mass Timber Centre of Excellence

It’s time to rethink what Scottish timber can do

Accelerate to Zero Beacon: Robert Hairstans, Edinburgh Napier University & NMITE

There’s rarely been a quiet day since we launched BE-ST a little over ten years ago. Yet recently, the scale and complexity of the projects and programmes we deliver with our partners has grown significantly. Many are leaning further into the challenges presented by the climate crisis, accelerating the pace of change they want to see happen. Others are leaning out, questioning whether the journey to net zero is as urgent as the post-COP26 political landscape would have had us believe.

At BE-ST, we like to deal in facts, robust evidence, and sound data. We trust the science. We read (a lot) and we try to understand how, in the context of a constantly shifting geopolitical landscape, we can support organisations of all shapes and sizes deliver a smarter transformation to a more sustainable, more affordable, better built environment. This is what our brand reflects. Built Environment-Smarter Transformation isn’t just a name. It’s the journey we’re on together. And when going on a journey, it’s often handy to have a guidebook with you.

That’s why we thought now was the right time to launch Smarter Transformation – a magazine dedicated to establishing the facts, exploring the evidence, and presenting the data, so we can build on a decade of projects, programmes, and partnerships, to help accelerate our smarter transformation to the better built environment we need.

In this, our first issue, we explore Scotland’s innovation potential as the UK’s Mass Timber Centre of Excellence, which could, if enabled effectively via sensible policy alignment, put Scotland at the forefront of a sustainable buildings revolution, bolster our local economies, create new workforces and supply chains, and deliver much needed public and private infrastructure at speed and scale, all the while impacting positively on the planet too. We hope you find it insightful.

Looking ahead, Smarter Transformation will tackle other key themes – the housing emergency, retrofitting our existing buildings, creating a competent workforce of the future, is it fabric first or fifth, and much, much more. And we need you to get involved too, contributing stories, news, solutions, and ideas to make this magazine as useful and insightful as possible as it grows into an essential guidebook, an almanac if you will, of best practice as we take the built environment on a smarter transformation. Enjoy.

STEPHEN GOOD, CEO

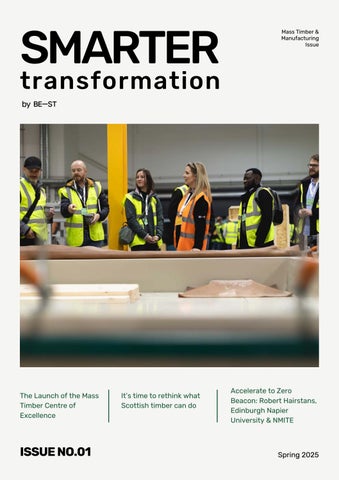

The UK’s built environment has taken a step forward with the launch of the Mass Timber Centre of Excellence, led by Built Environment - Smarter Transformation (BE-ST). This cutting-edge facility, housed at BEST’s Innovation Campus, is set to transform the industry by accelerating the adoption of homegrown mass timber solutions, fostering sustainability, and strengthening local economies.

By adopting UK-grown mass timber in construction at scale, we can strengthen the forestry and timber industry, create jobs, reduce reliance on imports, increase sustainable delivery of the built environment and reduce carbon emissions generated by the construction sector.

Mass timber is a group of engineered wood products created by compressing layers of wood to form large structural elements such as panels, beams, and columns.

The production of mass timber products not only generates less carbon than traditional construction materials such as steel or concrete but also supports the capture and storage of carbon dioxide in the built environment via the raw timber materials used in the process.

With £1.5 million invested in state-of-the-art equipment, the Centre is home to the most advanced mass timber production facility in the UK. It offers full-scale production capabilities for various mass timber products, including:

Cross Laminated Timber (CLT)

Nail Laminated Timber (NLT)

Glue Laminated Timber (Glulam)

Glued Laminated Timber Panels (GLT-P)

Nailed Cross Laminated Timber (NCLT)

At the heart of the Centre’s operations is the largest commercially available CNC machine in the UK, providing unparalleled precision and efficiency in timber manufacturing. The factory is anticipated to have an annual manufacturing output capacity of approximately 8,000m³ once fully operational.

The built environment is responsible for 40% of annual global emissions, with 27% being generated during the operation of buildings and 13% from construction and demolition. The Mass Timber Centre of Excellence aims to position the construction sector as part of the solution to reducing these emissions.

Mass timber significantly reduces the carbon footprint of buildings by using timber, which sequesters carbon as it grows and generates fewer emissions in its production than traditional materials like steel and concrete.

When managed sustainably, timber is also a naturally renewable resource that supports a circular economy and enhances biodiversity when sourced responsibly.

The Centre also seeks to strengthen the UK’s onshore timber economy by encouraging the use of homegrown timber, reducing reliance on imports.

Currently, the UK imports around 73,000m of mass timber per year. By creating higher-value timber products in the UK, such as mass timber, we can unlock significant economic and environmental benefits.

By investing in homegrown, sustainable, manufactured products for the sector, the UK can create new jobs across forestry, manufacturing, and construction, ensuring a skilled workforce for the future.

“By investing in mass timber, we are not just advancing low-carbon approaches to construction, we are also investing in economic growth, creating jobs, and addressing some of the UK’s key challenges.”

