STORY & PHOTOS BY ANNE GABBIANELLI

former log driver and man of many talents has found his niche on the shores of two lakes in the Millinocket region. Ambajejus and Chesuncook lakes both share the waters of the West Branch of the Penobscot River, which once served as a transportation corridor to move wood from the northern forests to Maine saw mills.

Chuck Harris worked supporting the log drive in the last years of its existence. That era ended in 1971. But he remained an outdoorsman, working for the Woods Department of Great Northern Paper (GNP).

“I stayed on the water to clean up the booms,” he said. That experience eventually blossomed into a quest to preserve the history of Maine log drivers.

In 1916, the Chesuncook Boomhouse was built about 35 miles from Millinocket via the Golden Road in Greenville. While that museum is referred to as a boomhouse, Harris says it’s also been called a boarding house — but either way, Harris’s mission remains steadfast: “I believe this house and the Ambajejus Museum can tell the log drivers stories.”

The museums give you a glimpse of the living quarters for the log drivers who were provided hearty meals and comfortable sleeping quarters.

I believe this house and the Ambajejus Museum can tell the log drivers stories.

“The log drivers were cowboys from the World War II era and they couldn’t tell their stories, so hopefully the museums do,” said Harris as he gave a tour of the Chesuncook Museum where he is in the process of sharing that history.

- CHUCK HARRIS

Chesuncook is a reservoir in Piscataquis County and is the third-largest body of fresh water in the state. Ambajejus is part of the The Pemadumcook Chain of Lakes in Penobscot County. Each of these lakes host boomhouse museums created by Harris who today is the docent — splitting his time between the two locations, which each offer an authentic representation of the life of a log driver.

“It’s a one-man show,” said Harris, a 76-year-old artist. His experience with art museums provided a perfect segue to creating the boomhouse museums.

The buildings once housed the many river drivers who helped move the logs along the Penobscot. Boomhouses get their name because they were central in creating a choke point for a containment boom, or a floating barrier, to collect the logs before they were floated downriver to a sawmill.

The Ambajejus Boomhouse was built in 1906, on an island on Ambajejus Lake.

“They came from Bangor as soon as the ice was out,” Harris said. “We had to sober them up and they stayed sober for the season, navigating typically 5,000 cord of wood in just one boom and the logs averaged 28 feet.” He added with a smile, “When I worked with the old fellows, I did the lugging and tugging — now I’m the old fellow!”

One of the ‘old fellows’ was Nelson Levasseur, the last supervisor of the Penobscot River drive, who Harris memorializes with his historical efforts. Levasseur gave Harris his first job on the William Hilton as a deck hand, helping navigate the booms established in Chesuncook Lake before releasing logs down river. In pointing to a newspaper picture of Levasseur, who was small in stature, Harris said, “He was a ‘man’s man,’” recognizing the independent manager who exuded kindness.

The first lumbering operation on the West Branch started in 1828, creating a way of life for those in the woods and on the water driving the logs down river to Bangor — the one-time lumber capital of the world. The operation was run by the Penobscot Log Driving Company and later GNP. Best estimates are that about 150 thousand cord of wood, mostly the size of telephone poles, were moved each year through Millinocket, Mattawamkeag, down stream through Old Town, and along into Bangor.

It took intense manual labor to build booms. Booms were a holding pen made of logs pegged together and later strung together with chains. The purpose was to gather the logs before being released via a sluice over Ripogenus (Rip) Dam, down the river into Ambajejus Lake, into North Twin Lake, and down the Penobscot.

In 1973, the Ambajejus Boomhouse was placed on the National Register of Historic Places, showing it worthy of preservation. It rests on a small island, and fell victim to vandals, but in the late 1980s Harris got to work resurrecting artifacts from the depths of the waterways and near the dams to recreate what life was like in a boomhouse. The Home Fireside stove, firmly planted in the kitchen, is the only original piece in the museum.

Millinocket native Rod Angotti, on a boat ride to tour one of the boomhouses, shared that there were no dams in the 1800s. Rip Dam was built in 1916 with a rudimentary road built to haul concrete for that dam’s construction. Several decades later, the iconic and well-traveled Golden Road, which runs between Millinocket and Greenville into Canada, was completed. With the passage of the Clean Water Act of 1972 and the completion of the Golden Road that same year, the log drives came to an end in northern Maine.

When asked about the most harrowing experiences on the river, Harris offered, “Oh, there’s too many to tell. I’m lucky to be alive. It was a dangerous job and you could drown the very first day on the job.”

Unmarked gravesites in Chesuncook Village speak of this danger.

Yet the work was addictive, added Harris. “The sound of the logs thumping into each other becomes a part of you and everything has to do with weather and wind.”

Continuing to reminisce while perched on a bench in the barn, surrounded by chains and tools of the log driving days, Harris mused, “What are the chances a kid from Delaware would end up here, living and watching Mother Nature everyday.”

The sound of logs thumping into each other becomes a part of you and everything has to do with the weather and wind.

- HARRIS

Harris discovered Maine on a family vacation when he was 12, and as a young adult he knew this was his home for good.

Noting the one-man show, the West Branch Historical Preservation Committee was established in 2017. Its purpose is to raise funds through grants and donations to support Harris’ continuing passion and efforts in paying tribute to a part of Maine’s history.

