BASIN TODAY

On June 22, 1963, more than 8,500 people gathered at a site south of Stanton, North Dakota, for the groundbreaking ceremony for the Leland Olds Station, the cooperative’s first power plant. This coal-fired plant was named after former chairman of the U.S. Federal Power Commission Leland Olds.

This year, Leland Olds Station is celebrating 60 years of dependable power. Read more about this milestone in the article Power You Can Depend On on page 6.

CONTENTS VOLUME 29 | NUMBER 1

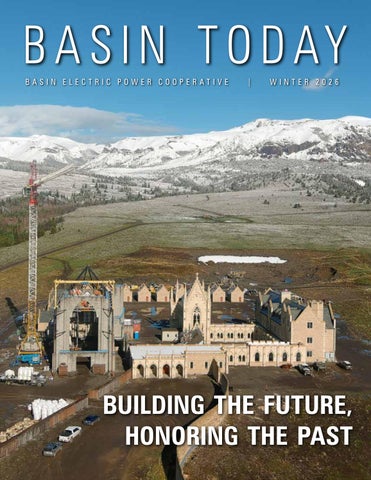

ON THE COVER

Quality work can’t be rushed if you want it to stand the test of time. Construction began in 2014 for the New Mount Carmel Monastery outside of Meeteetse, Wyoming, which is being built entirely by hand by the devoted monks who live and work there.

This unique and stunning project captured the attention of the team at Basin Electric subsidiary Wyoming Lime Producers, who continue to donate quicklime for the monastery’s construction.

Read more on page 14.

Photo credit: Carmelite monks in residence

IN EVERY ISSUE

2 CEO column: Financing the future of Basin Electric

4 In brief 8 Member focus 10 How we serve 17 Employee highlights

FEATURE STORIES

6 Power you can depend on: Leland Olds Station celebrates 60 years of reliability 12 Powering growth responsibly

14 Saying yes: Wyoming Lime Producers plays a part in building a monastery in the mountains

CONTRIBUTORS

Editor: Kalli Senske (communications@bepc.com)

Graphic designer: Joy Schnabel

Photographers: Joy Schnabel, Juan Thomas, Greg Wheeler

Writers: Erin Becker, Jenifer Gray, Dana Hager, Alison Kirsch, Kelly Miller

Scan the QR code with your cell phone to view stories online.

TODD BRICKHOUSE

FINANCING THE FUTURE OF BASIN ELECTRIC

We often talk about Basin Electric’s all-of-the-above energy strategy, a commitment to building a diverse portfolio that provides reliability for our members no matter what the days, weeks, and years ahead may hold. This energy strategy has been consistent since our founding almost 65 years ago: capitalize on the low-cost fuel sources within our service territory and minimize transportation costs of these fuels. As a result, our portfolio is largely fueled by mine-mouth coal, well-mouth gas, and horizon-mouth wind. As our cooperative continues to grow and power demand surges, an equally important approach is shaping our path forward: an all-of-the-above financing strategy.

This financing strategy means actively developing new channels of debt capital while strengthening and enhancing the financing tools we already rely on. By diversifying how we access capital, we maintain the flexibility, stability, and financial strength needed to support long-term investment and serve our members.

Today, Basin Electric is in the midst of one of the most significant periods of investment in our history. Just one year ago, we projected 10-year capital expenditures of $7.8 billion. Today, that forecast stands at nearly $11 billion, an investment level that will more than double our balance sheet. This growth is driven by new transmission development and the addition of reliable generation needed to serve rapidly growing traditional member load.

Basin Electric has navigated periods of transformational growth before. Between 1970 and 1986, the cooperative’s balance sheet grew nearly 100-fold as the system expanded to meet member needs. That era of growth,

guided by long-term planning and a member-focused vision, shaped the cooperative we are today and demonstrated the responsibility and commitment required to invest at scale.

Key components of our strategy

An all-of-the-above financing strategy is necessary to support the scale and pace of Basin Electric’s long-term investments. Diversifying funding sources allows us to access the lowest-cost debt available, maintain strong liquidity and financial flexibility, and adapt to changing market and project conditions. Just as importantly, this approach helps protect reliability and affordability for our members while supporting the A-level credit ratings that reduce borrowing costs and preserve long-term financial strength.

Our financing strategy relies on a balanced mix of tools. We expanded and extended our revolving credit line to $1.25 billion, providing the liquidity and flexibility needed to fund major projects. We have seen increased support from our existing banking partners and strong commitment from new partners, reinforcing this foundation.

Basin Electric also uses term loans as a tool to responsibly spread borrowing over time, working with partners such as CoBank, CFC (National Rural Utilities Cooperative Finance Corporation), the Bank of North Dakota, and others. In October 2025, Basin Electric issued $700 million in public bonds, only the second such issuance in our history. The offering was oversubscribed, with offers to purchase exceeding $4 billion, reflecting strong investor confidence and positioning the cooperative well for future capital needs. We are also exploring additional channels, including tax-exempt debt on appropriate projects, such as the recently announced Bison Generation Station.

Federal programs remain an important part of the mix. Basin Electric reentered the Rural Utilities Service program in 2025 and continues to evaluate federal borrowing opportunities to support future construction.