Sam Hart, Associate Director of Manufacturing and Housing at BE-ST

The Centre is more than just a manufacturing hub - it is a collaborative space for industry and academia. By working with experts in systems design, product approvals, and regulatory compliance, the Centre is here to help businesses develop innovative timber solutions for accommodation, public infrastructure, and commercial buildings. It will also be offering training and upskilling opportunities in mass timber manufacturing.

By scaling up the use of mass timber, the UK can transition towards a built environment that is lower in embodied carbon, more cost-efficient, locally sourced, higher-quality and sustainable.

The Centre offers a number of services:

Mass Timber Manufacturing: Full-scale production using the UK’s most advanced equipment.

Systems Design Support: Collaborative research with industry and academic experts.

Consultancy Services: Guidance on product approvals, regulations, and manufacturing processes.

Timber Processing: Partnering with trusted experts for felling, grading, kilning, and planing.

Training & Skills Development: Hands-on workshops to upskill the construction workforce.

Get involved

The Mass Timber Centre of Excellence is inviting businesses, policymakers, and construction professionals to explore the opportunities mass timber can offer, from adopting or manufacturing mass timber components or taking part in our skills programmes.

Get in touch to learn more about how we can support at hello@be-st.build

“The launch of this Centre will support the wider adoption of mass timber, helping to reduce carbon emissions, strengthen supply chains, and deliver much-needed non-domestic buildings and public infrastructure, such as schools, in a more efficient, less costly, higher quality, and lower-carbon way”

Lynsey Brydson, Director of Impact Programmes, BE-ST

Robert has been a leading figure in timber innovation and offsite construction throughout his career which spans both academia and industry. He has a dual role as both Director of the Centre for Advanced Timber Technology at the New Model Institute for Technology and Engineering (NMITE) and Professor of Offsite Construction and Innovative Structures at Edinburgh Napier University. Most recently Robert has taken on the role as lead for EDI, Skills and Training in the Centre for Net Zero High Density Buildings, a UKRI funded Green Economy Centre hosted by the University of Edinburgh.

His commitment to bringing academia and industry together has significantly advanced research in timber innovation and its applications in the construction industry and skills development. In 2023, this dedication was recognised with a Beacon Award at the BE-ST Accelerate to Zero Awards to acknowledge his contributions to the built environment and his strong support of BE-ST over the years. In 2024 he was also awarded the Structural Timber Pioneer Award and the Offsite Pioneer Award.

CEO of BE-ST, Stephen Good, said that Robert was awarded the Beacon Award for being “a major contributor and collaborator for truly impactful research and innovation.”

Robert’s journey into timber construction began with his first job at Oregon Timber Frame in the Scottish Borders. Through a Knowledge Transfer Partnership (KTP), he worked as a research engineer while pursuing his PhD at Edinburgh Napier University in the optimisation of timber platform frame construction. This experience of simultaneously undertaking academic research and industry practice laid the foundation for his approach to integrating innovation with real-world applications throughout his career.

“We were constantly facing this uphill battle of the perception that Scottish timber is low grade, not usable, twodimensional and unstable. But we’ve proven that’s simply not true.”

COP26 Homegrown Demonstrator

Recognising the value of the KTP model, Robert has continued to champion similar industry-academia partnerships. His work with BE-ST mirrors this through various collaborations lead by Robert between BE-ST, ENU and more recently NMITE to drive research and innovation in collaboration with industry partners while mentoring new talent to accelerate their careers.

Robert has been at the forefront of demonstrating the feasibility of Scottish timber for construction much of which has been recently accelerated via the BE-ST-led Transforming Timber project – a collaborative knowledge hub promoting the use of homegrown engineering and mass timber.

Through collaboration with forestry experts, sawmillers, and researchers, the project has successfully demonstrated that Scottish-grown timber can meet the necessary strength classifications and be used in mass timber products like cross-laminated timber (CLT). The success of this work has led to the commercialisation of UK mass timber, proving that a homegrown, sustainable timber supply chain is possible.

According to Robert, this use of timber has the potential to be a game-changer for both the construction and forestry industries. It helps to reduce carbon emissions by increasing the use of locally sourced timber, it creates jobs and economic growth within Scotland’s forestry sector and enhances sustainability by using a renewable, low-carbon material in construction.

One of NMITE’s collaborative initiatives with BE-ST has been the Timber Technology Engineering Design (Timber

These came about when Robert and his team identified a critical gap in skills and knowledge for timber construction professionals, leading to the development of a competency framework in partnership with key industry bodies such as Timber Development UK and the Structural Timber Association with funding support from the Housing Construction and Infrastructure Skills Gateway.

The TED 1 and TED 2 courses were designed to introduce timber technologies, sustainability principles, and practical design challenges to learners. TED 1 focuses on foundational concepts, while TED 2 builds on knowledge gained in the first course with more advanced timber construction and engineering principles.

The learners on these courses came for diverse backgrounds at different stages of their careers, something which is important to Robert as it provided an opportunity for the learners to learn from each other as well as the academic team and industry partners.

Student cohorts consisted of architects, architectural technologists, engineers and pre-construction managers from the length and breadth of the country.

“Timber TED provides some of the key learning for the use of timber technologies in construction - looking at why timber is a material choice, what you have to think about in terms of utilisation, what that looks like in terms of delivery, and how you take that and apply it into practical design challenges.”