BY JEN LYNDS

Richard Chambers, 17, a senior at Southern Aroostook Community School, drives the skidder during class at the Region Two School of Applied Technology’s Forestry Management and Operations program. – PHOTO BY DANIEL DOBBS

nside the classroom of the Region Two School of Applied Technology’s Forestry Management and Operations program, Kaley Whitman brushed her hands down the sides of her blue T-shirt.

Whitman and her classmates are learning the skills required for careers as professional loggers. The 16-year-old sophomore at Houlton High School is the lone female in the class.

Whitman was not intimidated by the gender imbalance, and she enrolled in the course to learn forestry skills and to send a message.

“Women can work in forestry just like men can,” she said. “And I was also sick of people doubting me. After every class, I go back and brag to all of my friends about what I learned and what I did in class that day. They are writing with pens, and I am using a chainsaw.”

Mark Thibodeau, the instructor for the class, said that logistics require the forestry program to take place at the Southern Aroostook Community School in Dyer Brook. Thibodeau, along with Educational Technician Vernon Upton, teaches students everything from safely operating chainsaws to tree felling and machine operation. The program has a woodlot, provided by Irving Woodlands, located behind the school.

“The most important thing we teach here is safety,” Thibodeau, who has 22 years of experience in the industry, stressed. “It is safety and respect for the machine that you run. I tell the students every day that a chainsaw does not care if you go home at the end of the day.”

The most important thing we teach here is safety. It is safety and respect for the machine that you run.

- MARK THIBODEAU

Houlton’s Region Two School of Applied Technology serves students in grades 9-12 from East Grand, Hodgdon, Houlton, Katahdin, and Southern Aroostook. The program offers real-world experience and best management practices to ensure that logging is done safely and sustainably.

Students who complete the program are eligible for an apprenticeship through the Certified Logging Program (CLP) and credits through the University of Maine at Fort Kent.

To stress this, students in the program receive the latest safety gear. They receive one to two months of safety training, first aid and CPR certification, and OSHA 10 certification to meet safety standards across construction or the general industry.

“The students spend a lot of time in the classroom before they head out into the field,” said Upton. “And we have freshmen right up through seniors. It isn’t like we have students who take this class once and they are done. We have some students who have been in this class their entire four years of high school.”

FROM PAGE 4

Nearby, several students sat at forestry simulators that trained them on how to use machinery such as skidders and forwarders. Students practiced operating, loading, and unloading the equipment with the simulators.

The school received a $480,000 John Deere forwarder alongside the two simulators in December 2024, thanks to a Maine Department of Education grant, made possible by Governor Janet Mills’ Maine Jobs and Recovery Plan.

Houlton’s Region Two School of Applied Technology is just one of several educational institutions that are training the next generation of foresters. The University of Maine has the most extended continuously accredited professional Forestry Program in the United States.

Adam Daigneault is the director of the School of Forest Resources at the University of Maine in Orono. There are approximately 100 undergraduates in the forestry program, he explained, and undergraduates don’t just spend all day in the classroom.

Daigneault said that students in the program will spend two-thirds of a typical day “dedicated to forestry or natural resource management,” he explained.

“At least three days of the week, they will be outside for several hours, primarily in our lab, the University of Maine’s University Forest,” he added. “The area that we manage is upwards of 14,000 acres. Lots of labs are carried out there.”

Daigneault said that during those labs, students observe the structure of the trees, the type of management conducted, and the response.

“They also observe which type of wildlife might be out there and which type of wildlife might prefer different types of habitat, which is driven by the type of trees, size of the trees, the spacing of the trees, things like that. I’d say 40 percent of forestry students’ time is spent outdoors,” he said.

In the last 10 years, Daigneault explained, 60 to 70 percent of the students in the program have come from out of state.

“They have largely come from New England, but they are not from Maine,” he said. “But they get linked up with employers here, and they end up staying, so we see a positive impact.”

Daigneault said that he thinks that students are most surprised by the fact that forestry is much more complex than they initially believed.

Students in class at the Region Two School of Applied Technology’s Forestry Management and Operations program practice on forestry simulators that train them how to use machinery such as skidders and forwarders.

“The science of forestry is really broad, and it includes landowner and ecological objectives,” he said. “It is not just about how to make the most money by cutting the most trees or anything like that. It is much more complex. We manage wildlife, we manage water and soil quality, and in the last decade or two, we’ve focused on our carbon and carbon sequestration…It is not just about cutting trees for timber’s sake only.”

Back in Dyer Brook, Thibodeau and Upton ushered the students to the 137-acre woodlot behind the school.

Thibodeau climbed into the operator’s cab on the forwarder to guide Kregan Leatham, a 17-year-old homeschooled senior, as he started the machine. Leatham gingerly moved the machine forward and received cheers from his classmates as he used the boom and grapple to pick up logs and return them to a nearby pile.

“We harvest and sell firewood to families in need,” Upton said. “That helps families around here and benefits the students as well.”

Brandon Whitman, 17, is a junior at Houlton High School. He said he enrolled in the course to “try something different,” and is enjoying it.

“I love to drive the skidder,” he acknowledged with a grin. the

He said he planned a future in the industry.