At the center of all of these financing options is the cooperative way. Our members remain our largest longterm investors, having contributed nearly $1.5 billion in patronage capital and an additional $275 million through the Member Investment Program. This shared investment strengthens our balance sheet and shows the trust our members place in the cooperative as we

work together to power the future and maintain a strong, stable financial foundation.

Member benefits of credit strength

Basin Electric’s financial strength is recognized by our financial stakeholders as well. We continue to maintain strong A-level credit ratings from all three major rating agencies, reflecting the sound stewardship of member investments and our disciplined approach to long-term planning, including strong cash reserves, stable long-term contracts with our members, disciplined rate setting, experienced governance and leadership, and a diverse portfolio of assets.

Strong credit ratings matter because they directly benefit our members by allowing Basin Electric to borrow at lower interest rates and provide greater flexibility in power and natural gas markets by reducing collateral requirements and expanding trading options. Together, these advantages help manage costs, support system reliability, and keep electricity affordable.

Looking ahead

Basin Electric forecasts show approximately $9 billion in long-term debt issuance over the next decade to support the growing energy demand. Managing a capital program of this scale requires diversification, discipline, and careful financial stewardship, principles that have guided the cooperative since its earliest days.

We move forward with confidence in our all-of-the-above financing strategy and with a clear focus on our mission of sustaining the quality of life for our members by providing reliable and affordable power produced in a safe and environmentally responsible manner.

I am grateful to our members for their continued trust and investment, to our financial partners for their support, and to our employees for their expertise and dedication as we pursue our all-of-the-above energy and financing strategies. We are building the next generation of cooperative infrastructure rooted in resilience, reliability, and a shared commitment to the communities we serve.

TODD BRICKHOUSE CEO and general manager

Basin Electric helps reduce flaring in the Bakken region

Basin Electric has approved a five-year program that will help reduce flaring in the Bakken region. The cooperative will purchase behind-the-meter generation in roughly 10 megawatt (MW) sizes from entities looking to sell power generated from flare gas in Western North Dakota.

Basin Electric has committed to purchase power until May 31, 2030. At that point, the cooperative will reassess the potential of renewing. Basin Electric’s new power plant, Bison Generation Station in Williams County, North Dakota, is expected to be completed by then, helping meet generation needs.

“This is a good solution to bridge Basin in meeting the load requirements in the area until Basin’s other generation build-out can be accommodated,” Jason Doerr, Basin Electric senior planning analyst, said.

https://bit.ly/Behind-The-Meter-Generation

Basin Electric partners with Mountrail-Williams to reduce transmission costs

Basin Electric is partnering with its member, Mountrail-Williams Electric Cooperative, headquartered in Williston, North Dakota, to develop transmission lines in three North Dakota locations.

“Basin Electric built a transmission line between Judson Substation (near Williston, North Dakota) and Tande Substation (near Tioga, North Dakota) in 2016. For three parts of that line, we worked with Mountrail-Williams to use double-circuit structures, one side of the structure carrying a 115-kV line and the other side carrying a 345-kV line. Near the new Springbrook substation, we

also built a section that could support a future double circuit,” Bobby Nasset, supervisor of civil engineering, said. “Mountrail-Williams now needs a new 115-kV line from Springbrook to East Fork, so Basin Electric finished building that 6.5-mile segment in early November. It will be energized in early 2026 when the Springbrook substation is complete.”

When a line is constructed as double-circuit, two independent sets of conductors are used on the same tower. This allows for higher power transfer capacity, improved reliability, cost efficiency and better land use.

https://bit.ly/MWEC-Partnership

Basin Electric transitions back to RUS oversight

Basin Electric began the process of transitioning back to rate oversight by the Rural Utilities Service (RUS) instead of the Federal Energy Regulatory Commission (FERC).

“This decision is due to a variety of factors, including access to low-interest funding from RUS,” Jim Horan, Basin Electric’s senior vice president and general counsel, said. “This is especially important as Basin Electric seeks to meet our growing capital needs to facilitate our projected load growth.”

https://bit.ly/Transition-to-RUS

Basin Electric selects PCL as general contractor for

Bison Generation Station

Basin Electric has selected PCL Construction (PCL) as the general contractor for the Bison Generation Station project following a year-long selection process. The search began in early 2025 with a wide pool of potential contractors, using an initial pre-qualification screening to gather key information before narrowing the field. Finalists submitted detailed project plans and attended in-person discussions about execution strategies and past successes, leading to PCL’s selection.

With design work still underway, Basin Electric and engineering partner Burns & McDonnell are now working closely with PCL to align construction packages with the contractor’s schedule and coordinate with major equipment suppliers as fabrication and delivery timelines progress.

https://bit.ly/BisonGen-GC-Selected

Existing double-circuit deadend structure.

Basin Electric to conduct feed study in Wyoming

The Wyoming Energy Authority and Governor Mark Gordon (R-WY) awarded Basin Electric $4 million for a Front-End Engineering (FEED) study to explore a second unit at Dry Fork Station.

The FEED study will be funded using Energy Matching Funds provided by the Wyoming Legislature and will look at the possibility of adding a second coal-fired generation unit at its Dry Fork Station in Gillette, Wyoming.