As the sector evolves, Robert sees an urgent need to expand the portfolio of training programmes like Timber TED to meet growing industry demands.

The importance of collaboration in the built environment

Robert firmly believes that collaboration is critical to the future of construction and the built environment. He highlights the importance of cross-sector collaboration in research and policy development.

“When you think of the supply chain, vertically and horizontally, all of the actors in play - you can only get to a point of success if there’s collaboration, trust, and partnership through that process.”

Robert sees collaborative procurement models and whole-life value approaches as the future of low carbon construction, ensuring that projects are not just delivered efficiently but perform optimally throughout their lifecycle.

For those interested in entering the field, Robert encourages seeing construction as a profession of the future. He wants to shift perceptions and attract individuals who are passionate about tackling climate challenges.

“Construction as a career has so many opportunities within it and shouldn’t be viewed as something you do if you can’t do something else. It should be up there with professions like medicine and law in terms of what you can achieve for society.”

He highlights the growing need for holistic knowledge and interdisciplinary skills, emphasising sustainability, embodied carbon, digital tools, and industrialised construction techniques. Future professionals will need to understand embodied carbon and whole-life performance of buildings, digital skills, interoperability, digital twins, manufacturing and off-site construction methods.

Robert also stresses that innovation in construction must be paired with new skills and educational programs.

“There’s a lot of work that needs to be done through research and innovation, but we must underpin that with the education and skills necessary to deliver that change.”

The future of timber construction and policy roadmaps

Looking ahead, Robert and his team are focused on aligning their research with the Timber in Construction Roadmap. Their priorities include scaling up the use of timber in construction to support net zero targets, addressing supply chain challenges and adapting to climate change impacts on forestry and furthering research into innovative timber products and their accreditation for widespread use.

Robert’s work demonstrates that timber has a vital role in the future of low carbon construction. Through a combination of research, education, industry partnerships, and policy engagement, he is pushing boundaries and driving systemic change.

His Beacon Award recognition is a testament to his impact, but for Robert, the real success will come when timber is fully integrated into mainstream construction, delivering low-carbon, highperformance buildings that benefit both people and the planet.

“There’s a lot more to do, but we’ve built a strong foundation. Now it’s time to scale it up.”

A consortium of leading timber technology organisations, including Built Environment – Smarter Transformation (BE-ST), the New Model Institute for Technology and Engineering (NMITE) in Hereford, and the University of Edinburgh, advanced a project to commercialise homegrown wood fibre insulation in the UK.

The primary focus of ‘Timber in Construction: Commercialisation of Homegrown Wood Fibre Insulation’ was to develop and validate English hardwood and softwood for use in the UK’s homegrown wood fibre insulation. By leveraging existing forestry and manufacturing supply chains, the project sought to increase the adoption of English-grown wood in construction, enabling a reduction in embodied carbon in the built environment.

Launched in October 2023, the project began with comprehensive desk-based research to review existing studies, identify knowledge gaps, and examine various factors such as tree species suitability, fire testing methodologies, and bonding agents. The findings from this phase informed the development of multiple wood fibre insulation formulations, which underwent rigorous testing, with a particular focus on fire performance.

"Our ultimate goal was to develop the best formula for UK-sourced wood fibre insulation. We wanted to demonstrate the feasibility of commercialising this sustainable solution, utilising the raw materials and expertise we had available to us. This not only presents a huge economic opportunity but also contributes to reducing embodied carbon in buildings and promotes the health attributes of wood fibre."

Robert Hairstans, Director for the Centre for Advanced Timber Technologies at NMITE

The UK possesses the renewable natural resources, internationally recognised expertise, and technical capabilities necessary to lead a sustainable and resilient approach to the built environment. Despite a 30% increase in wood fibre insulation revenues across Europe between 2020 and 2023, the UK currently does not have commercial manufacturers of wood fibre insulation. This project addresses this gap by developing the technical and quality assurance processes required for domestic production, thereby reducing reliance on imports and associated carbon emissions from transportation.

As of March 2025, the project finalised its outputs, including the final results on whether standardised wood fibre products could be manufactured from English woodland resources and their compatibility with large-scale manufacturing processes. These efforts aim to drive greater adoption of English-grown wood in construction, increase carbon storage within the built environment, and establish new supply chains for forestry and manufacturing.

Mateusz Sulkowski - Building from England's Woodlands:

Structural assessment of combined glulam utilising UKgrown hardwood timber.

Mateusz’s research focuses on the implementation of UK-grown hardwood with softwood to enhance the structural application of glulam. Three compositions of combined glulam made of beech, birch, and ash with Sitka spruce were examined to assess the structural improvements in bending strength and stiffness. Utilising hardwood in an effective and economical manner in the outer zones of glulam, where the tensile and compressive stresses are the greatest, allows for the enhancement of the mechanical properties of glulam.

The project is driven to promote the use of local homegrown timbers in the built environment and the expansion of healthy bio-diverse woodlands as a part of Wood into Management Forestry Innovation Funds.

The project addresses the relatively low use of homegrown hardwood timber in the built environment. Engineered wood products such as combined hardwood glulam can be one of many solutions to climate change. Increasing the use of wood in construction significantly contributes to removing carbon dioxide from the atmosphere and storing it during the building's lifetime, making glulam truly a sustainable product when sourced and utilised responsibly.