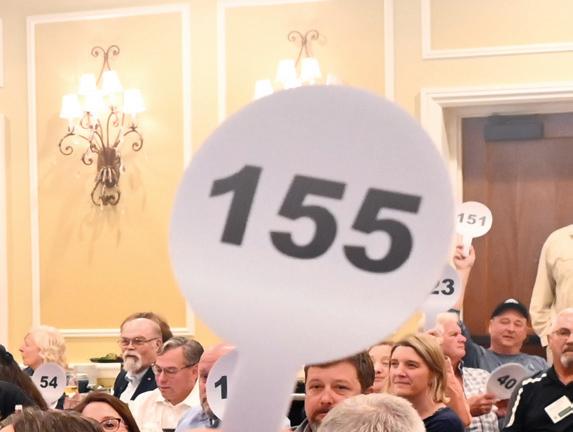

he Professional Logging Contractors (PLC) of the Northeast held its 30th Anniversary Annual Meeting May 8-9, raising a record $165,386 for Log A Load For Kids and presenting awards to businesses and individuals from across Maine and Vermont for their contributions to the logging industry.

The meeting was held at the Samoset Resort in Rockport, with more than 250 people attending the main events on Friday. This was the second annual meeting of the PLC since its expansion in 2023 from a Maine organization to a regional one serving loggers and forest truckers across the Northeast, and a milestone anniversary for the organization.

The annual meeting is the PLC’s largest event and highlighted by the Log A Load for Kids Auction raising money for three Children’s Miracle Network (CMN) Hospitals in Maine and Vermont. Families served by each of the CMN hospitals were in attendance for the event.

“Every year I am amazed by the generosity of this special group of people when it comes to supporting Children’s Miracle Network hospitals, and I could not be prouder of the result this year as we mark our 30th anniversary,” Dana Doran, Executive Director of the PLC, said. “The logging and trucking industry of the Northeast has faced a steadily mounting list of challenges in the three decades since the PLC was founded, yet no matter how tough things get, our members, supporters,

and friends step up every year at our Log A Load Auction for Kids to support the children and families served by CMN hospitals in Maine and Vermont. I am so grateful for the generosity shown here, and I know the families and kids are grateful as well.”

The Annual Meeting spanned two days, beginning Thursday with a tour of North Haven Island, including stops at a timber harvest site on the island, lunch at North Haven Brewing, a visit to North Haven Oyster Company, and an evening social gathering at the Samoset Resort.

The second day included a business meeting for all PLC Member contractors in the morning, with board and officer elections, as well as special presentations by Eric Kingsley of Innovative Natural Resource Solutions and Melissa LaCasse of Tanbark Molded Fiber.

The afternoon featured Dan Burns Live Chainsaw Carving and a Baxter Brewing Beer Tent and gathering outside the Samoset overlooking the ocean.

The evening events included the traditional Log A Load for Kids Auction, dinner, and the PLC awards ceremony. PLC’s special guests for the evening — Ryan, Ashley, and Jedi from the hit TV show Maine Cabin Masters — took part in the auction and donated items to the families from the Barbara Bush and Northern Light Hospitals, including a visit to the filming of an episode to help boost the total.

Awards were presented to the following individuals and organizations during the evening portion of the event:

PLC LOGGER OF THE YEAR AWARDS: These awards recognize PLC Logging Contractors for their commitment to the sustainability of the industry and logging as a profession. This year for the second time the award went to two companies, one from Maine and one from Vermont. The winners are: Lipsky Logging and Land Clearing of Stowe, VT; and Khiel Logging and Chipping of Denmark, ME .

PLC COMMUNITY SERVICE AWARD: This award is given annually to a PLC member, Supporting Member or affiliated organization that has demonstrated a significant commitment to giving back to their community. The winner this year is: JRS Logging Inc. of Fort Kent, ME .

PLC SUPPORTING MEMBER AWARD: The PLC Supporting Member of the Year Award is presented annually to a PLC Supporting Member that has demonstrated an unprecedented commitment to logging contractors in Maine. The winner this year is: Skowhegan Savings Bank of ME .

PLC PRESIDENT’S AWARD: The President’s Award is presented to individuals or organizations within the PLC which have a significant and positive impact on the PLC and the logging industry in Maine. The winner this year is: Will Cole, PLC President 2022-2024.

MASTER LOGGER SUPPORTER’S AWARDS: The Master Logger Supporter’s Awards were created to recognize individuals and organizations that have been outstanding supporters of the Master Logger Certification Program ® and the standard it represents. The winners this year are: T he New England Forestry Foundation and former Maine Forest Service Director Alec Giffen, who is current Senior Forest Science and Policy Fellow for NEFF.

PLC Supporting Member Acadia Insurance presented its annual ACADIA SAFETY AWARD to Comprehensive Land Technologies Inc. of China, ME .

The Annual Meeting is one of the PLC’s major fundraisers to benefit CMN hospitals. Last year the PLC raised a record $297,519 by the end of 2024 for the cause from its annual auction and two Log A Load golf tournaments, which are held in August and September. The PLC partners with the Barbara Bush Children’s Hospital (BBCH) and Northern Light Health Foundation in Maine for its annual Log A Load fund drive and the University of Vermont Children’s Hospital in Burlington, Vermont as well. All are CMN hospitals.