This in-depth review will explore whether building a new unit is feasible, what technical work would be required, and how it could help meet the region’s growing energy needs.

https://bit.ly/WY-FEED-Study

Basin Electric Leland Olds Station substation energized

Construction on the new Leland Olds Station substation is drawing to a close. The facility is one of Basin Electric’s largest substations, with room for future expansion.

Located near Stanton, North Dakota, the size of the 19.5-acre substation is directly correlated to the number of connected transmission lines. It includes nine line terminals: two 230-kV lines connected to two 345/230-kV transformers and seven 345-kV transmission lines. One of the 345-kV terminals connects to the Crane Creek Substation, part of Basin Electric’s East Loop 345-kV transmission project, while another serves the Oliver Wind interconnection.

https://bit.ly/LOS-Substation-Energized

/basinelectric

/company/basin-electricpower-cooperative /basinelectric

Read Basin Today online @ basinelectric.com/BasinToday

Read Basin Electric news online @ basinelectric.com/NewsBriefs

basin_electric

@basin_electric

Aerial view of Dry Fork Station in Gillette, Wyoming.

Aerial view of the Leland Olds Station substation.

POWER YOU CAN DEPEND ON LELAND

By Kalli Senske

OLDS STATION CELEBRATES 60 YEARS OF RELIABILITY

What feels effortless now—a simple flip of a switch— was once a struggle for entire communities. Not so long ago, electricity in rural America was scarce and uncertain.

That started to shift in the late 1960s when Basin Electric built its first power plant, the Leland Olds Station, which would become a landmark piece of the power grid. Today, that pioneering achievement is celebrating 60 years of keeping the lights on for Basin Electric’s members and rural America.

Named for Leland Olds, a leader in the effort to develop a regional approach to electric power supply, Leland Olds Station’s first generating unit began producing 220 megawatts (MWs) of power in 1966. With 2,785 tons of steel framework rising 163 feet above the prairie, the plant was built four miles southeast of Stanton, North

Dakota. At the time, it was the largest lignite-fired power plant in the Western Hemisphere, costing the cooperative $36 million to build.

Lignite coal was chosen as the fuel source because of its abundance and local availability. At the time, Assistant Secretary for Water and Power Development in the U.S. Department of the Interior Ken Holum said, “Lignite coal is going to work to generate cheap power for farmers, to provide a new major source of energy for the country, to provide jobs now and more jobs in the future for Dakota citizens.”

When Unit 1 went online, it began sending power to a growing Basin Electric membership—105 members in eight states. As demand grew, the need for additional generation became clear. In 1975, commercial operation started for Leland Olds Station Unit 2, a 440 MW unit

Construction of Leland Olds Station Unit 2 began March 6, 1972.

located adjacent to Unit 1. Construction of the second unit cost $109 million.

Powered by people

A plant can generate electricity, but it’s the people running it who truly keep power flowing. Their dedication and skill turn a facility into a community and a job into a shared mission.

When Tim Forsch, electrical supervisor, began working at Leland Olds Station in 1978, the shiny new facility made a big impression.

“Right away I noticed that the people were friendly and welcoming. Everyone took a lot of pride in their work and what the plant looked like,” Forsch reflects. “I remember being impressed by how environmental excellence and compliance were very high on the priority list—and it’s still that way today.”

Forsch has held a handful of positions since he began working at Leland Olds Station, and he says many have been challenging but enjoyable. Still, his favorite role might surprise you.

“One of the jobs we used to rotate into was giving tours around the plant,” Forsch shared. “They often consisted of local co-ops and members, sometimes high schoolers and job fair kids who were interested in how electricity was generated. It was fun to walk them through the process and share what we’re proud of.”

Tony Michlitsch, plant superintendent, has been with Leland Olds Station nearly 22 years and says the many roles he’s held at the plant have shaped his perspective.

“Every position I’ve had holds an important part in the operation of the plant, and I’ve really enjoyed them all. Each operates a different portion of the plant that ties in together with the other positions, so they’ve helped me understand how and why each position does what they do,” he says.

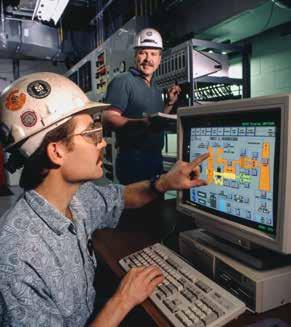

A tradition of improvement

As one might expect, a lot has changed at Leland Olds Station since it began operations 60 years ago. From an overhaul of the control system to scrubber installations, the plant is safer, more efficient, and environmentally compliant because of improvements and modernizations that have been made.

“It’s amazing how technology has changed,” Forsch says. “We started with large mechanical benchboards which formed and housed the boiler control panels, and our controls were largely pneumatic. Everything was very manual, where now we have most all of the processes controlled by computers.”

“In this industry, we have to continue to grow and change to keep people safe and make things run more efficiently,” Michlitsch added. “We are continuously planning for the next outage, looking for better parts or equipment, and developing new ways to make things better.”

Built to last

The reasons Leland Olds Station was originally constructed—meeting growing energy demand, modernizing agriculture, economic development, and energy reliability and independence—are still as relevant today as they were when the plant was first built. Leland Olds Station continues to stand as a vital resource for communities across the region, delivering reliable power to 139 member cooperatives in nine states and supporting the farms, businesses, and families who depend on it every day.