The alternative approach of combining hardwood and softwood together in glulam allows for a broader scope of application by improving the physical and mechanical properties of glulam. The enhancement of bending strength and stiffness allows for the design of larger beam span structures while utilising the precious material, which is wood, in a resourceful and economical manner.

The research examines whether glulam made of homegrown timber can be produced in accordance with relevant standards and industry best practices.

Confronting the production challenge of obtaining a sufficient adhesive bond strength between hardwood and softwood layers is a crucial milestone in obtaining a structurally feasible glulam.

The project demonstrates that incorporating hardwood into the glulam lamella combination, according to the EN 14080 requirements, indicated a boost in the structural integrity. The assessment of bending strength and stiffness properties indicated a substantial increase compared to regular homogenous softwood glulam. The results obtained in the research are proof of concept that combining hardwood and softwood brings potential challenges and vast opportunities to develop improved glulam. While the development of glulam has progressed through academic research, the scope of application of glulam within the built environment has become wider than ever. The emphasis on using sustainable materials is vast across the construction industry to reduce the impact of global warming. Therefore, the informed decisions made by architects and other consultants, supported by scientific research, are a vital part of achieving net-zero construction and reducing carbon footprint.

Partners Edinburgh Napier UniversityInstitute for Sustainable Construction Forestry Commission BE-ST

Social Bite, a charity and social business that aims to end homelessness, commissioned Ecosystems Technologies to deliver a new kind of housing for their Social Bite Village.

Social Bite, a charity and social business that aims to end homelessness, commissioned Ecosystems Technologies to deliver a new kind of housing for their Social Bite Village.

Ecosystems Technologies’ Nest House design utilises homegrown timber and offsite manufacturing techniques. Built as a completed module, it is delivered to site fully furnished using a “plug and play” system, meaning little onsite work is required. This form of modular construction offers a quick and efficient method of housing delivery, minimising on-site disruption.

Utilising homegrown timber in the Nest House has delivered significant value, both socially and environmentally. The structural components were manufactured from a combination of mass timber products and Scottish-grown cladding was installed to the external facades, all utilising local supply chains and a local workforce, which helps support local jobs and the Scottish economy.

Environmentally, the timber is sourced from responsibly managed and sustainable local forests, which remove carbon from the atmosphere, resulting in a building which is net zero carbon.

In providing accommodation for vulnerable and homeless people, this approach delivers a rapid and effective housing solution when compared to traditional construction methods.

To manufacture the mass timber components for the prototype, Ecosystems used the UK’s only vacuum press, found in BE-ST’s Innovation Factory alongside our other state of the art wood processing equipment.

“We believe that everyone, no matter their circumstances should be treated with respect and dignity, which these homes reflect in their design.”

Josh Littlejohn MBE, founder of Social Bite

The Nest House is a demonstrator for the new Social Bite Village proposed for South Lanarkshire to be delivered in Autumn 2025 and the Bill Sword Social Bite Recovery Village in Dundee in Spring 2026, to support people struggling with homelessness and addiction.

The Social Bite Village in South Lanarkshire will feature sixteen modular homes, including one for staff, and a community hub with shared living spaces and areas for group activities. Completion is expected around Autumn 2025. The South Lanarkshire Village will emulate the successful model of the Edinburgh Village, which has helped over one hundred residents since it opened in 2018.

The Dundee Village will consist of a 10-bed communal residence and 10 single occupancy houses, as well as a communal hub. The village will be a therapeutic community, encouraging socialisation and facilitating skills training through recovery services and personalised support to help residents who are struggling with addiction.

The prototype was unveiled inSt Andrews Square, Edinburgh, in November 2023 as part of Social Bite’s Festival of Kindness, was subsequently presented at Gleneagles Hotel and has been showcased at BE-ST since early 2024.

This is not the first Social Bite Village, with Social Bite having delivered eleven houses in Edinburgh in partnership with the team behind Ecosystems and Cyrenians in 2018. The Village initiative combined an innovative housing model with a supported community environment.

Social Bite is currently raising funds to support the delivery of their next two villages in Scotland.

How do we change the long-standing cultural misperception around building with Scottish timber? This is the question we have been trying to answer for the last ten years with our partners. Tired of hearing people say UK-grown timber is not as strong as European timber, that there are too many knots to be aesthetically pleasing, or that it’s not a safe enough building material because it burns, we wanted to prove that it could be, and how it could be, used safely as a high-value construction method.

Last week BE-ST launched the Mass Timber Centre of Excellence at BE-ST. If we’re looking for a sign of progress that perspectives are changing, this could be it.

The launch of the Centre is a testament to a ten-year journey taken by BE-ST, Edinburgh Napier University, and strategic industry partners to invest in wood and timber research and to validate mass timber as a high-value construction method. Currently, we are limited in what we can do with multistorey mass timber construction as building regulations guidance discourages or prevents the use of combustible materials in buildings over 11 metres in Scotland and 18 meters in England due to fire safety concerns. This is despite other countries, such as Canada, Norway, and more, building to heights of 40 metres and beyond.