The PLC’s Log A Load efforts have now raised more than $2.7 million since 1995. Founded in Maine in 1995 by a handful of loggers who were concerned about the future of the forest economy, the PLC has grown steadily to become a regional nonprofit which provides independent logging and forest trucking contractors a voice along with a suite of other forest certification programs which are grounded in responsible forest management. Board membership consists of only loggers, making it an organization that is run by loggers on behalf of loggers.

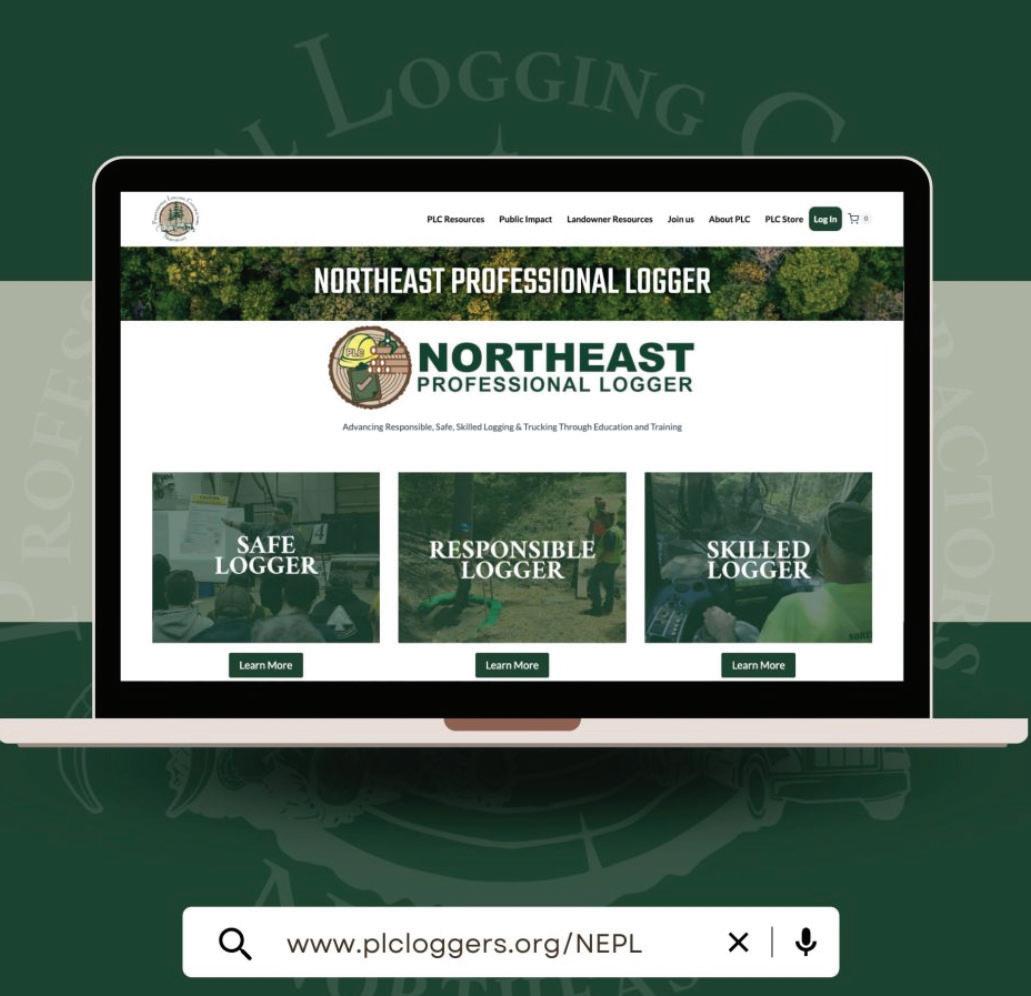

BY JEFF BENJAMIN, PLC DEPUTY EXECUTIVE DIRECTOR OF CERTIFICATION

The Professional Logging Contractors of the Northeast (PLC) is not known as a logger “training” organization. In fact, the word training does not even exist in our mission and vision statements. No one joins the PLC and asks, what do I have to do to become a logger? No one comes to us looking to be trained on how to successfully run a logging business from the ground up. Rather, our purpose is to educate and promote logging as a profession to the public, and to serve our members as they provide professional logging services to landowners and the forest products industry.

Logging contractors join the PLC because they recognize value in the work we do on their behalf — advocacy, promotion, and support. Safety and risk management have always been a focus of the PLC to ensure its members remain profitable by reducing losses. As a result, we have developed many “one-off” training initiatives to address specific needs in the industry. For example, in 2010 we first offered safety

training workshops throughout the region during mud season. Our partners in the insurance industry shared safety issues they were seeing on a recurring basis, and we worked with our members to address those issues. Over time this has become an annual program with more than a dozen logger and fleet safety workshops and 15-20 CPR courses offered throughout the region. More than 1,000 loggers participated in these workshops last year alone.

The Master Logger Certification Program® has also offered spring workshops over the past two decades. With a focus on best practices and responsible logging, these workshops provide on the ground learning opportunities for loggers throughout the region. More than 150 loggers participated in the workshops last year. The result is that the program has also developed a significant amount of valuable content and resource material over the years.