“Basin Electric stands as a symbol; it is more than just a power supplier,” according to a Basin Electric publication from February 1966. “The rural residents of the Missouri Basin … have created one of the largest homegrown ventures in the region. They have done it in a way that (is) incontrovertibly sound according to business principles. They have done it by themselves and for themselves. The benefits will flow to the entire region.”

Basin Electric employees Joe Fiedler and Tim Forsch doing Y2K preparations at Leland Olds Station in 1998.

The power line had to climb more than 1,800 feet in elevation, crossing steep, heavily vegetated hillsides with limited access.

RURAL SKILLS, GLOBAL IMPACT MONTANA LINEWORKERS IN GUATEMALA

By Alison Kirsch

Last February, two lineworkers from Fergus Electric Cooperative, a Class C member of Basin Electric, traded the wide-open skies of central Montana for the steep canyons and rough trails of Cocalitos, a remote Guatemalan village. Their mission: bring reliable electricity to a community without it.

When the project was announced, Danyon Rice and Darek Dygert chose to put their names forward, joining a team of 14 Montana lineworkers headed for Guatemala. “It was brought to us by our manager, who was looking for lineworkers to volunteer for the trip,” Rice says. “It’s a unique opportunity to be able to travel down there and help people who have never had electricity.”

The project was part of a long-running effort through National Rural Electric Cooperative Association

International, the nonprofit arm of America’s electric cooperatives, to bring reliable electricity to rural communities in Guatemala. For more than 30 years, volunteer lineworkers from the United States have helped build and improve power systems, train local crews, and connect villages that have never had electricity.

When Rice and Dygert arrived in Cocalitos, the contrast was immediate. “It was quite a culture shock,” Dygert says. Rice saw it the same way. “The lack of infrastructure, from plumbing and traffic laws to even what people ate, surprised me the most,” he says. “It was a whole different world from what we are used to, but everyone there was smiling.”

Geographically, the landscape posed one of the biggest challenges. “The vegetation and terrain were different

Photos courtesy of Darek Dygert from Fergus Electric Power Cooperative

from what we were used to in Montana,” Dygert recalls. The power line had to climb more than 1,800 feet in elevation, crossing steep, heavily vegetated hillsides with limited access.

Despite the unfamiliar setting, the job was the same: set the pole right, build the line straight, make it safe, and make it last.

Line construction was done largely by hand, and equipment was limited. Plans changed daily based on weather, terrain, and available materials. When something did not work, solutions came from experience and teamwork.

“There were challenges, but lineworkers are pretty good at figuring out solutions,” Dygert says. “Our group was especially good at problem-solving.”

The crew worked alongside local villagers who helped dig holes, carry materials, and learn basic wiring. Communication was often nonverbal, but cooperation came quickly. “We just had to find other ways to communicate,” Dygert says. “We were able to understand each other pretty well.” Rice adds, “When you want to communicate with people, you always find a way.”

Over ten workdays, the crew accomplished a lot:

• Installed 23 poles

• Strung roughly two miles of power line, including spans over 1,500 feet

• Wired 23 homes, with seven more under construction that will later connect

• Improved the village school with three windows and two ceiling fans

When the lights finally came on, the impact was immediate. Roughly 100 people in Cocalitos gained access to electricity, changing daily life and opening new opportunities for work and learning. “It was humbling to see the effect we had on them,” Dygert says. Rice adds that access to electricity will help the village grow, from everyday routines to long-term infrastructure.

For both men, the experience left a lasting impression. “All in all, it was a great experience, and I’m grateful I got to do it,” Dygert says.

The trip reinforced what rural electric cooperatives have always known: strong training, shared values, and a commitment to the work travel anywhere. From Fergus County to a remote village in Guatemala, the same approach applies. Do the job right, take care of people, and leave something that lasts.

Equipment was limited, and much of the line construction was done by hand in Guatemala.

Montana lineworkers installed power poles in the misty hills of Cocalitos as part of an NRECA International rural electrification project.

WITH THE OPERATIONS TEAM HOW WE SERVE

By Kelly Miller

Teamwork and safety are two of Basin Electric’s core values. For James Rueb, coalman at Antelope Valley Station, these values are paramount to his role in providing electricity for rural America.

Though he started at the plant in September 2023, Rueb became familiar with several of Basin Electric’s North Dakota facilities during his prior 27 years as an industrial painter doing work at Antelope Valley Station, the Great Plains Synfuels Plant, and Leland Olds Station.

Antelope Valley Station is located near the Great Plains Synfuels Plant and the Coteau Properties Company’s Freedom Mine. Much of the station’s fuel supply comes from the Great Plains Synfuels Plant in the form of lignite fines—particles of coal too small for use in the gasification process. This helps Basin Electric be a responsible steward of the environment by minimizing any waste of North Dakota’s precious coal resources.

In his role as coalman, Rueb keeps coal flowing from the Freedom Mine to the plant through a system of conveyors, loads railcars that carry coal from the mine to Leland Olds Station, and dumps railcars of pebble lime used in the scrubbers. He also manages coal supplies in the live storage barn so there is always a way to get coal to the plant in instances where operations may need to be temporarily diverted.

Maintaining equipment the plant relies on for continued operation is no small task. Part of Rueb’s duties include cleaning the coal chutes after every bunker is emptied and helping clean the plant to ensure a safe working environment is preserved.