Extensive global research has explored and demonstrated that mass timber can achieve adequate safety in structures

beyond these heights when designed, manufactured, and constructed with due consideration given to the relevant concerns. In our current Built by Nature research project, we are working alongside the Edinburgh Fire Research Centre at the University of Edinburgh to compile this research, identify any gaps, and establish the views and understanding of a broad selection of UK built environment stakeholders. This evidence will directly support multiple workstreams that are advancing the UK Government’s recently published Timber in Construction Roadmap 2025 which promotes (among other things) the safe, sustainable use of timber as a construction material. It will also support the necessary changes to help solve many of the built environment's challenges, from lowering carbon emissions to delivering much needed public infrastructure. BE-ST has been involved in the shaping of the roadmap from its inception.

Mass timber might not be the most viable solution for delivering traditional housing as creating solid floor, wall, and roof panels uses more timber than the highly efficient timber framing construction method. However, mass timber is particularly suited to multi-story projects or non-domestic buildings that have requirements for large, clear spans, dimensional stability, or high racking resistance. This means it could be a key solution to lowering the carbon emissions of the construction sector and delivering high quality, efficient, sustainable and more affordable multi-storey buildings such as schools or hospitals.

A key milestone on our journey to validating the applications of UK-grown mass timber construction use was the founding of Transforming Timber - a collaborative knowledge hub promoting the use of homegrown mass timber. Transforming Timber is dedicated to making the business case for mass timber, to make it the first-choice material for specifiers, designers and contractors, and as a result, contributing towards a sustainable society and a thriving forestry industry.

Transforming Timber was established through a £1.5m Innovate UK-funded programme and delivered by BE-ST, Edinburgh Napier University, NMITE, Ecosystems Technologies, University of Edinburgh, and BSW Timber. This work has provided a foundation that means that Edinburgh Napier University and BE-ST are now further investing in the Mass Timber Centre of Excellence with a validated proposition to provide the sector with resources and support for mass timber innovation, manufacturing and skills. The Centre has launched to support the transformation of built environment delivery and increase the use of mass timber in construction through commercially available equipment and facilities, as well as expertise, research and skills training.

Through ten years as an innovation centre focused on changing perspectives and validating the use of homegrown mass timber, we have also invested in partnerships and projects that have delivered real, tangible economic, environmental and social benefits. BE-ST has supported the creation of 5,356 jobs, many of which have been in timber-related sectors, including over 40 created at Ecosystems Technologies, a sustainable and natural material offsite manufacturer in Invergordon. We have also procured a further £1.5m of commercially available equipment that has supported businesses like Ecosystems Technologies to double in value year on year and to deliver high-quality, sustainable housing and schools across the UK. This equipment will significantly increase Ecosystems Technologies’ manufacturing capacity and support their delivery of pipeline projects, which are already programmed through to Q3 2026.

When we take a step back, a key part of our success has been working with our partners since we began in 2014 to build momentum for homegrown mass timber manufacturing in the UK.

We want the Mass Timber Centre of Excellence to build on this at scale and pace, for it to be the breeding ground for the timber and forestry sector, where it can access the benefits that come with investing in and building mass timber and the supply chain, and for Scotland’s people and economy to reap the benefits.

Everyone, from the public through to construction sector, is now aware of asbestos: its prominence as a building material, its fatal health impacts, and the length of time it took to change perceptions around its use.

History may be repeating itself with silica dust, warns Dr. Scott McGibbon, Director at Pvotal Consultancy and BE-ST Innovation Champion.

With many common construction materials containing silica (including plaster, brick, cement, concrete, plasterboard, grout, mortar, natural and engineered stone, sand, asphalt and tile), the construction industry is currently dealing with a major health and safety hazard, and it is deeply impacting our people, our workforce and their families. Silica dust does not only affect those working directly on construction sites. It affects their families, friends and loved ones who can be exposed to the same negative health impacts through second-hand exposure.

Silica dust is present in 97% of construction materials, including brick, plasterboard, stone, sand and gravel. Inhaling particles from these materials, whether that be short- or long-term exposure, can develop into serious and life changing long-term illnesses. Normally classified as

interstitial lung diseases (ILD), these are a group of over 100 chronic lung disorders which include silicosis, COPD and cancers, that cause inflammation and scarring, making it hard to breath because the lungs struggle to get enough oxygen.

Numerous public health, governmental and industry organisations are reporting silica dust exposure and its impacts as a quickly emerging global crisis. Globally, it is estimated between 45,000 - 50,000 people die annually from silica dust exposure. According to the Health & Safety Executive (HSE) an estimated 600,000 workers are exposed to silica in the UK each year and that silica is “the biggest risk to construction workers after asbestos.”

There is close to an estimated 600 UK workforce deaths per year from direct silica dust exposure. However, this number is difficult to pin down, not least because in 2013 the UK government removed silicosis from the list of notifiable diseases, says Scott. He tells us, “It’s almost impossible to track and assess the actual extent of the problem as it is also harder to link exposure to Respirable Crystalline Silica (RCS) which result in ILDs to any particular employer.”

Adding to the scale of the problem is the lack of understanding and awareness of the dangers and risks from indirect exposure to silica dust.

It was recognised in 1997 by the European Union as a Group 1: Carcinogenic to humans.