That is why we have decided to organize our training and outreach efforts into one program called the Northeast (NE) Professional Logger. All training and continuing education material, including in-person workshops and online videos, will be promoted under the “brand” NE Professional Logger. We realize that being a professional logger means operating in a safe manner, taking responsibility for high standards, and having advanced technical skills.

The three tenets of the program — Safety, Responsibility, and Skill — apply to entry-level operators as well as experienced logging contractors. NE Professional Logger has over 20 online, entry-level modules for safety (including: PPE, separation of operations, first aid, lock-out & tag-out for logging equipment, and flammable & combustible liquids), and for responsible logging (including: forest & harvest certifications, protection of water, erosion control, forest management, protection of ecosystems, forest rules and regulations, and logging business fundamentals).

Professional loggers recognize the need for continuous improvement and skill development. As such, we offer ongoing training opportunities to: 1) reinforce safety and responsible logging practices; 2) introduce new technology (e.g. Avenza mapping software); and 3) develop new skills in business, leadership, and communication. Through our partnership with the Maine Community College System, we also train the next generation of logging equipment operators and truck drivers through the Mechanized Logging Operations and Forest Trucking Program (MLOFT). Finally, we offer the classroom portion of commercial driver licensing (CDL) education so new truck drivers can obtain their CDL permit. Development and reinforcement of technical skills is an ongoing practice for professional loggers and the PLC takes this role very seriously.

NE Professional Logger is the umbrella program where we organize, develop, and deliver our training programs. You can find more information about upcoming workshops, online courses, and resource materials on our website at plcloggers.org. Remember that access to these events and materials is free to Master Loggers and members of the PLC.

OF PROFESSIONAL LOGGING CONTRACTORS OF THE NORTHEAST

The Mechanized Logging Operations and Forest Trucking (MLOFT) Program, a unique hands-on training course that prepares students for careers in the logging industry, is currently in its ninth year of classes at an active harvest site in central Maine.

The certificate program for operators of mechanized logging and forest trucking equipment will run for 20 weeks. Classes began June 23 on the Kennebec Valley Community College (KVCC) Alfond Campus on U.S. Route 201 in Hinckley and will run through Nov. 6. Students transitioned from classroom and forest instruction to equipment operation in late July.

“This program continues to address Maine’s shortage of qualified logging operators and forest truckers in an efficient and affordable way,” Dana Doran, Executive Director of the Professional Logging Contractors of the Northeast (PLC), said. “There is no better opportunity for anyone interested in starting a career in the logging industry, and thanks to continued federal support due to the efforts of Maine’s congressional delegation, as well as the generosity of industry sponsors and supporters including the Bill and Joan Alfond Family Foundation and Skowhegan Savings Bank, students are able to access this training at little to no cost.”

The program is administered by Northern Maine Community College (NMCC) in partnership with the PLC and includes a strong emphasis on safety as well as giving students an understanding of the variables of timber growth, tree species, and markets. Students pay no tuition or fees. The program provides all personal protective equipment (PPE) and scholarships from Skowhegan Savings Bank to assist with living expenses. Local housing is available at reduced cost to students who live beyond a reasonable commuting distance from the program thanks to support from the Bill and Joan Alfond Family Foundation.

The opportunity to earn a CDL-A permit and receive preparation for the state driving exam was a significant addition to the program in 2023 and has expanded opportunities for graduates while increasing benefits to Maine logging employers who need more mechanized logging operators and truck drivers. Students in the program harvest timber and operate trucks using sophisticated

state-of-the-art machines like those they will encounter in the logging industry. The hands-on experience students gain operating equipment is an opportunity unavailable anywhere else in Maine and neighboring states.

This project is funded 100% by a $1M grant from the U.S. Department of Labor, Employment and Training Administration.

The program was created in 2017 by the Maine Community College System, the PLC, and industry partners. Dozens of graduates are working in Maine’s logging industry today, and the demand for additional equipment operators and truck drivers remains high due to the rapidly aging workforce in the logging industry.

Graduation for the students will be held on Nov. 6.

students talk to PLC Board Members Chuck Ames, at center with yellow helmet, Brian Souers, second from right, and Kurt Babineau, at right, during a board visit to the program in September.

Joey Guimond of J. Guimond Logging, Inc., second from right, placed first in the Komatsu Forwarder Contest Championship in Escanaba, Michigan on Saturday, Sept. 6. Ryan Ouellette of R. Ouellette & Son Logging, Inc., second from left, placed ninth. Both companies are based in Wallagrass, Maine and are members of the Professional Logging Contractors of the Northeast.

Master Logger Joey Guimond of J. Guimond Logging, Inc. placed first in the Komatsu Forwarder Contest Championship in Escanaba, Michigan on Sept. 6, beating more than 20 other competitors in the challenging and fastpaced contest.

The contest is part of the Great Lakes Logging & Heavy Equipment Expo. Guimond, of Fort Kent, won the 2025 championship by showcasing operator skill through tasks like loading logs, dragging them through a hoop, and precise log placement. The event highlights Komatsu equipment and Guimond qualified to compete in it after placing second in the Komatsu loader competition at the Northeastern Forest Products Equipment Expo in Bangor in May.

J. Guimond Logging, Inc., based in Wallagrass, is a member of the Professional Logging Contractors of the Northeast (PLC). The company is certified by the Master Logger Certification Program®.