When repairs or updates to equipment are needed, Rueb also assists with the lockout-tagout process, cutting off the power supply to a piece of equipment so people can safely work on it.

James Rueb, coalman at Antelope Valley Station.

Maintaining operations at a facility like Antelope Valley Station requires skilled employees, like Rueb, who have a strong understanding of how their systems work and what steps to take to get equipment back online if something goes wrong, all while watching out for their teammates. Safety is a constant priority, and personal protective equipment and frequent communication are essential to ensuring everyone returns home safely at the end of each shift.

The coalman job can quickly become dangerous if appropriate safety measures aren’t taken. Working around constantly moving conveyor systems and large equipment requires a lot of focus, situational awareness, and diligence in following proper protocols. With all that activity, “keeping your wits about you” is critical, Rueb says. Not only is staying in peak mental condition important, but physical strength is also important when it comes to cleaning chutes and shoveling coal.

Rueb is certainly no stranger to North Dakota weather and the extremes our seasons can bring. He recalls several stretches last winter where temperatures plunged below negative 40 degrees, which can be taxing when performing manual labor outdoors.

Precipitation also creates its own challenges. Rain can result in chutes getting clogged, and snow can cause coal to freeze into railcars. No matter the conditions, Rueb and the team at Antelope Valley Station have to keep things operational for Basin Electric’s members. In these instances, team members will use specialized equipment, such as air lances and air chippers, to loosen and clear debris from the chutes and railcars.

Though equipment breakdowns are generally considered a nuisance, Rueb views them in a positive light. “You learn a lot. Other people’s knowledge is just the greatest thing ever. As they come up, you try to teach others things you know to make their jobs easier, too.”

Rueb and his teammates are in constant contact with the control room operators. He says their knowledge and the previous experience these individuals have working the same jobs as those on the plant floor is incredibly valuable.

Rueb jokes that “nice summer evenings when everything works well” are the days he most enjoys being a coalman. But in all seriousness, he says, “The satisfaction of knowing I did my part, left the next crew in good shape, and knowing there will be electricity when I get home is what makes me enjoy what I do and realize the impact my job has on those at the end of the line.”

Rueb has a lot to say about the quality of team members he works with daily. From those on the plant floor, to his supervisor and the control room operators, he pays the highest regard to those making sure the plant continues to run smoothly, efficiently, and in the safest manner possible. He says, “I’m fortunate to be working with good, honest, hard-working people. I appreciate that.”

Reflecting on the plant’s role in providing power for Basin Electric’s members, Rueb adds, “We’re a reliable source of energy and use the minerals around us to make electricity. We are a very safe, well-functioning plant.”

Disclaimer: On Dec. 29, 2025, Rueb started a new position as scrubber attendant at Antelope Valley Station.

Rueb clears the grizzlies leading to the silos, ensuring the coal flows freely.

POWERING GROWTH RESPONSIBLY

By Erin Becker

Electricity plays a role in nearly every part of our day by powering devices, keeping our homes comfortable, and supporting businesses that provide essential services. As energy needs continue to grow, so do the responsibilities that come with planning, producing, and delivering reliable power.

Recently, the Basin Electric Board of Directors authorized a Class A rate increase of approximately $6 per megawatt-hour, or 10%, beginning Jan. 1, 2026. Rate increases are never easy, which is why Basin Electric is focused on transparency around what’s driving the change and how we are responsibly planning for the future.

Why wholesale power costs are increasing

Every step in the electricity distribution process carries unique costs—fuel, labor, and infrastructure—that ensure the system runs safely and efficiently. Electricity rates reflect the real costs of providing power, supporting upgrades, and distribution buildouts as the membership grows. Rate adjustments help the system remain reliable and ready for the future.

The drivers behind the 2026 rate increase include:

• Growth in traditional load: This includes a variety of sectors, including agriculture, oil and gas, ethanol, manufacturing, and residential demand.

• Commodity price variability: Fluctuations in commodity prices affect the cost of fuel for Basin Electric and sales revenue at its subsidiaries.

• Increase in planning reserve margins: Southwest Power Pool will require Basin Electric to

have higher capacity reserves, increasing capital expenditures, operating costs, and purchase power.

• Investments in reliability: Basin Electric will continue to make investments in system reliability, including upgrading existing facilities and reducing outage cycle times.

Growth is part of Basin Electric’s story

From 67 initial members in 1961 to 139 today, responsible growth has long been a part of Basin Electric’s legacy. However, Basin Electric is entering a new era with significant interest in large load and delivery point requests from its membership.

Historically, a three- or a five-megawatt (MW) load was considered a “large load.” Today, some proposed projects within Basin Electric’s service territory would require 50 MW, 100 MW, or more. It took more than a century to build the infrastructure that serves today’s electric needs, yet the same scale of development is now being requested in just a few short years.

The Large Load Commercial Program

Given the potential magnitude of these loads and the significant investment required to serve them, Basin Electric worked with its members to develop a program with processes that enable us to serve these loads while mitigating the risk of serving them to our current membership. The Large Load Commercial Program is not designed to be a barrier but rather a tool to support members navigating this significant large load growth.