Scott says, “With silicosis not being recognised in the list of notifiable diseases, this makes it 30 times harder for the workforce if they've been affected to actually get a claim." When people do make a claim, severe legal consequences can be there for those responsible. Several high-profile cases have exemplified this. In 2023 the UK’s biggest successful silicosis compensation claim to date was awarded £3.5 million in damages, whilst a major legal case in the US saw $52.4 million awarded to a silica victim.

There is a hesitancy for people to recognise or share their challenges with silicosis, but the effects should not be underplayed.

Scott says, "There is no treatment for silicosis at all... If you get silicosis, it’s a continual downward spiral - there is no levelling off the condition - not helped by the lack of worthwhile treatments," for both those endangered by direct exposure, and those who could be affected by indirect exposure.

Scott highlights a saddening case where a former female mining quarry employee was diagnosed with silicosis from silica dust exposure when working as an administrative worker in 2019. As a result, she is now more susceptible to severe illness with having a severely compromised immune system.

Adding to this case, Scott remarked, “a number of recent studies found an association between the exposure to cement-based materials and the risk of hospital admission for cardiovascular or respiratory causes, particularly strong for children and the elderly.”

The origin of silicosis was recognised as far back in Hippocratic times (c460BC – 370BC), yet still communities are affected. The Indian Village of Budhpura in Rajasthan is deeply impacted by silicosis on a community-wide scale. Scott shares, “It's called ‘The Village of the Dead’ because there is not a male over 40. They all work in the quarries.”

Moreover, family members who work in silica dust environments can bring home the microscopic granules embedded in their clothing, then contaminating the home environment, and potentially exposing loved ones, as silica particles can be released into the air even when they are not actively working with the materials.

As a former stonemason with almost 40 years of industry experience, Scott has witnessed silica dust's devastating effects on colleagues. He is motivated to prevent silica related diseases and create not only safer working environments but also advocate for safer outdoor and indoor air quality as a critical public accessibility and awareness issue: “Everyone should be able to breathe safely without risking poor health outcomes. In doing so, we can create healthier, more accessible, and informed communities.”

He is leading multiple initiatives to address knowledge gaps, improve industry standards for managing this hazardous material, and look to shift industry culture from reactive approaches towards proactivity through his consultancy and project work. Among them, Scott is currently working to raise awareness about silica dust's dangers through the creation of a Residents, Clients & Construction Professionals Silica Excellence toolkit, called ReACT, funded by Chartered Institute of Building (CIOB).

"We’re trying to arm people with knowledge, understanding and a bit of competency that they can make more valued judgments," Scott says.

As well as working directly with construction industry organisations through his consultancy, Scott is looking to develop several cutting-edge digital practice and training tools focussing on silica health and safety for construction sites.

Scott says, "We've actually helped them or advised them on integrating controls properly ... right now, what they had was siloed approaches. They have risk assessments, but those don’t always translate into what actually happens on-site. We need to move to more flexible, dynamic, real-time management and monitoring."

"If we’re trying to bring people into the industry, surely you want to make them feel safe?"

– Scott McGibbon

The toolkit construction needs

The toolkit being developed focuses on silica awareness to bridge the knowledge gap in the field and includes resources for improving understanding of silica dust risks and mitigation strategies. His toolkit has two key focuses. Firstly, to offer the opportunity to residents and clients to improve their understanding and awareness of the silica dust dangers: the impact it has and offer guidance strategies. Secondly, initiatives targeted at construction managers and professionals who can lack sufficient understanding of silica dust's dangers, but who can make the largest difference in ensuring proper processes, protocols and procedural strategies are in place on site.

The creation of the toolbox will include the SAFE tool bringing together existing construction industry focused resources and RCS control and exposure best practices. It will consist of digital and printable materials to help residents, clients, and construction professionals learn more about what construction materials and products contain silica, the type of works that are higher risk, what this means in terms of workplace safety, and best practices for silica dust control and exposure approaches.

Additionally, it is developing a RCS skills training needs analysis (RiSK) playbook to identify the skills needed for working safely with silica. It will provide practical tools like checklists and assessment guides to help construction professionals to effectively identify skills gaps and support improving their silica safety training needs, as well as identifying industry recognised silica training.

Scott is calling for collaboration and for individuals to take a step up and look to embed silica safety knowledge into everyday practice. The big thing is moving away from this culture of: 'It's just dust, it's part and parcel of the job.”

Construction has a duty to stop silica dust from continuing to cause harm and treat it the same as asbestos. The construction workforce and their families deserve betterstringent protection, competent management and a culture of excellence to better protect our people and save lives.

If you or someone you know has been affected by silica or silcosis, please see the Scottish-based charity Asbestos Action.

The demand for low carbon construction skills is growing.

With the Passivhaus Equivalent Standard being implemented in the coming years, fuel poverty exposing the consequences of not retrofitting our existing buildings, and increased interest in renewable technologies, a workforce equipped with low carbon construction skills is needed more than ever.

BE-ST offers courses for all levels to upskill and reskill the workforce for net zero.

Visit www.be-st.build to book a training course.

Learn from the UK’s top Passivhaus practitioners in this hands-on training using our bespoke rigs and simulations of real-life scenarios and challenges.

Who’s it for? Construction and built environment professionals and practitioners.

Working with colleges to upskill construction operatives in low carbon skills to work on Passivhaus projects, the Low Carbon Passport programme aims to upskill 1000 people a year.