“It is no surprise to us that Joey won in Michigan,” Dana Doran, Executive Director of the PLC, said. “Northeast loggers are as skilled as any in the world and operators from the Fort Kent area are among the best of the best. We are proud to see the title held by a member of the PLC, and also to recognize PLC Affiliated Contractor Ryan Ouellette of R. Ouellette & Son Logging, Inc. of Wallagrass, ME, who placed 9th in Michigan in the same tough competition.”

Guimond said he has been running a forwarder since before he could drive, and his company still owns one but he switched to running a feller buncher four years ago. Amazingly, he was not able to practice in the forwarder before the competition.

“No, I didn’t; my forwarder has been broke for a month waiting on an engine so I could not practice, but it’s kind of one of those things you don’t forget how to do,” Guimond said. “It definitely felt good to win. I kinda went there not knowing what to expect but once I did my first run and saw where I was at, I knew I had a chance to win so I really focused after that.”

Forwarders transport logs from the woods to roadside landings using a loading grapple to pick up cut logs or bunches of logs and generally work with processors that harvest trees and then limb them and cut them to specific lengths. The forwarder competition includes an obstacle course of challenges designed to test every aspect of the machine’s capabilities.

“The hardest part was the middle obstacle where you get to pick up 2 logs between two tall stakes and you can’t touch them,” Guimond said.

Maine’s loggers are a vital part of the state’s forest products sector, which is worth an estimated $8.1 billion annually. Logging contributed an estimated $582 million to the state economy in 2021.

Founded in Maine in 1995 by a handful of loggers who were concerned about the future of the forest economy, the PLC has grown steadily to become a regional nonprofit which provides independent logging and forest trucking contractors a voice along with a suite of other forest certification programs which are grounded in responsible forest management. Board membership consists of only loggers, making it an organization that is run by loggers on behalf of loggers.

Learn more about the PLC at www.plcloggers.org

Recently, spruce budworm has been turning heads in Northern Aroostook County.

In June 2024, the caterpillars’ extensive feeding damage caused reddish-brown hues to develop on spruce and fir trees. Maine Forest Service surveys revealed 3,400 acres of damage from the caterpillars visible from the air. Then, 2024 branch sampling of the overwintering budworm estimated roughly 300,000 acres with building populations.

Spruce budworm is not new to Maine’s forests; it is a native species that is always present, but it can occasionally outbreak and cause significant tree mortality. In areas with building outbreak populations, their natural enemies (predators, pathogens, and weather) are no longer able to keep budworm populations low and stable.

During the last major outbreak in the 1970s, Maine used a foliage-protection strategy that focused on insecticide treatments to keep valuable trees alive during an active outbreak. Using that approach, roughly seven million acres of spruce and fir trees were

As expected, budworm populations persist above treatment thresholds in some parts of the state, particularly in areas not treated in 2025. In some cases, spruce budworm populations in treated areas may also increase from the current outbreak in Canada extending into Maine. Sampling throughout this fall will help pinpoint those hot spots and provide a first look at what areas may be eligible for treatment in 2026 to reduce spruce budworm impacts. Keeping our forests healthy is a shared effort. Landowners with smaller woodlands (~20-2000 acres) are part of an EIS solution.

We anticipate a program to subsidize treatment costs on smaller woodlands in Northern Aroostook County in 2026.* If you are interested in learning more about participating in the spruce budworm response in 2026, please fill out the interest form at maine.gov/sbw or contact the Maine Forest Service for assistance at (207) 287-2431 or foresthealth@maine.gov.

still damaged or killed. This caused waves of change in Maine including diminished water quality and disruptions to the natural resources and their dependent communities for the decades that followed.

The difference today is the development and success of a new management approach: Early Intervention Strategy (EIS). Initially developed and tested in Atlantic Canada, EIS aims to reduce spruce budworm populations early – when they are still low – but on the rise instead of waiting until populations have exploded to help trees.

The goal of EIS is not to eliminate spruce budworm, but rather to knock down populations in areas where they are poised to overwhelm control by their natural enemies. This new approach to treatment timing has drastically reduced tree damage and the size of the areas needing to be managed.

In response to the elevated populations of spruce budworm, timberland owners and managers in Maine formed the Maine Budworm Response Coalition (MBRC). Together with numerous agencies and organizations, including the Maine Forest Service and the Spruce Budworm Task Force, a plan to manage spruce budworm was crafted.

After months of monitoring, planning, public communication, outreach, and a helpful stretch of good weather and bud growth, the MBRC coordinated aerial treatments to curb growing spruce budworm populations in May 2025. Precise application technology and target-specific insecticides ensured efficient applications, and the response was considered an operational success: budworms that died because they ate the insecticide were present in treated stands along with abundant evidence of budworm death from natural enemies, including insects. Aerial surveys in July 2025 confirmed healthy and green spruce-fir forests that had been treated earlier in the season in contrast to untreated adjoining areas.

*Note: We cannot guarantee that lands of all interested owners will be eligible for treatment.

Spruce budworm populations, funding, sensitive areas, forest composition, interest and other factors will all drive the eligibility of specific areas for enrollment.