What the program does:

• Minimizes rate impacts to Basin Electric members: Helps insulate existing members from the costs and risks of serving non-traditional new loads such as data centers.

• Shared opportunity: Strengthens local economies, and all members share in member growth, cost savings, and returns.

• Safeguards financial strength: Reduces the risk of stranded assets, protects Basin Electric’s credit rating, and supports responsible capital investment.

• Enables flexibility: Provides a clear process that supports system growth while prioritizing member interests.

Looking ahead

Meeting growing energy needs requires careful planning, wise investments, and clear communication. By addressing wholesale power costs and planning responsibly for energy growth, Basin Electric ensures a reliable, affordable power supply for all members today and for generations to come.

Helpful tools for member conversations

If you’re talking about recent rate changes, we’re here to help. Visit basinmembers.com for free, ready-to-use communication tools designed to make member communication clear and effective.

Basinmembers.com is a member-only website. For access, use your cooperative email address to create an account.

SAYING YES: WYOMING LIME PRODUCERS PLAYS A PART IN BUILDING A MONASTERY IN THE MOUNTAINS

By Jenifer Gray

Wyoming: quiet, peaceful, rugged, and beautiful. The perfect place to build the New Mount Carmel Monastery. With its Gothic architecture and stunning detail work, the monastery might seem out of place in the vast wilderness, but it’s not alone. The monastery, spanning 500 acres of a wild and remote valley outside of Meeteetse, keeps company with the wind, the gurgling creek water, and of course, the devoted Carmelite monks who live and work there.

Construction of the monastery began in 2014. Its stones carved by the monks themselves, its design modeled on centuries-old Carmelite tradition, and its progress sustained entirely through prayer, labor, and the generosity of countless strangers. Building a structure meant to last for generations takes not only hard work and patience, but materials to stand the test of time, specifically mortar, and not just any mortar would do.

When the conversation about building a new monastery started, a visiting English stonemason suggested

using Roman-style quicklime mortar. Quicklime is highly exothermically reactive with water, the added strength and reduced set times from this reaction make it ideal as a key component in mortar and cement. The self-healing properties of a quicklime mortar also make it stand the test of time.

A University of York professor who happened to be a “mortar guru” from the United Kingdom, confirmed the advice. “Use quicklime; the good stuff is in Frannie, Wyoming.” He was referring to Basin Electric’s subsidiary Wyoming Lime Producers.

The lime plant is located about two hours from the monastery and plays a critical role in its construction.

With recommendation in hand, Brother Joseph, who works as a stonemason on the project, reached out to Wyoming Lime Producers in the spring of 2024 asking for a bucket of quicklime.

A glowing sunset over the New Mount Carmel Monastery outside of Meeteetse, Wyoming.

Daryl Mecham, senior sales manager at Pete Lien & Sons, which operate Wyoming Lime Producers for Dakota Coal Company, received the call. “I spoke with Daryl who was very, very kind, and he said to swing by and they’d give us some five-gallon buckets,” Brother Joseph says.

When he arrived to pick up his first five-gallon buckets, the staff greeted him warmly, though with understandable caution. Quicklime is notoriously temperamental: highly reactive, scorching hot when slaked, and capable of exploding if mishandled.

With quicklime in hand, Brother Joseph returned to the monastery intent on figuring out how to use it. “I threw on a hazmat suit, face shield, and a respirator. I had no idea what to expect,” he recalls. What came next was dramatic: the reaction shot ten feet into the air like a volcanic geyser. It marked the beginning of a long, careful learning curve.

“It’s been a humbling process to learn how to use the quicklime safely and efficiently,” he says. Over time, he and the other monks developed a safe, consistent method to produce the ancient mortar that will bind their monastery together for generations.

What started as a small test, filling a few five-gallon buckets, quickly grew into a larger commitment. Now in its second year of donations, Wyoming Lime Producers has contributed approximately 10 tons of lime to support the monastery’s ongoing construction. Each ton is mixed, slaked, and carefully transformed into a mortar that cures not by water but by air, strengthening for decades.

Brother Joseph, trying to avoid taking advantage of anyone’s generosity, made several attempts to open a payment account with Wyoming Lime Producers. Each time, their response was some version of, “We’ll sort that out later.”

But “later” never came.

Pete Lien & Sons also employs Tucker Green, the plant’s site manager. Behind the scenes, Green quietly advocated for the monastery. He shared the story up the chain, first with leadership at Pete Lien & Sons and eventually with Basin Electric’s Executive Leadership Team and board of directors. Once they heard the story and saw the images, they felt what the employees had already sensed: this wasn’t simply a request for material. It was an opportunity to help build something meaningful.

The donation was approved.

Brother Joseph, who works as a stonemason on the project, carefully sets a stone in place.

“Supporting this project resonated deeply with the team, not solely because of religious alignment, but also because it represented doing the right thing for the right reasons,” Green says. “The collaboration has been smooth and uplifting, with the monastery coordinating pickups due to limited onsite storage. In return, Wyoming Lime Producers gets to witness the transformation through photos and updates, a reminder of the tangible impact their contribution is making.”

Construction of the chapel, the heart of the monastery, is expected to be completed in the next five to seven years. When finished, it will stand as a rare example of American Gothic stone construction built entirely by hand, by prayer, and by perseverance. Only a few remaining buildings and walkways will follow, completing a project decades in the making.