Who’s it for? College students in built environment related fields.

To inspire the next generation into careers in the built environment, this programme offers hands-on workshops in Passivhaus, retrofit, digital skills and MMC.

Who’s it for? 13-24-year-olds.

Accredited vocational training, supported by AI technology, to understand learner’s pathways within construction delivery through a competency-based approach. Training covers Passivhaus, retrofit and digital skills.

Who’s it for? Industry new-starts, apprentices, returners to work or those who have taken a career break.

Join us on 28th May 2025 at BE-ST Innovation Campus for a full day of practical and theoretical learning with crosslaminated timber.

Who’s it for? Construction and built environment professionals and practitioners.

Nearly five years have passed since Clydebank’s Queens Quay Heat District Network, the first large-scale water source of its kind in Scotland, became operational.

The Queens Quay Energy Centre takes energy from the River Clyde to supply heat to key buildings in their region, including the Clydebank Leisure Centre, Clydebank College, and residents at local housing developments.

Alasdair Bryson and Amanda Kean from West Dunbartonshire Council and Jack Devlin of Clydebank Housing Association, who are all involved in the project, share insights into the impact it has had on their communities, lessons for institutions interested in district heating, and the potential for expansion.

For both the Council and Housing Association, Queens Quay aimed to tackle fuel poverty for tenants.

Jack, Clydebank Housing Association, shares his experience with an outgoing tenant before the project started: “They were paying around £300-£400 a month on energy bills due to issues with the electric storage heaters. Because of our inability to take action at the time, the tenant decided to leave, so we were looking at ways to assist tenants in reducing their energy costs.

“With electric storage heaters, high bills were inevitable, so our goal for the project was to help tenants reduce our bills and keep tenants in the home.”

The inability to properly heat the homes could lead to mould, dampness, and health problems, so addressing this issue was critical on multiple levels.

Alasdair from the Council agrees: “The first 146 domestic flats connected up would have come from colder, more difficult to heat places, and potentially other electric storage or heating.”

Queens Quay was a huge success in reducing the bills of these communities: “For the Dumbarton Road flats, many residents’ heating costs have been reduced by 2/3s. That's a huge win.” “From a fuel poverty point of view, you can provide that lower cost of energy,” Amanda adds.

As well as large cost reductions, the Council sees many tenants happy with the district heating systems, receiving no complaints about the new heating.

Another benefit is at a housing level: “Being able to turn the thermostat on and get instant heat or instant hot water's a big plus for them. It's not just the actual ability to reduce our costs. It's having control over how they heat their home.”

An underpinning theme in our conversation on Queens Quay was the price of gas and electricity in the current market, which is a significant consideration when rolling out a new heating system to different communities.

Amanda says: “If you're looking at making a just transition from gas to district network, you have to find a sensible, ideally low energy tariff. And one of the main sticking points is the cost of electricity.”

However, the council is currently exploring options for renewable electricity generation for Queens Quay to produce their own electricity.

For other local authorities looking at district heating, she advises, “you need to develop a robust plan for electricity generation because otherwise you're never going to get the figures to stack up in a sustainable just transition.”

Alasdair emphasises the impact that current taxation arrangements have on the gas and electric dilemma: “You can imagine the expansion that could be made if the subsidy enjoyed by gas was rebalanced in favour of low carbon electric fuelled heat sources. People would be demanding heat networks be connected up with that kind of pricing structure.”

For the Clydebank Housing Association, funding made their involvement in the project possible, sought partly through the Scottish Government’s Low Carbon Initiative Funding, as well as through private finance.

Jack advises that others should find out actual costs as early as possible: “After getting costs in, we've had to go back to our funding provider twice to get an increase in funding to allow us to go ahead with the project. I would really advise you nail down the costs.”

Both parties are just getting started and want to continue with the project and its expansion to connect to more homes and public buildings.

West Dunbartonshire Council is actively working to expand its reach with ambitious plans. There is potential to extend the network eastward towards Glasgow, making it a more regional model for heat decarbonisation.

Clydebank Housing Association also sees it as a huge opportunity in the next ten years and is keen to continue expanding. Funding and legislation support are noted as crucial to this being successful.

Scotland’s first large-scale water source District Heat Network five years on is a huge success for the Council, Housing Association, and the communities the system supplies to.

However, for this to be rolled out to other areas, expansion for this project and beyond is contingent on investment and policies that encourage these initiatives. With the repeal of Scotland’s Heat in Buildings Bill and other national policies playing a crucial role in the future of district heating, it is even more important that Government, and the wider built environment and energy communities, look at the role they can play.

The Construction Leadership Forum (CLF) has published a new report assessing the quality, usefulness, and validity of data currently held by building owners across Scotland. Named ‘The National Existing Buildings Database’, this report represents a key step in understanding the information available on Scotland’s building stock. The report findings lay the foundation for a national database that, once developed, will provide local authorities with an invaluable resource to support large-scale retrofitting of housing stock.

Through a series of engagement sessions with key stakeholders from both the public and private sectors, the research team made up of Robert Gordon University, BE-ST and CLF’s Data Working Group members identified what data we already have available and commonalities in data sets as well as key challenges, including data gaps, reliability concerns, and the need for a cyber-secure platform that integrates real-time data. Issues around data protection, interoperability, and supply chain alignment were also highlighted as barriers to overcome in the delivery of the database.