NORTHERN TOURNAMENT: PLC Log A Load for Kids Northern Maine Golf Tournament underway on Sept. 12 at JaTo Highlands Golf Course in Lincoln.

The Professional Logging Contractors (PLC) of the Northeast once again demonstrated the logging industry’s commitment to children’s health this summer, raising a combined total of more than $116,000 at its annual Log A Load for Kids golf tournaments in Maine.

On Friday, Aug. 22, the PLC hosted its seventh annual Southern Maine Log A Load for Kids Golf Tournament at Lake Kezar Country Club in Lovell, raising a record-breaking $55,211 for the Barbara Bush Children’s Hospital (BBCH) in Portland. Just weeks later, on Friday, Sept. 12, the organization held its 29th annual Northern Maine Log A Load for Kids Golf Tournament at JaTo Highlands Golf Course in Lincoln, where another $60,982 was raised for Northern Light Eastern Maine Medical Center in Bangor. Both hospitals are Children’s Miracle Network Hospitals. Together, the tournaments drew more than 80 teams, both

selling out well in advance. The funds raised will support research and training, purchase specialized medical equipment, pay for uncompensated care, and benefit the critical work of Neonatal Intensive Care Units (NICUs) and pediatric programs.

At the southern tournament, PLC Executive Director Dana Doran announced the record fundraising total alongside Jacob, a young cancer survivor, and McKenzie, a survivor of infantile Pompe disease, both former Champion Children for BBCH.

“That’s almost $8,000 more than last year,” Doran told participants. “On behalf of kids like Jacob and McKenzie who are here today and all the other kids you serve, thank you so very much for coming today. We will see you next year on August 28!”

In Lincoln, under sunny skies at JaTo Highlands, Doran praised the generosity of participants and sponsors when announcing the Northern Maine total. “This is a fantastic number, we couldn’t be happier,” he said. “I know many of you have an experience with the hospital with a child, grandchild, niece or nephew, someone in your lives who has been impacted, and that’s why we do this. Thank you so very much and we will see you at the tournament again next year.”

The Lincoln event also included a visit from Miracle II, a new, donor-funded, state-of-the-art ambulance specially designed to transport premature babies and critically ill newborns. The ambulance is now part of Northern Light’s emergency fleet, ensuring the safe transfer of infants to the only Level III NICU north of Portland. That unit provides care for more than 450 newborns each year, about 150 of whom require specialized transport from community hospitals.

Since 1996, the PLC has partnered with the Northern Light Health Foundation (formerly Eastern Maine Health Systems Foundation) on the Log A Load fundraising effort. In 2019, BBCH joined the effort, further expanding its impact, and in 2024, the University of Vermont Children’s Hospital became a partner. UVM serves as a regional referral center for critically ill or injured pediatric patients, housing a Level III NICU, a pediatric intensive care unit, and a wide range of pediatric specialties.

Thank you to the sponsors, supporters, and players who made the tournaments a success!

of the

View all of our w all special Sections cial Sect View all of our special Sections

Afall walk in the woods reminds us how impressive Maine’s forests are. Maine is the most forested state in the country, with over 17.5 million acres of forestland. These diverse forests—ranging from young to mature, conifers to hardwoods—are vital as we face changing conditions from droughts, storms, and invasive plants, insects, and diseases.

Forest resilience measures how well forests adapt and respond to changing conditions. A resilient forest can resist disturbances, such as intense windstorms, or recover after insect outbreaks. While some trees or species may be lost, the forest ecosystem endures.

An example of a dense forest stand that could benefit from thinning. Reducing tree density can increase forest

Eligible practices enhance forest resilience by promoting multiple tree ages and species, freeing resources for remaining trees, reducing tree health risks, and ensuring new trees grow. Eligible practices also support other forest goals, including recreation, clean air and water, and tree growth and quality.

There are many actions a landowner can take to increase the resilience of their forestland. For example, thinning to remove trees in an overly dense forest can improve the health of remaining trees.

These trees may be more likely to survive drought stress or diseases. Removing invasive plants from a forest creates space for native trees, wildflowers, and shrubs. Native plants provide important wildlife habitat while being less desirable for ticks. However, actions that increase forest resilience can be costly. Fortunately, the Maine Forest Service is launching a new financial incentive program, the WoodsWISE Resilience Program.

Through the WoodsWISE Resilience Program, we can help Maine landowners apply stewardship actions or “practices” that may otherwise be cost-prohibitive. Within the program, eight practices are eligible for financial incentives:

Early Forest Practices:

• Pre-commercial thinning: Reducing the number of trees in young or sapling-sized forest:

• Early commercial thinning: Reducing the number of trees in a forest where part of the trees can be sold.

• Crop tree release: Removing trees to favor those of the preferred form, vigor, or species.

Regeneration Practices:

• Harvesting to promote tree regeneration: The intentional removal of trees to create space and resources for regeneration (seedlings, sprouts, or established small trees).

• Tree planting: Planting tree seedlings to meet landowner objectives.

• Regeneration protection: Temporary tree cages or exclosures to protect small trees or seedlings from animal browsing.

Forest Health Practices:

• Sanitation cutting: Removing specific trees or tree species to reduce the threat of diseases, insects, fungi, or other health concerns.

• Invasive plant control: Using mechanical or chemical methods to remove invasive plants.