For Wyoming Lime Producers, the donation has become a reminder of what true community development looks like: offering expertise, giving freely, and supporting a cause that builds something far bigger than a single organization.

For the monks, it is a miracle unfolding in slow motion; a monastery, built stone by stone, through God’s providence and the generosity of those moved to say yes.

And for Brother Joseph, it is something simpler still:

“When someone looks you in the eye and offers you the chance to do God’s work, whether you’re a monk or a lime producer, you say yes.”

Intricate detail work, designed by hand, can be found throughout the monastery. Construction of the chapel is expected to be complete in five to seven years.

Photos courtesy of Carmelite monks in residence

CONNECTED THROUGH MUSIC, BOUND BY FAITH

By Erin Becker

Music has always had the power to bring people together, crossing the boundaries of time and culture. It speaks a language beyond words and forms connections across generational divides. Within this shared language, faith often finds its voice, expressed through melody, rhythm, and the simple act of playing together with purpose.

For Nate Swenson, Basin Electric manager of Operational Technology, music is more than a hobby; it’s a passion. Swenson plays percussion for Asher, a band of five musicians who play fiddle, banjo, guitar, bass, and drums. They perform a variety of genres, including old and contemporary Irish, British, and American folk and country music. One of their recent performances was at the 2025 Basin Electric Annual Meeting.

Asher’s cooperative debut

“Performing at the annual meeting was a fun and unique opportunity for us,” Swenson says. “We began the evening playing on a smaller stage where the social

was held, then we unplugged and set up next door to perform on a full stage during the banquet. It was the first time we’d been asked to play on two stages, but the transition was smooth and seamless.”

While logistics went smoothly, performing in front of an audience of cooperative peers, coworkers, and senior leaders brought a different kind of pressure.

“It’s always more nerve-racking to play when you know the people in the crowd,” Swenson says. “However, I was very humbled by the positive comments I received from coworkers across Basin Electric after our performance. I’m grateful for the opportunity to share our talents and passion with everyone who attended.”

Keeping rhythm in music and life

Swenson’s interest in music started around age three or four when he saw a drummer perform live. “Since that moment, I’ve been hooked,” Swenson says.

Nate Swenson showcasing passion, discipline, and creativity beyond the workday.

I WAS VERY HUMBLED BY THE POSITIVE COMMENTS I RECEIVED FROM COWORKERS ACROSS BASIN ELECTRIC AFTER OUR PERFORMANCE. I’M GRATEFUL FOR THE OPPORTUNITY TO SHARE OUR TALENTS AND PASSION WITH EVERYONE WHO ATTENDED.”

Nate Swenson, Basin Electric manager of Operational Technology

He jokes that his first instruments were bowls and spoons, but his percussion collection has grown significantly since then. Currently, Swenson owns a full trap set, a djembe, congas, and a bodhrán, a traditional Irish drum, which he began playing specifically for Asher’s set list.

Perhaps one of the most remarkable aspects of Asher’s story is how its members find time for music while balancing full-time jobs and raising their own families— when combined include a total of 25 children.

“It’s not uncommon to have a kid or two at rehearsals,” Swenson says. “We definitely wouldn’t be able to do this without the encouragement and support of our spouses.”

Swenson has felt this support from Basin Electric, too.

“Basin Electric’s focus on family values is very important to me,” Swenson says. “While there are times we may put in extra hours in the IT department, I’ve always felt very supported with work-life balance.”

Faith that binds

One of Asher’s biggest motivations is to connect with Christian culture and play wholesome music the whole family can enjoy, reflecting their shared values. The band’s name also derives from the Tribe of Asher in the Bible, which is remembered for its blessing, abundance, and quiet faithfulness.

“While we all have a passion for music, it’s our faith that binds us; we are all devout Catholic families with strong family values,” Swenson says. “It is not unusual to see each other at Mass and other faith-based events.”

Swenson’s story is about balancing work, music, faith, and family. Whether he’s managing technical operations by day or sitting behind a trap set by night, he brings the same steady commitment to both. It’s a rhythm that works, and one he’s grateful to keep.

Asher performing on the main stage during the 2025 Basin Electric Annual Meeting banquet.

RETIREES

Wally Scheresky retired from his position as lead yard operator at Antelope Valley Station on Oct. 1 after 22 years with the cooperative.

“ Wally’s dedication, reliability, and positive attitude have made a lasting difference to everyone who worked with him,” Tanner Winckler, coal and yard supervisor at Antelope Valley Station and Leland Olds Station, says. “He will truly be missed, and we wish him nothing but the best in this next chapter.”

Wanda Leier retired as administrative assistant III at Leland Olds Station on Oct. 17 after seven years with the cooperative.

“Wanda consistently demonstrated pride in her work and was always eager to take on new tasks and responsibilities,” Angie Wick, administrative supervisor at Leland Olds and Antelope Valley Station, says. “During her time at Leland Olds and Antelope Valley, she was the kind of teammate who never hesitated to step in and help out where needed. People knew they could count on her not just because she was organized and dependable, but because she genuinely cared about helping others. I want to thank her for her dedication to Basin Electric and wish her all the best in retirement.”

Dara Hausauer retired from her position as administrative assistant III at Dakota Gas on Dec. 2, concluding a 30-year career with the cooperative.