Future developments are expected to incorporate digital twins and archetypal pattern books so that property owners can model and test retrofit strategies with more confidence.

The overarching ambition of the database is to create a single point of access for accurate and up-to-date building data across Scotland. By integrating information from multiple sources, this database will identify and address knowledge gaps on building archetypes, use automation to collate and refine data into a centralised, accessible resource, support informed decision-making for large-scale retrofit programmes, and foster collaboration between the public and private sectors to accelerate retrofit at scale.

A national open-source database has the potential to transform Scotland’s approach to building management, retrofitting, and energy efficiency. It would empower individuals and organisations to make informed investment decisions while ensuring that public funding is used effectively. With coordinated efforts across the country, the project would help stabilise demand, maintain a consistent supply of materials and services, and enhance cost efficiencies by pooling resources from private, social, and owner-occupied housing sectors.

To guide future research and development, the report outlines ten research work packages designed to align with existing national and local initiatives, de-risk the project by ensuring each phase contributes to a broader, coordinated strategy, and ensure that every stage of development delivers standalone value while contributing to the overarching goal of establishing a National Existing Buildings Database.

"The Existing Buildings Database will give key stakeholders the information they need to plan and optimise this work, while its collaborative approach will create a clear pipeline, allowing local contractors to upskill, manufacturers to supply the right systems, and the Scottish economy to benefit through job creation and long-term opportunities."

-

John McKinney, co-chair of the CLF Data Working Group and Build Scotland

1. What inspired you to join the built environment sector?

I’ve always enjoyed maths and problem-solving, so studying civil & structural engineering felt like a natural choice. After graduating, I realised it wasn’t quite the right fit, so I shifted towards timber and offsite construction. It’s been a great balance of desk work and hands-on problem-solving in the factory – which is something I really enjoy.

2. What’s your career been like up to this point?

It’s been quite varied. I started in academia, quit a PhD, had a brief stint in industry, and then found my way to BE-ST. Each step has helped me build a broad range of skills. I may not be a specialist, but I’m a true generalist – always ready to tackle something new.

3. What’s your biggest professional achievement?

Public speaking has been a big one for me. It’s something I’ve always found nerve-wracking, so being part of a panel at BE-ST Fest last year was a huge step out of my comfort zone. To my surprise, I actually enjoyed it. It was a proud moment, and I’ve learned that the more you do it, the easier it gets – although the pre-panel nerves are still there.

4. What’s your life motto?

“What’s for you won’t go by you” – for someone who is not particularly philosophical, I am a big believer in fate. But maybe this is just what I tell myself when something doesn’t go the way I hoped it would?

5. What would you change in the built environment?

There’s a lot I’d like to see evolve, but I’m especially passionate about increasing the use of timber in construction. It’s a sustainable material and a key part of reducing the sector’s impact on the climate. Changing outdated perceptions and raising the awareness of timber in construction is something I try to do on the daily.

6. What do you like most about your job?

The variety. No two days are the same, and I love it! One day I’m doing desk-based R&D, and the next I’m on the factory floor making Cross Laminated Timber panels. It keeps things super interesting.

7. Hobbies and interests

My hobbies seem to have a theme of self-sufficiency, I love to DIY – we are just about to take on a big house reno (obviously integrating sustainable construction and retrofit solutions), to grow on my allotment, sew and repair clothes as well as training as a competitive weightlifter – I like to keep busy in my spare time!

Advertise in BE-ST’s new quarterly magazine to reach a highly engaged audience of 179K+ built environment professionals.

Showcase your innovations, services, or insights alongside industry leaders in our newly established publication. Gain visibility, drive brand awareness, and connect directly with those shaping a smarter, more sustainable built environment.

1 2 3 4

*all sizes are listed width x height

To discuss advertising opportunities please contact:

Hannah Lloyd, Business Development Manager Hlloyd@be-st.build

BE-ST Fest will play host to transformative discussion and knowledge exchange on how we can accelerate our journey to zero carbon through a packed programme of events taking place from September to November.

Paisley Town Hall | 5th Nov

BE-ST Fest 25 will bring together inspiring keynotes, offer attendees practical skills for the net zero transition, networking opportunities with professionals and advocates, and access to an expo showcasing the latest technologies and innovations.

Paisley Town

For three years, the International Retrofit Conference has been a platform for the industry leaders, policymakers and innovators to come together and discuss the possibility. In 2025, we're cutting through the noise to tackle the real barriers of large scale retrofit.

Celebrating the heroes accelerating the journey to a net zero built environment.

The Accelerate to Zero Awards recognise the businesses, organisations and individuals making the biggest contribution to decarbonising the built environment and supporting the just transition to net zero.

The awards ceremony will take place at an evening reception on Thursday 6th November 2025 at in Glasgow - venue to be announced.

The BE-ST Fest Fringe will gather the entire ecosystem, including academia, commercial and residential landlords, emergency influencers, industry leaders, the next generation, policymakers, the public sector, and the supply chain. This series of events will span three months, offering a packed program throughout Scotland, the UK, and beyond.

This is your opportunity to get involved in BE-ST Fest through hosting your own Fringe event.

Visit www.be-stfest.org for the latest updates.