The WoodsWISE Resilience Program will launch later this winter and is open to landowners with 10 or more forested acres. Eligible landowners include private or family ownerships, federally recognized tribes, municipalities, and conservation groups.

If you are a forest landowner in Maine, consider exploring the WoodsWISE Resilience Program and applying for support to help strengthen the health and future of your forest. To learn more about the program, visit the WoodWISE website https://tinyurl.com/svxjkdff or contact the Maine Forest Service at 207-287-2791 or forestinfo@maine.gov.

Treeline’s story begins not with a fleet of trucks or a bustling service center, but with one chainsaw and a horse named Captain. From that humble start, Owner and President Brian Souers built a company that has become a cornerstone of Maine’s forest products industry. What began as a forest management business has grown into a diverse operation providing jobs, products, and community support throughout the region.

The strength of Treeline has always been its people. For example, Bob Bethune, who, as Treeline’s Operations Manager, has spent four decades ensuring the responsible stewardship of Maine’s forests and keeping wood flowing to the mills that rely on it. Robert Bailey, with more than two decades as Treeline’s Woodyard Manager, is known for running one of the cleanest woodyards west of the Penobscot River. For three decades, Rick Muncey has maintained Treeline’s equipment, preventing breakdowns, reducing hazards, making repairs, and minimizing the risk of wildland fires.

Other amazing people at Treeline are Dick Chesley, Keith Crocker, Em Tash, Kevin Osnoe, Heath Libby, Rick Irish, and Bill Emery. These are just a few that have been with Treeline for over 20 years, committed to the company that’s been committed to them and their community since its founding. Each of these key people will be quick to share their success with their amazing team. Being a “Treeliner” is a term of pride, and many of those working here have worn it for decades!

From sustainable forest management, firewood, truck and equipment repair, and maintenance services to quality parts and supplies, mobile SP Tools trucks, land development and sales, earth work, lumber products, rental properties, home construction, and heating and plumbing services, everything Treeline does has its roots in Maine’s magnificent forests.

We deliver this wide array of products and services thanks to the lessons learned, skills earned, and evolving customer needs. Treeline has never stopped learning and innovating to serve our customers and support our community.

While the past is important, Treeline always looks forward. We know that our success is due to the dedication of our people who serve our customers so well. That is why we are raising the bar to become an employee-centric company with leadership shared by all those working here.

We also strive to invest in and improve our community’s future: Treeline Making a Difference (TMD) is a non-profit created and supported by Treeline employees and friends. TMD invests resources into our community by giving back to those in need. Investments like these are important and Treeline is proud to be able to support our community in this way.

From one horse and a dream, to a company that touches lives across Maine, Treeline stands as proof of what perseverance, community, and innovation can achieve. The past laid the foundation, the present is built on hard work and heart, and the future shines brightly with possibilities — for Treeline, for its people, and for the community it proudly serves.

y the end of September, Maine had experienced 750 wildfires, burning 473.6 acres. While this past spring and early summer’s wildfire activity was very much on par with the State’s 20-year average (408 fires burned 336.5 acres from January through July 2025), conditions began to rapidly deteriorate in August. As very dry weather progressed to various stages of drought throughout much of the State, daily wildfire danger ratings increased to High and Very High for many days in August and September. Maine ended up seeing 251 wildfires in August alone, over twice the number seen in any August in more than two decades.

The leading causes of Maine’s wildfires in 2025 have been debris/open burning (23%), equipment or vehicle malfunctions (21%), and recreational campfires (16%). Most debris and campfire incidents stemmed from improper extinguishment or being left unattended. One key aspect of our wildfire prevention effort is the State’s Online Burn Permit System (maineburnpermit.com). This platform is connected to the daily Wildfire Danger Report (mainefireweather.org), which provides updates on current fire weather conditions that help communities and local fire departments make informed decisions on open burning activities. When wildfire danger ratings are elevated to High or above, the online system stops issuing burn permits to the public to limit potential ignition sources and reduce risk.

As the stewards of the most heavily forested state in the nation, the Maine Forest Service proudly embraces a mission centered on wildfire preparedness and risk reduction.

Our leadership and collaborative efforts with Maine’s fire service, FEMA, the Maine Emergency Management Agency, forest landowners, community leaders, and regional and national partners ensure a coordinated and effective response to wildfire threats.

Training is a key area of focus: we equip Forest Rangers and Maine’s fire service with specialized wildfire response techniques and incident management skills. By participating in mutual aid agreements, Maine Forest Rangers gain valuable experience from out-of-state mobilizations, which they bring back to enhance local preparedness and response strategies.

Modern equipment and technology are also critical to our success. National lightning detection and heat signature systems enable rapid notification of wildfire starts in remote areas. The Maine Forest Service aviation program, the only one of its kind in New England, plays an invaluable role in assisting ground forces with water bucket drops, transport of personnel and equipment, and providing aerial situational awareness. These resources ensure a quick response to incidents, with most areas in Maine reachable within an hour.

Despite these efforts, severe conditions can still lead to wildfires burning out of control. Preparedness is a shared responsibility. We encourage residents to take an active role in wildfire planning—on their properties and in their communities. Contact your local Forest Ranger for guidance and support. Together, we can reduce risks and protect Maine’s forests.