She began her time a t Basin Electric in accounting before moving through several departments, including Human Resources, construction, reception, and ultimately returning to Human Resources. Hausauer spent the last 12 years of her career supporting the maintenance department.

“Dara has been a reliable and dedicated member of our team.” Nate Fandrich, E&I maintenance superintendent at Dakota Gas, says. “Her consistent performance, dependability, and willingness to support colleagues have been greatly valued. We appreciate her years of service and wish her a fulfilling and well-earned retirement.”

In retirement, Hausauer looks forward to spending quality time with family and friends. She says she plans to “be spontaneous and enjoy the great outdoors and any adventures as they arise!”

Kirby Mutschelknaus retired from his position as mechanical maintenance field technician at Dakota Gas on Dec. 12, concluding a 24-year career with the cooperative.

Mutschelknaus began his time at Basin Electric working in coal and ash gasification area maintenance. He earned a diesel mechanic degree from North Dakota State College of Science in Wahpeton.

“Kirby worked hard and was mechanically intelligent,” Quinn Messer, maintenance supervisor at Dakota Gas, says. “He was very easy to get along with, communicated well, and was always in a good mood. He was very dependable, a steady worker, and loved to joke around, and was laughing most of the time. He was a great asset to the crew. Senior and other techs often came to him for advice or information on jobs that were new or unfamiliar. He was just a good guy to talk to and get along with. His work speaks for itself.”

He plans to enjoy his retirement to the fullest.

Jim Alt, E&I supervisor at Dakota Gas, retired on Dec. 29. He began working as a E&I technician on May 15, 2000, and was promoted to supervisor in 2015, a position he held until retirement.

“It has been a privilege to work with Jim,” Nate Fandrich, E&I maintenance superintendent at Dakota Gas, says. “His commitment, reliability, and positive attitude set a standard for excellence. He leaves behind a strong legacy of teamwork and mentorship, and his presence will truly be missed. We thank him sincerely for his remarkable service and wish him a well-deserved joyful retirement.”

In retirement, he and his wife plan to spend time assisting their elderly parents, enjoy time at their Lake Tschida property, continue farming during the summers, and travel to warmer destinations in the winter months.

RETIREES

Robyn Miller retired from her position as maintenance designer II at Dakota Gas on Dec. 30, concluding a 31-year career with the cooperative.

Her experience at Basin Electric spanned engineering and drawing support for Dakota Gas.

“Robyn’s dedication has contributed to the success of Dakota Gas for three decades,” Slade Ternes, engineering

SERVICE AWARDS

supervisor at Dakota Gas, says. “Her technical expertise and willingness to help has made for a career that will have a lasting impact for years to come. On behalf of Dakota Gas and the engineering department, may your next chapter be filled with good health, new adventures, and time for the things you enjoy most.”

In her retirement, Miller plans to travel, enjoy time with her grandchildren, exercise, relax, and enjoy life.

SERVICE AWARDS

Aaron Folk

20 years

Maintenance planner/scheduler

Antelope Valley Station

Shawn McConnell

20 years

Lead yard operator

Antelope Valley Station

Jordan Schantz

20 years

Lead communication technician

Beulah TSM

Brad Grueneich 20 years

Shift/shop maintenance supervisor

Dakota Gas

Edward Min 20 years

Scrubber supervisor

Laramie River Station

Scott Schroeder 20 years

Scrubber operator

Laramie River Station

KUDOS

Bryan Jensen 20 years

Fertilizer field technician

Dakota Gas

Mike Moos 20 years

Shift supervisor

Antelope Valley Station

Tyler Sorenson 20 years

Coal/yard supervisor

Laramie River Station

Cole Johnson 20 years

Control room operator

Antelope Valley Station

Josh Peterson 20 years

Field maintenance supervisor

Dakota Gas

Andre Twite 20 years

Process operations

field technician

Dakota Gas

Doug Leidholm 20 years

Shift supervisor

Antelope Valley Station

Jason Sauer 20 years

Chemical products

field technician

Dakota Gas

First Last

Faye Miller honored with NASBA Distinguished Service Award

Faye Miller, chief auditor at Basin Electric, was honored by the National Association of State Boards of Accountancy (NASBA) during its 118th Annual Meeting in Chicago, Illinois.

Miller was awarded the NASBA Distinguished Service Award on Oct. 28 for her unwavering commitment to collaboration and strong governance. Over the course of her career, she has taken on numerous key roles within NASBA, including director-at-large, Central regional director, and chair of both the Audit and Communications Committees.

“I am extremely proud and grateful to receive the Distinguished Service Award,” Miller says. “This recognition is a true highlight of my professional career, and I am honored to be acknowledged by an organization that plays such a vital role in our profession.”

Her influence extends well beyond the national organization. In North Dakota, Miller has played an integral part in shaping the state’s accounting landscape, having led both the State Board of Accountancy and the State CPA Society. She also continues to support the profession as a long-serving member and former chair of the CPA Examination Review Board.

Whether you’re turning the lights on or brewing your morning coffee, electricity is vital to our way of life. It powers our communities and keeps us safe. That’s why we’re investing in infrastructure that strengthens reliability, ensuring power today and for generations to come. AFFORDABILITY